SrNdMnO wave-absorbing material and preparation method thereof

A wave absorbing material, metal nitrate technology, applied in chemical instruments and methods, other chemical processes, electrical components, etc., can solve problems such as adverse effects of electronic equipment, communication signal interference, failure to work properly, and reduce lattice distortion. , The effect of improving the absorbing performance and increasing the eddy current loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

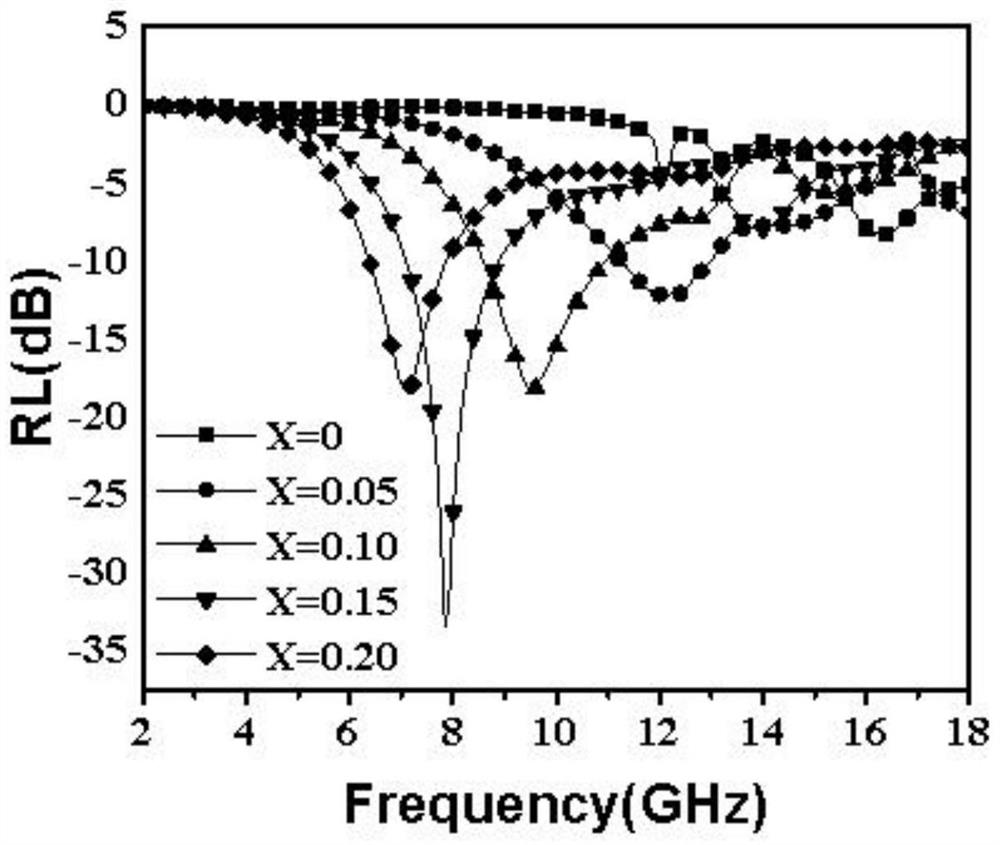

[0035] According to the molecular formula Sr 0.95 Nd 0.05 MnO 3Weigh 0.34 g of neodymium nitrate, 3.12 g of strontium nitrate and 5.55 g of manganese nitrate with a purity of ≥99.9%, and then weigh 9.78 g of citric acid according to the molar ratio of metal ions (strontium ion, manganese ion and neodymium ion) to citric acid 1:1.5 g, citric acid and distilled water are mixed to obtain a citric acid solution, then strontium nitrate, manganese nitrate and neodymium nitrate are added to the citric acid solution, the resulting solution is put into a water bath, and constant temperature magnetic stirring is continued at 80 ° C (stirring The speed is 280r / min), and the gelation reaction is carried out for 3h to obtain a gel. The gel is dried in a blast drying oven at 90°C, and the obtained dried product is pre-sintered at 1000°C for 2h. The obtained material was put into a muffle furnace and calcined at 1350 ° C for 2 h to obtain an oxide wave absorbing material, which was denoted...

Embodiment 2

[0037] According to the molecular formula Sr 0.9 Nd 0.1 MnO 3 Weigh 0.67 g of neodymium nitrate, 2.91 g of strontium nitrate and 5.47 g of manganese nitrate with a purity of ≥99.9%, and then weigh 9.64 g of citric acid according to the molar ratio of metal ions (strontium ion, manganese ion and neodymium ion) to citric acid 1:1.5 , citric acid and distilled water were mixed to obtain a citric acid solution, then strontium nitrate, manganese nitrate and neodymium nitrate were added to the citric acid solution, the resulting solution was put into a water bath, and the constant temperature magnetic stirring was continued at 80 ° C (stirring speed). 300 r / min), gelation reaction was carried out for 3 h to obtain a gel, the gel was dried in a blast drying oven at 100 °C, and the obtained dried product was pre-fired at 1000 °C for 2 h. The obtained material was put into a muffle furnace and calcined at 1350 °C for 2 hours to obtain an oxide wave absorbing material, which was denot...

Embodiment 3

[0039] According to the molecular formula Sr 0.85 Nd 0.15 MnO 3 Weigh 0.99g of neodymium nitrate, 2.71g of strontium nitrate and 5.39g of manganese nitrate with a purity of ≥99.9%, and then weigh citric acid according to the molar ratio of metal ions (strontium ion, manganese ion and neodymium ion) to citric acid 1:1.5 9.50g, citric acid and distilled water were mixed to obtain a citric acid solution, then strontium nitrate, manganese nitrate and neodymium nitrate were added to the citric acid solution, the resulting solution was put into a water bath, and the constant temperature magnetic stirring was continued at 80 ° C ( The stirring speed is 320r / min), and the gelation reaction is carried out for 3.5h to obtain a gel. The gel is dried in a blast drying oven at 110°C, and the obtained dried product is pre-fired at 1000°C. 2h, put the obtained material into a muffle furnace and calcined at 1350°C for 2h to obtain an oxide wave absorbing material, denoted as Sr 0.85 Nd 0....

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com