Method for controlling retaining ring planeness and produced retaining ring and semiconductor manufacturing system

A technology for manufacturing systems and retaining rings, applied in the direction of working carriers, etc., can solve the problems of low production efficiency, no consideration of processing, waste of grinding fluid and polishing pads, etc., and achieve the effects of saving costs, improving production efficiency, and saving consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

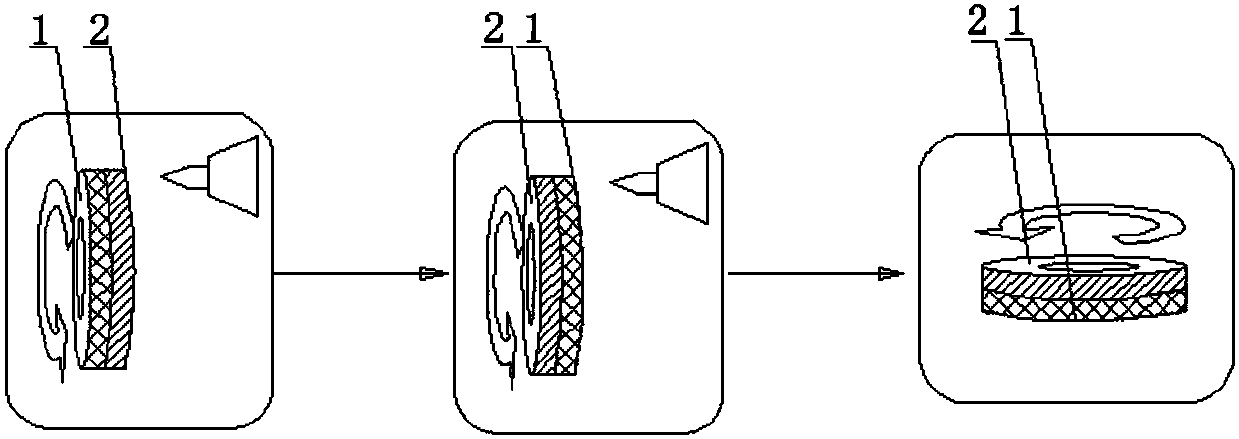

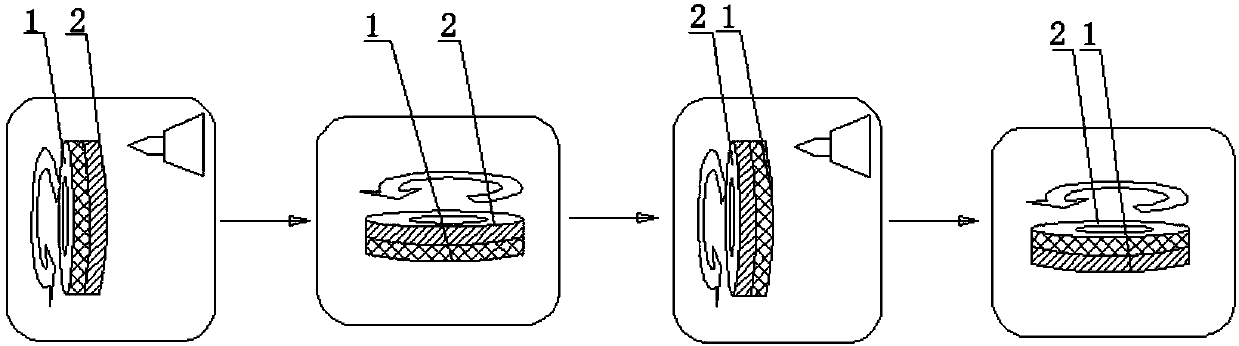

[0039] combine figure 2 As shown, the present embodiment provides a method for controlling and maintaining the flatness of the ring, which includes the following steps:

[0040] Turning the base plate surface 1 of the retaining ring, and then grinding the base plate surface 1;

[0041] The resin surface 2 of the retaining ring is machined by turning, and then the resin surface 2 is ground.

[0042] In order to ensure the grinding accuracy of the wafer, there are strict requirements on the parameters of the retaining ring during manufacture. Among them, flatness is the main parameter. Wherein, the flatness refers to the deviation of the macro-concave-convex height of a plane from the ideal plane, and the lower the value of the flatness, the smaller the deviation from the ideal plane.

[0043] It can be seen that in this embodiment, by increasing the grinding of the base surface 1 of the retaining ring, before processing the resin surface 2 of the retaining ring, the flatnes...

Embodiment 2

[0057] This embodiment provides a retaining ring produced according to the method for controlling the flatness of the retaining ring described in the first embodiment. The retaining ring includes: a base plate and a resin ring, the resin ring is coaxially arranged on the base plate, the flatness of the resin ring is less than or equal to 0.008mm, and the flatness of the base plate is less than or equal to 0.008mm. It can be seen that the retaining ring can meet the consumables for semiconductor CMP, especially the flatness requirement of the 200mm Retainer Ring. Wherein, the method for controlling and maintaining the flatness of the ring has been introduced in detail in the first embodiment above, and the technical solution disclosed in the second embodiment includes the technical solution disclosed in the first embodiment, and the content protected by the first embodiment also belongs to For the protection content of the second embodiment, the same parts will not be repeated....

Embodiment 3

[0067] This embodiment provides another semiconductor manufacturing system, which includes the retaining ring described in the second embodiment. The retaining ring includes: a base plate and a resin ring, the resin ring is coaxially arranged on the base plate, the flatness of the resin ring is less than or equal to 0.008mm, and the flatness of the base plate is less than or equal to 0.008mm. The technical solution disclosed in the third embodiment includes the technical solution disclosed in the second embodiment, and the content protected in the second embodiment also belongs to the protected content of the third embodiment, and the same parts will not be repeated.

[0068] Of course, the semiconductor manufacturing system also includes other devices.

[0069] For example, it consists of a rotatable grinding disc, a polishing pad arranged on the grinding disc, a holding head for holding a wafer and pressing it against the polishing pad, a slurry supply nozzle, and the like. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface smoothness | aaaaa | aaaaa |

| surface smoothness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com