Grinding machine for steel rail welding seam of high-speed railway

A technology for high-speed railways and rails, used in grinding machines, machine tools suitable for grinding workpiece planes, grinding/polishing equipment, etc., can solve the problems of uneven height, low efficiency, uneven welds, etc. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

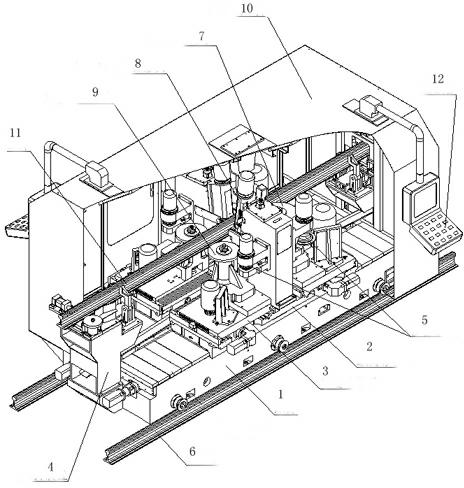

[0019] As shown in Figures 1-4, the high-speed railway rail weld seam grinder of the present invention includes a bed 1, a longitudinally moving carriage 2, a transverse feed carriage 3, a clamping device 4, a trimming device 5, a grinding head, and a bed 1 installed in

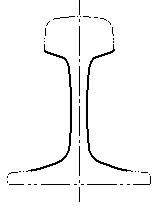

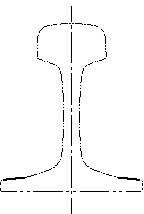

[0020] On the basis of the profile rail 6, the longitudinal moving carriage 2 is installed on the V-flat guide rail of the bed 1, and the longitudinal moving carriage 2 is equipped with a cross-feed carriage 3 and three sets of grinding heads, which are respectively on both sides of the rail. The rail waist curve grinding head 7, the rail foot 1:9 slope grinding head 8 and the rail foot side grinding head 9; the dressing device 5 is installed on the column of the 1:9 slope grinding head 8, and has the same shape as the rail waist curve Forming and dressing grinding wheel with diamond roller, the outer circle of the forming grinding wheel is used to grind the weld seam of the rail, so that the curve shape of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com