Preparation method of three-dimensional ordered carbon-based porous wave-absorbing material based on native wood

A three-dimensional ordered, wave-absorbing material technology, applied in the preparation/purification of carbon, chemical instruments and methods, other chemical processes, etc., can solve the problems of single-oriented absorption, limited preparation methods and raw materials, etc., to improve impedance matching, The effect of increasing the magnetic loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

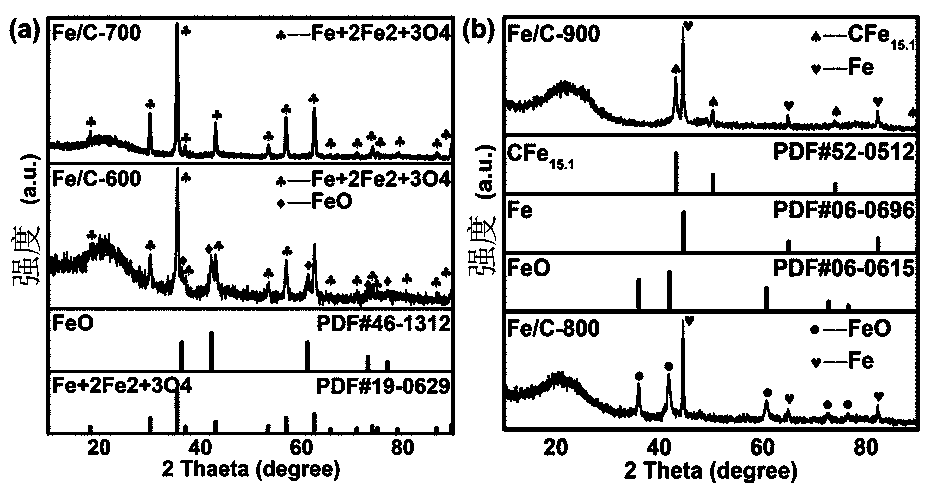

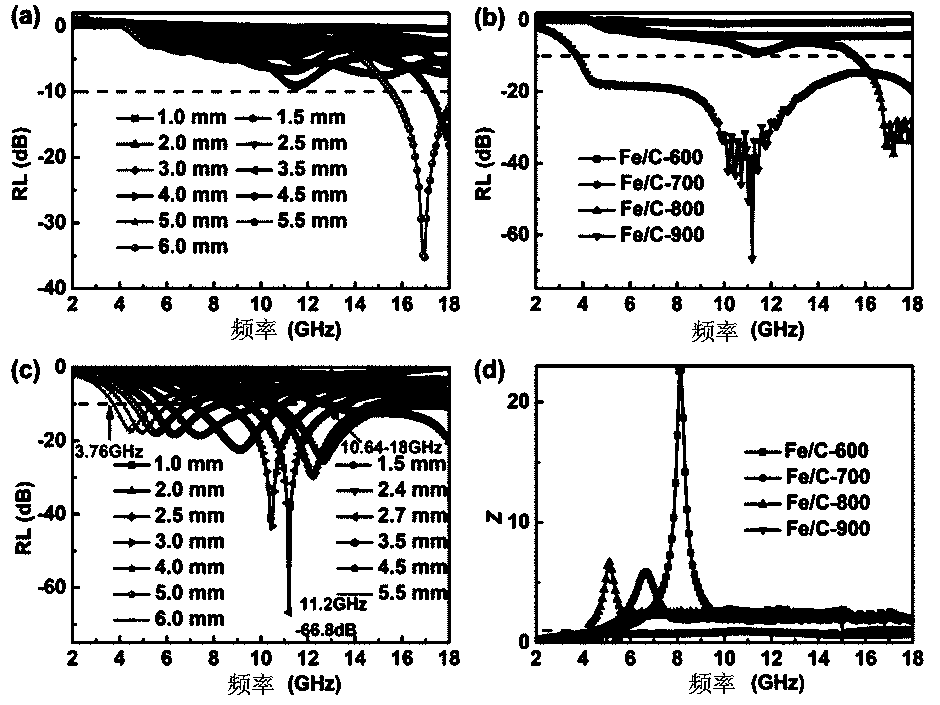

Method used

Image

Examples

Embodiment Construction

[0015] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0016] The preparation method of the three-dimensional ordered carbon-based porous wave-absorbing material based on native wood involved in the present invention comprises the following steps:

[0017] Step 1. Pretreatment of raw wood: first cut the raw wood (pine wood as an example) into a predetermined size of cuboid (or other required shape), then soak the wood block for 1 to 2 days, and then wash it repeatedly with deionized water Wood blocks several times, and finally dry the wood blocks at 50-70°C.

[0018] Soaking the wood block for 1 to 2 days in step 1 can facilitate the subsequent washing steps, and repeatedly washing the wood block with deionized water can remove impurities on the surface that are easy to remove. In this embodiment, an oven is used for drying.

[0019] Step 2, pre-carbonization: put the dried wood blocks in step...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com