Rare earth ReCrO3 magnetic wave-absorbing material and preparation method thereof

A magnetic wave-absorbing and rare-earth technology, applied in chemical instruments and methods, and other chemical processes, can solve problems such as poor temperature stability, high density of magnetic wave-absorbing materials, and easy corrosion, and achieve good corrosion resistance and temperature stability , wide absorption frequency band, good oxidation resistance and corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

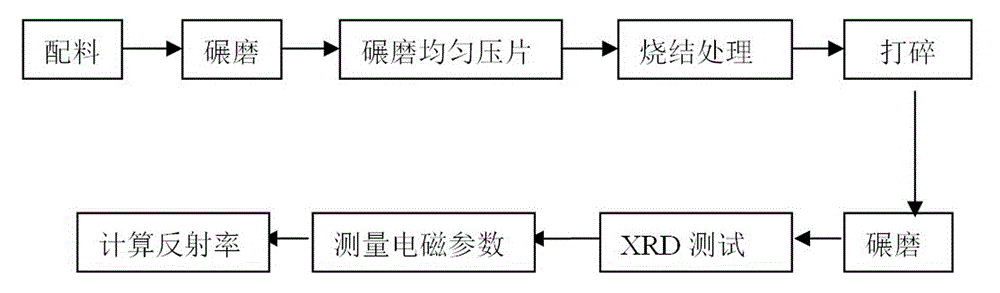

[0033] Preparation of SmCrO 3 The specific steps are:

[0034] 1) Sm with a purity ≥ 99.50% 2 o 3 、Cr 2 o 3 Powder as raw material, according to SmCrO 3 Stoichiometric ratio ingredients of molecular formula;

[0035] 2) Grind in an agate bowl mill for half an hour to mix well;

[0036] 3) Press the uniformly mixed powder into flakes with a diameter of 1.5cm and a thickness of 0.3~0.8cm, with a pressure of 20~30MPa;

[0037] 4) After the powder is mixed evenly, the pressed flakes are sintered in the atmosphere at a temperature of 1500 °C;

[0038] 5) Carry out 1500℃×24 sintering heat treatment on the thin slice in the atmosphere, that is, the sintering temperature is 1500℃ for 24h;

[0039] 6) Break the sintered flakes into fine powder with particle size less than 0.3mm.

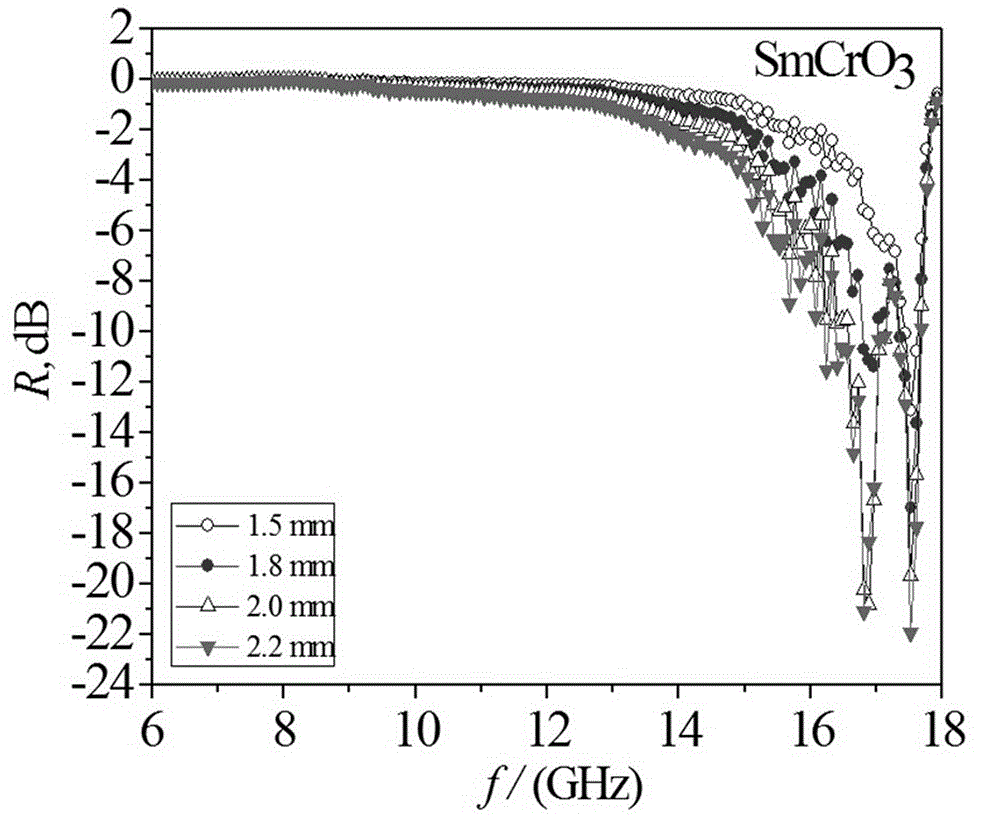

[0040] Product testing by SmCrO 3 Powder: paraffin wax = 4:1 (mass ratio) mixed to make coaxial samples with outer and inner diameters of 7mm and 3mm respectively, and thicknesses of 1.3mm, 1.5mm an...

Embodiment 2

[0046] Preparation of EuCrO 3 The specific implementation steps are:

[0047] 1) Eu with purity ≥ 99.50% 2 o 3 、Cr 2 o 3 Powder as raw material, according to EuCrO 3 Stoichiometric ratio ingredients of molecular formula;

[0048] 2) Grind in an agate bowl mill for half an hour to mix well;

[0049] 3) Press the uniformly mixed powder into flakes with a diameter of 1.5cm and a thickness of 0.3~0.8cm, with a pressure of 20~30MPa;

[0050] 4) After the powder is mixed evenly, the pressed flakes are sintered in the atmosphere at a temperature of 1500 °C;

[0051] 5) Carry out 1500℃×24 sintering heat treatment on the thin slice in the atmosphere, that is, the sintering temperature is 1500℃ for 24h;

[0052] 6) Break the sintered flakes into fine powder with particle size less than 0.3mm.

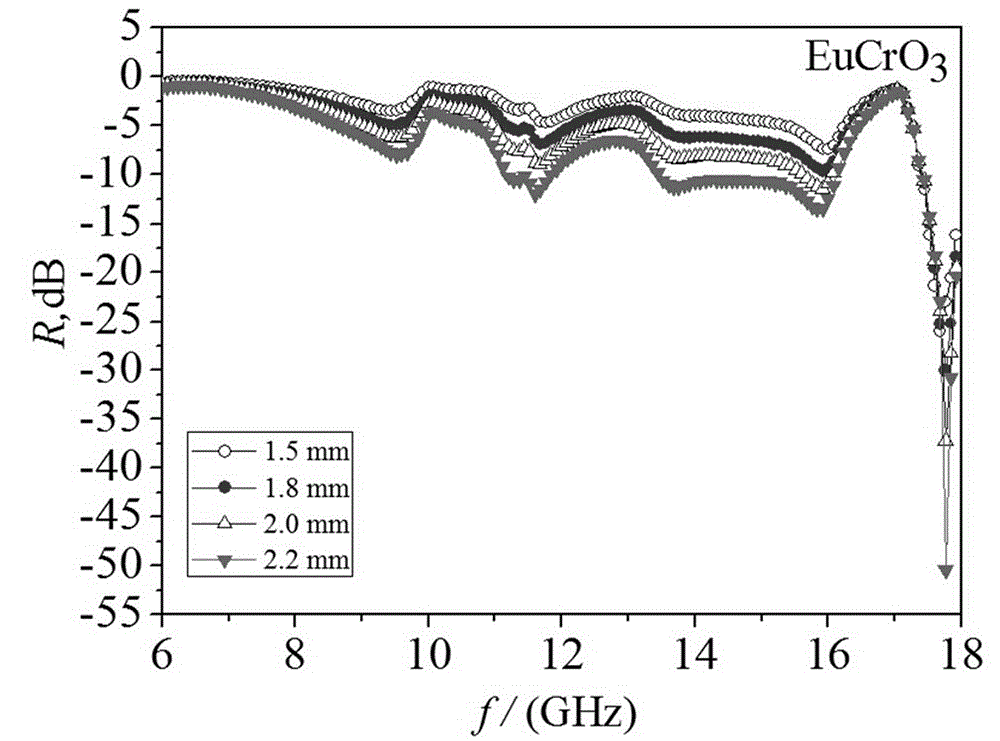

[0053] Product testing: by EuCrO 3 Powder: paraffin wax = 4:1 (mass ratio) mixed to make coaxial samples with outer and inner diameters of 7mm and 3mm respectively, and thicknesses of 1...

Embodiment 3

[0057] Preparation of DyCrO 3 The specific implementation steps are:

[0058] 1) Dy with a purity ≥ 99.50% 2 o 3 、Cr 2 o 3 Powder as raw material, according to DyCrO 3 Stoichiometric ratio ingredients of molecular formula;

[0059] 2) Grind in an agate bowl mill for half an hour to mix well;

[0060] 3) Press the uniformly mixed powder into flakes with a diameter of 1.5cm and a thickness of 0.3~0.8cm, with a pressure of 20~30MPa;

[0061] 4) After the powder is mixed evenly, the pressed flakes are sintered in the atmosphere at a temperature of 1500 °C;

[0062] 5) Carry out 1500℃×24 sintering heat treatment on the thin slice in the atmosphere, that is, the sintering temperature is 1500℃ for 24h;

[0063] 6) Break the sintered flakes into fine powder with particle size less than 0.3mm.

[0064] Product Test: By DyCrO 3 Powder: paraffin wax = 4:1 (mass ratio) mixed to make coaxial samples with outer and inner diameters of 7mm and 3mm respectively, and thicknesses of 1....

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com