Automatic and rapid feed delivery device and discharge device

A feeder, fast technology, applied in the direction of grain processing, etc., can solve the problem of low conveying speed, achieve the effect of short grinding time, avoid spillage, and avoid grinding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

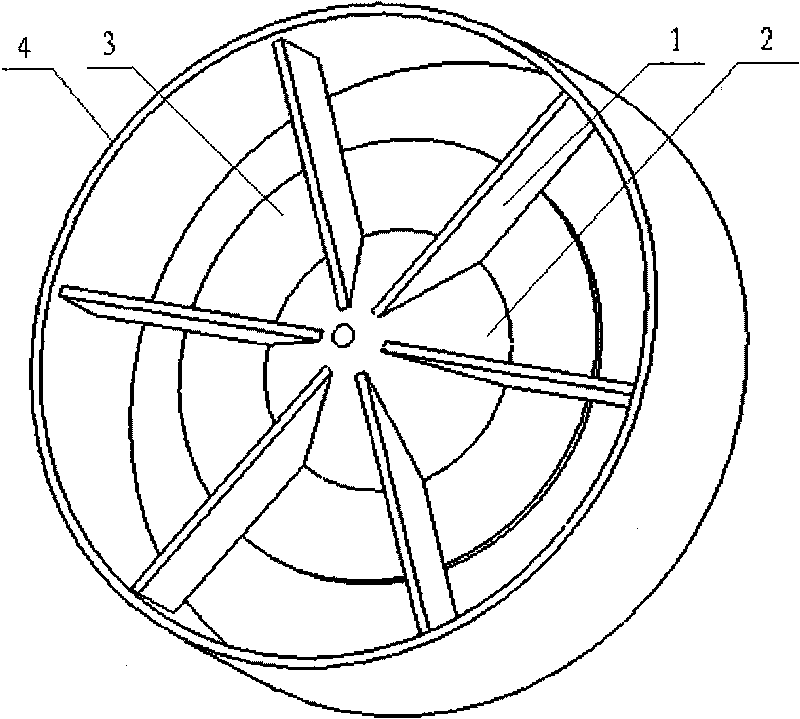

[0018] A kind of feeder, refer to figure 1 , comprising a back plate 3, on which a conical tube 2 is arranged, a wing plate 1 is connected to the conical tube 2 and the wing plate 1 stands on the back plate 3, and the wing plate 1 extends from the area of the back plate 3 To the outside of the back plate 3 , a cylindrical body 4 is sheathed on the wing plate 1 .

Embodiment 2

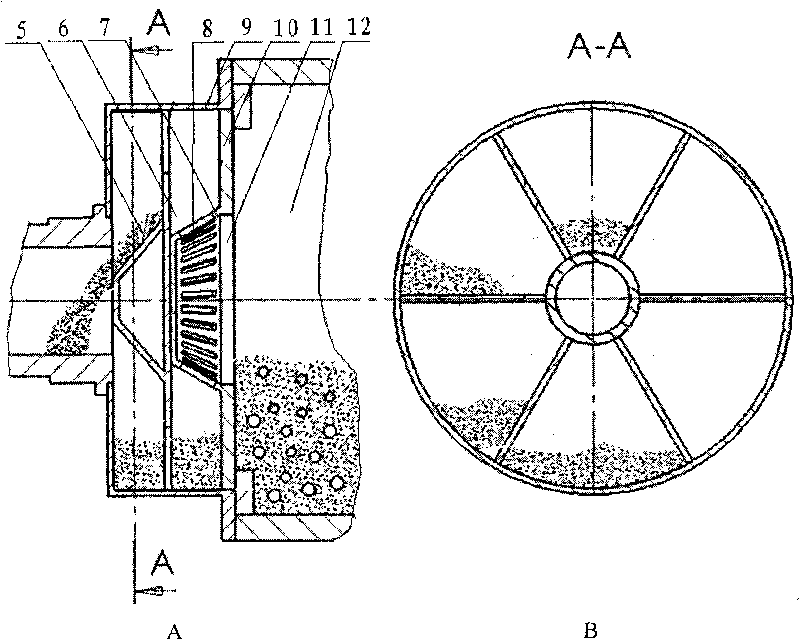

[0020] A discharger is characterized in that it comprises: a feeder and an overflow screen,

[0021] Described feeder comprises back plate 3, is provided with conical cylinder 2 on back plate 3, is connected with wing plate 1 on conical tube 2 and wing plate 1 stands on the back plate 3, and described wing plate 1 Extending from the area of the back plate 3 to the outside of the back plate 3, the cylinder body 4 is sleeved on the wing plate 1, and the feeding port of the feeder is formed between the back plate 3 and a port of the cylinder body 4 An annular hole, the discharge port of the feeder is another port of the cylinder 4;

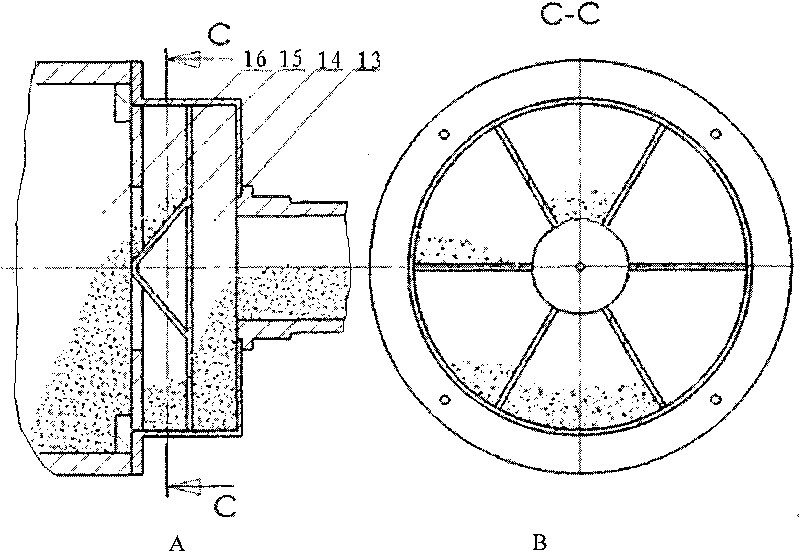

[0022] The overflow screen includes an annular back plate 10, on which a cylinder 9 and a conical cap 7 are arranged, on which a sieve hole 8 is arranged, and the inner hole 11 of the annular back plate 10 is located in the cone On one side of the conical cap 7, the warehouse 6 formed by the annular back plate 10 and the cylinder 9 is located on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com