Preparation method and application of iron phosphate

A technology of iron phosphate and lithium iron phosphate, which is applied in the preparation/purification of carbon, chemical instruments and methods, phosphorus compounds, etc., can solve the problems of affecting the performance of lithium iron phosphate, high cost of ferric salt, and high cost of environmental protection treatment, To achieve the effect of being beneficial to washing, high utilization rate and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

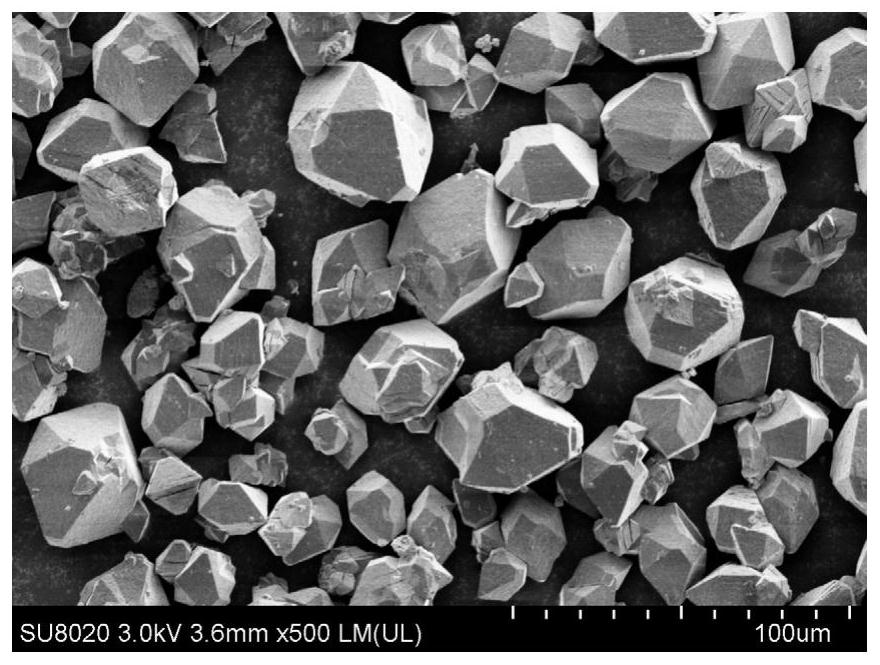

[0055] (1) Preparation of iron phosphate

[0056] Slowly add 554g of 85% phosphoric acid into a 2L beaker filled with 1014g of deionized water, stir with a glass rod to obtain a 30% phosphoric acid solution, and then slowly add the weighed 111.8g of iron flakes to a solution containing 30 % phosphoric acid solution (in order to avoid the evaporation of water in the beaker during the long-term heating process, cover the beaker with a watch glass in advance), and then put the beaker into a water bath for heating, and the heating temperature is 55 degrees , and kept at this temperature for 16 hours, after 16 hours, the iron sheet was completely dissolved, and filtered, and the bright green Fe(H) was obtained after filtration. 2 PO 4 ) 2 The solution and 3.354 g of tetrabutyl titanate accounting for 3% of the mass of the iron source were transferred into a 5L glass reaction kettle. After the addition was completed, the reaction kettle was stirred at a rotating speed of 300 r / min...

Embodiment 2

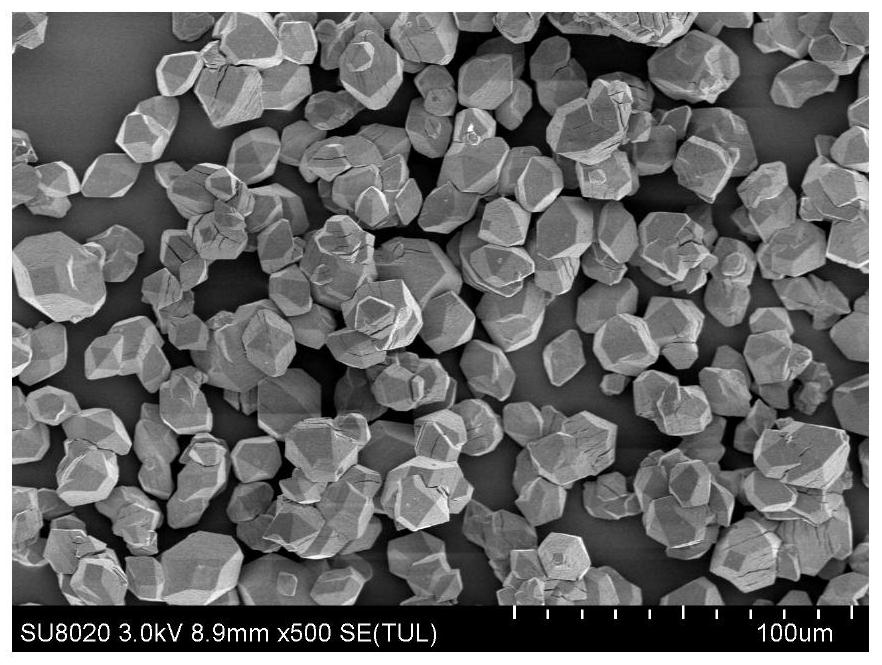

[0062] (1) Preparation of iron phosphate

[0063] Slowly add 530.4g of 85% phosphoric acid into a 2L beaker containing 879g of deionized water, stir with a glass rod to obtain a 32% phosphoric acid solution, and then slowly add the weighed 111.8g of iron powder to the solution containing 2L of 32% phosphoric acid solution (in order to avoid the evaporation of water in the beaker during long-term heating, cover the beaker with a watch glass in advance), and then put the beaker into a water bath for heating, and the heating temperature is 50 10 hours at a constant temperature at this temperature, after 10 hours the iron powder is completely dissolved, filter, and filter to obtain bright green Fe(H 2 PO 4 ) 2 The solution was transferred to a 5L glass reaction kettle. After the addition was completed, the reaction kettle was turned on and stirred at a speed of 300 r / min. At the same time, the glass reaction kettle was heated at a heating temperature of 80 degrees. When the solu...

Embodiment 3

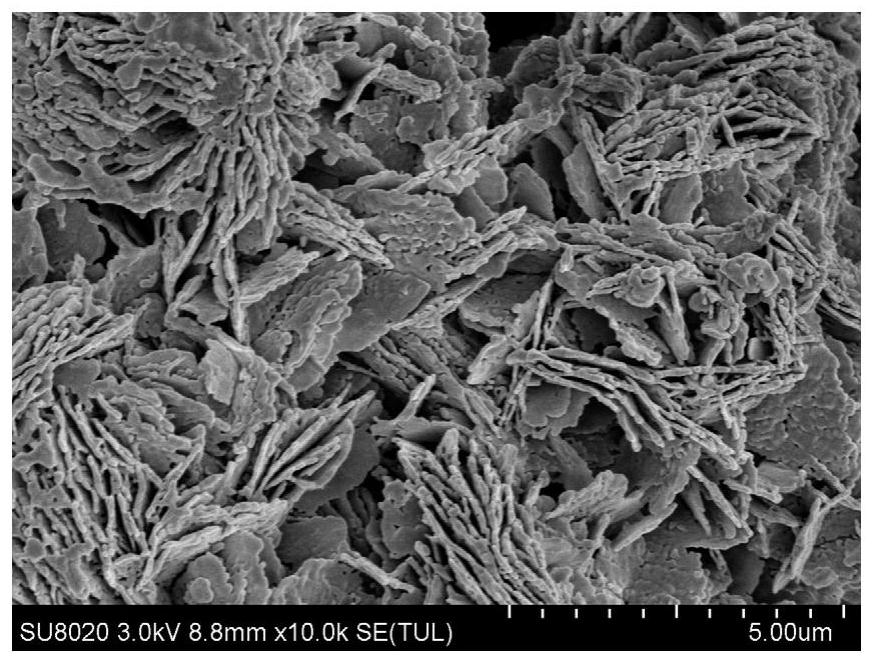

[0068] (1) Preparation of iron phosphate

[0069] Slowly add 530.4g of 85% phosphoric acid into a 2L beaker filled with 1203g of deionized water, stir with a glass rod to obtain a 26% phosphoric acid solution, and then slowly add the weighed 111.8g iron flakes to the beaker containing In 2L of 26% phosphoric acid solution (in order to avoid the evaporation of water in the beaker during long-term heating, cover the beaker with a watch glass in advance), and then put the beaker into a water bath for heating, and the heating temperature is 55 16 hours at a constant temperature at this temperature, after 16 hours the iron flakes are completely dissolved, filter, and filter to obtain bright green Fe(H 2 PO 4 ) 2 The solution and 2.236g magnesium hydroxide (accounting for 2% of the iron source mass) were transferred into the 5L glass reaction kettle. After adding, the reaction kettle was stirred at a rotating speed of 300r / min, and the glass reaction kettle was heated at a heating...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com