Dispersing agent for fluorescent brightener, fluorescent brightener aqueous dispersion, preparation method of dispersing agent, as well as preparation method and application of fluorescent brightener aqueous dispersion

A technology of fluorescent whitening agent and water-based dispersion, applied in dyeing method, textile and papermaking, etc., can solve the problems of poor compatibility, adverse effect of whitening effect, poor whitening effect, etc., and achieve short grinding time and negative effect. Small, brightening and even effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

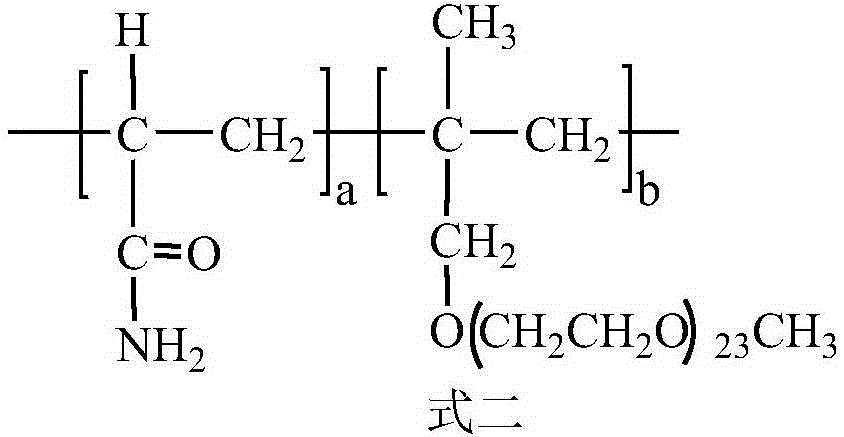

[0029] A kind of dispersant for fluorescent whitening agent of the present embodiment, described dispersant is prepared by following method, comprises the following steps:

[0030] Dissolve 0.3 mol of acrylamide and 0.1 mol of allyl polyoxyethylene ether (n=23) monomers in 30 grams of deionized water respectively, and dissolve 0.02 mol of ammonium persulfate in 20 grams of water, and then, under stirring conditions, control The temperature is 79-81°C. Add the monomer and the ammonium persulfate initiator aqueous solution dropwise into a four-necked flask containing 100 grams, and the dropping time is controlled at 2-3 hours. After the dropping is completed, keep warm for 3-4 hours. After cooling, the dispersant for fluorescent whitening agent is obtained, and its solid content is 36.7%.

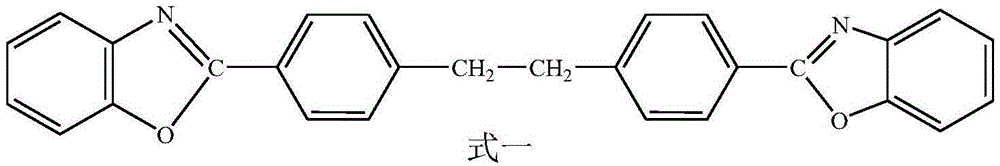

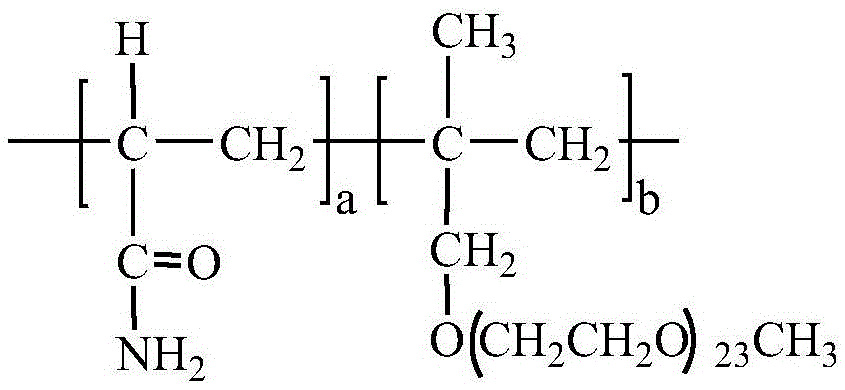

[0031] Utilize gel permeation chromatography to record that the weight-average molecular weight of described dispersant is 12500, and its molecular structural formula is as shown in formula t...

Embodiment 2

[0039] A kind of dispersant for fluorescent whitening agent of the present embodiment, described dispersant is prepared by following method, comprises the following steps:

[0040]Dissolve 0.4mol of acrylamide and 0.1mol of allyl polyoxyethylene ether (n=23) monomers in 30 grams of deionized water respectively, and dissolve 0.02mol of ammonium persulfate in 20 grams of water, and then, under stirring conditions, control The temperature is 79-81°C. Add the monomer and the ammonium persulfate initiator aqueous solution dropwise into a four-necked flask containing 100 grams, and the dropping time is controlled at 2-3 hours. After the dropping is completed, keep warm for 3-4 hours. After cooling, the dispersant for fluorescent whitening agent is obtained, and its solid content is 37.5%.

[0041] The weight-average molecular weight of the dispersant measured by gel permeation chromatography is 14800, and its molecular structure is shown in Formula II.

[0042] A kind of aqueous di...

Embodiment 3

[0048] A kind of dispersant for fluorescent whitening agent of the present embodiment, described dispersant is prepared by following method, comprises the following steps:

[0049] Dissolve 0.5 mol of acrylamide and 0.1 mol of allyl polyoxyethylene ether (n=23) monomers in 30 grams of deionized water respectively, and dissolve 0.01 mol of ammonium persulfate in 20 grams of water, and then, under stirring conditions, control The temperature is 79-81°C. Add the monomer and the ammonium persulfate initiator aqueous solution dropwise into a four-necked flask containing 100 grams, and the dropping time is controlled at 2-3 hours. After the dropping is completed, keep warm for 3-4 hours. After cooling, the dispersant for fluorescent whitening agent is obtained, and its solid content is 38.8%.

[0050] The weight-average molecular weight of the dispersant measured by gel permeation chromatography is 16800, and its molecular structure is shown in Formula II.

[0051] A kind of aqueou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com