Coking middling coal coarse grinding and flotation method in coking

A flotation method and rough grinding technology, applied in flotation, solid separation, grain treatment, etc., can solve the problems of deteriorating the subsequent tail coal concentration and dehydration effect, complex chemical system, poor flotation effect, etc., and achieve environmental protection. , The effect of low processing cost and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

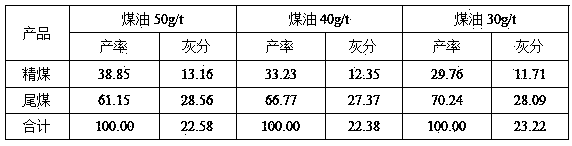

[0021] Embodiment 1: conventional flotation experiment

[0022] According to the conventional flotation method, the specific steps are as follows:

[0023] (1) The heavy medium coal in the coal preparation plant enters the 3mm grading sieve, and the material on the sieve is crushed by the crusher, and the output particle size is less than 3mm;

[0024] (2) The crushed product is mixed with the undersize of the grading sieve, and the coal slime whose particle size is less than 0.5mm is removed by a desliming sieve;

[0025] (3) The 3~0.5mm dense medium coal is mixed with water to form a slurry with a concentration of 65%, and the ball mill is used for wet grinding to achieve basic dissociation of the material;

[0026] (4) Mix the grinding product with -0.5mm coal slime, then add water to adjust the slurry concentration to 80 g / L;

[0027] (5) The flotation experiment adopts XFDM-1.5 single-cell flotation machine with a cell volume of 1.5L and a spindle speed of 1800 r / min; k...

Embodiment 2

[0033] Embodiment 2: No reagent flotation experiment

[0034] Adopt the scheme of the present invention, concrete steps are as follows:

[0035] (1) The heavy medium coal in the coal preparation plant enters the 3mm grading sieve, and the material on the sieve is crushed by the crusher, and the output particle size is less than 3mm;

[0036] (2) The crushed product is mixed with the undersize of the grading sieve, and the coal slime whose particle size is less than 0.5mm is removed by a desliming sieve;

[0037] (3) 3~0.5mm dense medium coal is mixed with water to form a slurry with a concentration of 65%, and the ball mill is used for wet grinding to basically dissociate the material;

[0038] The parameters of wet grinding: the mill speed is 1400r / min, the mass ratio of grinding medium to material is 32.84:1, the grinding time is 2min, and the content of -200 mesh in the grinding product is 33.8%;

[0039] (4) Mix the grinding product with -0.5mm coal slime, then add wate...

Embodiment 3

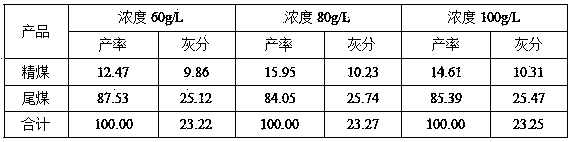

[0044] Embodiment 3: No reagent flotation experiment

[0045] The specific operation steps of this example are the same as those of Example 2, except that in step (4) water is added to adjust the pulp concentration to 80g / L, and then flotation is carried out by using the chemical-free flotation method. The results obtained are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com