HoFeB/Fe3O4 wave-absorbing composite material and preparation method thereof

A composite wave-absorbing material, ho5fe17b17 technology, applied in the direction of inorganic material magnetism, boron/boride, iron oxide/iron hydroxide, etc., can solve the problems of easy uneven mixing, difficult preparation, large ball milling loss, etc., to achieve the preparation The process is simple, the anti-oxidation ability is strong, and the effect of absorption frequency band is wide

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

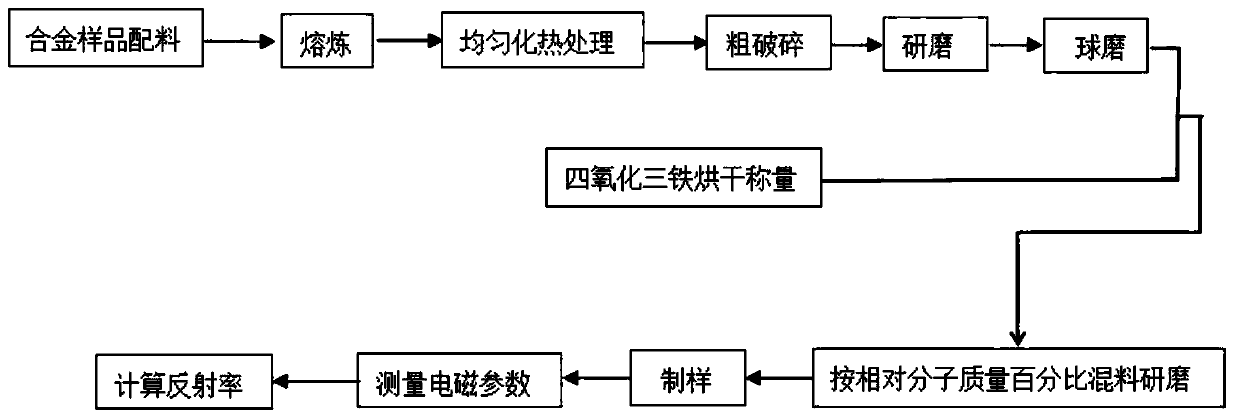

[0024] Such as figure 1 As shown, a HoFeB / Fe proposed by the present invention 3 o 4 The preparation method of composite magnetic wave-absorbing material comprises the following steps:

[0025] Step 1. Ho, Fe, and B elemental substances with a purity ≥ 99.95% are pressed by Ho 5 Fe 17 B 17 Stoichiometric (atomic percent) ingredients of molecular formula;

[0026] Step 2. Smelting in a standard electric arc furnace under the protection of argon, in order to ensure that the composition of the alloy is uniform, turn over and smelt repeatedly for 3 to 4 times;

[0027] Step 3. Take out the smelted ingot and seal it in a vacuum quartz tube, heat it at 800°C for 120 hours, and then quench it with ice water;

[0028] Step 4. The cooled alloy ingot obtained in step 3 is broken into coarse powder with particle size less than 0.5mm, and sieved under 300 mesh sieve;

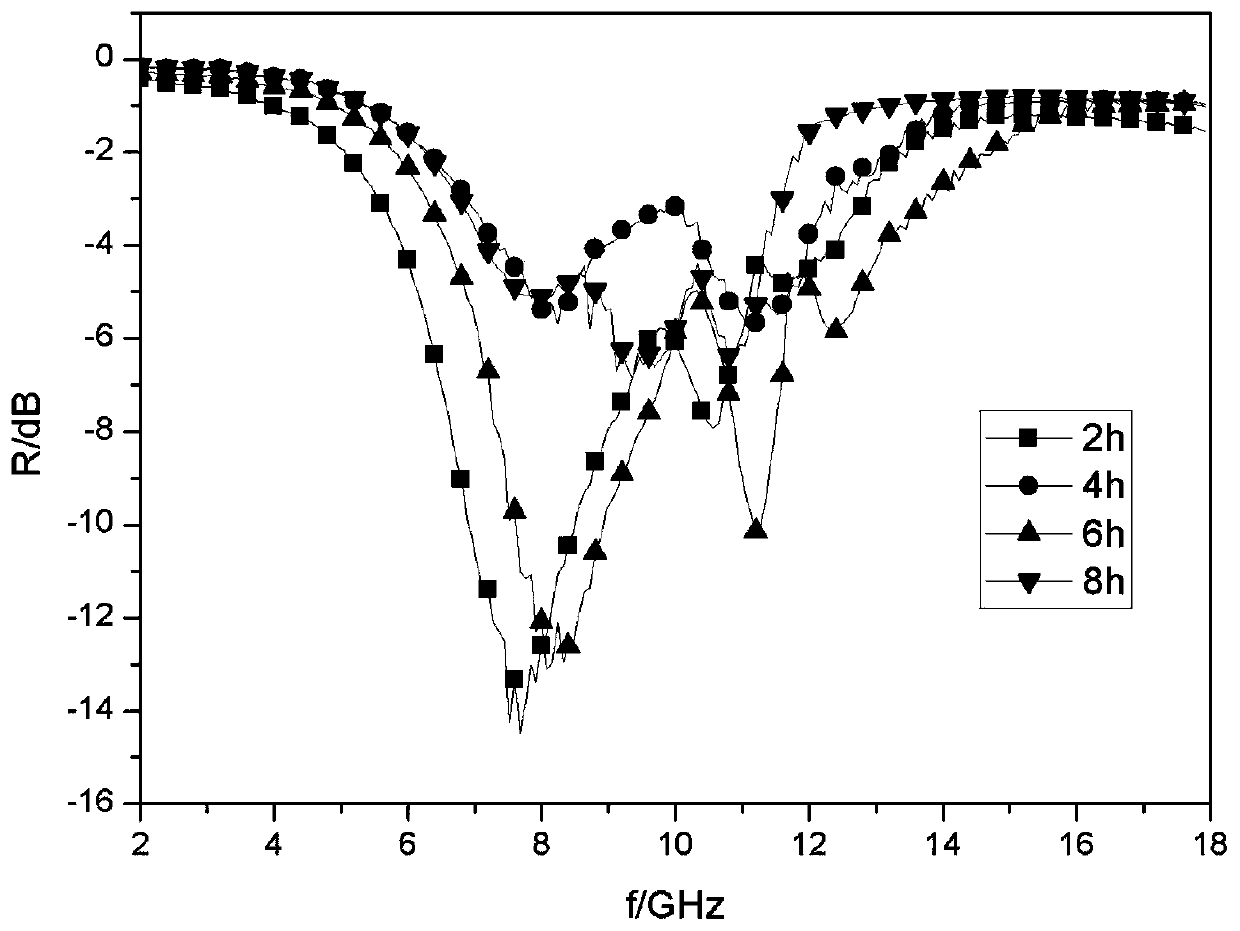

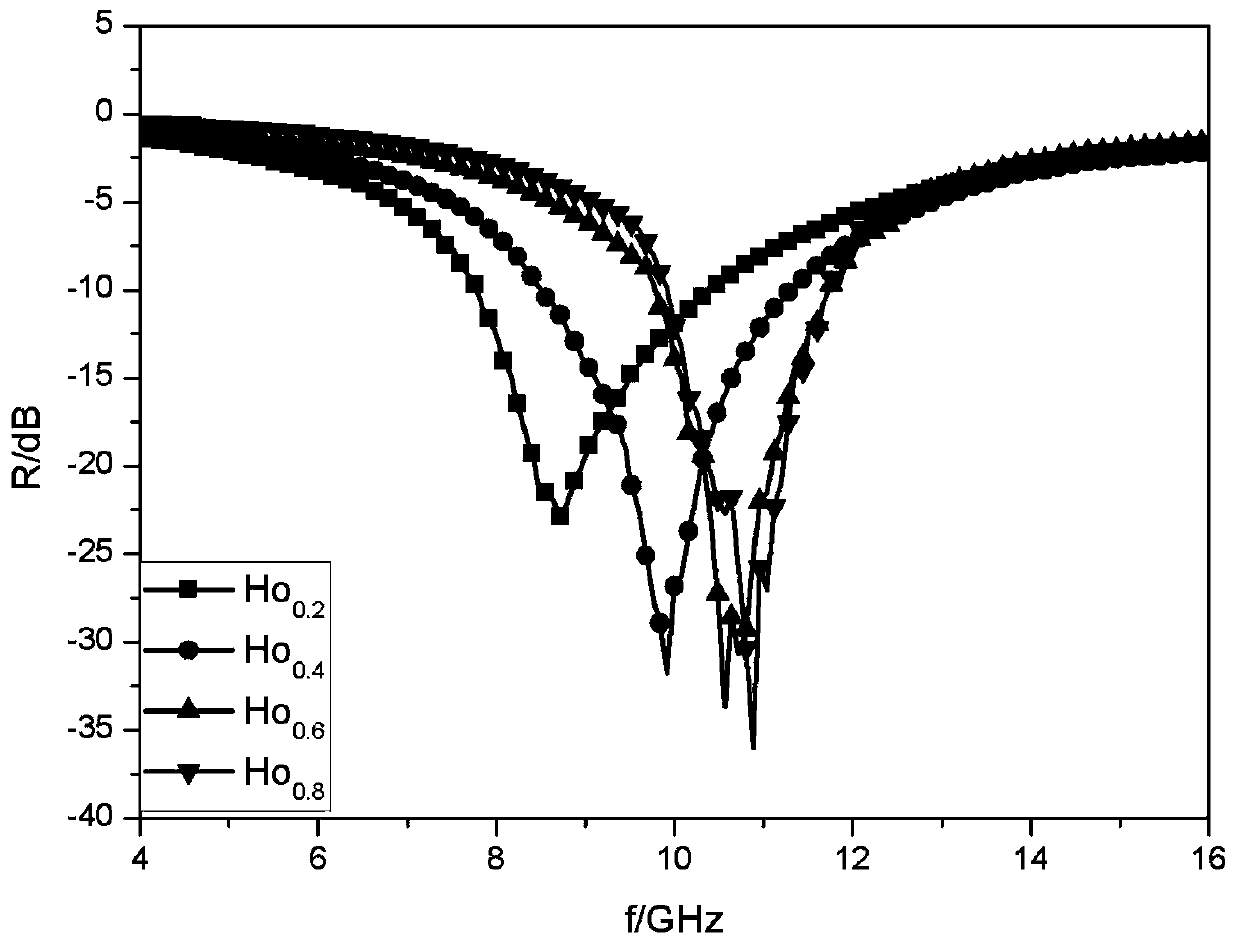

[0029] Step 5. The alloy ingot coarse powder obtained in step 4 is placed on a high-energy ball mill for 2 hours u...

Embodiment 2

[0034] Such as figure 1 As shown, a HoFeB / Fe proposed by the present invention 3 o 4 The preparation method of composite magnetic wave-absorbing material comprises the following steps:

[0035] Step 1. Ho, Fe, and B elements with a purity of ≥99.95%, press Ho 5 Fe 17 B 17 Stoichiometric (atomic percent) ingredients of molecular formula;

[0036] Step 2. Smelting in a standard electric arc furnace under the protection of argon, in order to ensure that the composition of the alloy is uniform, turn over and smelt repeatedly for 3 to 4 times;

[0037] Step 3. Take out the smelted ingot and seal it in a vacuum quartz tube, heat it at 800°C for 120 hours, and then quench it with ice water;

[0038] Step 4. The cooled alloy ingot obtained in step 3 is broken into coarse powder with particle size less than 0.5mm, and sieved under 300 mesh sieve;

[0039] Step 5. The alloy ingot coarse powder obtained in step 4 is placed on a high-energy ball mill for 4 hours under the protectio...

Embodiment 3

[0044] Such as figure 1 As shown, a HoFeB / Fe proposed by the present invention 3 o 4 The preparation method of composite magnetic wave-absorbing material comprises the following steps:

[0045] Step 1. Ho, Fe, and B elements with a purity of ≥99.95%, press Ho 5 Fe 17 B 17 Stoichiometric (atomic percent) ingredients of molecular formula;

[0046] Step 2. Smelting in a standard electric arc furnace under the protection of argon, in order to ensure that the composition of the alloy is uniform, turn over and smelt repeatedly for 3 to 4 times;

[0047] Step 3. Take out the smelted ingot and seal it in a vacuum quartz tube, heat it at 800°C for 120 hours, and then quench it with ice water;

[0048] Step 4. The cooled alloy ingot obtained in step 3 is broken into coarse powder with particle size less than 0.5mm, and sieved under 300 mesh sieve;

[0049] Step 5. The alloy ingot coarse powder obtained in step 4 is placed on a high-energy ball mill for 6 hours under the protectio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com