Ruddlesden-popper homologous perovskite structure ceramic powder and preparation method thereof

A perovskite structure and ceramic powder technology, which is applied in the field of ceramic powder preparation, can solve the problems of slow reaction, impure powder, and difficult control, and achieve low sintering temperature, short grinding time, and good formability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Example 1 Preparation of SrTiO 3 Powder

[0053] Specific steps are as follows:

[0054] (1) Design the sample composition and calculate the ratio, and weigh the raw materials according to the stoichiometric ratio;

[0055] (2) Add 0.05 mol of Sr(NO 3 ) 2 Dissolve in a beaker filled with deionized water, place the beaker on a magnetic stirrer and stir to completely dissolve to obtain clear Sr(NO 3 ) 2 solution, called A solution;

[0056] (3) Use another beaker to weigh 100 ml of ethanol and 10 ml of glacial acetic acid and mix evenly, then slowly drop 17.3480 ml of tetrabutyl titanate into the solution with a pipette, continue to stir and make it completely Dissolve to obtain a transparent solution, which is called B solution;

[0057] (4) Add an appropriate amount of nitric acid solution to A solution to make A solution acidic;

[0058] (5) Slowly drop B solution into A solution, make it fully stirred and mixed evenly, and call it C solution;

[0059] (6) Dis...

Embodiment 2

[0065] Example 2 Preparation of Sr 4 Ti 3 o 10 powder

[0066] Except that the content of strontium nitrate was changed to 0.01 mol, the content of tetrabutyl titanate to 10.4088 ml, citric acid to 84 g, and the final sintering temperature to 1050°C, the rest was the same as in Example 1.

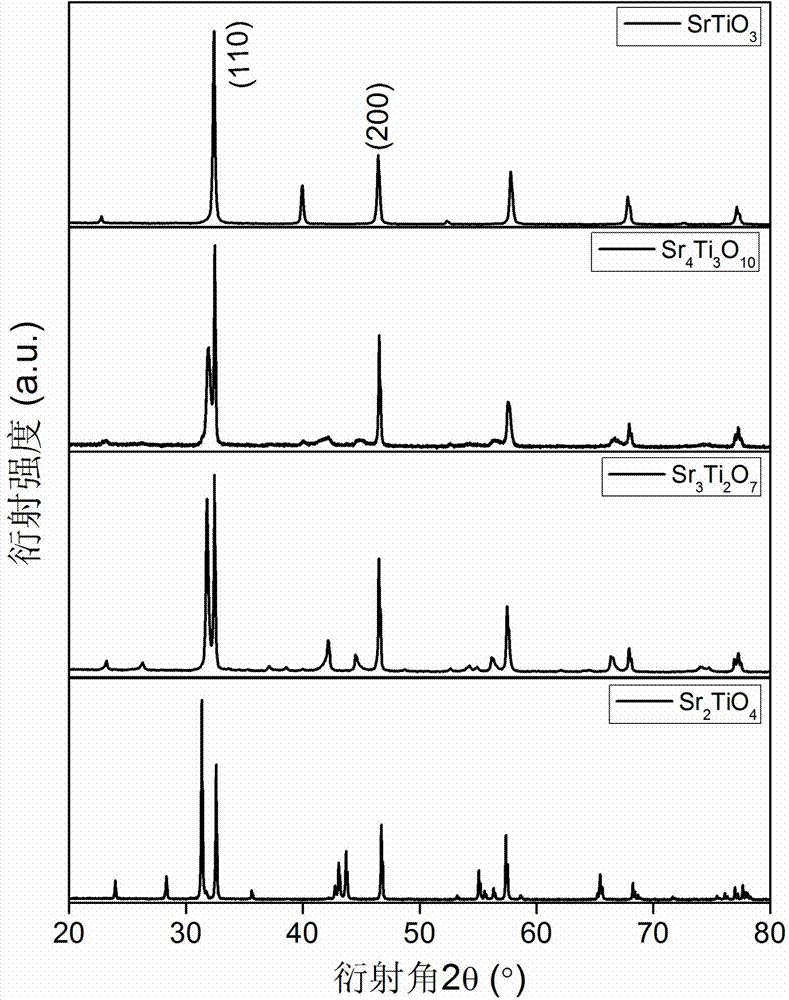

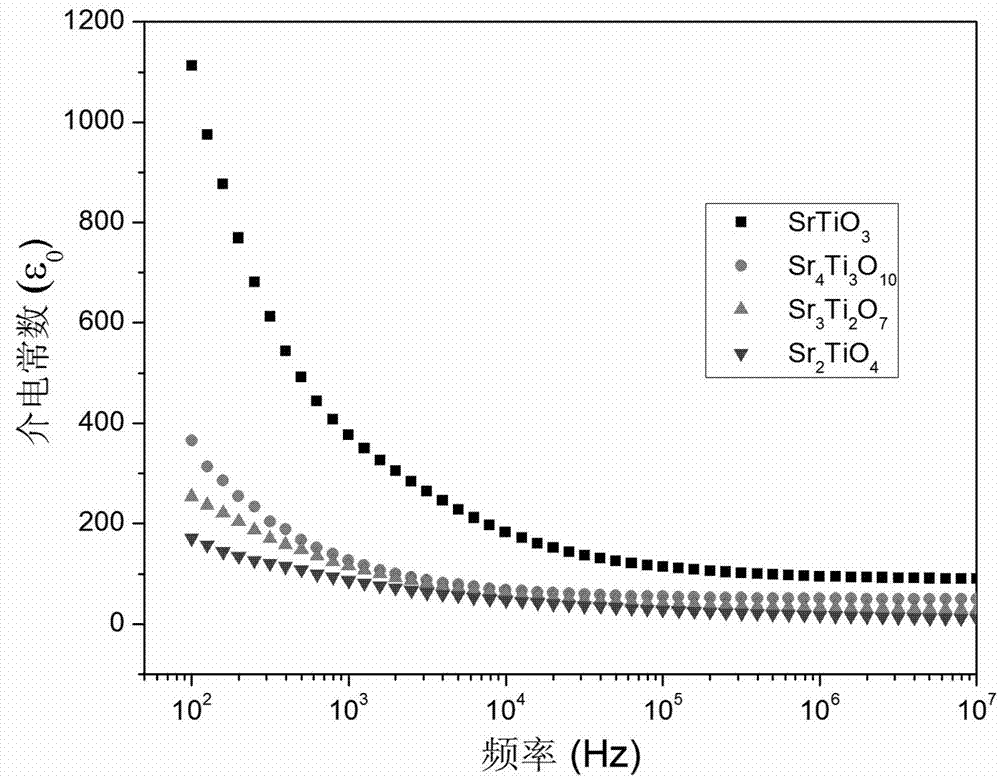

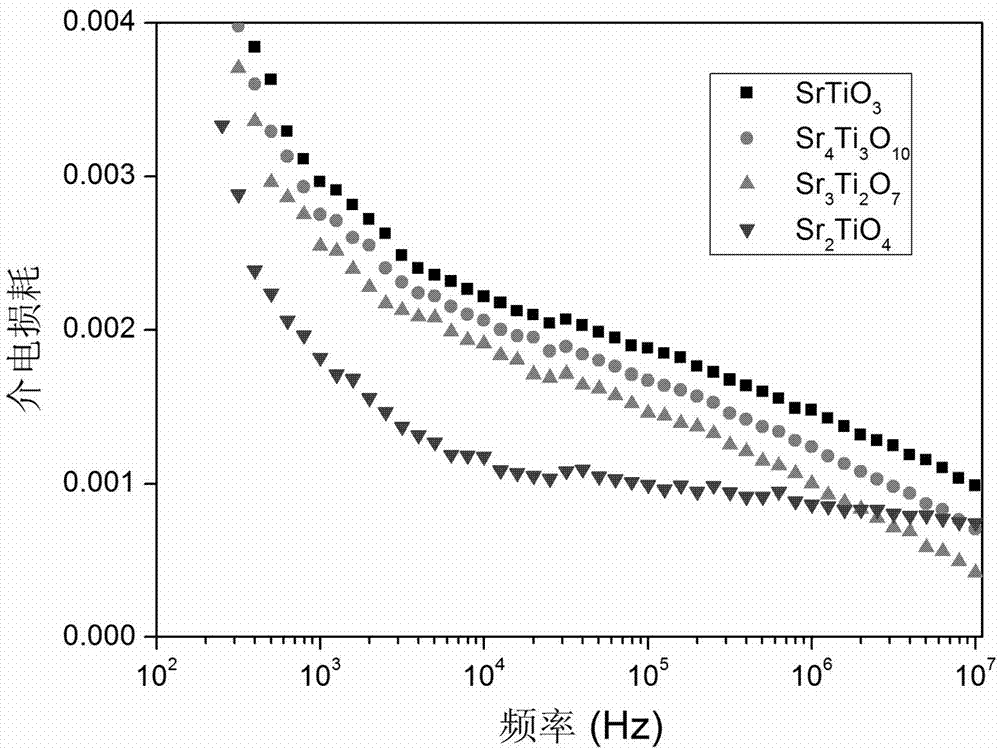

[0067] Determination of Sr by XRD phase analysis 4 Ti 3 o 10 The powder is a pure single-phase substance. Through the test and analysis of the dielectric constant, it is known that Sr at 100 kHz 4 Ti 3 o 10 The dielectric constant of the powder pressed block is 54, and the dielectric loss value is very small.

Embodiment 3

[0068] Example 3 Preparation of Sr 3 Ti 2 o 7 powder

[0069] Except that the content of strontium nitrate was changed to 0.02 mol, the content of tetrabutyl titanate to 13.8784 ml, the content of ethanol to 90 ml, the content of glacial acetic acid to 9 ml, the content of citric acid to 118 g, and the final sintering temperature to 950°C, the rest was the same as in Example 1.

[0070] Determination of Sr by XRD phase analysis 3 Ti 2 o 7 The powder is a pure single-phase substance. Through the test and analysis of the dielectric constant, it is known that Sr at 100 kHz 3 Ti 2 o 7 The dielectric constant of the powder pressed block is 41, and the dielectric loss value is very small.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com