Preparation method and application of microwave absorbing diatom mud coating

A technology of diatom mud coating and microwave absorption, applied in radiation-absorbing coatings, coatings, coverings/linings, etc., can solve the problems of poor environmental adaptability, poor stability, and poor durability, and achieve low preparation costs and good dispersion , the effect of a wide range of sizes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

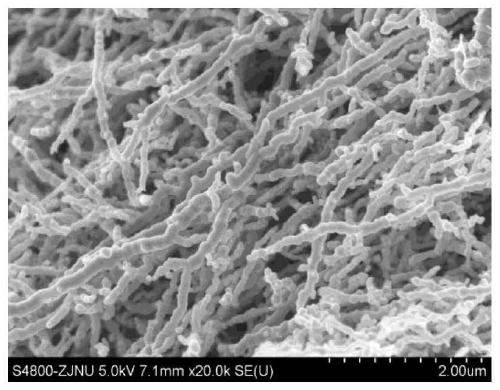

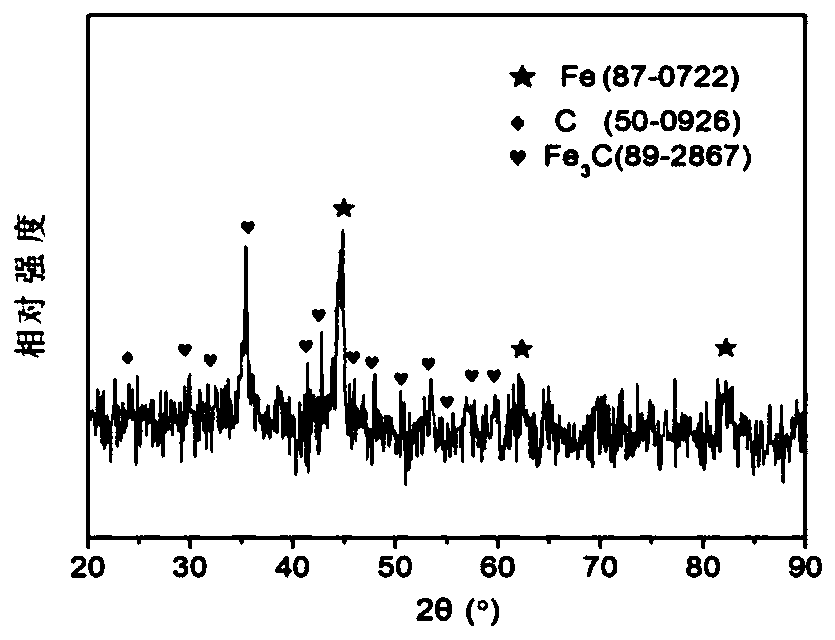

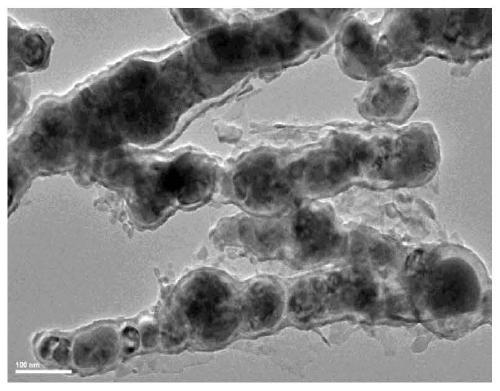

[0037] Add 0.01mol (0.05mol L -1 )FeSO 4 ·7H 2 O and 200 mL of water, stirred magnetically at room temperature, gave a light green solution. 0.02mol (0.1mol·L -1 )KBH 4 Add it into a beaker and stir it magnetically for 30 minutes. After the reaction is complete, cool it, separate it by magnetic separation, and wash it. Dry at 60°C for 6 hours to obtain the desired iron fibers. 0.3 grams of iron fiber was loaded with a ceramic ark of 6 cm × 3 cm × 1.5 cm, 2 mL of benzene was added to the ark, the ark was placed in a single-temperature tube furnace, and the reaction was carried out at 400 ° C for 2 h under nitrogen protection (the heating time was 1h). After the reaction was completed, it was cooled to room temperature with the furnace under the protection of nitrogen.

[0038]The resulting product is black, and the product's morphology, phase, structure, selected area electron diffraction pattern and Raman spectrum observed under a transmission electron microscope are as...

Embodiment 2

[0040] The steps are the same as in Example 1, but when the iron fiber is prepared, the iron salt is ferrous ammonium sulfate, and its iron ion concentration is 0.2mol L -1 , the organic substance is toluene, and its volume is 1 mL. The resulting product is black, and the morphology observed under the scanning electron microscope is as follows: Figure 6 As shown, it can be seen that the product is a fiber with a fiber diameter of 0.13-0.27 μm and an aspect ratio of 12.20-23.30. Static magnetic properties such as Figure 7 As shown, the saturation magnetization is 80.63emu·g -1 .

Embodiment 3

[0042] Using the product in Example 2 as a microwave absorber, soak the dry diatom ooze powder and the microwave absorber in water for 10 minutes, and then stir it electrically for 30 minutes to obtain a microwave-absorbing diatom ooze coating. The mass ratio of diatom mud dry powder, microwave absorber and water is 1:1.5:18. Distribute it on the wall by scraping (the construction schematic diagram is as follows Figure 8 shown), in order to measure the performance, distribute it on a 180cm×180cm metal plate, prepare a wave-absorbing coating plate with a thickness of 1.55-8.0mm, and a coloring layer and a light-receiving layer of 0.3-0.5mm on the surface, and measure it after 2 days of curing Its microwave absorption performance is Figure 9 shown. It can be seen that the maximum reflection loss is –43.7dB, of which the reflectivity is less than –10dB in the 2-18GHz frequency band; the reflectivity is less than –20dB in the 2.0-15.44GHz frequency band; the effective bandwidt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com