Patents

Literature

47results about How to "Enhanced magnetic loss" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

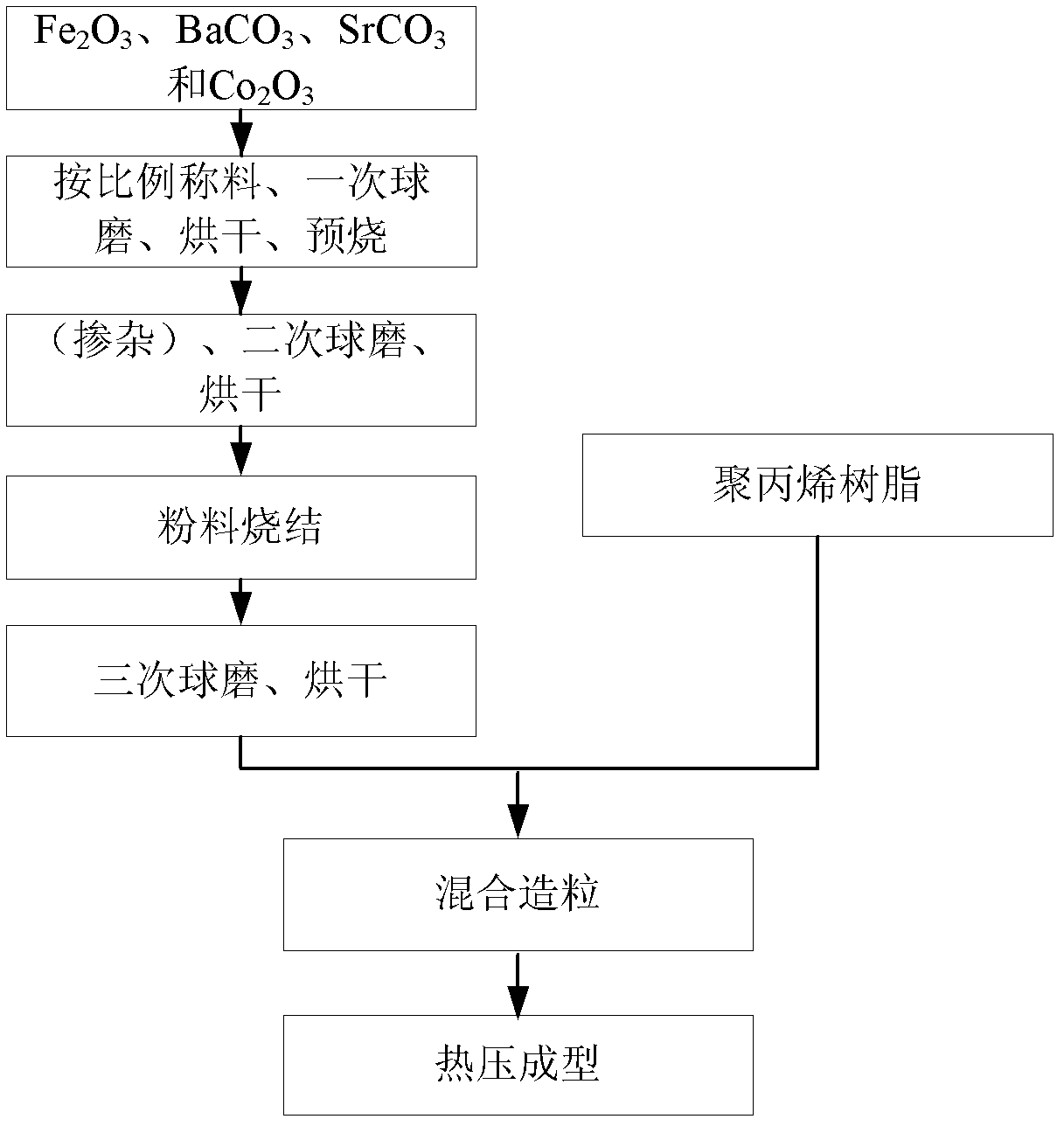

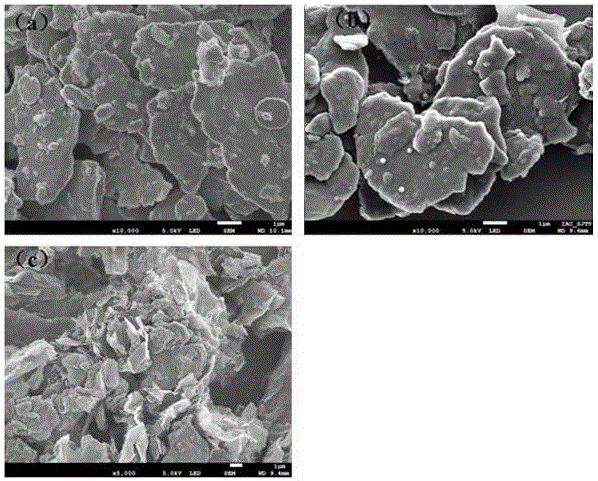

Microstrip antenna composite substrate material and its preparation method

Belonging to the technical field of electronic materials, the invention relates to a microstrip antenna composite substrate material and its preparation method. The composite substrate material is formed by compounding 70-90 parts by mass of a main phase material and 10-30 parts by mass of an auxiliary phase material, wherein, the main phase material is a Co2Z hexagonal ferrite which has a molecular formula of Ba3-xSrxCo2Fe24O41 (with x located in the range of 0-1.5), and the auxiliary phase material is polypropylene resin. The preparation method consists of: 1) material weighing, mixing, first ball milling and drying; 2) presintering; 3) secondary ball milling and drying; 4) sintering; 5) tertiary ball milling and drying; 6) compounding and granulation; 7) thermoforming, etc. The composite substrate material has an isomagnetic dielectric property and low loss in a frequency scope of 300MHz-3GHz, and has certain flexibility at the same time. The preparation method in the invention is simple and easy to operate, and convenient for mastering and popularization. Employment of the composite substrate material as a microstrip antenna substrate is conducive to reduce microstrip antenna weight and volume, and is in favor of enhancing the bandwidth and radiation efficiency of microstrip antennas.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

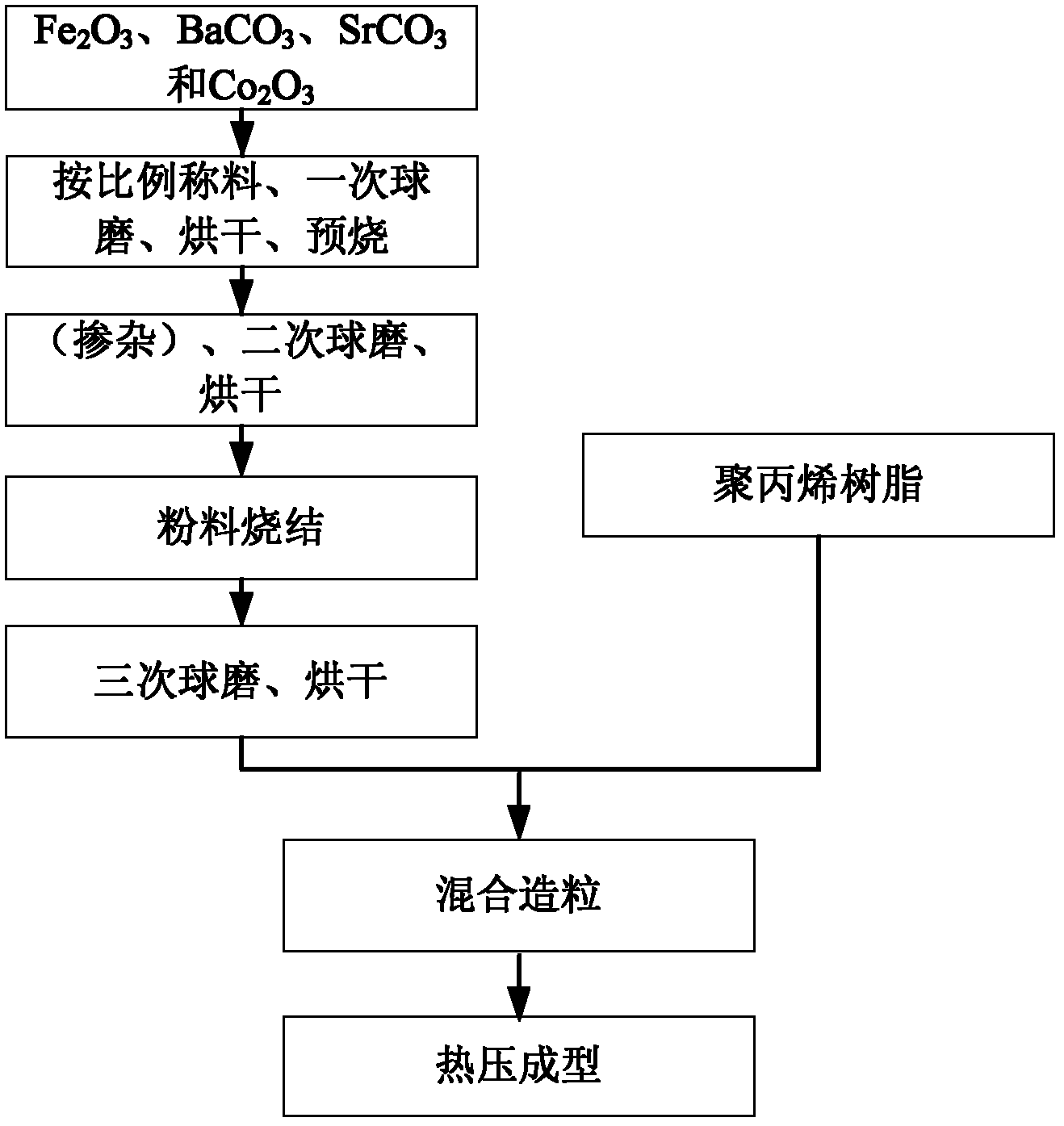

FeCoNi@C/carbon fiber aerogel composite absorbing material and preparation method thereof

ActiveCN110983492ASimple manufacturing methodFacilitate large-scale applicationOther chemical processesArtifical filament manufactureCarbon compositesCarbon fibers

The invention discloses a FeCoNi@C / carbon fiber aerogel composite absorbing material. The composite absorbing material comprises a carbon fiber matrix and a FeCoNi@ carbon composite nanosphere, wherein the FeCoNi@ carbon composite nanosphere is loaded on the surface of the carbon fiber matrix. The composite absorbing material takes carbon fibers as the matrix, and the microspherical FeCoNi@C derived from FeCoNi-MOF is loaded on the surface of the matrix; the prepared composite material solves a problem that a single carbon material and a monometallic MOF derivative material lack a plurality ofeffective electromagnetic wave loss mechanisms to cooperate, the good impedance matching is obtained, the better absorption efficiency is achieved, and the composite material is an ideal selection ofa novel light-weight and efficient microwave absorbing material.

Owner:SOUTHEAST UNIV

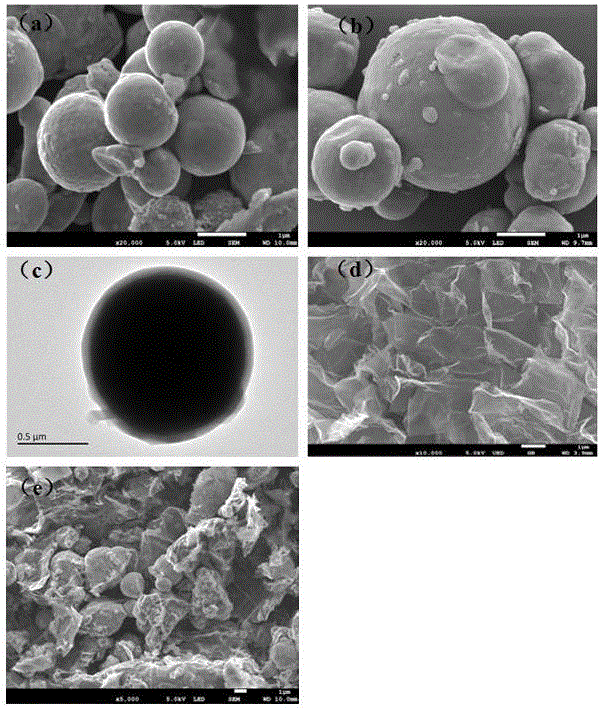

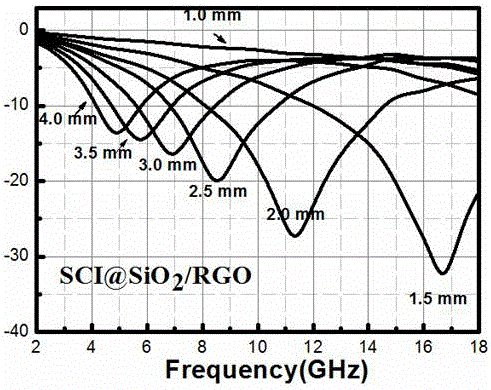

Graphene-based ternary composite wave-absorbing material and preparation method thereof

InactiveCN106800916ALow dielectric constantImproved Impedance Matching CharacteristicsOther chemical processesMicrowaveSilicon dioxide

The invention relates to the technical field of microwave absorption, in particular to a graphene-based ternary composite wave-absorbing material and a preparation method thereof. The preparation method comprises the steps of firstly, preparing silicon dioxide-coated carbonyl iron core-shell composite particles by using a sol-gel method, then preparing graphite oxide by using an improved Hummers method, evenly dispersing the graphite oxide into dispersion liquid of the silicon dioxide-coated carbonyl iron core-shell composite particles, and finally, using an ultrasonic reduction method to enable graphite oxide to be reduced into graphene so as to prepare the graphene-based ternary composite wave-absorbing material. The preparation method provided by the invention is simple and efficient; the prepared composite wave-absorbing material is more excellent in wave absorbing performance, high in wave absorbing strength, wide in wave absorbing bandwidth and smaller in density compared with a pure carbonyl iron binary composite wave-absorbing material and a pure graphene and carbonyl iron or graphene binary composite wave-absorbing material; the graphene-based ternary composite wave-absorbing material also has regulation performance, and can realize strong wave absorption under different frequencies by adjusting the thickness of a coating layer SiO2, the mass ratio of graphene to the coated core-shell composite particles and the thickness of the ternary composite material.

Owner:INST OF DONGGUAN TONGJI UNIV +1

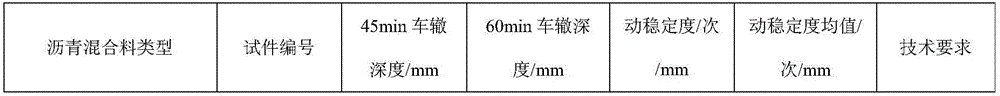

Asphalt pavement material rapidly restored through microwave heating

ActiveCN106082740AChange electromagnetic parametersImprove absorption efficiencySolid waste managementMicrowaveSlag

The invention discloses an asphalt pavement material rapidly restored through microwave heating. Aggregates in the asphalt pavement can be partially or completely substituted by modified steel slag. The modified steel slag is obtained through partially or completely converting Fe2O3 on the surface of a raw material industrial solid waste common steel slag into magnetic Fe3O4 in a surface component conversion or modification mode. The modified steel slag is uniformly dispersed in the asphalt pavement to make the asphalt pavement have uniform microwave absorption capability and realizen a uniform heating effect. An asphalt film wrapped on the surface of the modified steel slag can rapidly recover fluidity in the microwave heating restoration process, so the microwave heating efficiency and the microwave restoration speed of the asphalt pavement are greatly improved. The wave absorption efficiency and the heating rate of the asphalt pavement are 2 or above times those of traditional asphalt pavements, the cost is low, and the maintenance and restoration effects and the working efficiency of the asphalt pavement are greatly improved.

Owner:SOUTHEAST UNIV

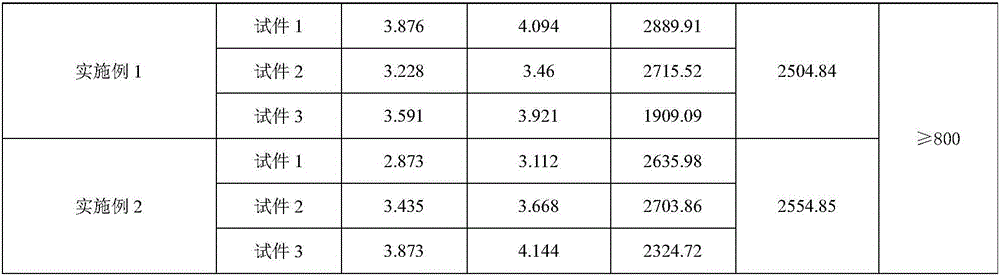

Preparation method of three-dimensional ordered carbon-based porous wave-absorbing material based on native wood

PendingCN110734048AChange the absorbing performancePromote graphitizationOther chemical processesCarbon preparation/purificationTube furnaceCarbonization

The invention provides a preparation method of a three-dimensional ordered carbon-based porous wave-absorbing material based on native wood. The preparation method comprises the following steps: S1, cutting the native wood into cuboids with preset sizes, soaking the formed wood blocks for 1-2 days, repeatedly washing the wood blocks with deionized water multiple times, and finally drying the woodblocks at 50-70 DEG C; S2, putting the wood blocks dried in the step S1 into a tubular furnace, carrying out heating to 350-450 DEG C, and keeping the wood blocks at the temperature for 0.5-1 hour toobtain pre-carbonized charcoal blocks; S3, mixing the pre-carbonized charcoal blocks with Fe (NO3) 3 having a concentration of 0.05 to 0.2 mol / L, and carrying out drying at a temperature of 50 and 70DEG C; and S4, putting a product obtained after drying in the S3 into the tubular furnace, carrying out heating to a preset temperature, keeping the product at the temperature for 0.5-1 hour, and taking out a sintered product when the temperature decreases to room temperature, thereby obtaining the three-dimensional ordered carbon-based porous wave-absorbing material. The three-dimensional orderedcarbon-based porous wave-absorbing material obtained by using the method can be used as an excellent wave-absorbing material with light weight, small thickness, wide absorption frequency band and strong absorption characteristics.

Owner:HARBIN INST OF TECH AT WEIHAI +1

Electromagnetic shielding rubber material

The invention discloses an electromagnetic shielding rubber material. Conducting materials are uniformly distributed in rubber matrix. The electromagnetic shielding rubber material comprises the following components in parts by mass: 100 parts of rubber matrix, 20 to 30 parts of carbon black, 20 to 55 parts of nickel-plated carbon nanotubes, 5 to 15 parts of metal powder, 2 to 4 parts of sulphur,1 to 3 parts of a vulcanizing agent DCP, 1 to 2 parts of an accelerant TMTD, 1 to 2 parts of an accelerant CZ, 2 to 5 parts of a coupling agent KH-570, 1 to 2 parts of hydroxyl silicone oil, 2 to 4 parts of a plasticizer DBP, 2 to 5 parts of a dispersing agent, 0.5 to 1 part of an antiager TK-100, and 0.5 to 1 part of an antiager TK-101. The electromagnetic shielding rubber material is excellent in mechanical property and electrical and thermal conductivity, high in Electromagnetic shielding effectiveness, and medium in cost, and has excellent integrated quality.

Owner:TAICANG GUANLIAN POLYMERIC MATERIAL

Absorbing agents, preparation method, application and absorbing materials of magnetic fluorocarbon materials

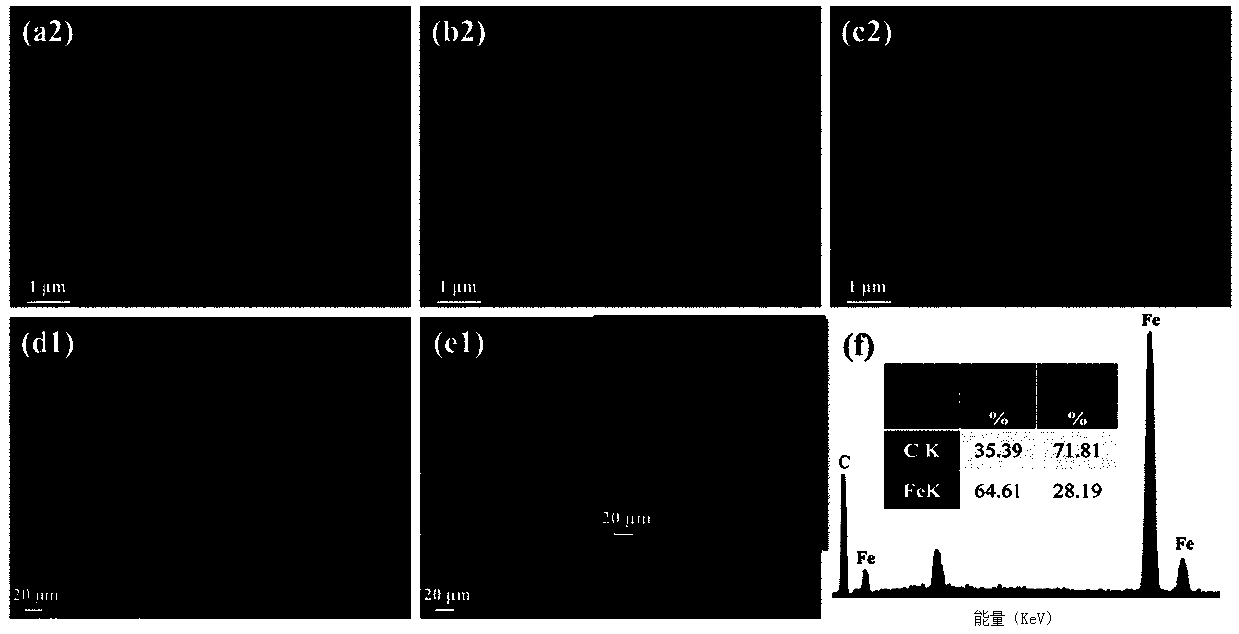

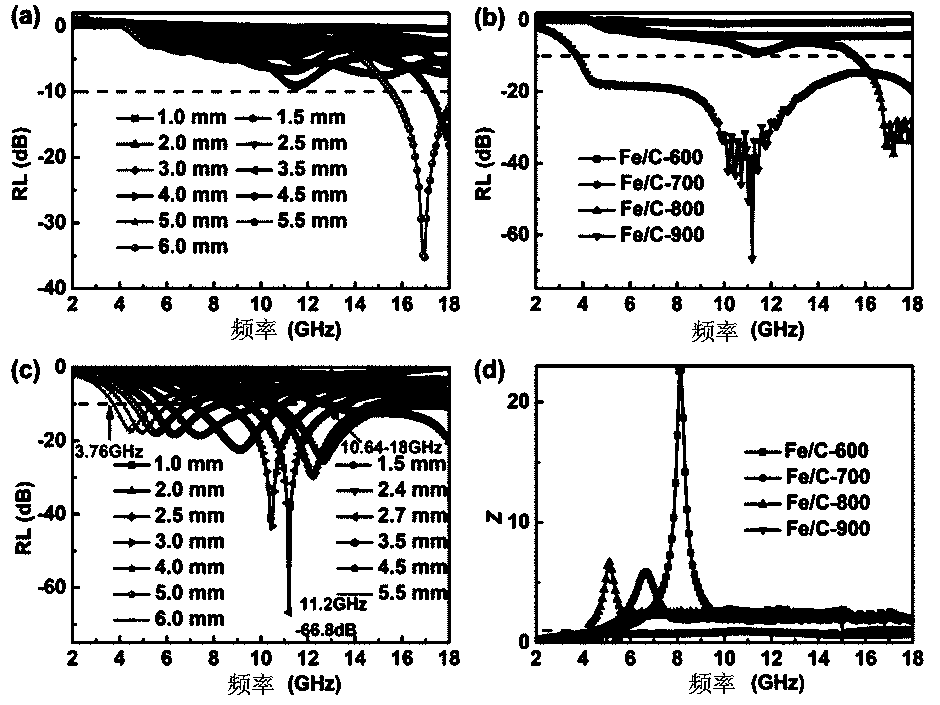

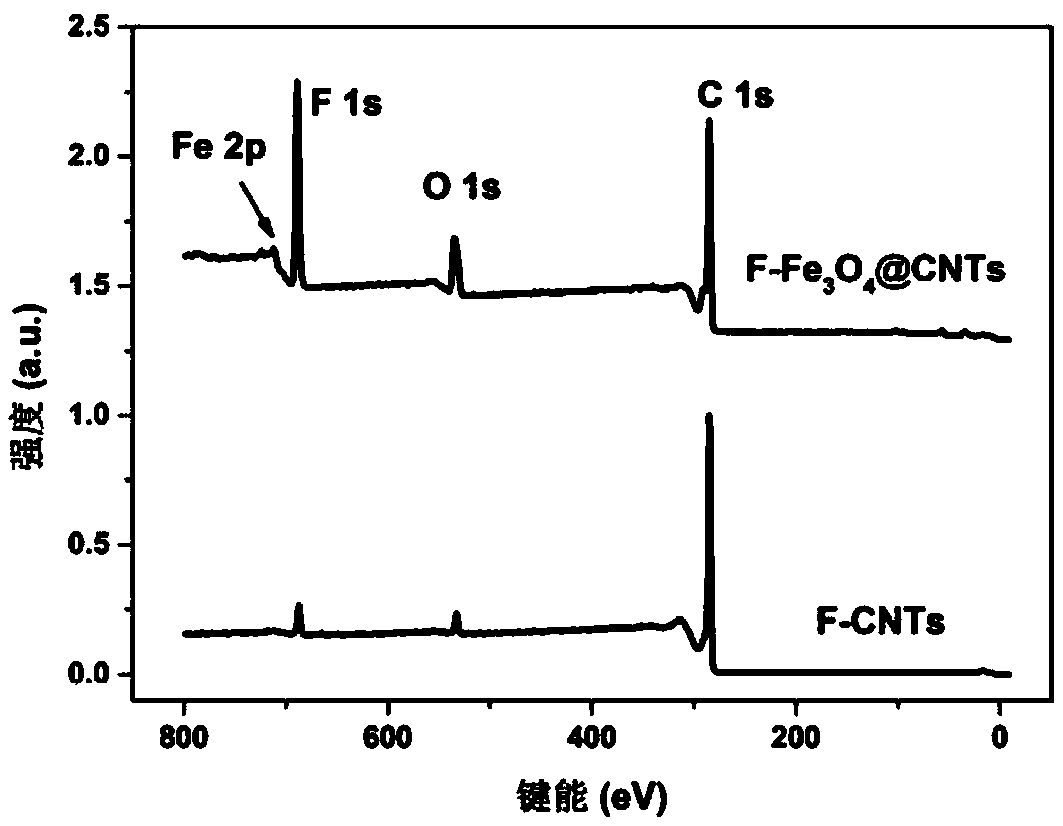

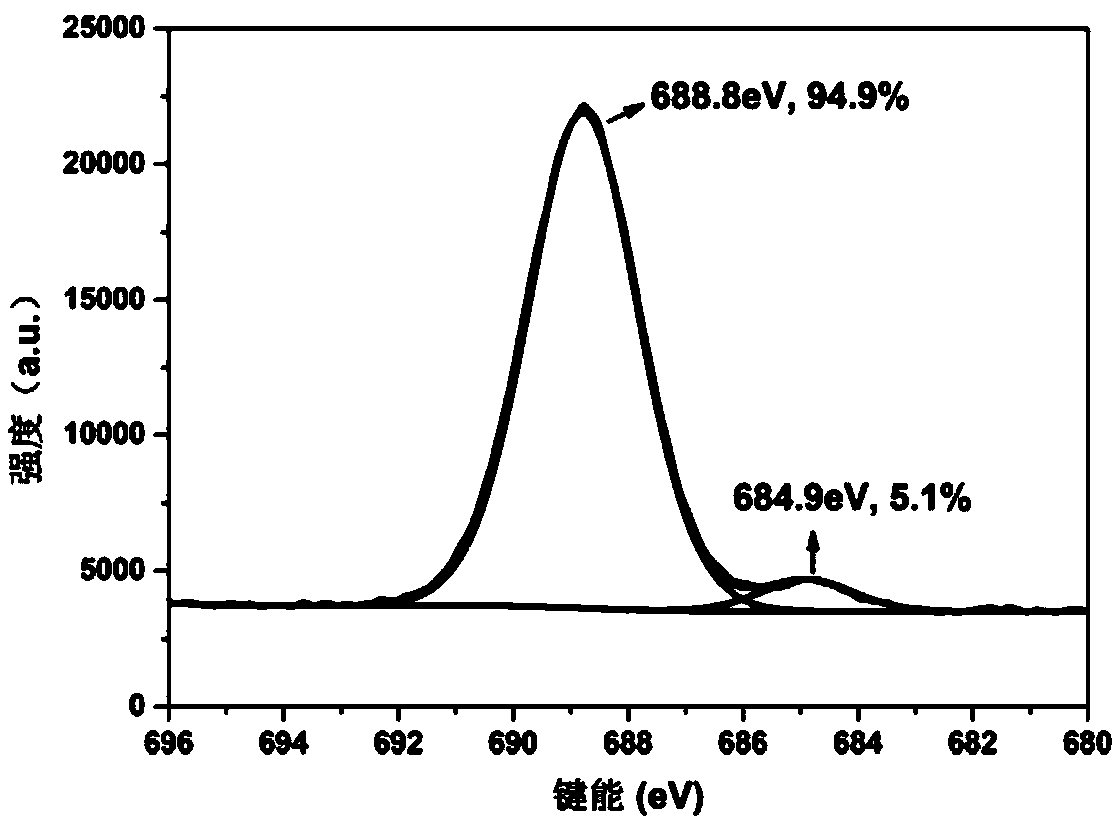

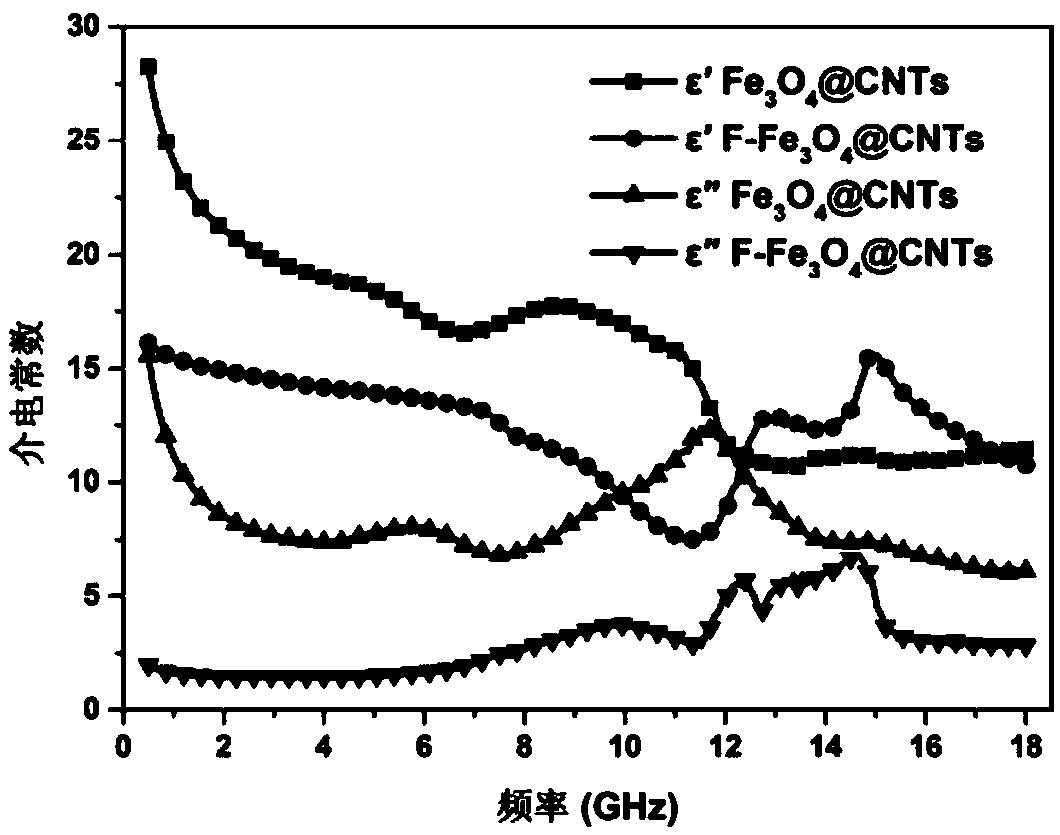

InactiveCN108682527ASimple processLow costMagnetic/electric field screeningCarbon nanotubesMagnetite NanoparticlesCarbon nanotube

The invention belongs to the technical field of absorbing materials and relates to absorbing agents, a preparation method, application and the absorbing materials of magnetic fluorocarbon materials. The preparation method includes: firstly, magnetic nanoparticles are loaded on carbon materials to prepare ferriferrous oxide @ carbon material composites, and then the ferriferrous oxide @ carbon material composites are fluoridized at 0-30 DEG C. The absorbing agents, the preparation method, the application and the absorbing materials of the magnetic fluorocarbon materials have the advantages that: on the one hand, the introduction of the ferriferrous oxide can increase the magnetism of carbon nanotubes; on the other hand, the ferriferrous oxide can improve the fluorination reaction activity of the carbon nanotubes; therefore, fluorinated carbon nanotubes with high fluorination degree can be prepared at lower temperature, thereby being beneficial to reduce the dielectric constant of the absorbing agents. Therefore, the magnetic fluorinated carbon nanotubes have high permeability and low dielectric constant to show good impedance matching, thereby having strong absorbing intensity and wide absorbing frequency band and meeting the requirements of 'light, thin, strong and wide' of novel absorbing materials.

Owner:SICHUAN UNIV

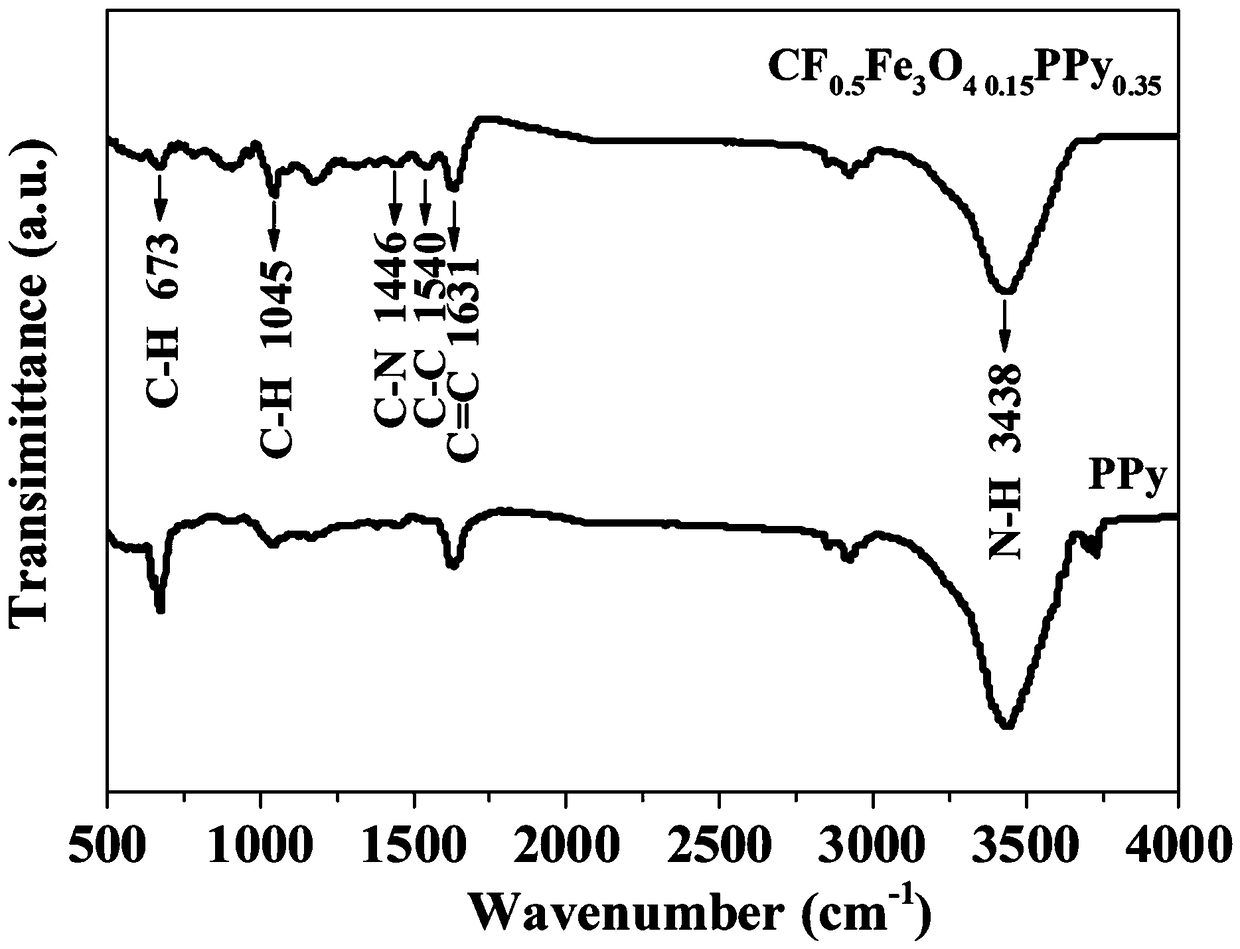

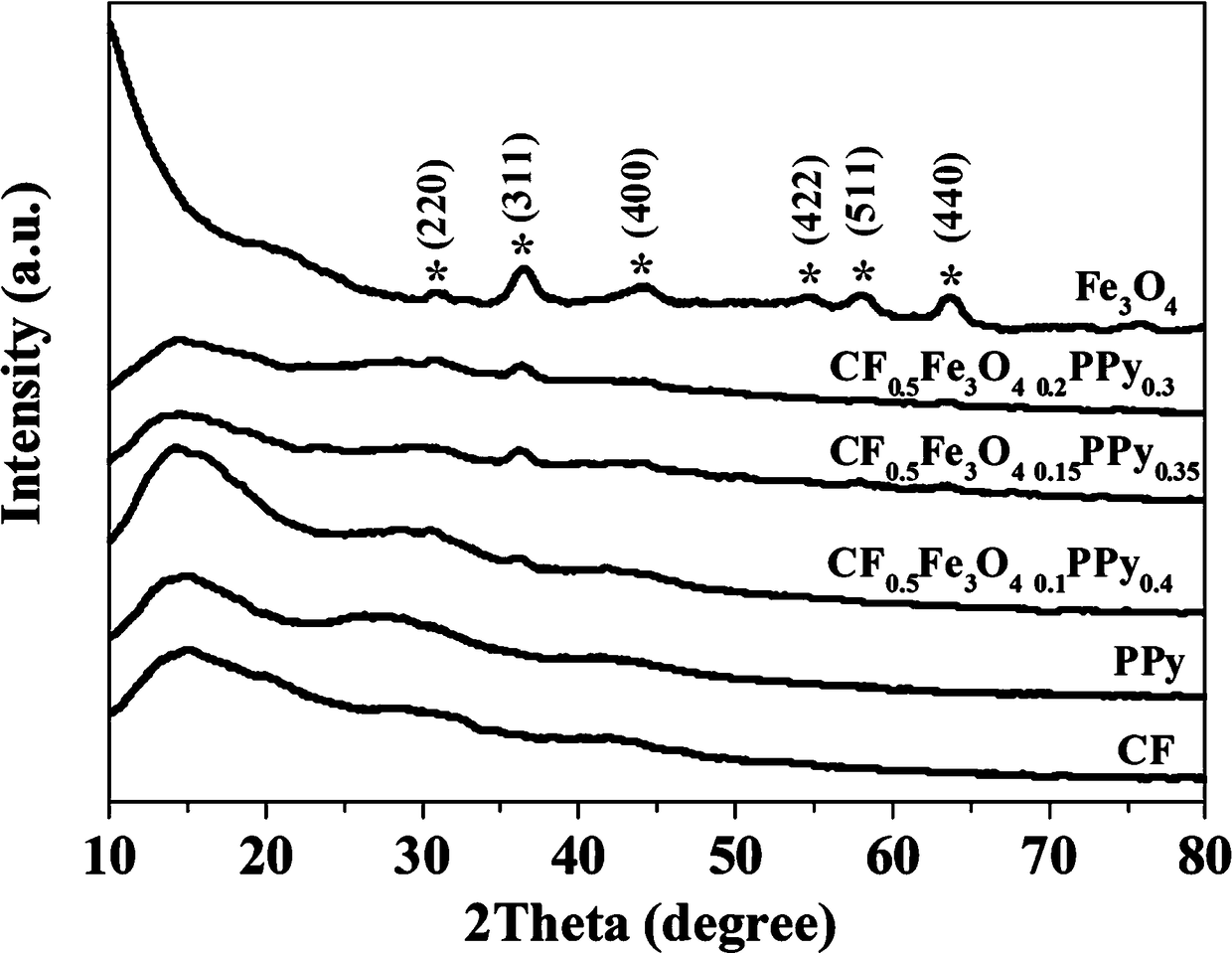

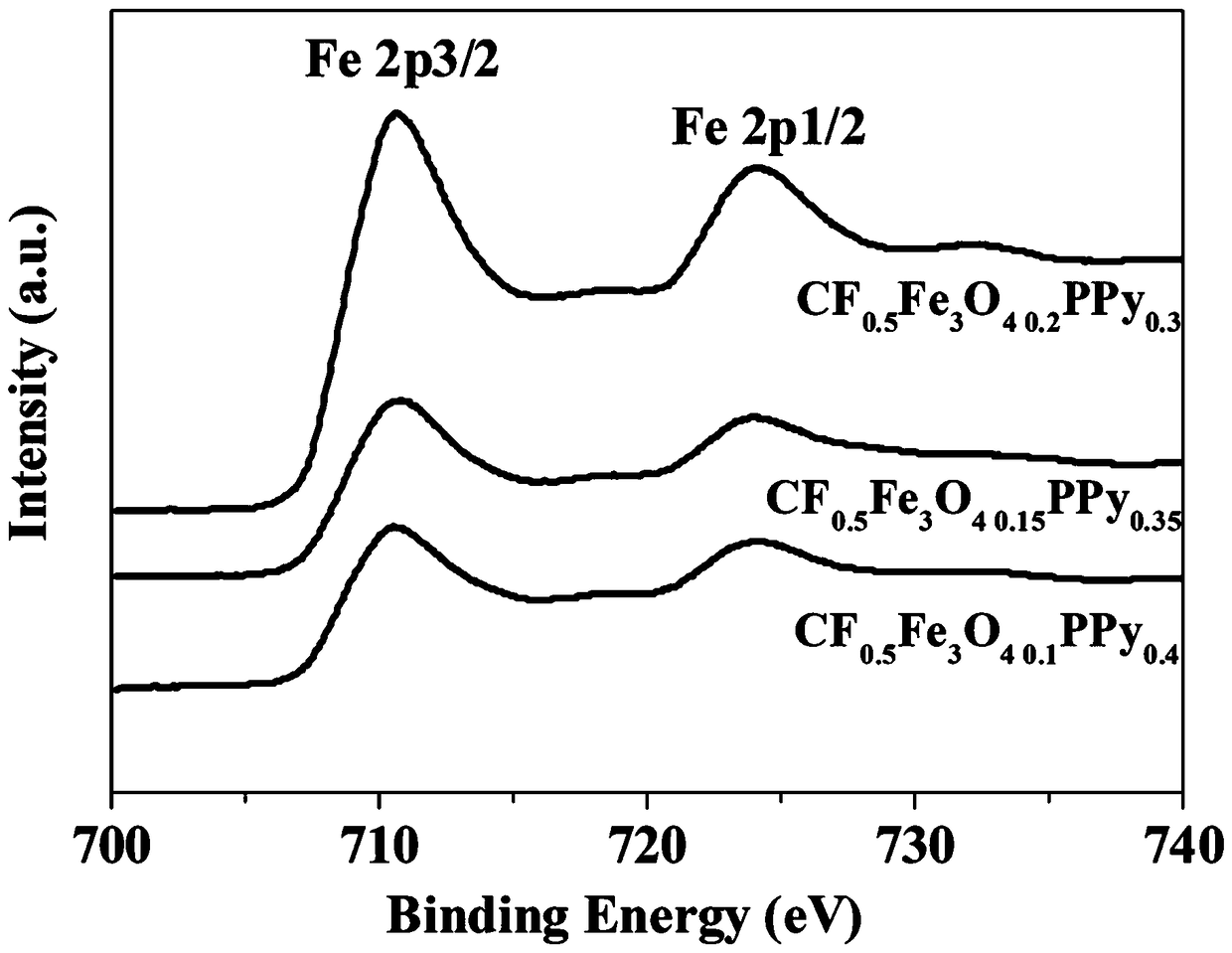

Ferroferric oxide/polypyrrole composite material and preparation method thereof

The invention disclose a ferroferric oxide / polypyrrole composite material and a preparation method thereof. The collagen fiber adopted as a dispersion base is uniformly dispersed into nano ferroferricoxide, and in-situ polymerization is performed so as to generate polypyrrole adopted as a dielectric-type wave absorber for wrapping the collagen fiber, so that the problem that nano materials are easy to cluster is solved, and translation of the nano materials is prevented. The fiber material utilizes ferroferric oxide as a magnetic medium wave absorber and polypyrrole as the dielectric-type wave absorber so as to absorb attenuation electromagnetic waves together, and meanwhile, the magnetic loss dielectric loss performances of the collagen fiber are enhanced. The selected materials are extensive in source and low in cost; the preparation process is simple and environmentally friendly, and is low in equipment dependency degree, so that the preparation method is an effective way for preparing dual-functional ferroferric oxide / polypyrrole nano composite fiber materials.

Owner:SICHUAN UNIV

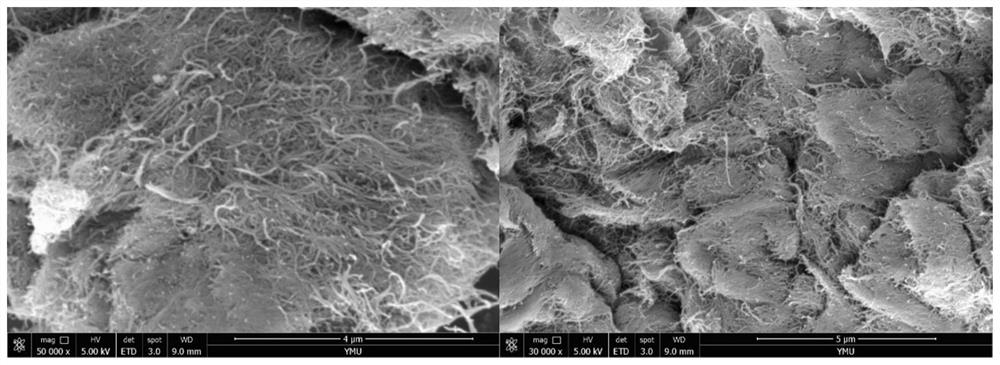

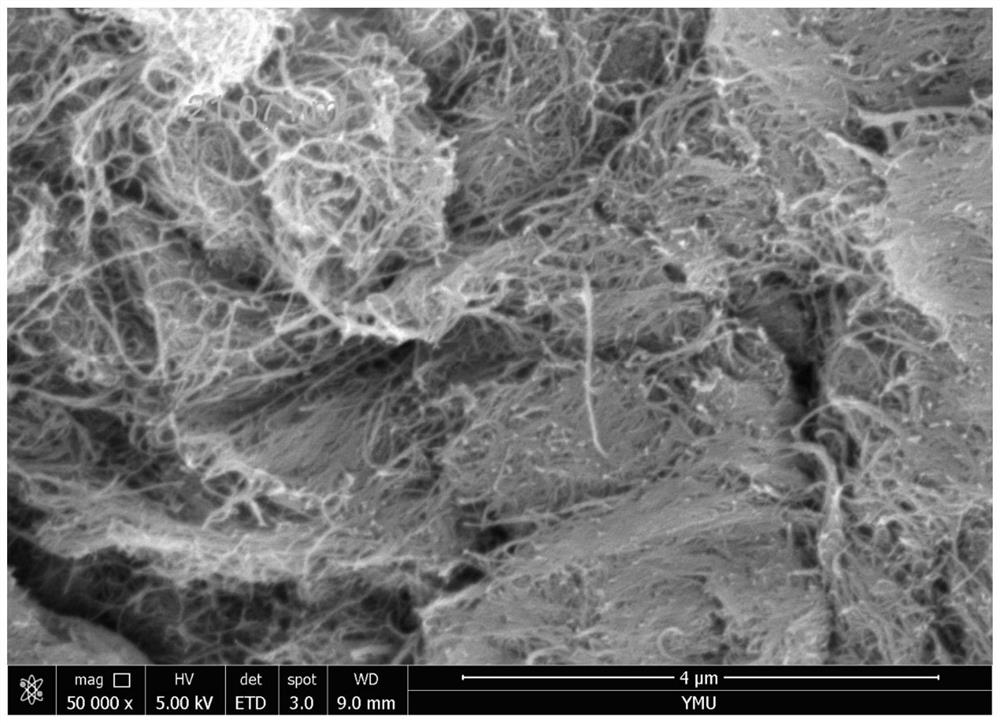

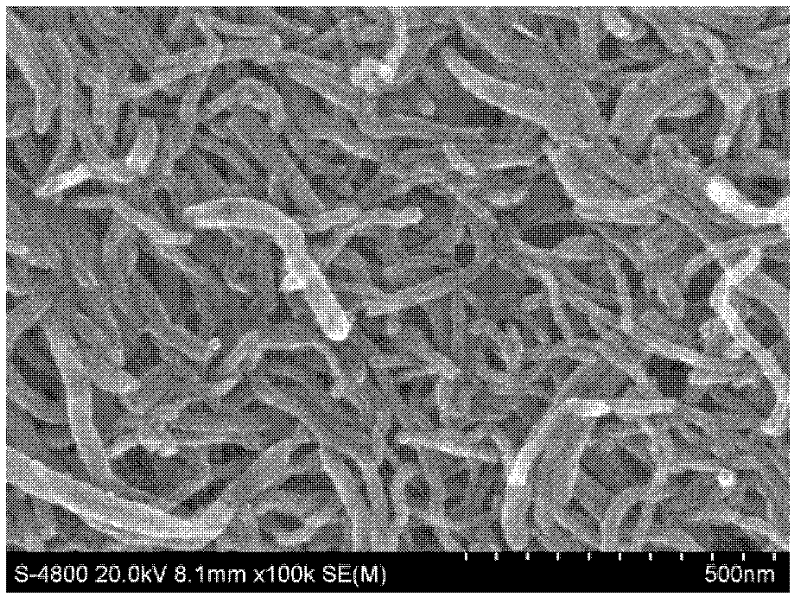

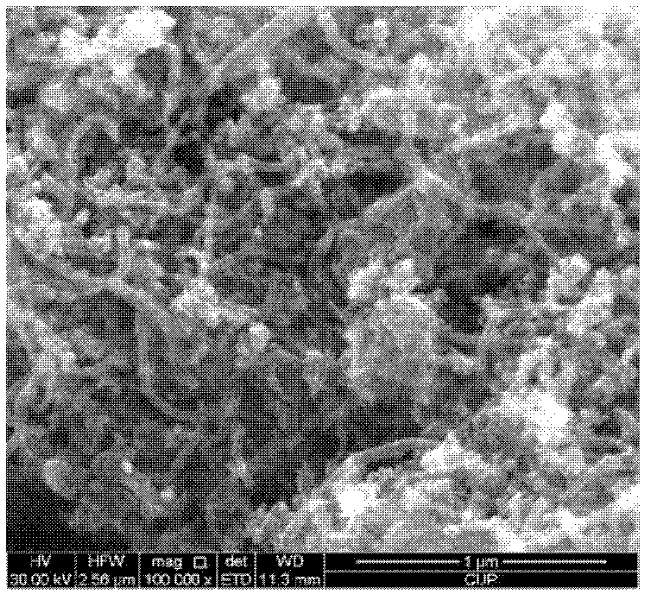

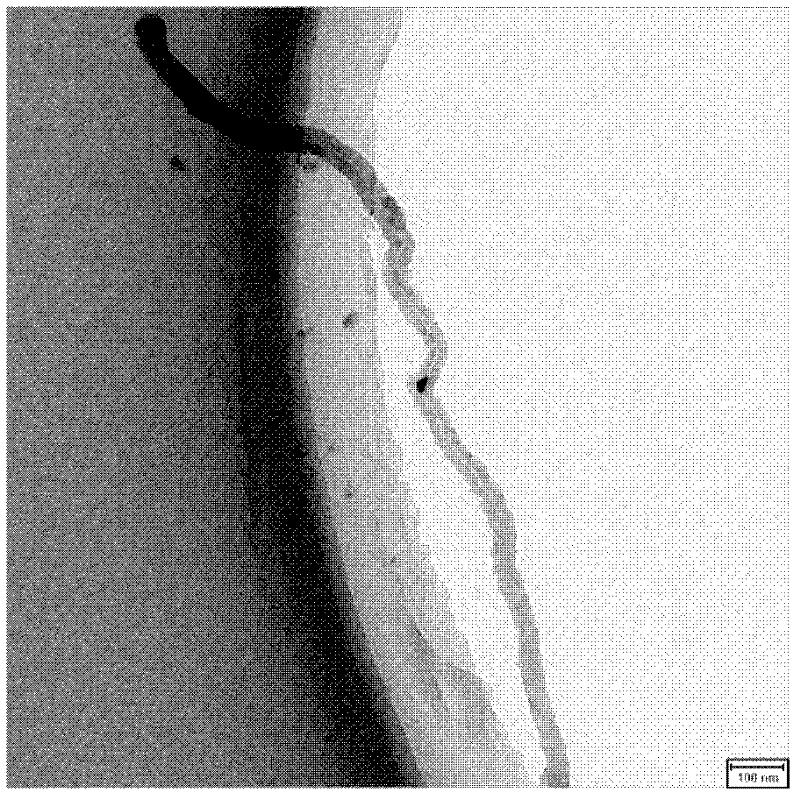

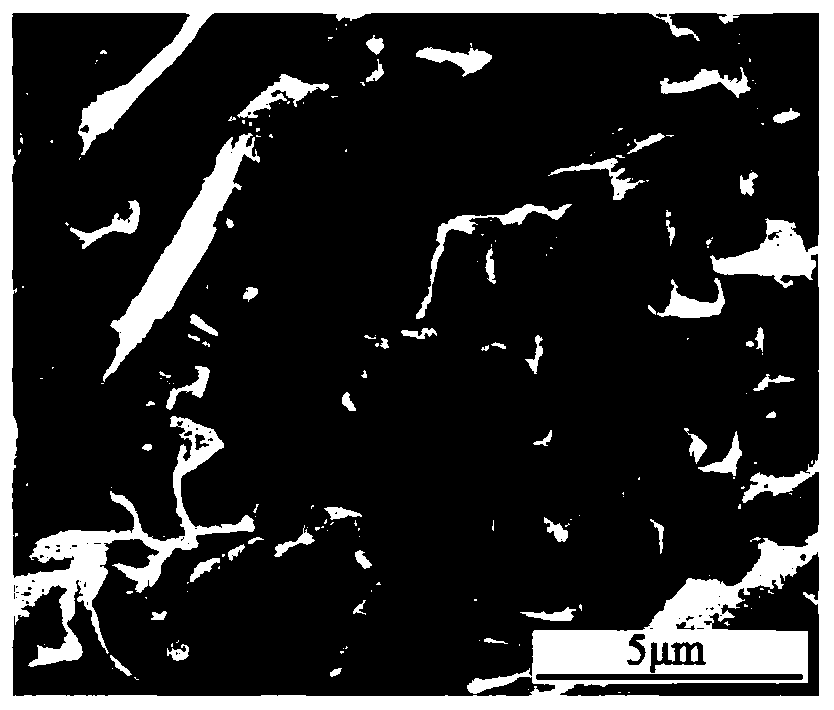

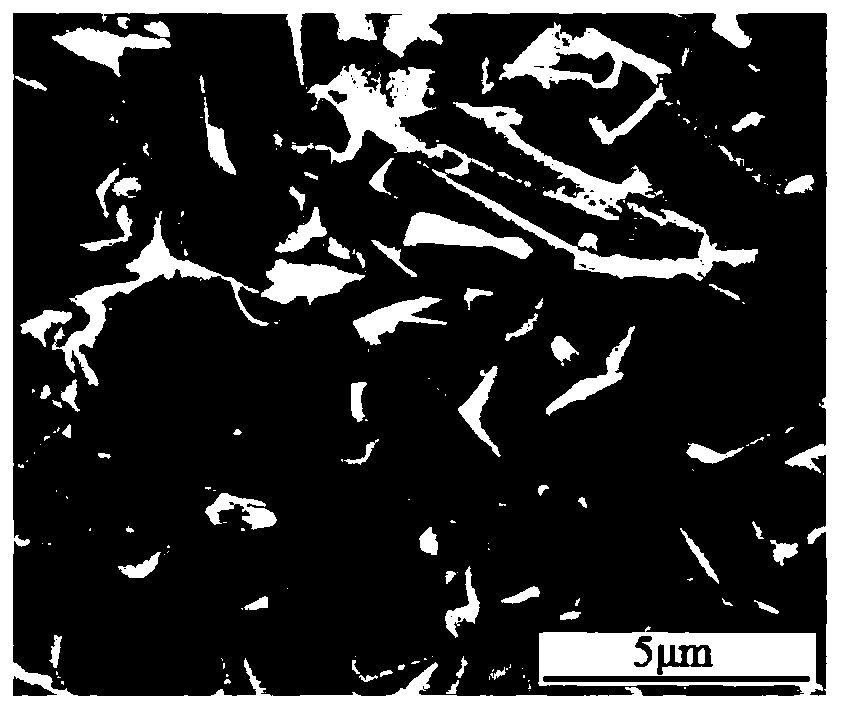

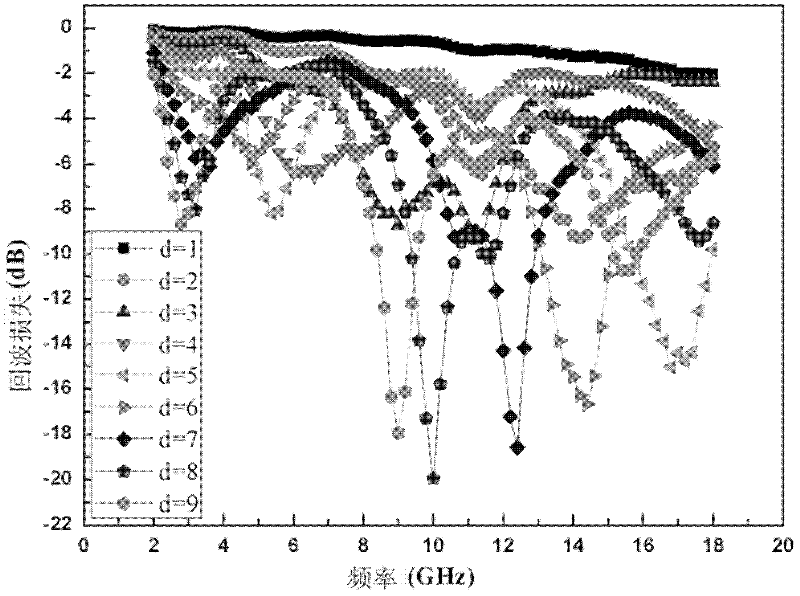

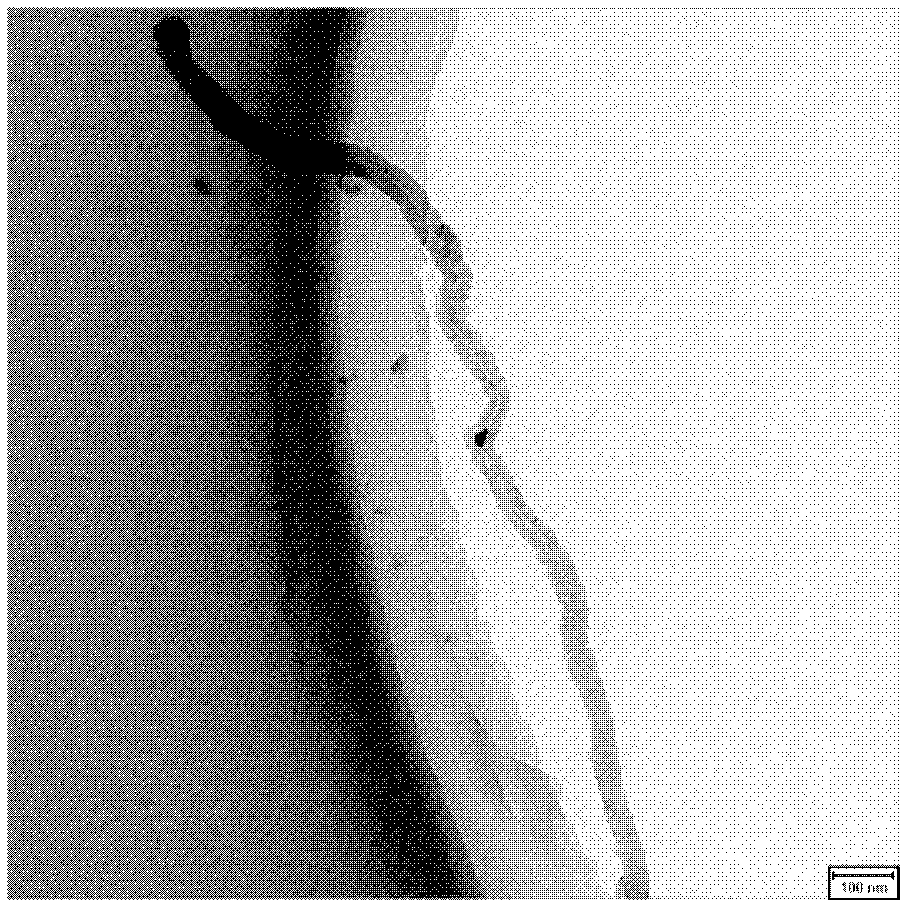

Soft magnetic nanocrystalline metal or alloy sheet-shaped particles with internal grain orientation and microwave absorbing material

InactiveCN110993238AEnhanced magnetic lossEnhanced low frequencyMagnetic/electric field screeningMagnetic materialsMicrowaveBroadband absorption

The invention relates to the technical field of electromagnetic functional materials, in particular to soft magnetic nanocrystalline metal or alloy sheet-shaped particles with internal grain orientation and a microwave absorbing material. The soft magnetic nanocrystalline metal or alloy sheet-shaped particles with the internal grain orientation are obtained by taking spherical or spheroidic soft magnetic metal or alloy particles with a certain grain size as a raw material and carrying out wet ball milling or stirring milling. According to the invention, grain orientation is introduced into soft magnetic nanocrystalline metal or alloy absorbent particles, and the obtained soft magnetic sheet-shaped particles have significantly improved magnetic loss, especially at the frequency of 4 GHz orbelow, and can be used as a high-quality microwave absorbent to effectively improve the low-frequency and broadband absorption performance of the wave-absorbing material.

Owner:WUHAN UNIV OF TECH

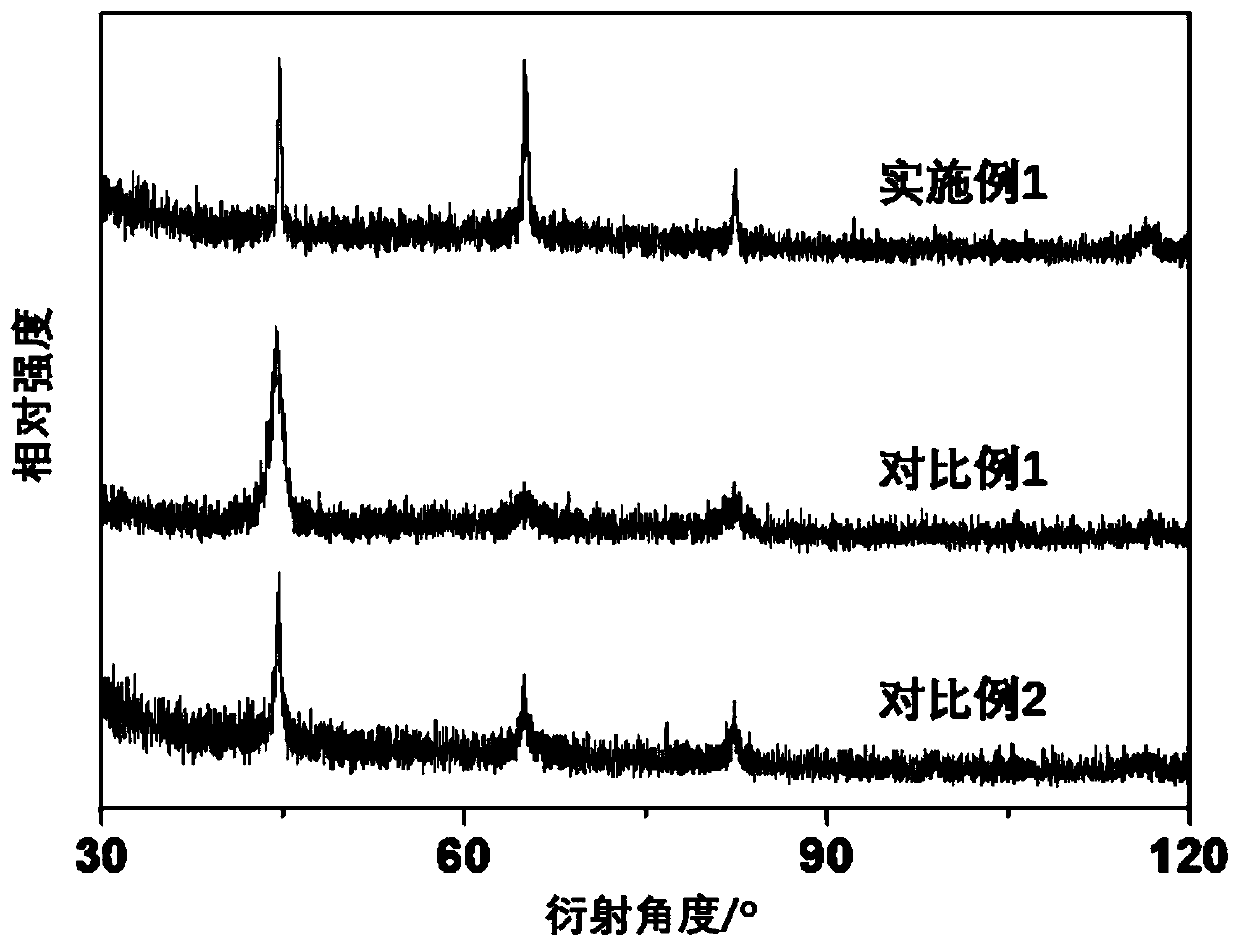

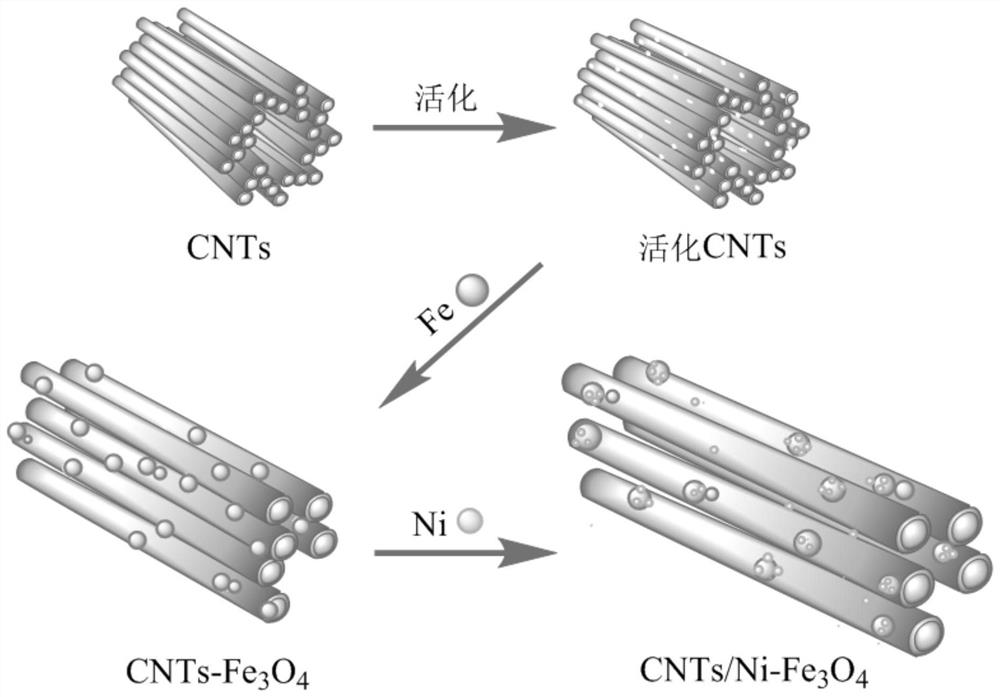

Preparation method of CNTs/Ni-Fe3O4 functional material

InactiveCN112185639AIncreased electron transport capacityHigh catalytic activityOther chemical processesMagnetic/electric field screeningPtru catalystMethane yield

The invention relates to a preparation method of a CNTs / NiFe3O4 functional material, and belongs to the technical field of functional nano composite materials and environmental biology. The preparation method of the CNTs / NiFe3O4 functional material comprises the following specific steps: purifying and activating multiwalled carbon nanotubes; preparing CNTsFe3O4: preparing the CNTs / NiFe3O4 nano composite material. The CNTs / NiFe3O4 functional material prepared by the invention is used as an efficient biological catalytic material and a wave-absorbing material, has the characteristics of promoting oxidation-reduction reaction and electron transfer, is used as a stabilizer and a catalyst in sewage treatment anaerobic digestion reaction, can improve the methane yield and produce biomass energy,can play a role once being added, and has a good application prospect. The catalyst is good in dispersity in a reactor and uniform and consistent in reaction, and can be recycled to save the cost.

Owner:KUNMING UNIV OF SCI & TECH

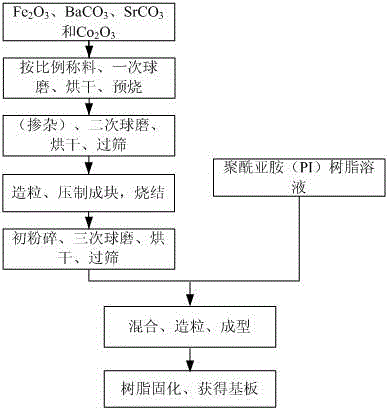

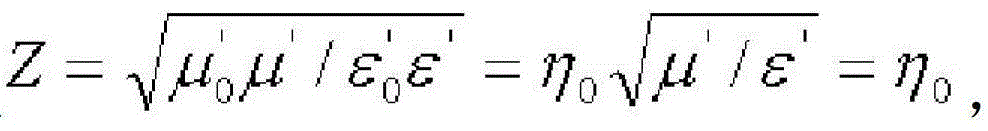

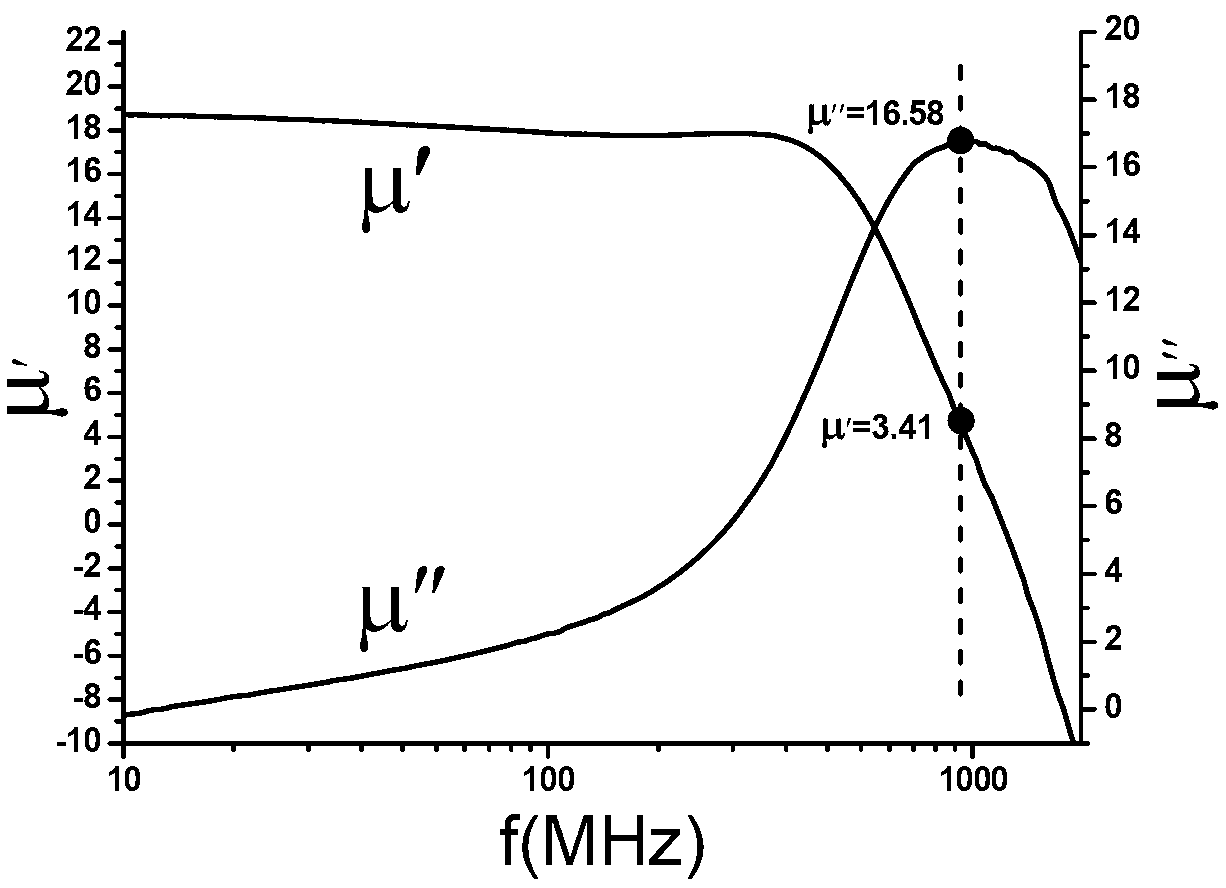

Ferrite-base composite magnetic dielectric antenna substrate material and preparation method thereof

The invention discloses a ferrite-based composite magnetic dielectric antenna substrate material and a preparation method thereof, which is composed of a main phase material with a mass ratio of 85% to 90% and an auxiliary phase material with a mass ratio of 15% to 10%; The main phase material is Co2Z type hexagonal ferrite, and its molecular formula is Ba3-xSrxCo2Fe24-yO41, wherein the value range of x is 0~1.5, and the value range of y is 0~4. The auxiliary phase material is polyimide resin. The magnetic-dielectric composite substrate material provided by the present invention has lower magnetic permeability and higher dielectric constant in the frequency range of 300 MHz to 3 GHz, higher miniaturization factor, and lower magnetic loss and dielectric loss at the same time ; Better resistance to mechanical shock than conventional ceramic substrate materials. It not only helps to reduce the weight and volume of the antenna, but also improves the bandwidth of the microstrip antenna and suppresses the generation of surface waves.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

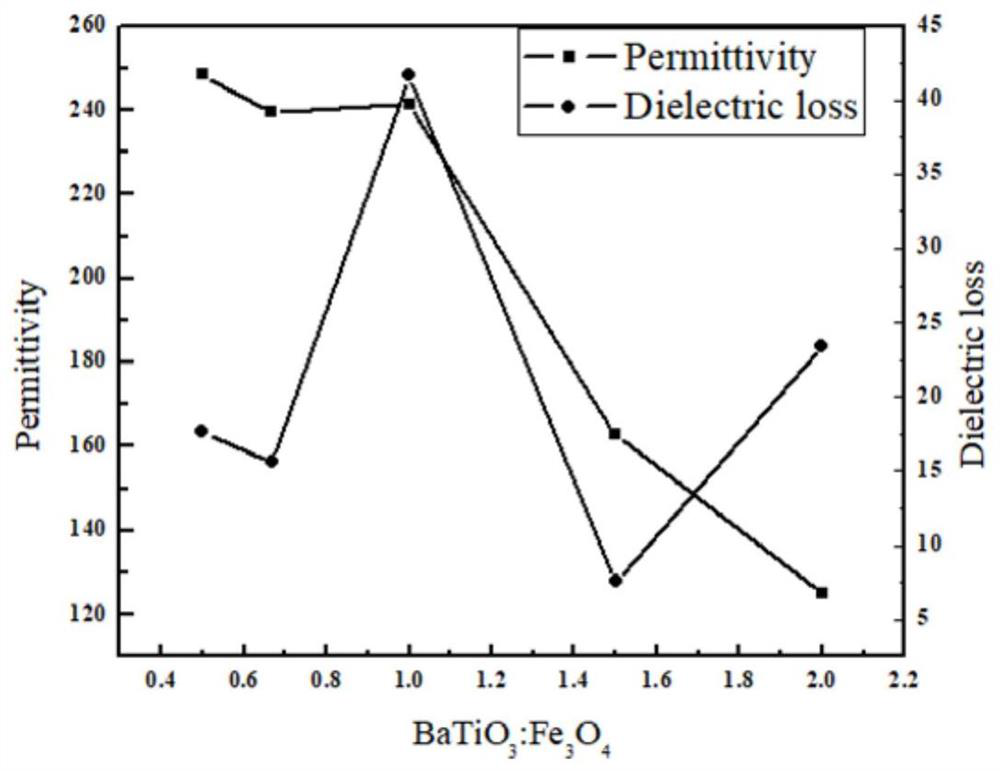

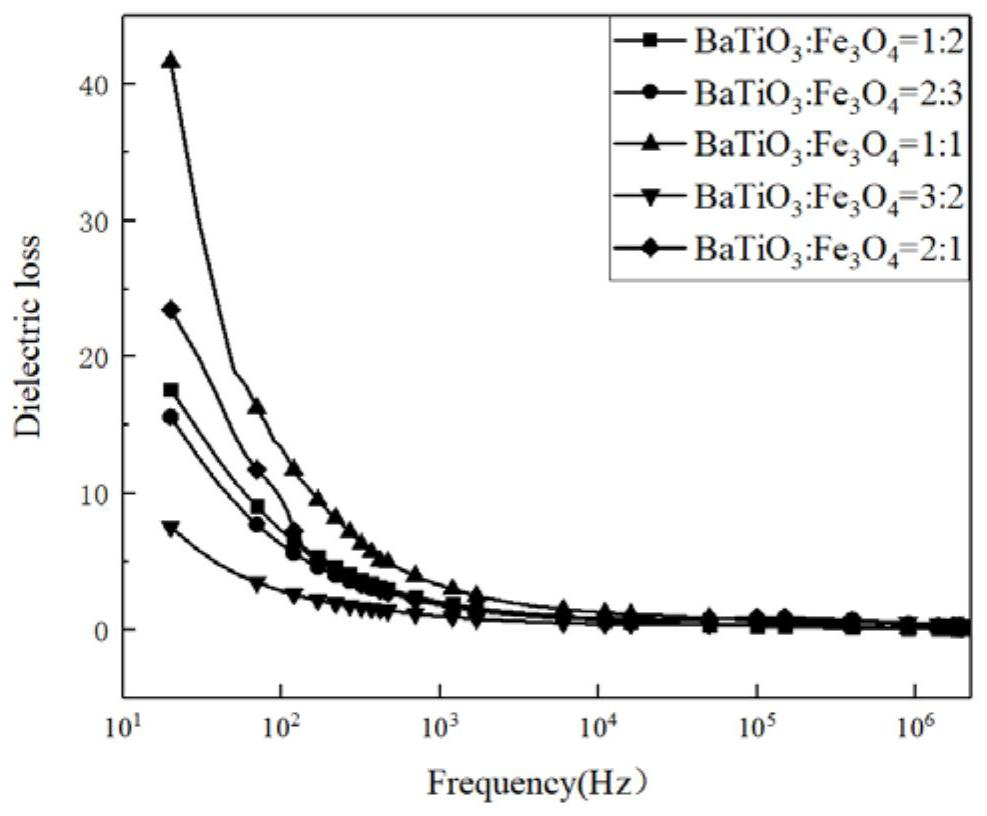

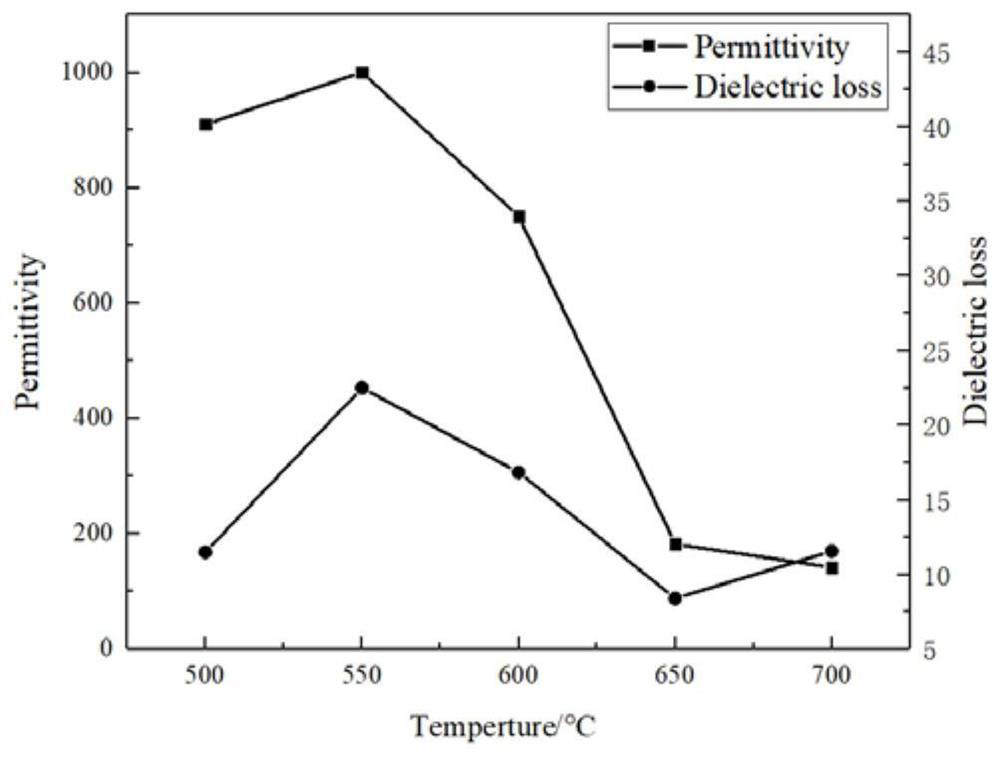

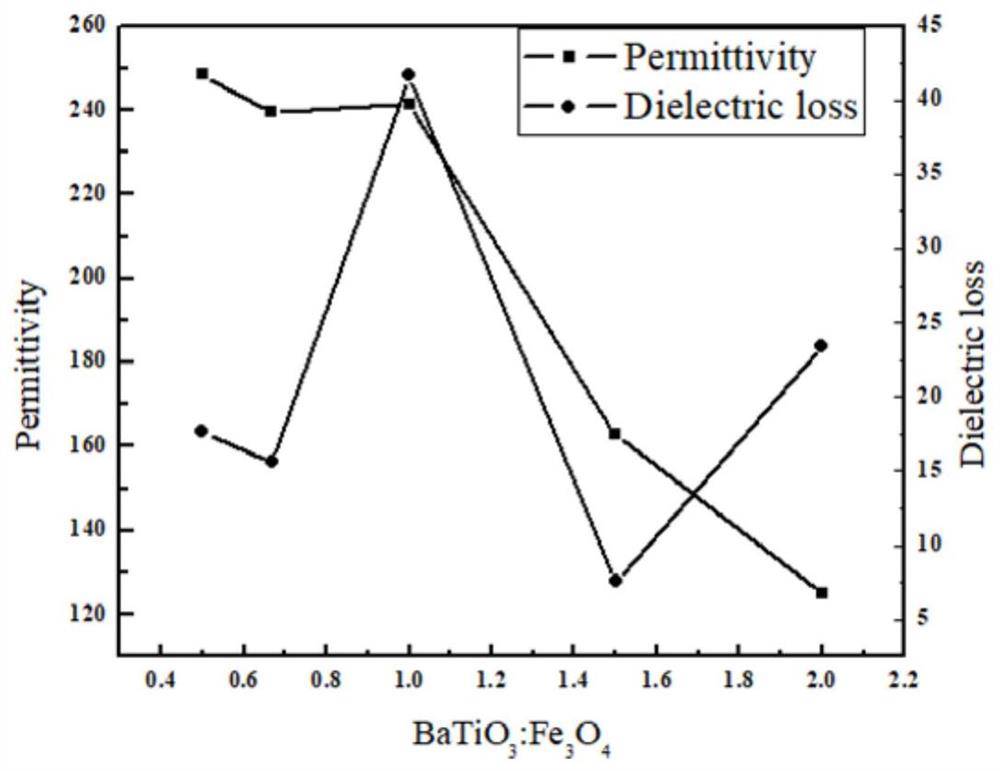

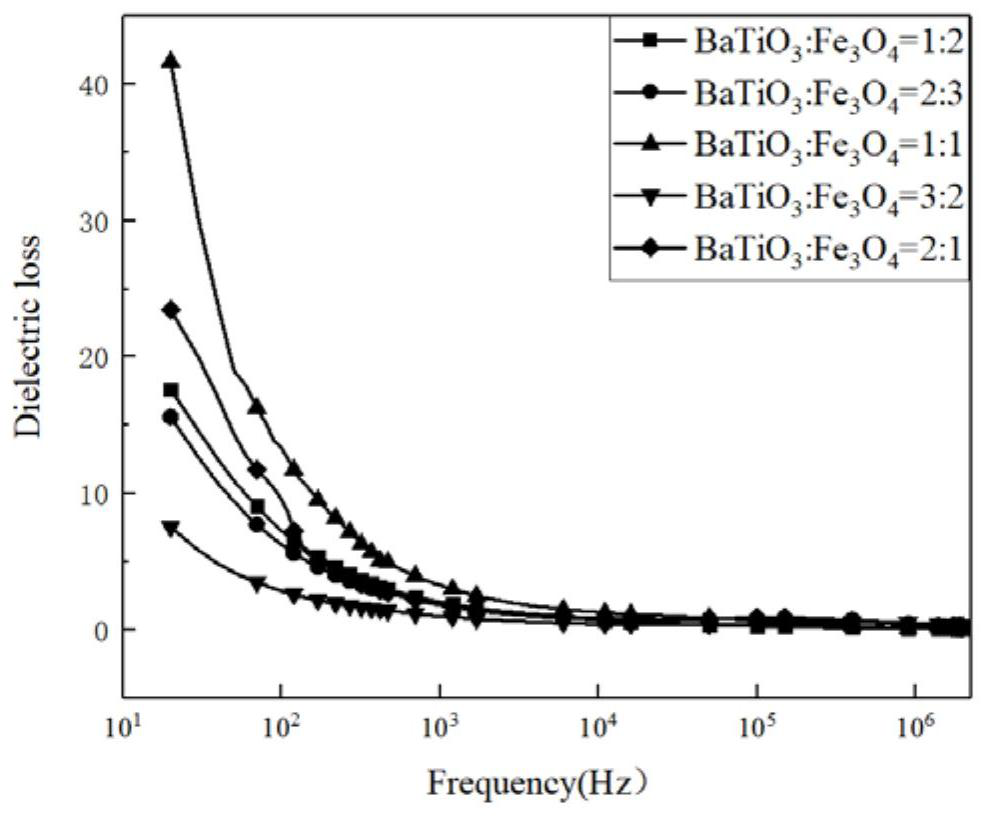

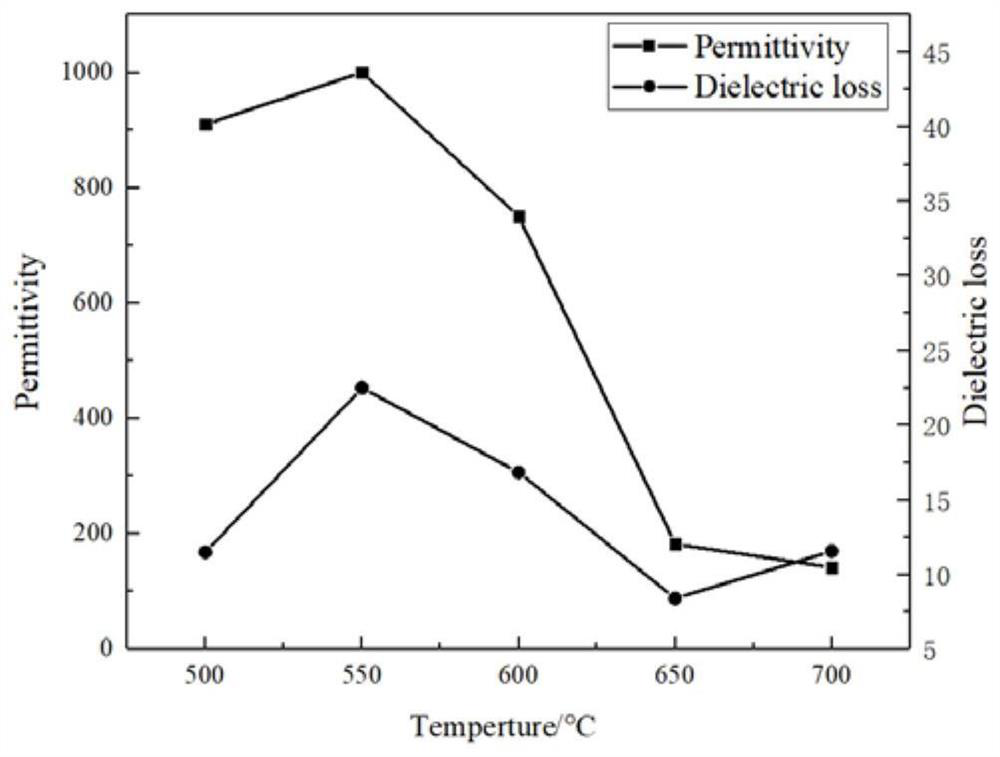

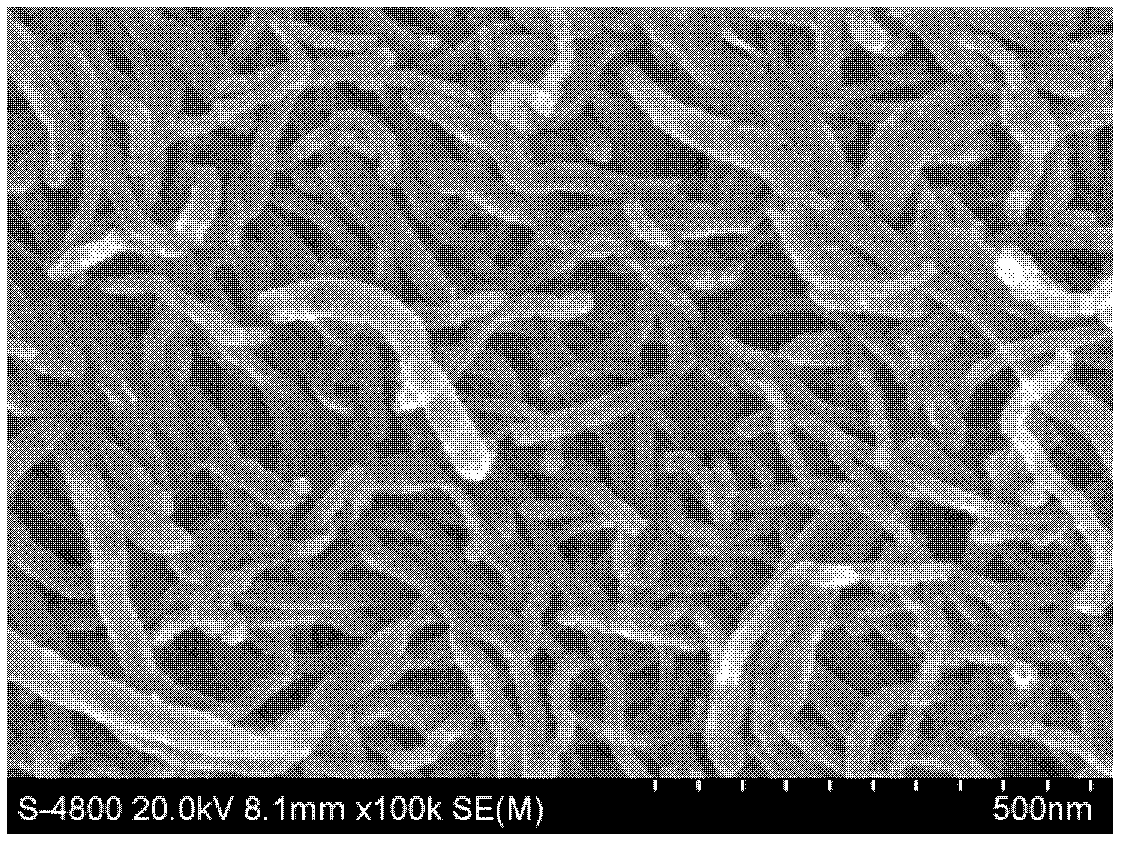

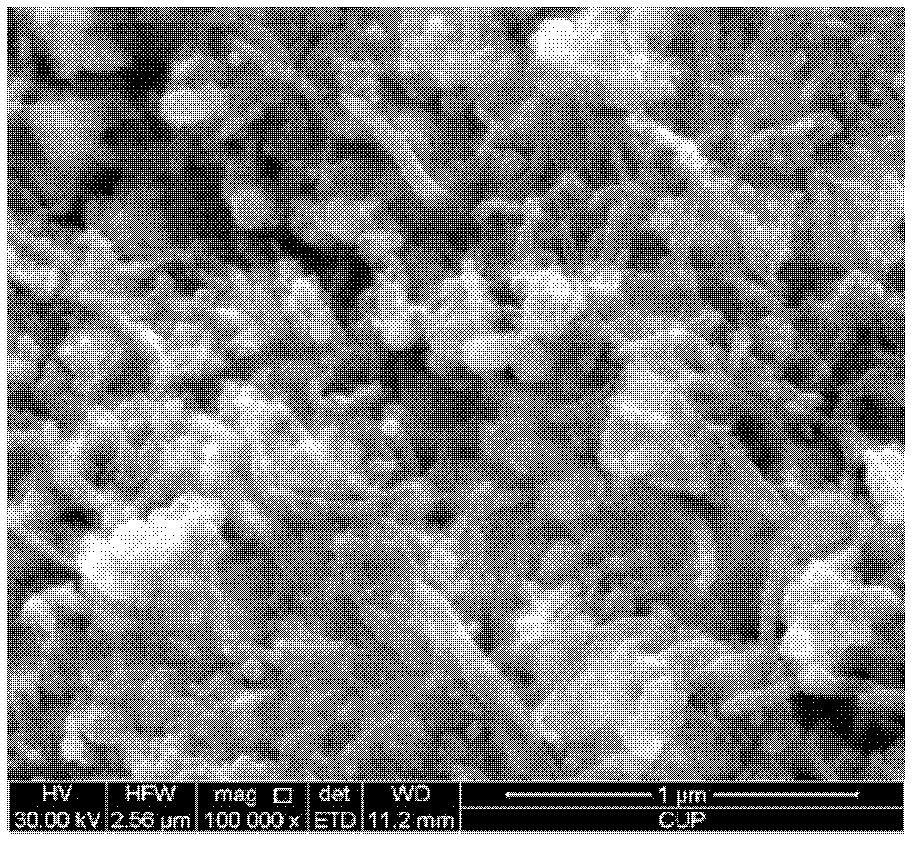

Preparation method of nano barium titanate/ferroferric oxide hybrid material with high wave-absorbing performance

ActiveCN113329608AStrong absorption capacityReduce direct reflectionAlkaline earth titanatesMaterial nanotechnologyBarium titanatePhysical chemistry

The invention relates to a preparation method of a nano barium titanate / ferroferric oxide hybrid material with high wave-absorbing performance. According to the preparation method, nano Fe3O4 particles are directly deposited on the surface of nano BaTiO3 in situ in a solution to form hybrid material powder, nano Fe3O4 forms surface contact on the surface of nano BaTiO3 to generate a large number of interfaces, and due to the fact that a large number of defects and ions are accumulated on the two sides of the interfaces to form electromagnetic wave barriers, electromagnetic waves of all frequency bands are strongly absorbed and scattered. After the powder is formed, the hybrid material has very high electrical loss and magnetic loss. When the the frequency is 20 Hz-3 GHz, the dielectric constant is 10-1000, and the electrical loss is 0.1-44.3; when the frequency is 10 Hz-1 GHz, the magnetic conductivity is 3.69-9.5, and the magnetic loss is 6.7-15.9; and when the thickness of the hybrid material is 2 mm, the reflectivity of the hybrid material at 2 GHz ranges from-9.84 dB to-29.4 dB, and the absorptivity ranges from 89.62% to 99.89%. The nano barium titanate / ferroferric oxide hybrid material has good electromagnetic wave absorption performance, and is especially suitable for being used as a wave-absorbing material or an electromagnetic shielding material.

Owner:东北大学秦皇岛分校

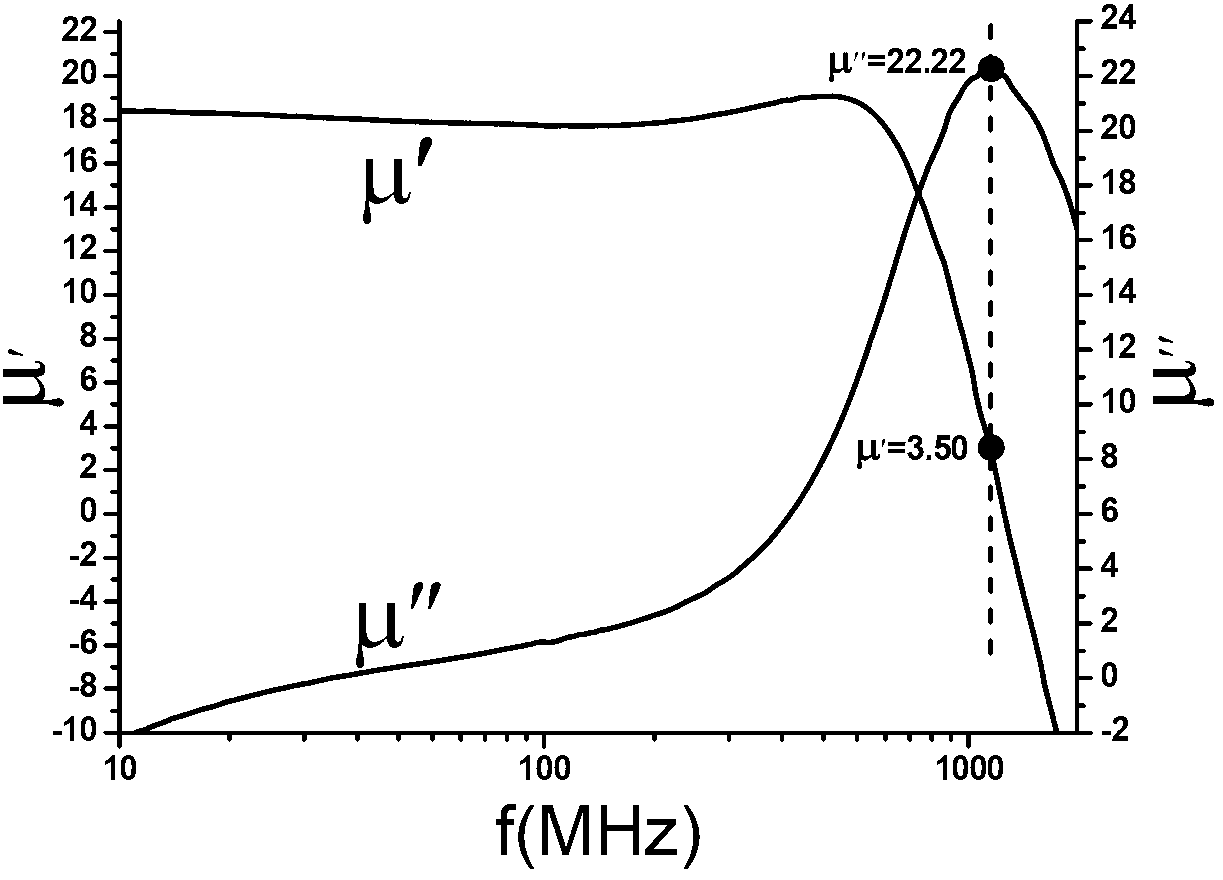

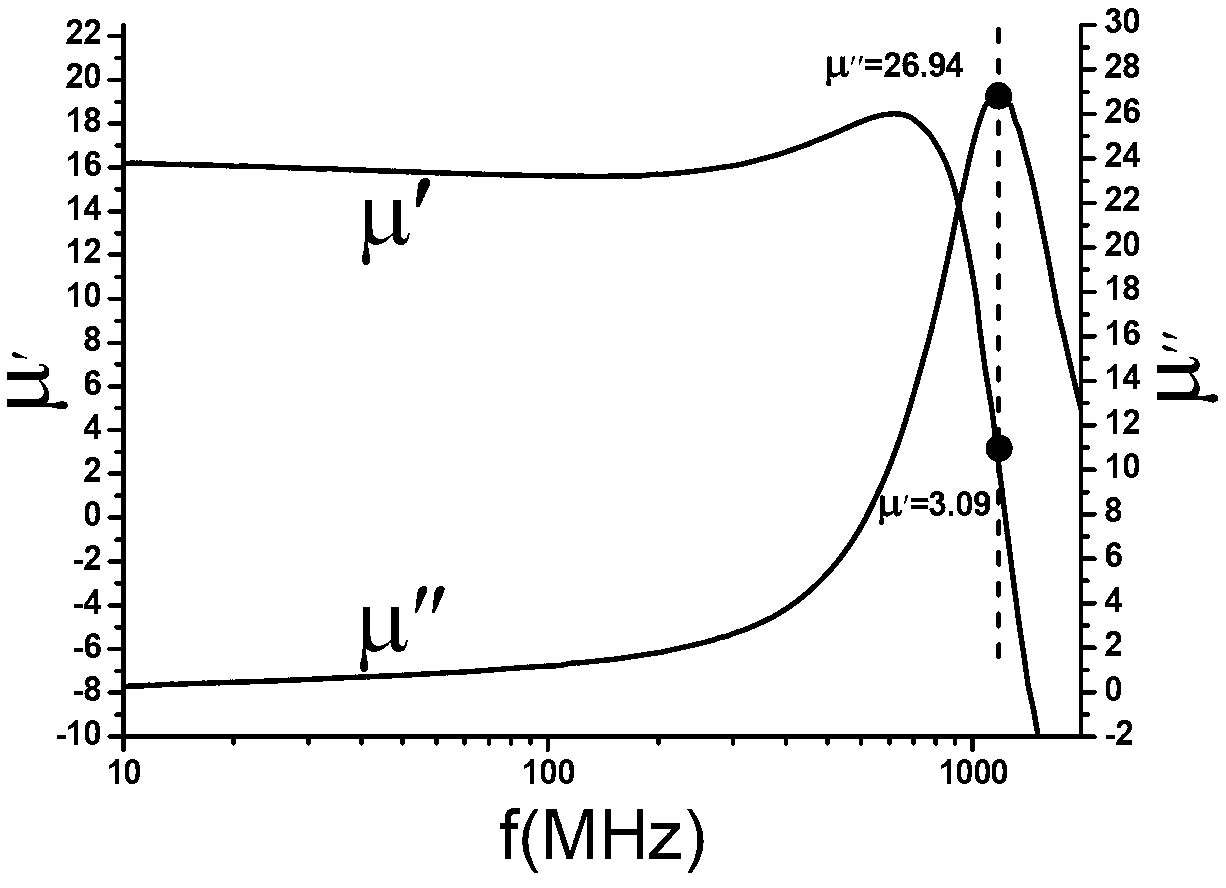

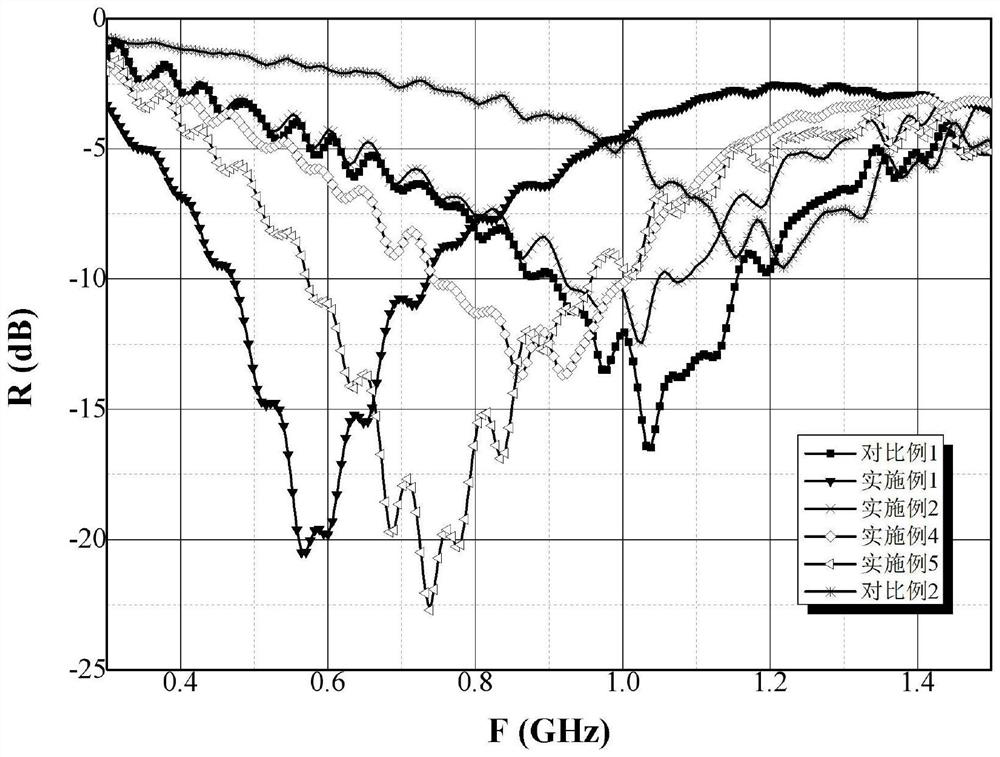

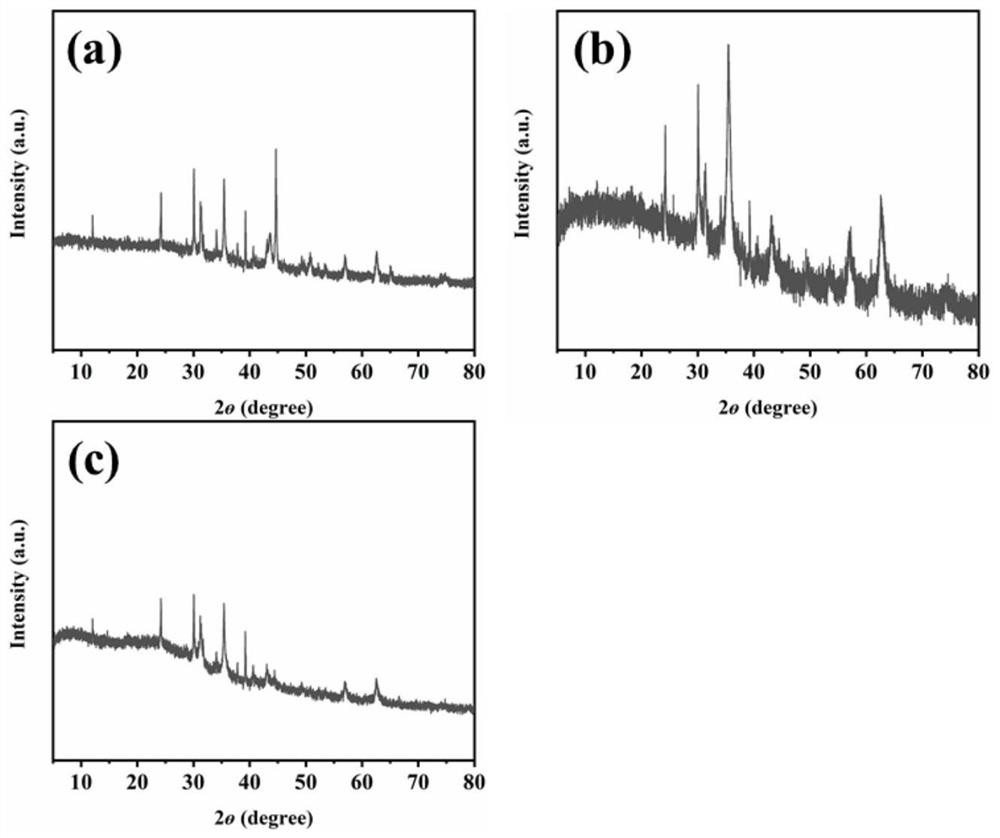

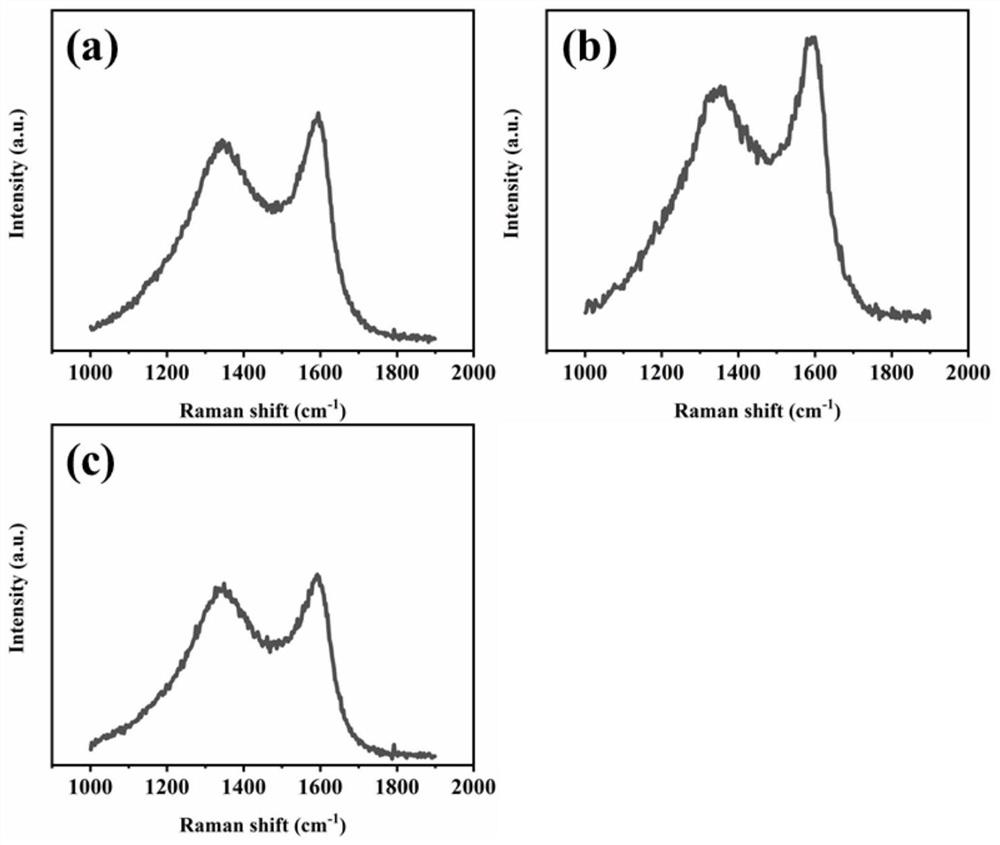

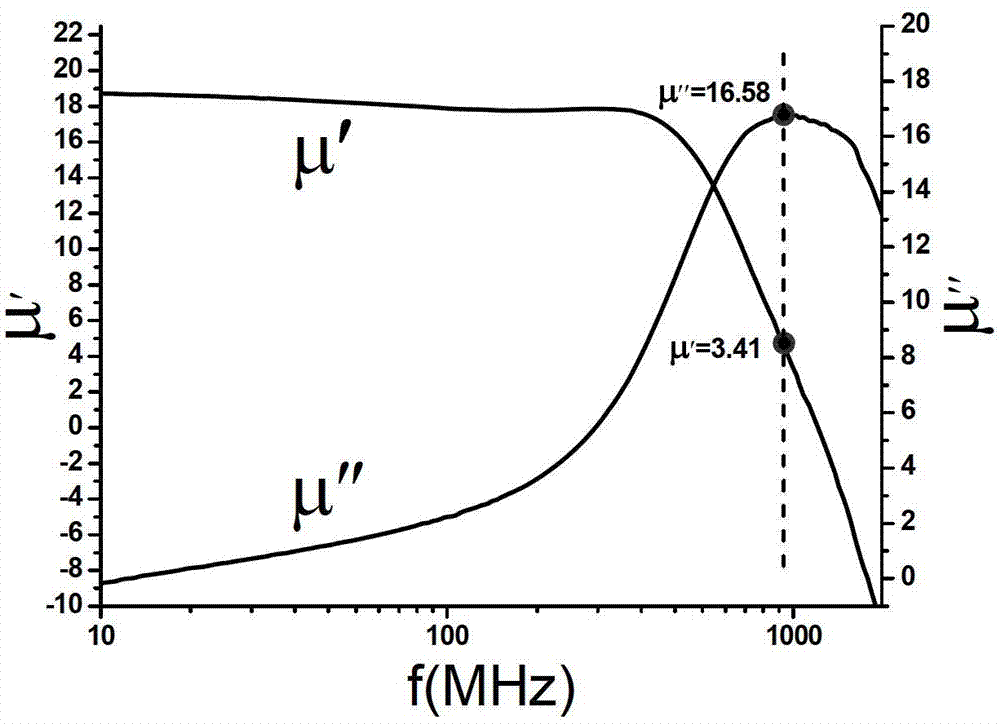

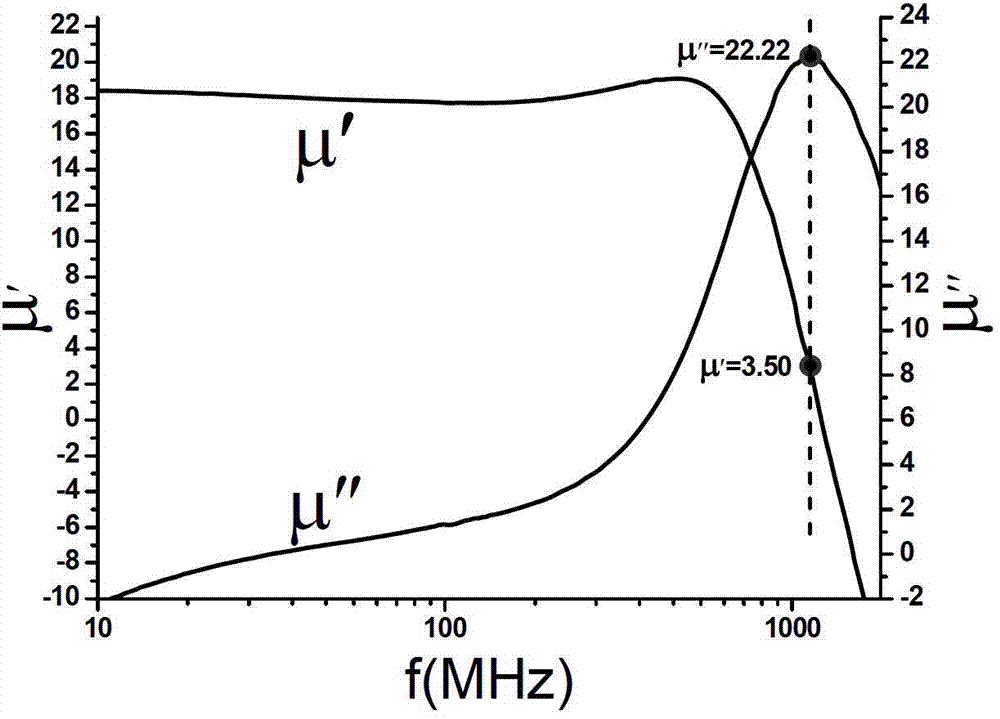

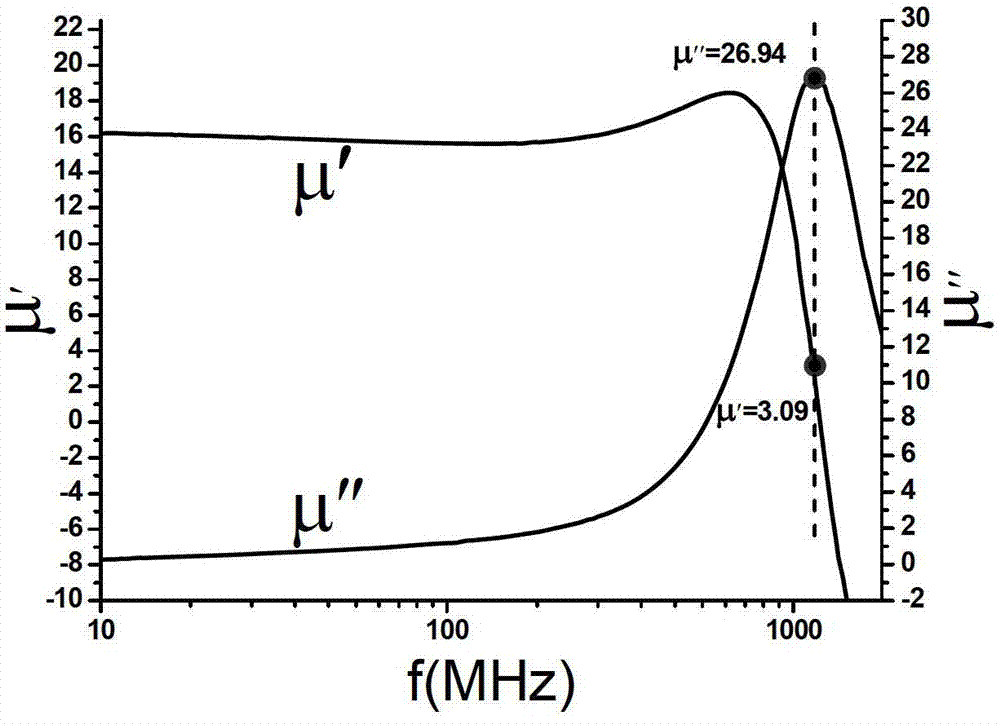

Hexagonal ferrite material with high magnetic loss in L wave band and preparation method thereof

The invention discloses a hexagonal ferrite material with high magnetic loss in L wave band and a preparation method thereof, relates to the material technologies and in particular relates to a magnetic material technology. The chemical component of the material is (Ba[1-x]Srx)3Co2Fe24O41, wherein x is equal to 0.0 or 0.2 or 0.4 or 0.6 or 0.8. The hexagonal ferrite material has the advantages of high magnetic loss, high electrical resistivity and excellent high-frequency soft magnetic properties in the L wave band.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Electromagnetic shielding material with chemically plated iron modified carbon nano-tubes and method for preparing same

ActiveCN102634779AImprove magnetismGood application effectMaterial nanotechnologyMagnetic/electric field screeningMaterials preparationHigh density

The invention discloses an electromagnetic shielding material with chemically plated iron modified carbon nano-tubes and a method for preparing the same, belonging to the technical field of nano-material preparation, wherein multi-wall carbon nano-tubes which are subjected to surface acidification pretreatment and pretreatment are added to chemical plating solution and every carbon nano-tube is covered with a metal iron layer with ferromagnetism by a chemical plating method, so that the magnetic property of the carbon nano-tubes is improved; therefore, the integrated application properties ofthe carbon nano-tubes are also greatly improved while the original excellent properties of the carbon nano-tubes are maintained; as a result, the carbon nano-tubes can be applied to nano-ferromagnetism research, high-density memories and electromagnetic shielding materials.

Owner:BEIHANG UNIV

High-magnetic-loss and wideband FeCo electromagnetic wave-absorbing material and preparation method thereof

InactiveCN108555314AHigh saturation magnetizationEnhanced magnetic lossMaterial nanotechnologyMagnetic/electric field screeningCobalt acetateAlloy

The invention belongs to the field of electromagnetic wave-absorbing materials and particularly relates to a high-magnetic-loss and wideband FeCo electromagnetic wave-absorbing material and a preparation method thereof. The preparation method comprises the steps of carrying out ultrasonic treatment on the raw materials of ferrous chloride and cobalt acetate in a mixed solution, and adding ammoniawater and a reducing agent, so as to generate solvothermal reaction, thus obtaining the FeCo electromagnetic wave-absorbing material. The preparation method has the advantages of short synthesis period, simple process flow and low cost; and the FeCo alloy wave-absorbing material prepared by virtue of the preparation method has high magnetic loss and wideband wave-absorbing performance.

Owner:QINGDAO UNIV

Water-borne corrosion-preventing camouflaging coating with spiral carbon fiber load nickel prepared through reduction method and preparing method of coating

ActiveCN104774535ARust removal requirements are not highStrong adhesionAnti-corrosive paintsRadiation-absorbing paintsFiberEpoxy

The invention discloses a water-borne corrosion-preventing camouflaging coating with spiral carbon fiber load nickel prepared through a reduction method and a preparing method of the coating. The coating is formed by a first composition and a second composition according to the mass ratio of 1:1; the first composition comprises, by mass, 80-120 parts of water-borne epoxy resin, 0.2-0.8 part of antifoaming agent and 5-15 parts of distilled water; the second composition comprises, by mass, 20-30 parts of water-borne epoxy curing agents, 0.08-0.15 part of antifoaming agent, 1-1.5 parts of dispersing agents, 20-30 parts of superfine talcum powder, 15-30 parts of zinc phosphate, 0-20 parts of iron oxide red, 15-30 parts of titanium dioxide and 15-30 parts of spiral carbon fiber load nickel chirality wave absorbing agents. The invention further discloses the preparing method of the coating. The spiral carbon fiber load nickel chirality wave absorbing agents are prepared by adopting the reduction method, and the coating is good in corrosion-preventing property, high in electromagnetic wave absorption rate, capable of resisting an acid-base environment and good in dirt resistance, and has a good effect of protecting the surface of a hull.

Owner:JIANGSU UNIV OF TECH

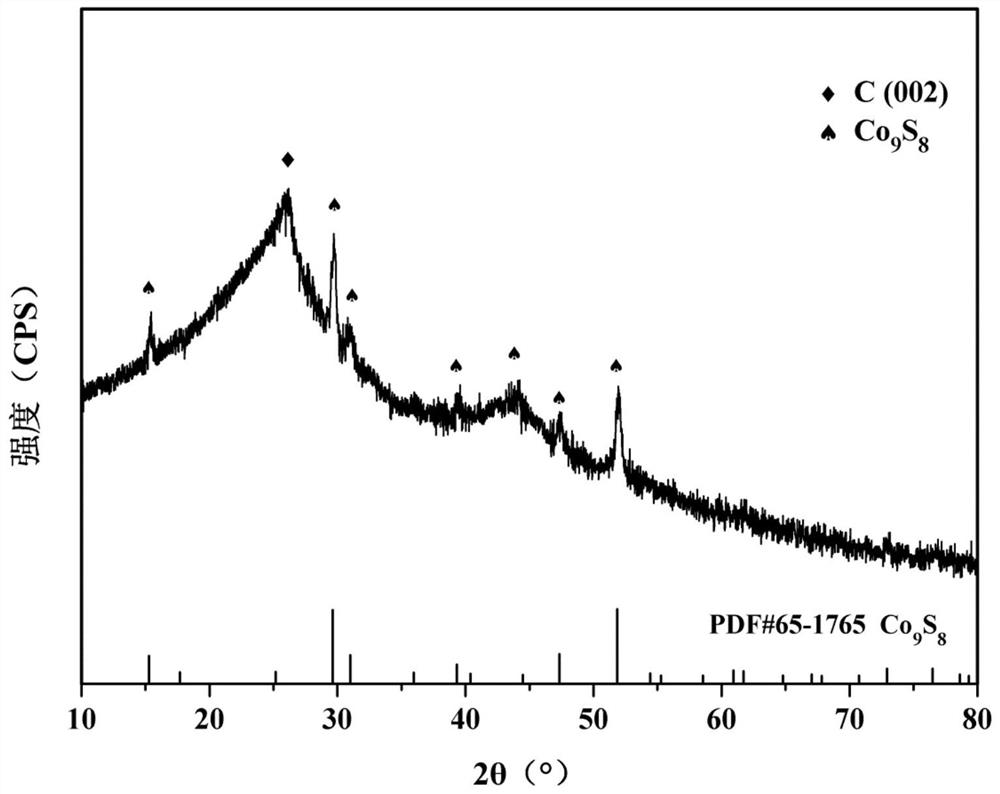

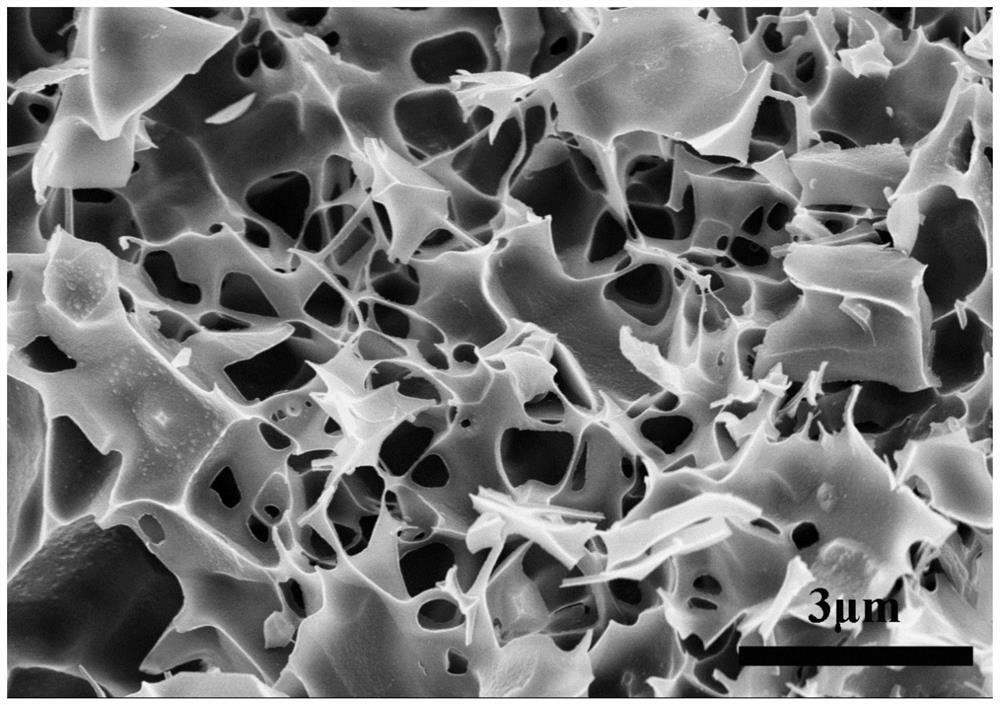

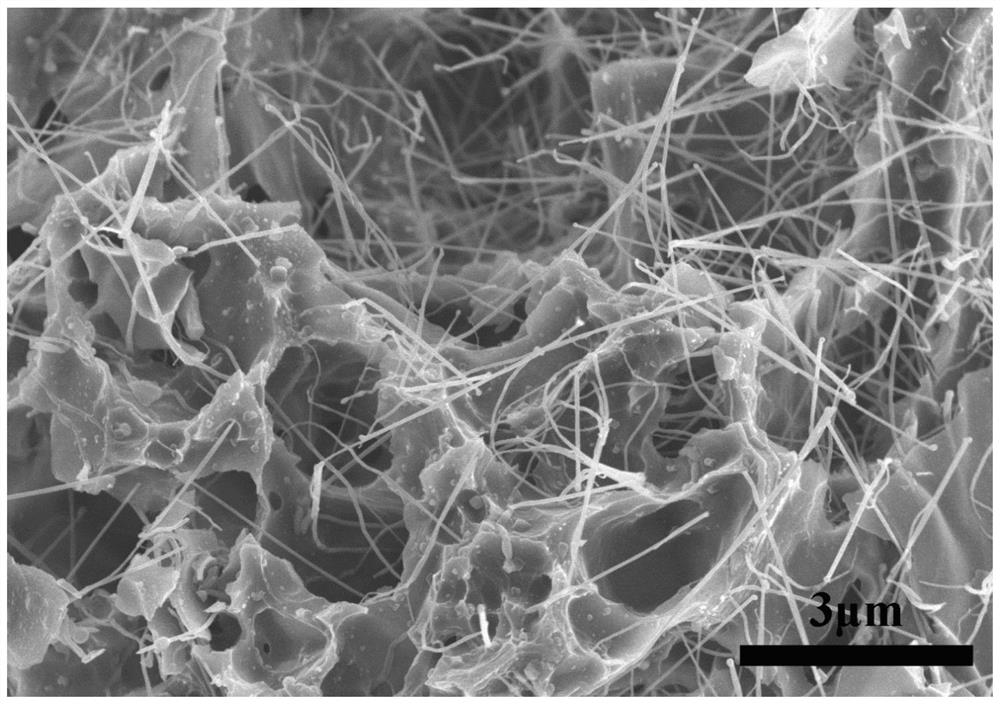

A kind of porous carbon@carbon nanotube absorbing material and its preparation method

ActiveCN109880591BWon't meltSpecial Electromagnetic PropertiesOther chemical processesSucroseThiourea

The invention provides a porous carbon@carbon nanotube absorbing material and a preparation method thereof, comprising the following steps: step 1, adding thiourea, sucrose and cobalt chloride hexahydrate into a saturated sodium chloride solution, and dispersing evenly to obtain Mixed solution C; Step 2, ultrasonically freeze-dry the mixed solution C to obtain solid D; Step 3, pyrolyze solid D under a protective atmosphere at 590-610°C to obtain solid E; Step 4, grind solid E Then add water, sonicate, filter, collect the solid, and dry it in vacuum to obtain solid F; Step 5, pyrolyze the solid F under a protective atmosphere at 890-910°C to obtain a porous carbon@carbon nanotube absorbing material. The porous carbon@carbon nanotube wave-absorbing material prepared by the invention has obvious porous structure, low filling amount and good wave-absorbing performance.

Owner:宁波维创柔性电子技术有限公司

Method for preparing wave-absorbing material by means of wool fibers

ActiveCN106832866AEnhanced magnetic lossHigh absorption strengthOther chemical processesLow speedFreeze-drying

The invention discloses a method for preparing a wave-absorbing material by means of wool fibers, and belongs to the technical field of wave-absorbing materials. The method comprises the steps that firstly, a surfactant and water are mixed, then nano ferroferric oxide is added, low-speed emulsification is adopted, then high-speed emulsification is performed, and an emulsified mixture is mixed with polyethylene glycol to obtain modified liquid; secondly, wool is smashed and carbonized, and then added into the modified liquid to be soaked, the ferroferric oxide is loaded on the surface of the carbonized wool, and modified wool is obtained for standby application; thirdly, manganese dioxide powder, a stabilizer, a complexing agent and sodium alginate are taken and added into deionized water, stirring mixing is performed, then nickel chloride hexahydrate is added, and stirring reaction is performed to obtain a sodium alginate gel fluid containing metal; and fourthly, the gel fluid and the modified wool are mixed, and then solidified after a calcium chloride solution is added dropwise, freeze drying is performed after solidification, and the wave-absorbing material can be obtained. The wave-absorbing material prepared through the method disclosed by the invention is low in density and wide in bandwidth range, all electromagnetic waves can be fast attenuated by means of the wave-absorbing material of the material composition and structure, and wide application prospects are achieved.

Owner:河北伟成毛毡有限公司

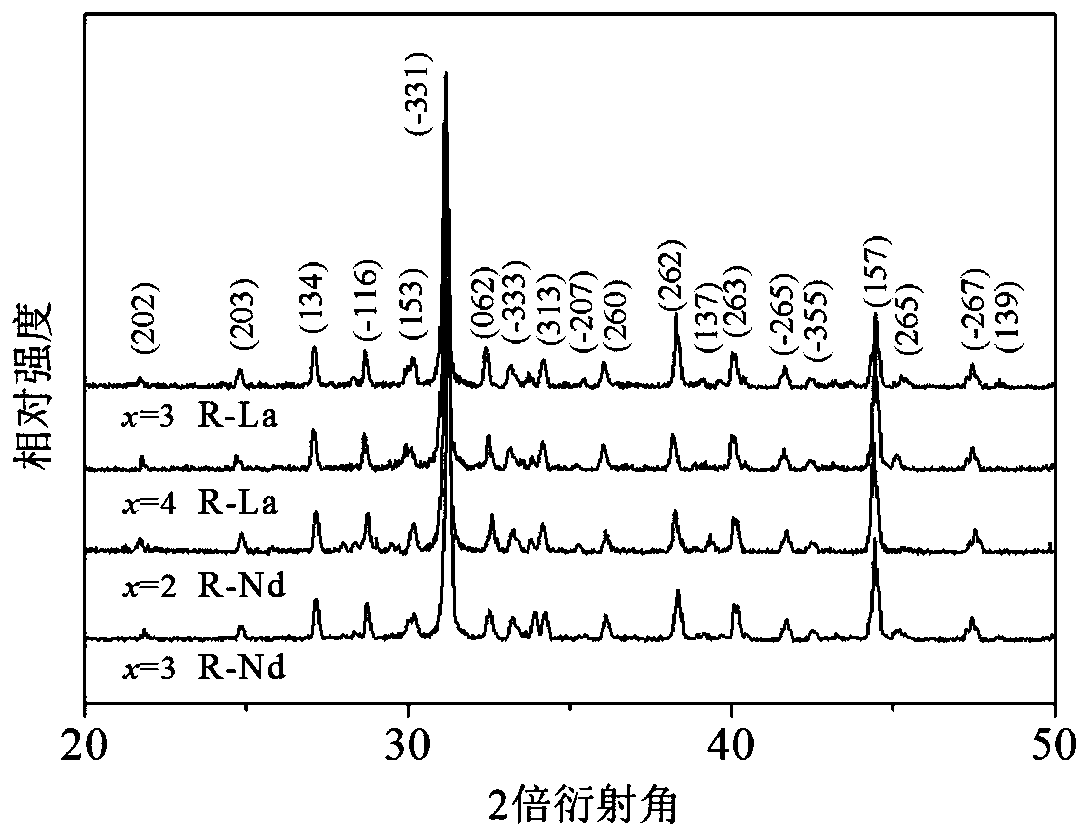

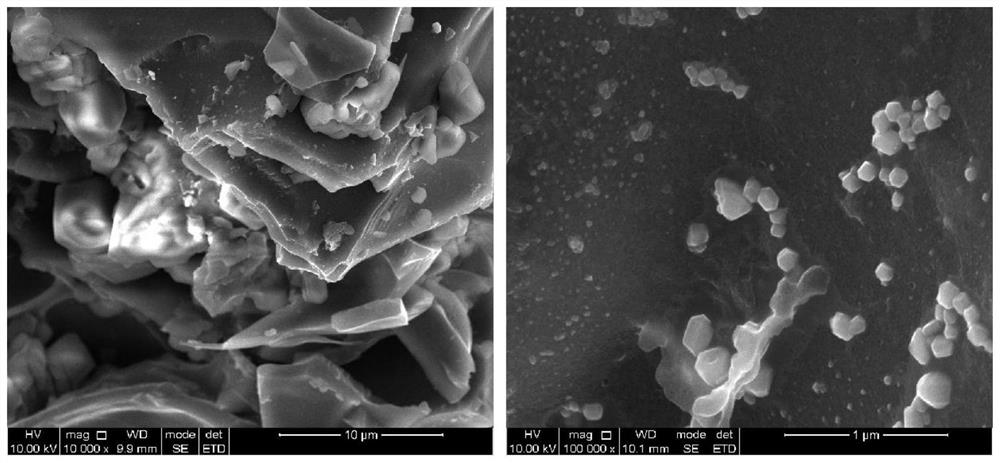

Flake like ceramic wave absorbing material and preparation method thereof

ActiveCN110922181AExcellent electromagnetic loss characteristicsGood microwave impedance matching characteristicsOther chemical processesRare-earth elementSpace group

The invention discloses a flake like ceramic wave absorbing material and a preparation method thereof. The chemical formula of the wave absorbing material is Ba<12-x>R<x>Fe<28>Ti<15>O<84>, 2<=x<=4, and R represents rare earth elements: La or Nd. The wave absorbing material is layered oxide having a monoclinic crystal structure, the space group is C2 / m; the monoclinic crystal structure is randomlydistributed sheet shaped or flake like grains, the diameter is 2 to 7 [mu]m, and the thickness is 1 to 2 [mu]m. The invention also provides a preparation method of the wave absorbing material. The preparation method comprises following steps: (1) preparing sol; (2) preparing primary powder; and (3) preparing the waving absorbing material. Due to the sheet / flake like microstructure feature of the wave absorbing material, after the wave absorbing material is doped and modified by magnetic elements, the wave absorbing material has an excellent electromagnetic loss feature and a good microwave impedance matching characteristic; moreover, the wave absorbing material has a good microwave absorbing feature in a range of 2 to 18 GHz; the optimal reflection loss is lower than -17 dB, the reflectionloss is lower than -10 Db, and the frequency band width is greater than 4.0 GHz.

Owner:HUNAN INSTITUTE OF ENGINEERING

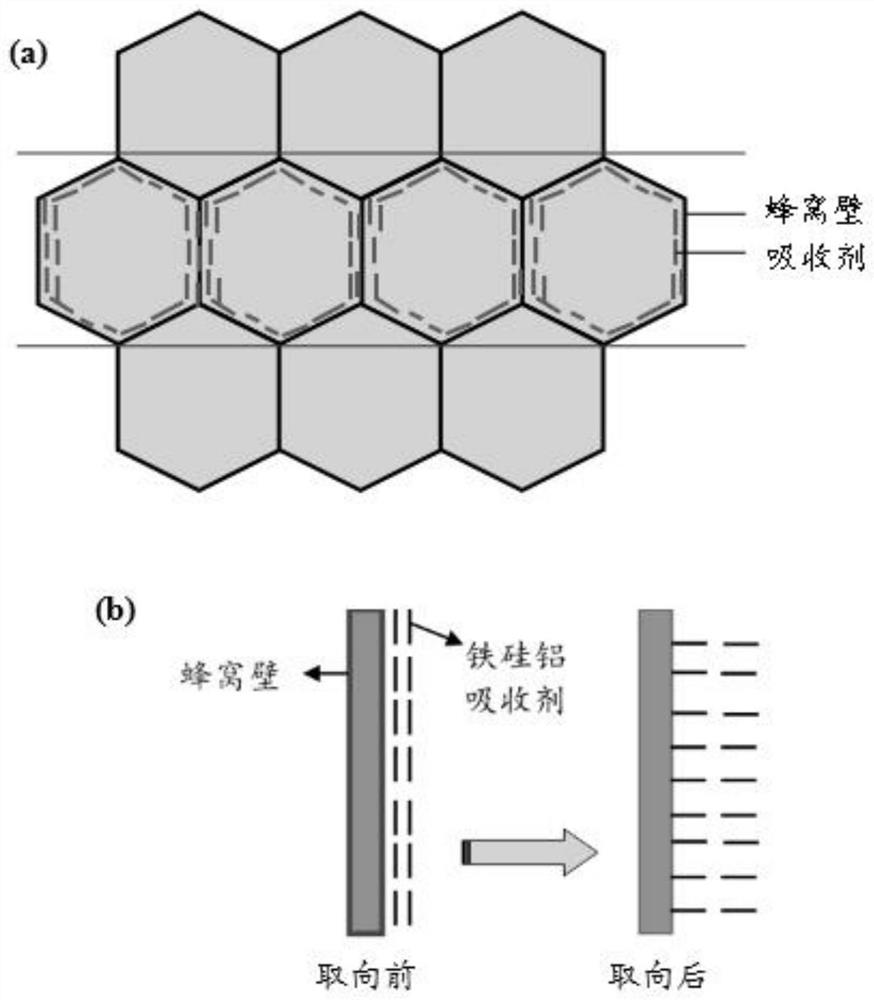

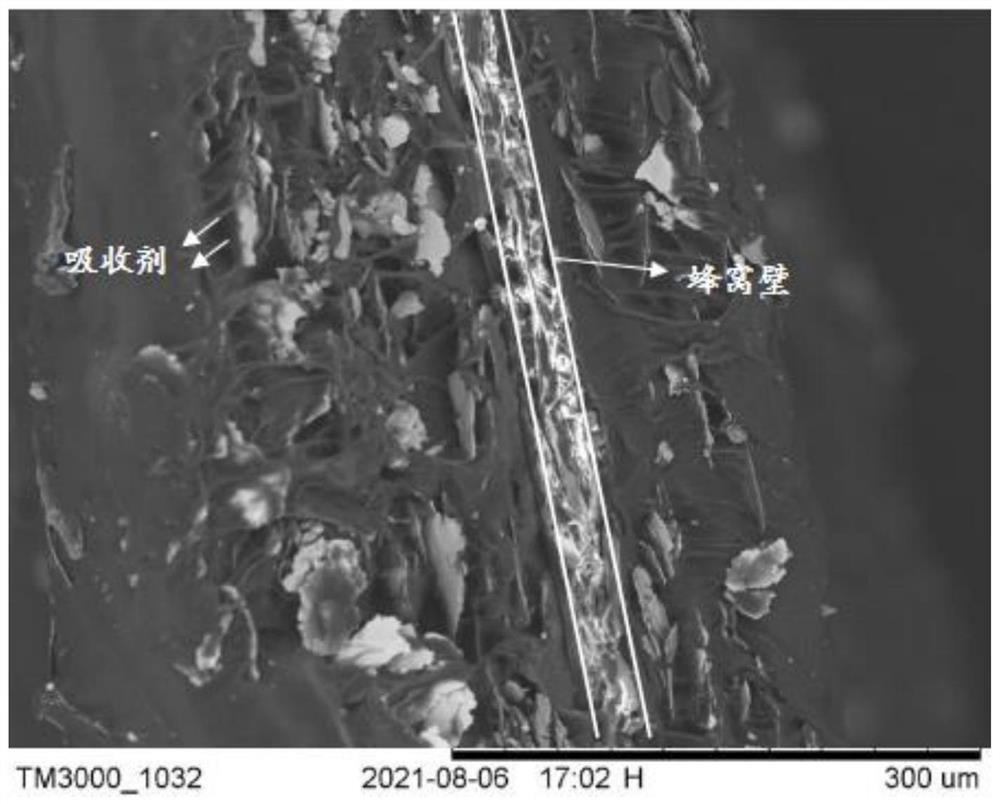

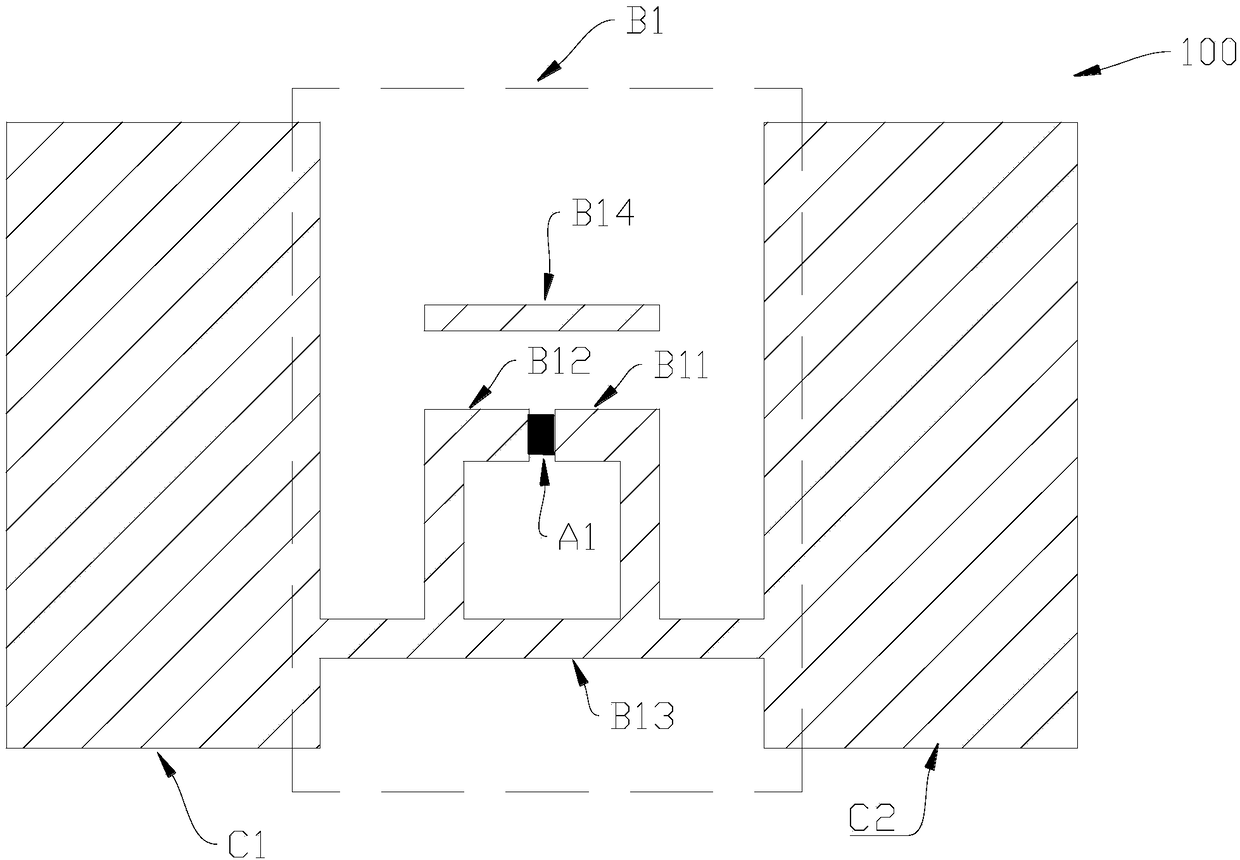

Oriented honeycomb wave-absorbing material and preparation method thereof

ActiveCN114069251ARaise the degree of orientationEnhanced magnetic lossMagnetic/electric field screeningAntennasPolymer scienceSlurry

The invention discloses an oriented honeycomb wave-absorbing material and a preparation method thereof, and belongs to the technical field of electromagnetic wave functional materials. The preparation method comprises the following steps: (1) dipping treatment of a honeycomb base material: dipping the honeycomb base material in magnetic absorbent slurry to obtain a honeycomb material coated with a magnetic wave-absorbing coating; and (2) orientation and molding of the honeycomb material: rotating the honeycomb material coated with the magnetic wave-absorbing coating in a magnetic field for 6-12 hours, and then heating and curing to obtain the oriented honeycomb wave-absorbing material. An impregnation method and a magnetic field induction method are combined, on the basis of an existing honeycomb structure wave-absorbing material, the spatial arrangement of the absorbent on the honeycomb wall is changed by applying a magnetic field, the orientation degree of the absorbent is improved, the obtained honeycomb material has remarkably improved magnetic loss, and especially in a P frequency band, and the low-frequency absorption performance of the wave-absorbing material is effectively improved.

Owner:NANJING UNIV

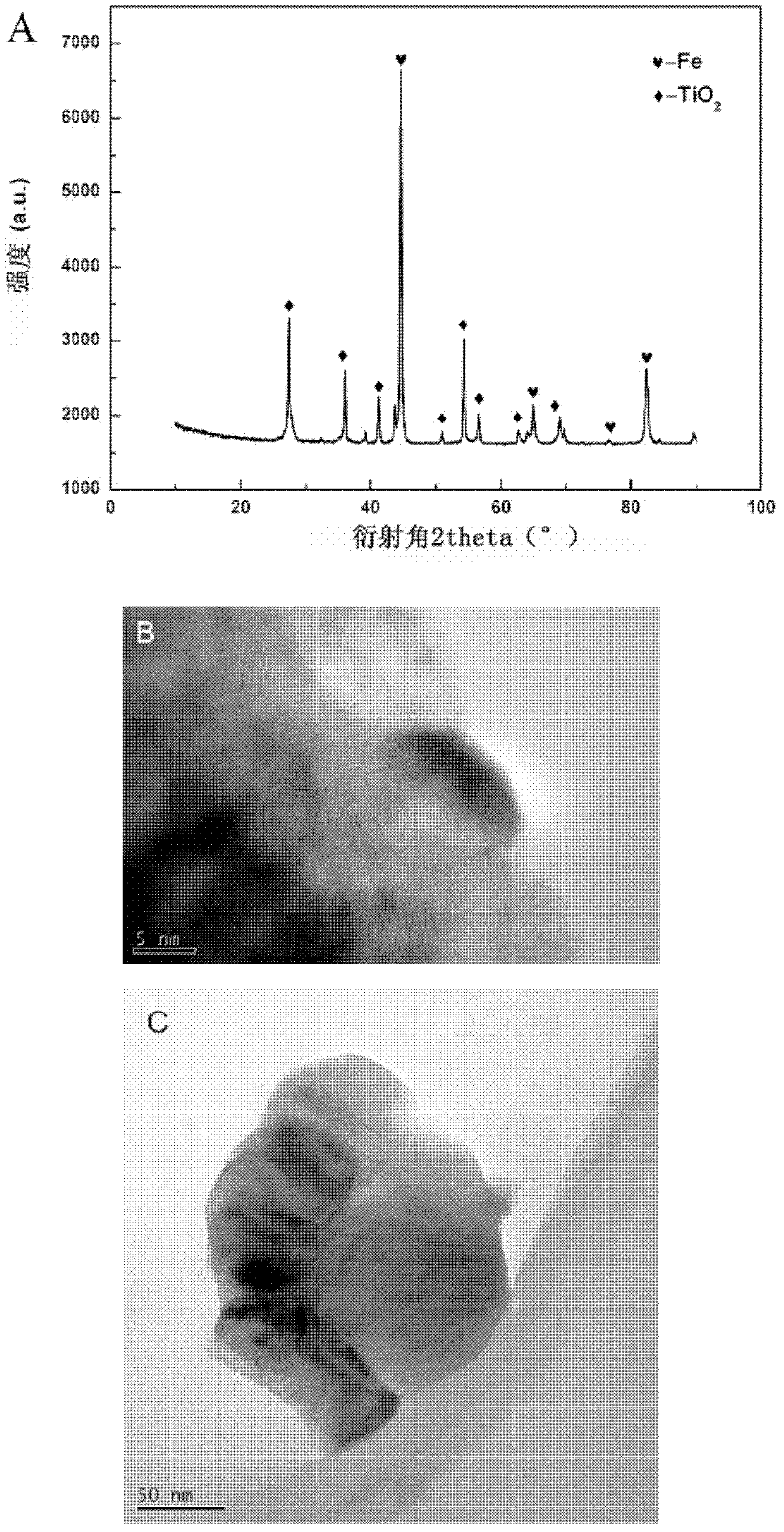

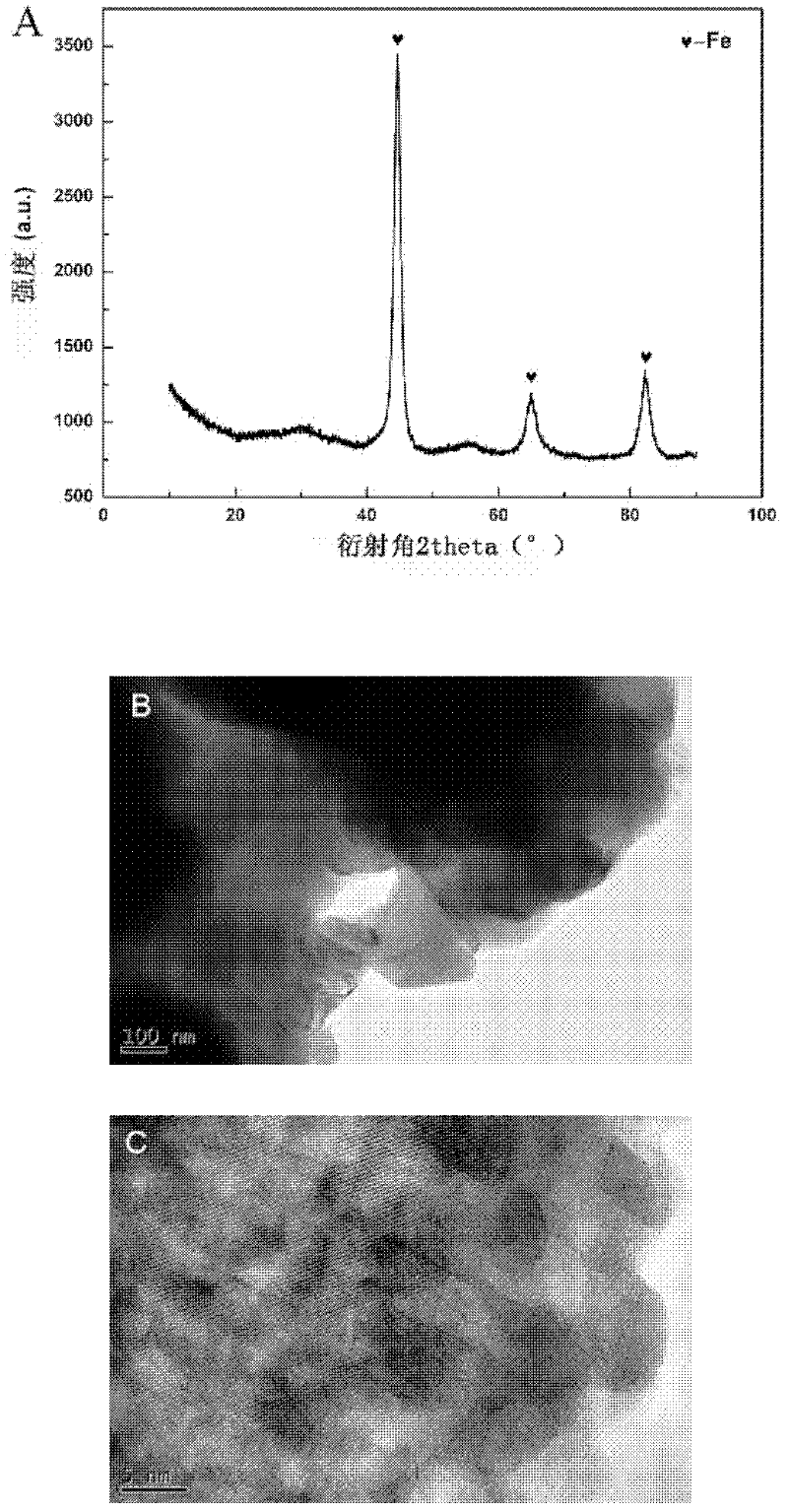

Metal-semiconductor electromagnetic wave absorption type nano composite material and preparation method thereof

InactiveCN102416467AWith multiple resonance propertiesStrong resonance absorptionMagnetic/electric field screeningInorganic material magnetismRadar systemsChemical reaction

The invention relates to the field of an electromagnetic wave absorption material, in particular to a metal-semiconductor electromagnetic wave absorption type nano composite material with a plurality of resonance properties and a preparation method thereof based on mechanical and chemical modification and synthesis. The material has excellent full-radar-band absorption properties. The composite material is Fe / TiO2, two ingredients are closely linked, and the grain size of Fe is 20-60nm, the grain size of TiO2 is 25-65nm. The preparation method comprises: (1) iron oxide, titanium powder and TiO2 powder of 5-15 percent of the total mass of the former two materials are milled for 30-40 hours in a high-performance mill for mechanical and chemical reaction, wherein the mass proportion of ironoxide and titanium powder is 1.70-1.90; and (2) the obtained powder is annealed in an annealing furnace, the annealing temperature is 350-960 DEG C, and the annealing time is 10-90 minutes. Since strong absorption can be realized in the frequency band of 2-18GHz, the composite material can be used as a surface coating of a stealth aircraft. Meanwhile, the problems of electromagnetic wave conflicts of the X-band (10-12.4GHz) and Ku-band (12.4-18GHz) in mobile phones, intelligent transmission, local area networks and radar systems can be solved.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Preparation method and application of tremella derived carbon-based magnetic particle loaded wave-absorbing material

InactiveCN113060767AImprove use valueRich sourcesMagnetic/electric field screeningFerroso-ferric oxidesTremellaFreeze-drying

The invention discloses a preparation method and application of a tremella derived carbon-based magnetic particle loaded wave-absorbing material. Tremella is taken as a raw material of the wave-absorbing material, magnetic particles are absorbed by swelling foaming to enter the inside of the tremella, the tremella derived carbon-based magnetic particle loaded wave-absorbing material is prepared through freeze drying and one-step carbonization, and a simple, green and low-cost preparation method is provided. By simply controlling the concentration of metal ions, the regulation and control of microstructures such as a pore structure and a layered structure can be realized, and meanwhile, the coexistence of magnetic loss and dielectric loss of the material is realized. By using a freeze-drying technology, the inherent hierarchical structure and nanopore structure of tremella can be reserved, and metal ions are fixed at initial positions, so that the absorption performance of the tremella derived wave-absorbing material can be improved. The special structure endows the wave-absorbing material with the characteristics of small thickness, light weight and strong absorbing capacity.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

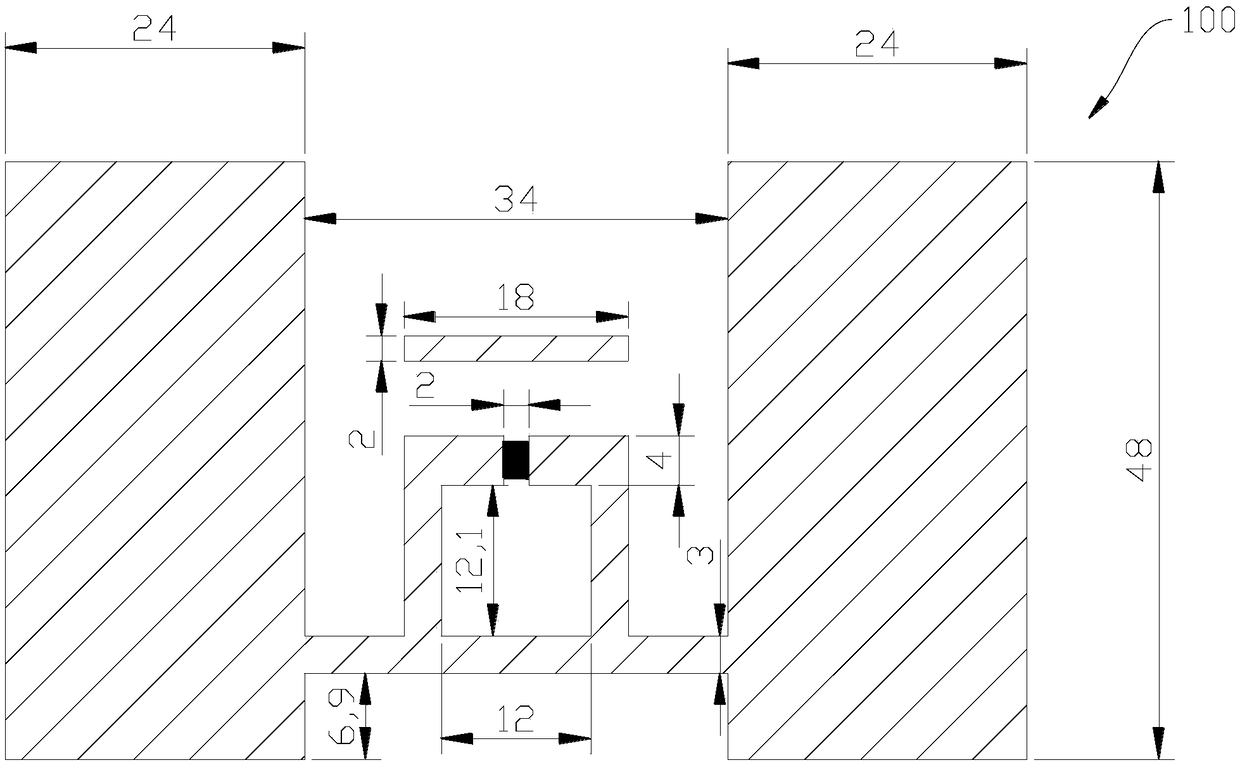

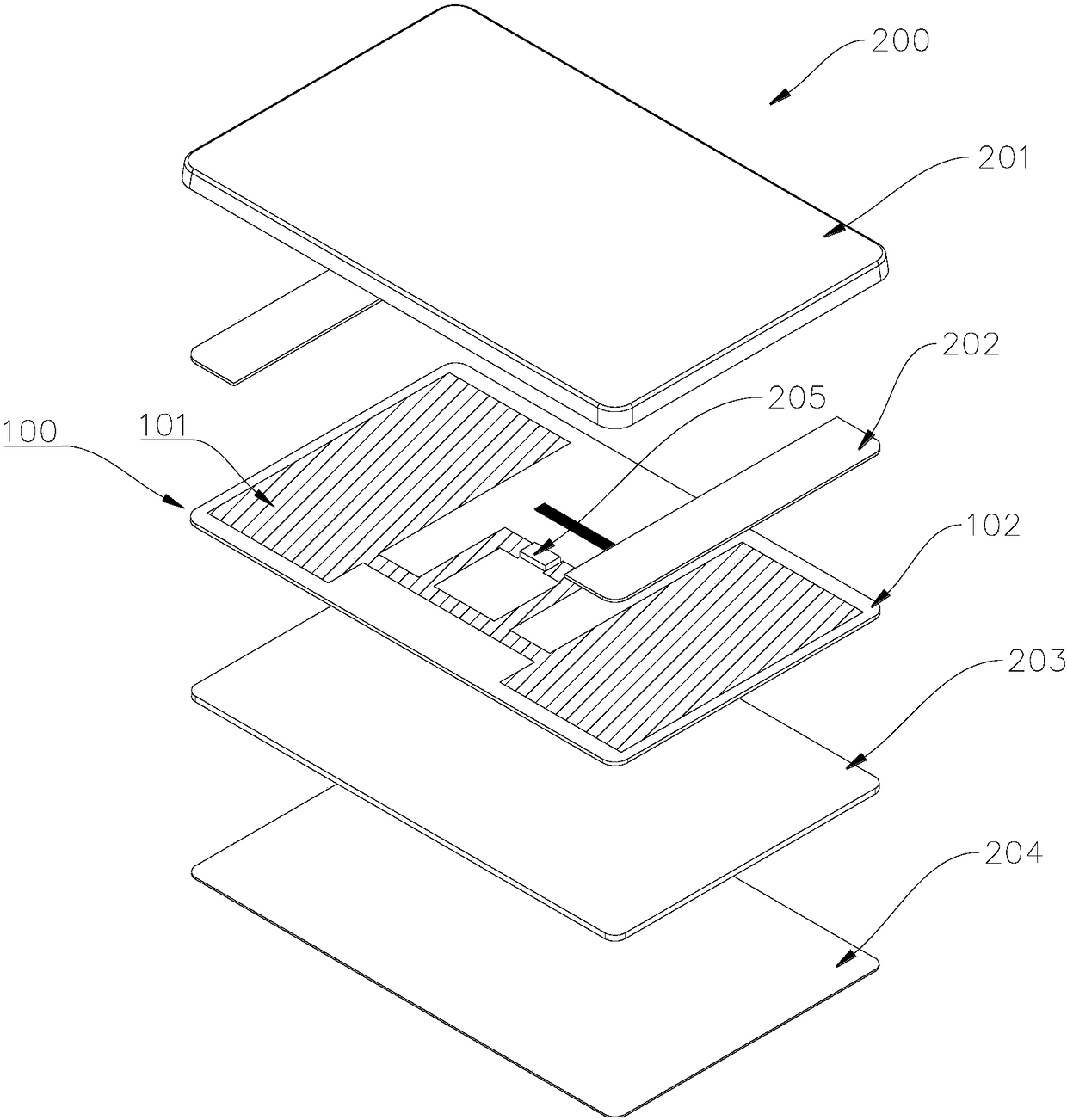

RFID antenna, RFID label and RFID antenna manufacturing method

PendingCN108550977ALow costMeet the scaleAntenna supports/mountingsRadiating elements structural formsAdhesion forceSlurry

The invention relates to an RFID antenna, an RFID label and an RFID antenna manufacturing method, wherein the slurry of the RFID antenna is nickel slurry. The nickel slurry satisfies the conditions described as follows: viscosity is 85-115Pa*s; linear resolution is lower than 200 [mu]m; resistivity is lower than 80 m[omega] / Sq; and an adhesion force is higher than or equal with 625N / cm<2>. The RFID antenna, the RFID label and the RFID antenna manufacturing method have advantages of reducing RFID antenna cost, saving energy and reducing emission.

Owner:SHENZHEN ZHENHUA MICROELECTRONICS

A feconi@c/carbon fiber airgel composite wave-absorbing material and its preparation method

ActiveCN110983492BSimple manufacturing methodFacilitate large-scale applicationOther chemical processesArtifical filament manufactureCarbon fibersMicrowave

The invention discloses a FeCoNi@C / carbon fiber airgel composite wave-absorbing material. The composite wave-absorbing material includes a carbon fiber matrix and FeCoNi@carbon composite nano-microspheres, and the FeCoNi@carbon composite nano-microspheres are loaded on the surface of the carbon fiber matrix. In the present invention, carbon fiber is used as a matrix, and microspherical FeCoNi@C derived from FeCoNi-MOF is loaded on its surface. The prepared composite material solves the lack of multiple effective electromagnetic wave loss mechanisms of a single carbon material and a single-metal MOF-derived material. The problems, good impedance matching and better absorption efficiency are obtained, and it is an ideal choice for new lightweight and efficient microwave absorbing materials.

Owner:SOUTHEAST UNIV

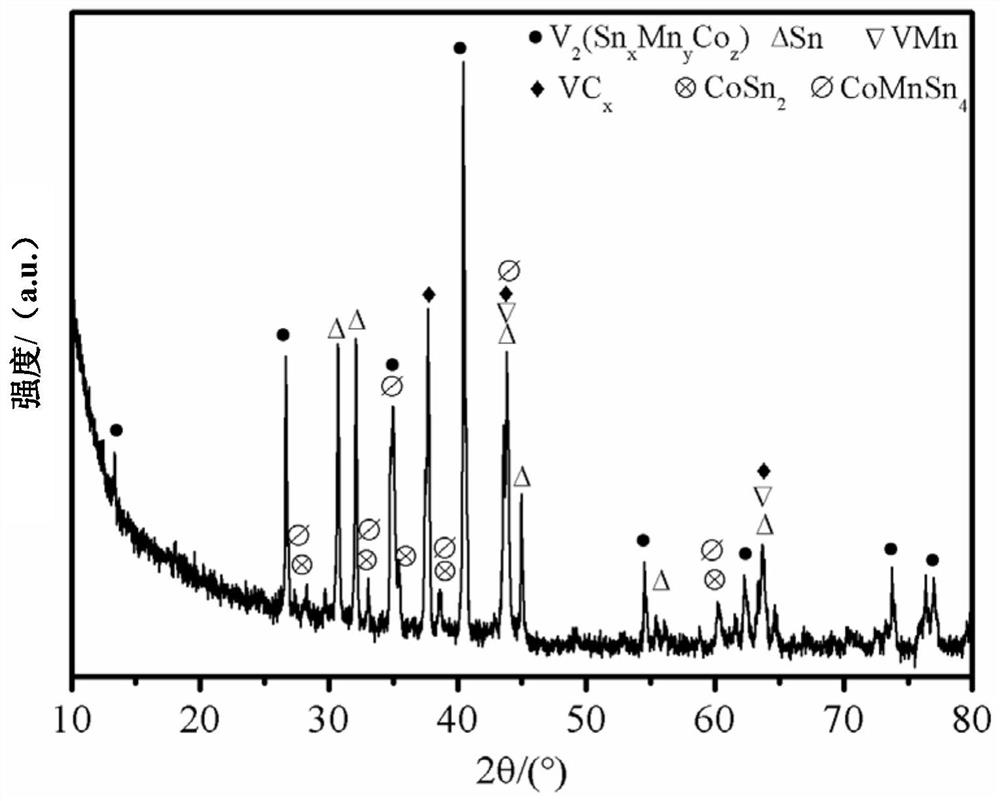

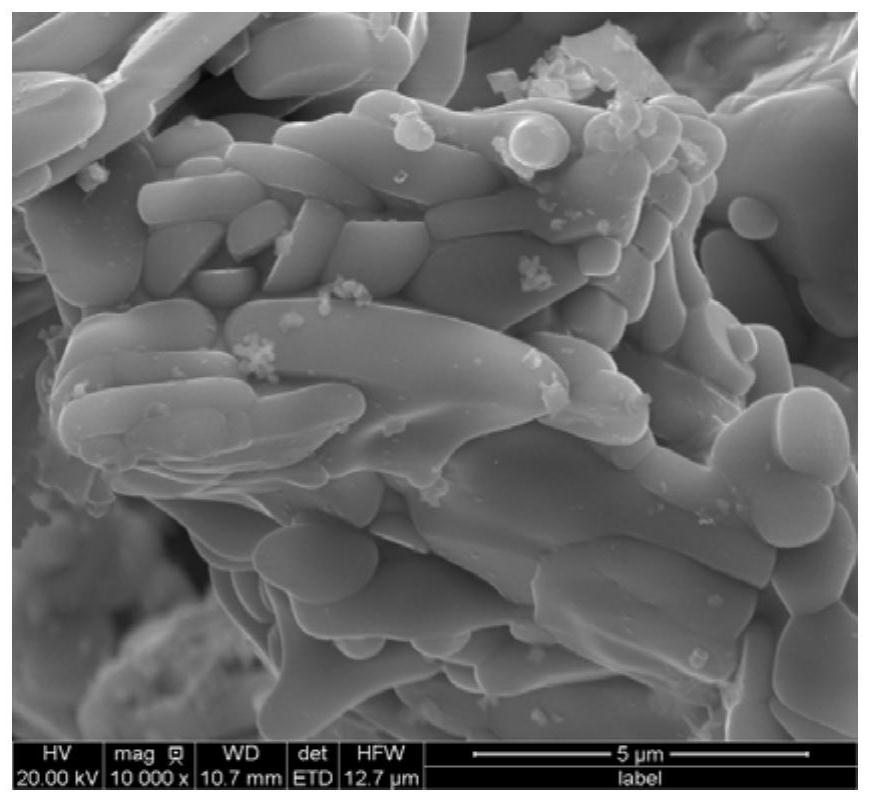

A novel five-element layered magnetic material, its preparation method and application

ActiveCN111477419BEffective absorptionAchieve synthesisInorganic material magnetismInductances/transformers/magnets manufactureChemical compositionElectrochemistry

The invention discloses a novel five-element layered magnetic material, its preparation method and application. The chemical composition of the five-element layered magnetic material is expressed as A 2 (B x C y D. z )E 1 , where A is any one of Ta, Sc, Hf, V, Nb, Mo, Zr, Cr, Ti elements, B is any one of Al, Sn, Ga, In elements, C and D are magnetic element, and C and D are different, 0<x<1, 0<y<1, 0<z<1, and x+y+z=1, E is any one or both of C and N elements The combination. The novel five-element layered magnetic material of the invention has potential application prospects in the fields of electrochemical catalysis, wave absorption and the like.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

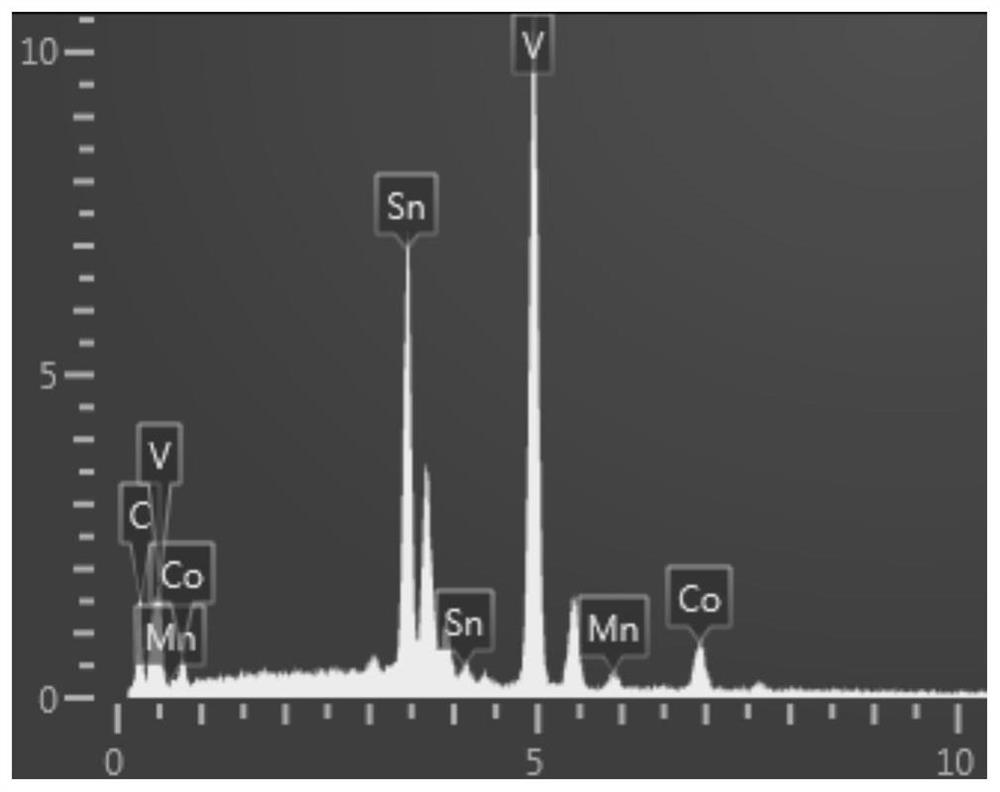

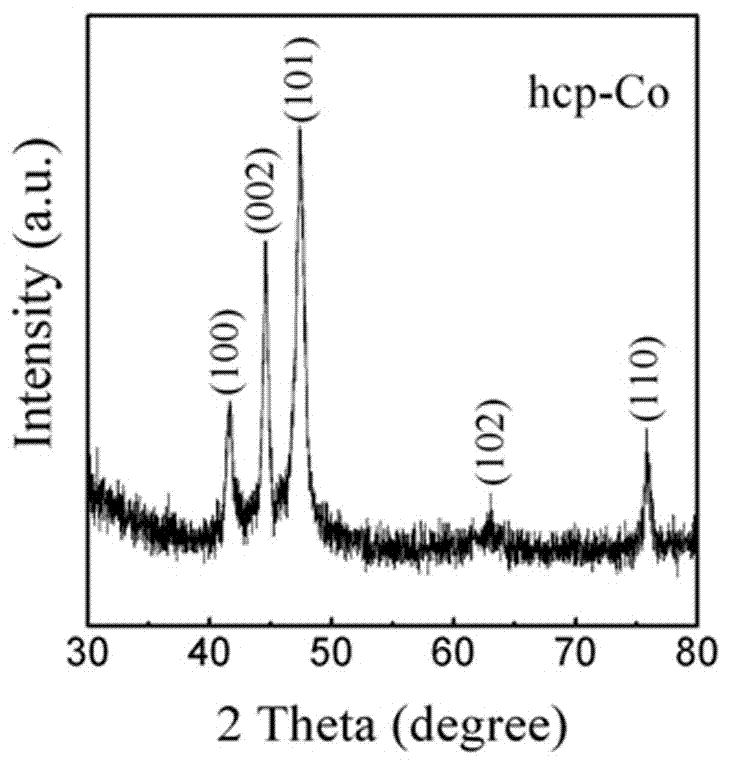

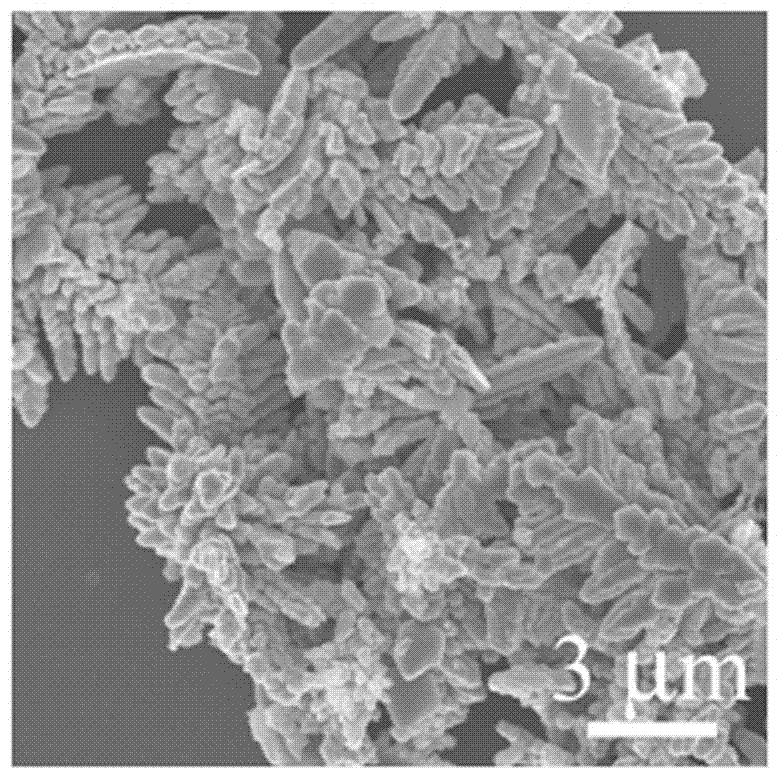

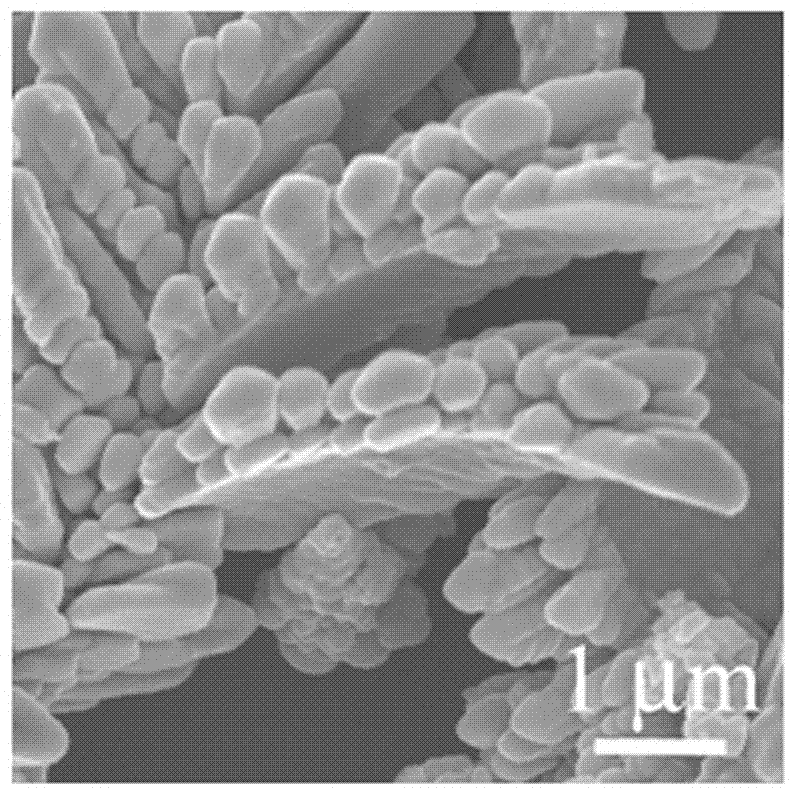

Self-assembly of a two-dimensional sheet-like constituent unit into a three-dimensional dendritic magnetic cobalt nanomaterial

ActiveCN105252017BHigh shape reproducibilityHigh temperature and high shape reproducibilityBranch lengthPyromellitic acid

A two-dimensional sheet-like component unit self-assembles into a three-dimensional dendritic magnetic cobalt nanomaterial, which is used as a composite microwave absorbing material. Its characteristics are that the backbone length of the three-dimensional dendritic magnetic cobalt nanomaterial is 2‑9 μm, and the branch length is 1‑ 4 μm, the basic constituent unit is a sheet structure, and its particle size is 200-500 nm. The three-dimensional dendritic magnetic metal cobalt nanomaterial is composed of the face-face oriented connection growth of the sheet-like constituent units; its preparation method: (1) Prepare six Cobalt chloride hydrate solution; (2) Prepare sodium hydroxide solution; (3) Add the solution of step (2) to the solution of step (1) and mix thoroughly; (4) Add pyromellitic acid and sodium hypophosphite Mix well with the solution in step (3); (5) treat the solution in step (4) under hydrothermal conditions, wash the product with deionized water and absolute ethanol, and then dry it in a vacuum to obtain dendritic magnetic metal cobalt nanomaterials.

Owner:SHENYANG POLYTECHNIC UNIV

Hexagonal ferrite material with high magnetic loss in L wave band and preparation method thereof

The invention discloses a hexagonal ferrite material with high magnetic loss in L wave band and a preparation method thereof, relates to the material technologies and in particular relates to a magnetic material technology. The chemical component of the material is (Ba[1-x]Srx)3Co2Fe24O41, wherein x is equal to 0.0 or 0.2 or 0.4 or 0.6 or 0.8. The hexagonal ferrite material has the advantages of high magnetic loss, high electrical resistivity and excellent high-frequency soft magnetic properties in the L wave band.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Preparation method of nano-barium titanate/iron tetroxide hybrid material with high wave-absorbing performance

ActiveCN113329608BStrong absorption capacityReduce direct reflectionMaterial nanotechnologyAlkaline earth titanatesBarium titanateHybrid material

Owner:东北大学秦皇岛分校

Electromagnetic shielding material for electroless cobalt plating of modified carbon nanotubes and preparation method of electromagnetic shielding material

InactiveCN102634777BImprove magnetic propertiesGuaranteed MagneticLiquid/solution decomposition chemical coatingModified carbonCurie temperature

The invention discloses an electromagnetic shielding material for electroless cobalt plating of modified carbon electroless and a preparation method of the electromagnetic shielding material, which belong to the technical field of preparation of nanomaterials. The preparation method includes acidification pretreatment and pretreatment of multi-walled carbon nanotubes, and successfully coating metallic cobalt to the surfaces of the multi-walled carbon nanotubes. By using the material, original poor magnetic property of the multi-walled carbon nanotubes can be improved evidently, and magnetic loss can be increased evidently. In addition, the metallic cobalt has high Curie temperature and has magnetism even under high temperature. Therefore, the multi-walled carbon nanotubes coated with the metallic cobalt can serve as a high-temperature-resistant electromagnetic shielding material.

Owner:BEIHANG UNIV

Reduction helical carbon fiber loaded nickel water-based anti-corrosion stealth coating and preparation method thereof

ActiveCN104774535BRust removal requirements are not highStrong adhesionAnti-corrosive paintsRadiation-absorbing paintsWater basedEpoxy

The invention discloses a water-borne corrosion-preventing camouflaging coating with spiral carbon fiber load nickel prepared through a reduction method and a preparing method of the coating. The coating is formed by a first composition and a second composition according to the mass ratio of 1:1; the first composition comprises, by mass, 80-120 parts of water-borne epoxy resin, 0.2-0.8 part of antifoaming agent and 5-15 parts of distilled water; the second composition comprises, by mass, 20-30 parts of water-borne epoxy curing agents, 0.08-0.15 part of antifoaming agent, 1-1.5 parts of dispersing agents, 20-30 parts of superfine talcum powder, 15-30 parts of zinc phosphate, 0-20 parts of iron oxide red, 15-30 parts of titanium dioxide and 15-30 parts of spiral carbon fiber load nickel chirality wave absorbing agents. The invention further discloses the preparing method of the coating. The spiral carbon fiber load nickel chirality wave absorbing agents are prepared by adopting the reduction method, and the coating is good in corrosion-preventing property, high in electromagnetic wave absorption rate, capable of resisting an acid-base environment and good in dirt resistance, and has a good effect of protecting the surface of a hull.

Owner:JIANGSU UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com