Multiferroic wave absorbing material and preparation method thereof

An iron-absorbing and layered technology, which is applied in the field of modified multiferroic microwave absorbing materials and its preparation, can solve the problems of inability to provide high magnetic loss, weak magnetic properties, and difficulty in achieving impedance matching, and achieve good microwave absorption characteristics, absorption The effect of wide frequency bandwidth and easy control of process conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

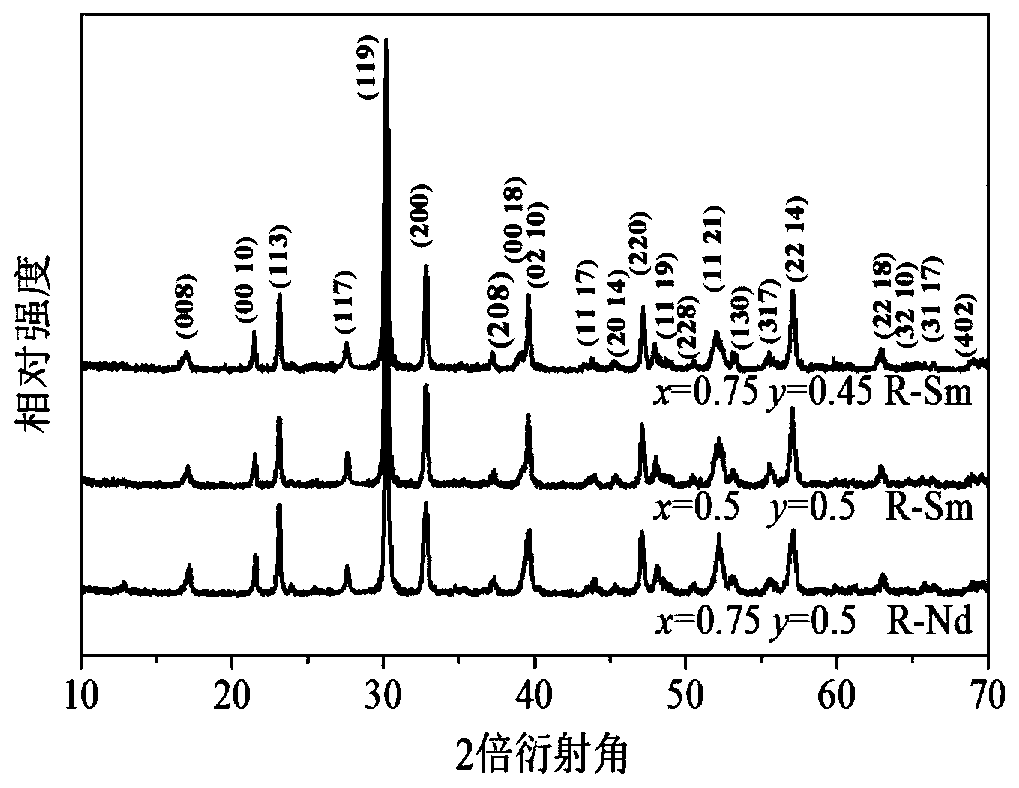

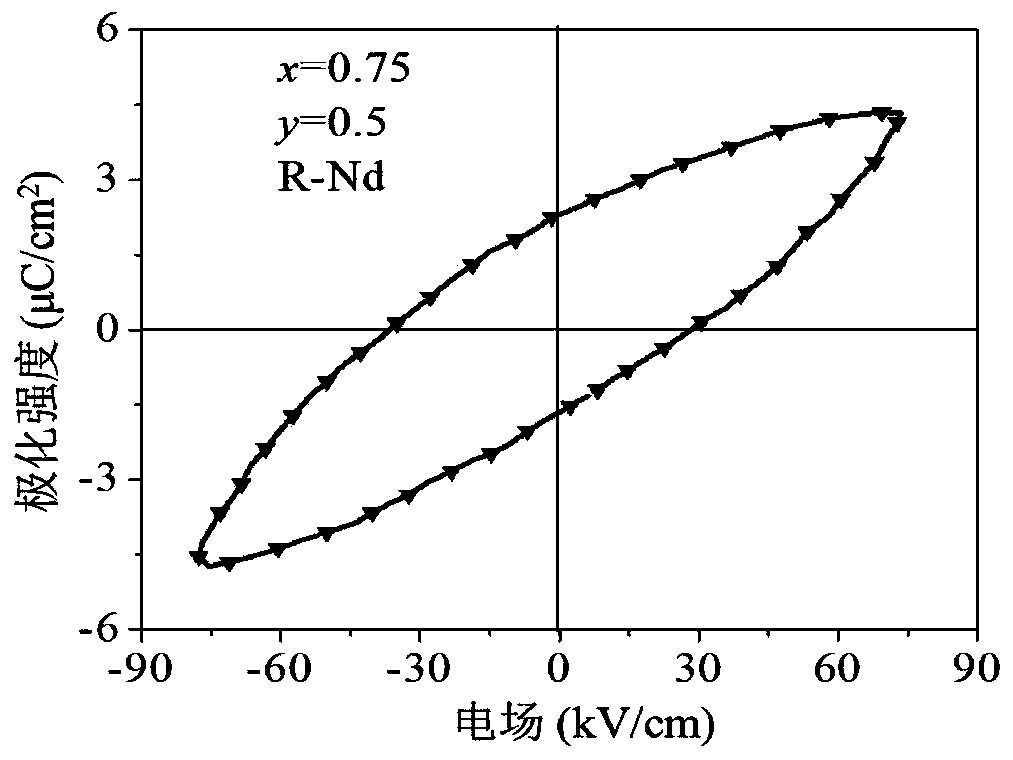

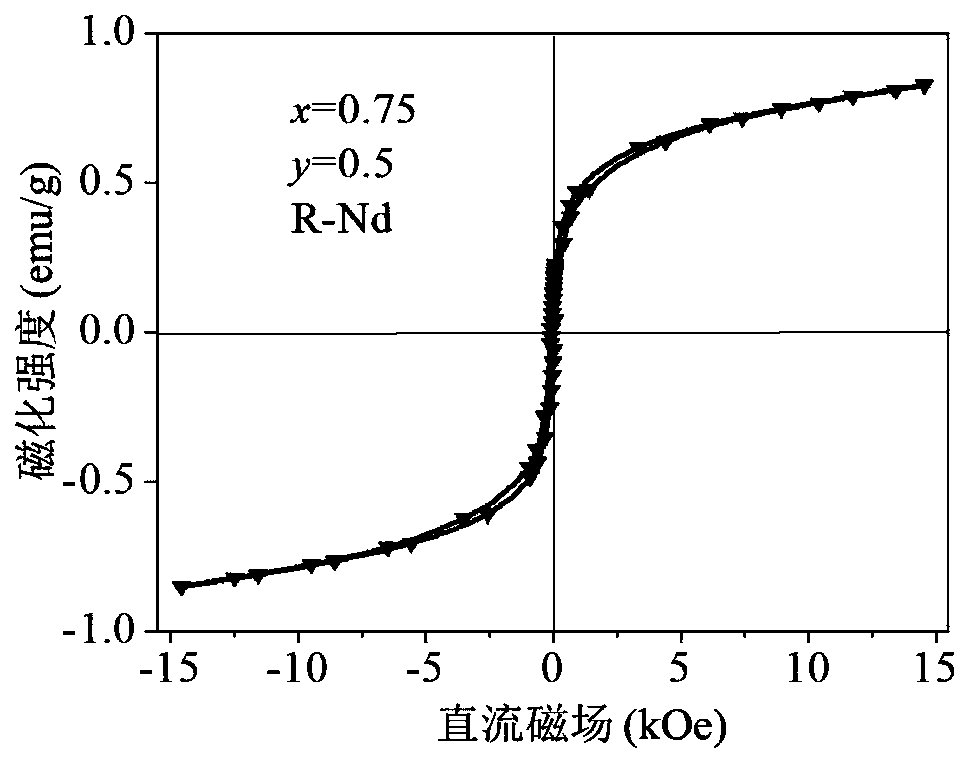

[0045] The chemical formula of the multiferroic absorbing material in this embodiment is Bi 5-x R x Fe 1-y Ni y Ti 3 o 15 ( x =0.75, y =0.5; R is Nd); its preparation method is:

[0046] (1) Bi 4-x R x Ti 3 o 12 Preparation of sol: Weigh 78.82g bismuth nitrate pentahydrate (99% purity), 16.43g neodymium nitrate hexahydrate (99% purity) and 51.05g titanic acid according to the stoichiometric ratio of Bi:Nd:Ti 3.25:0.75:3 Add 500mL of deionized water, 23.52g of ethylenediaminetetraacetic acid (98% of purity) and 61.85g of citric acid (98% of purity) into n-butyl ester (98% of purity), heat and stir to obtain a uniform mixture; then use Adjust the pH value to neutral with ammonia water, place it in a water bath at a constant temperature of 90°C, heat and stir for 4 hours, and obtain a stable and uniform Bi 4-x R x Ti 3 o 12 Sol;

[0047] (2) Bi 4-x R x Ti 3 o 12 Preparation of powder: Place the sol obtained in step (1) in a drying oven at 160°C and dry for 4 h...

Embodiment 2

[0060] The chemical formula of the multiferroic absorbing material in this embodiment is Bi 5-x R x Fe 1-y Ni y Ti 3 o 15 ( x =0.5, y =0.5; R is Sm), its preparation method is:

[0061] (1) Bi 4-x R x Ti 3 o 12 Preparation of sol: Weigh 84.89g bismuth nitrate pentahydrate (99% purity), 10.66g samarium nitrate pentahydrate (99% purity) and 51.05g titanic acid according to Bi:Sm:Ti stoichiometric ratio 3.5:0.5:3 Add 500mL of deionized water, 23.52g of ethylenediaminetetraacetic acid (98% of purity) and 61.85g of citric acid (98% of purity) into n-butyl ester (98% of purity), heat and stir to obtain a uniform mixture, and then use Adjust the pH value to neutral with ammonia water, place it in a water bath with a constant temperature of 85°C, heat and stir for 5 hours, and obtain a stable and uniform Bi 4-x R x Ti 3 o 12 Sol;

[0062] (2) Bi 4-x R x Ti 3 o 12 Preparation of powder: the Bi obtained in step (1) 4-x R x Ti 3 o 12 The sol was dried in a drying ...

Embodiment 3

[0071] The chemical formula of the multiferroic absorbing material in this embodiment is Bi 5-x R x Fe 1-y Ni y Ti 3 o 15 ( x =0.75, y =0.45; R is Sm), its preparation method is:

[0072] (1) Bi 4-x R x Ti 3 o 12 Preparation of sol: Weigh 78.82g bismuth nitrate pentahydrate (purity 99%), 15.99g samarium nitrate pentahydrate (purity 99%) and 51.05g titanic acid according to the stoichiometric ratio of Bi:Sm:Ti 3.25:0.75:3 Add 500mL of deionized water, 31.56g of ethylenediaminetetraacetic acid (98% of purity) and 59.95g of citric acid (98% of purity) into n-butyl ester (98% of purity), heat and stir to obtain a uniform mixture; then use Adjust the pH value to 7 with ammonia water, place it in a water bath with a constant temperature of 90°C, heat and stir for 4 hours, and obtain a stable and uniform Bi 4-x R x Ti 3 o 12 Sol;

[0073] (2) Bi 4-x R x Ti 3 o 12 Preparation of powder: the Bi obtained in step (1) 4-x R x Ti 3 o 12 The sol was dried in a drying...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| optical bandwidth | aaaaa | aaaaa |

| optical bandwidth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com