A novel five-element layered magnetic material, its preparation method and application

A magnetic material, layered technology, applied in the field of materials, can solve the problems of not getting the target product, stoichiometric ratio shift, long holding time, etc., to achieve the effect of expanding the scope of use, improving the magnetic loss, and increasing the magnetic properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

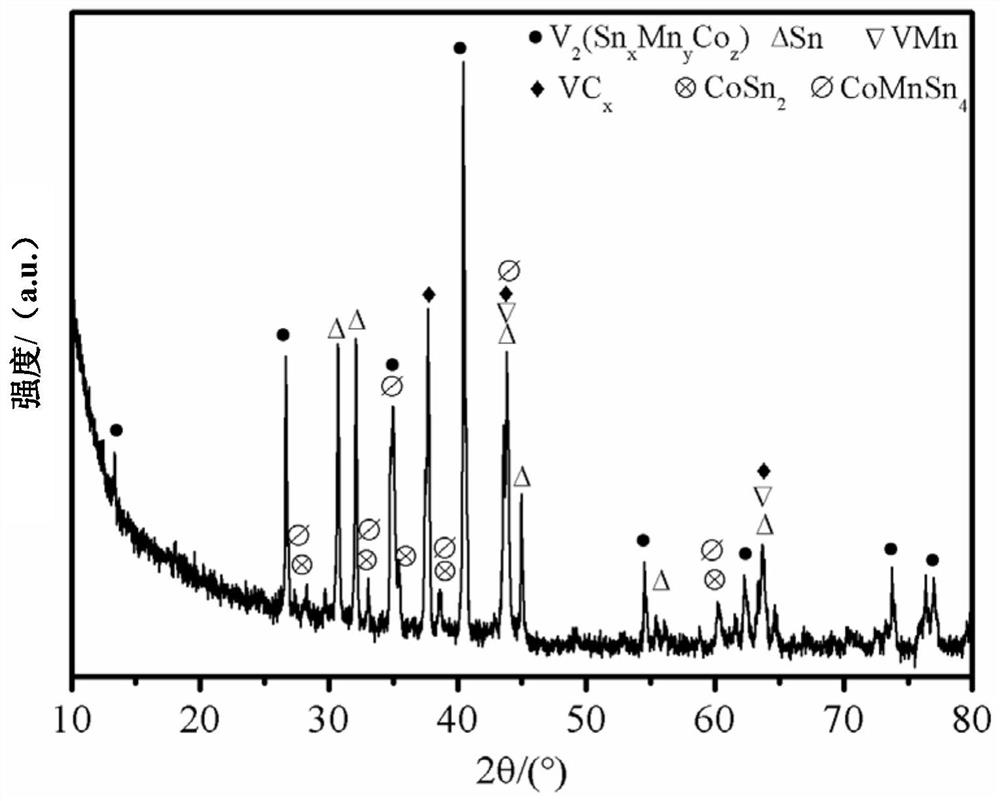

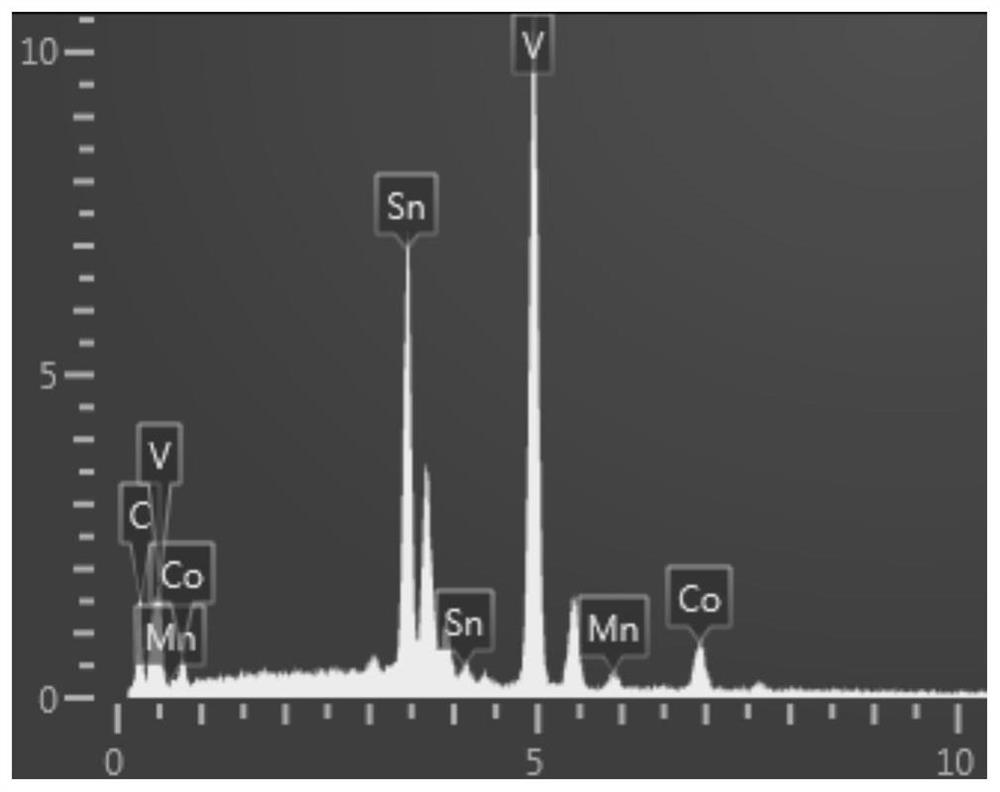

[0054] Embodiment 1: In this embodiment, the novel five-element layered magnetic material is V 2 (Sn x mn y co z ) C powder material.

[0055] The V 2 (Sn x mn y co z ) The preparation method of C powder is as follows:

[0056] (1) Weigh V powder, Sn powder, Co powder, MnCo alloy powder, carbon powder, inorganic salt (NaCl+KCl) according to the molar ratio of 4:1:0.99:0.99:1:3, and the above materials Grind and mix to obtain a mixture.

[0057] (2) Put the mixture in a corundum crucible and put it into a high-temperature tube furnace for reaction. The reaction conditions are as follows: the reaction temperature is 1300° C., the holding time is 60 minutes, and the inert atmosphere is protected. After the temperature of the tube furnace dropped to room temperature, the reaction product in the crucible was taken out.

[0058] (3) Wash the reaction product with deionized water and alcohol: put the reaction product into a beaker, add deionized water, stir and ultrasonica...

Embodiment 2

[0061] Embodiment 2: In this embodiment, the novel five-element layered magnetic material is V 2 (Sn x Fe y co z ) C powder material.

[0062] The V 2 (Sn x Fe y co z ) The preparation method of C powder is as follows:

[0063] (1) Weigh VC powder, Sn powder, Fe powder, Co powder and carbon powder according to the molar ratio of 2:1:0.01:0.01:1, grind and mix the above materials to obtain a mixture.

[0064] (2) Put the mixture in a corundum crucible and put it into a high-temperature tube furnace for reaction. The reaction conditions are as follows: the reaction temperature is 500° C., the holding time is 720 minutes, and the inert atmosphere is protected. After the temperature of the tube furnace dropped to room temperature, the reaction product in the crucible was taken out.

[0065] (3) Wash the reaction product with deionized water and alcohol: put the reaction product into a beaker, add deionized water, stir and ultrasonically clean for 30 minutes, then let it ...

Embodiment 3

[0068] Embodiment 3: In this embodiment, the novel five-element layered magnetic material is V 2 (Sn x Fe y Ni z ) C powder material.

[0069] The V 2 (Sn x Fe y Ni z ) The preparation method of C powder is as follows:

[0070] (1) Put V 2 o 5 Powder, Sn powder, Fe powder, FeNi alloy powder, carbon powder and KCl inorganic salt are weighed according to the molar ratio of 2.5:1:0.99:0.50:1:1.5, and the above materials are ground and mixed to obtain a mixture.

[0071] (2) Put the above powder mixture into a graphite mold, and then sinter by SPS. The sintering conditions are: 1100°C for 120min, heating rate of 100°C / min, argon protection, and pressure of 37MPa. After the reaction was over, the product was taken out.

[0072] (3) Remove the graphite paper on the surface of the obtained block, and then polish it to a mirror surface with sandpaper of different meshes, put it in an oven at 50° C., and take it out for 12 hours to obtain a block material.

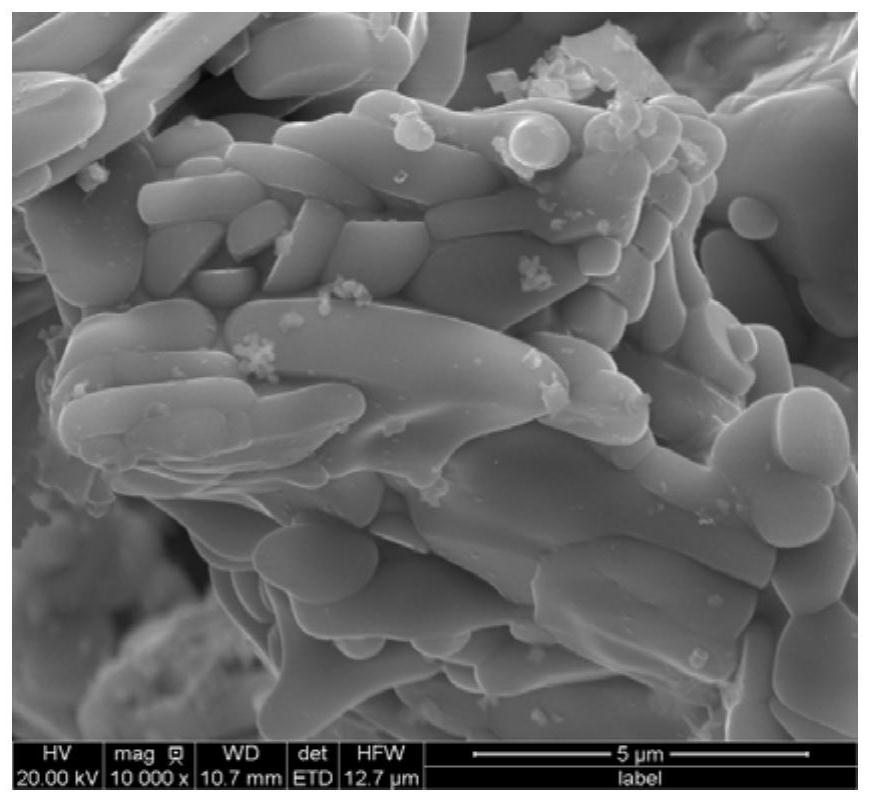

[0073] Figur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com