Patents

Literature

35results about How to "Improve eddy current loss" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

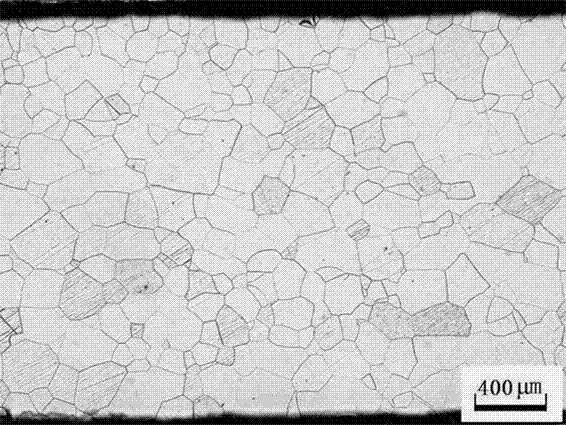

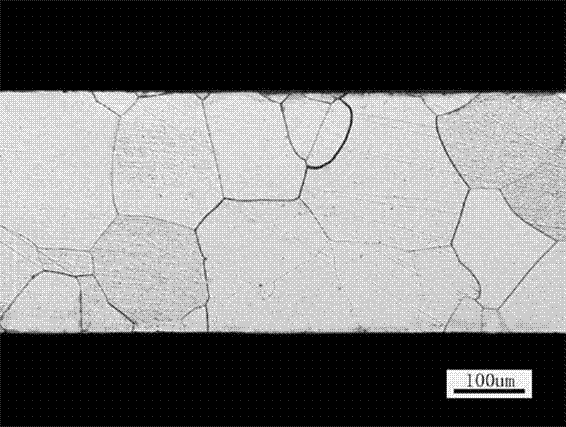

Non-oriented electrical steel with excellent magnetic performance and Rm not smaller than 600 MPa

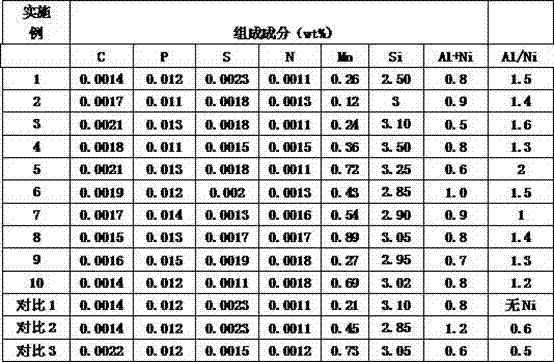

The invention discloses non-oriented electrical steel with excellent magnetic performance and Rm not smaller than 600 MPa, wherein the non-oriented electrical steel is composed of the following components by weight percent: 2.5-3.5% of Si, 0.1-1.0% of Mn, not more than 1.0% of Ni and Al, not larger than 0.005% of N, not larger than 0.015% of S, not larger than 0.003% of C and not larger than 0.05% of P; the production steps are as follows: smelting and continuously casting a bloom; heating the continuously cast bloom; hot rolling; coiling; normalizing; pickling and cold rolling; continuous annealing; and naturally cooling to the room temperature for future use. The mechanical properties and magnetic performance of the non-oriented electrical steel disclosed by the invention can simultaneously satisfy the requirements of motor steel, namely, Rm is not smaller than 600 MPa, Rel is not smaller than 500 MPa, P1.0 / 400 is not larger than 17 W / kg, B 5000 is not smaller than 1.66 T, and stators and rotors are processed by the same electromagnetic steel plate to reduce the time and material costs.

Owner:武汉钢铁有限公司

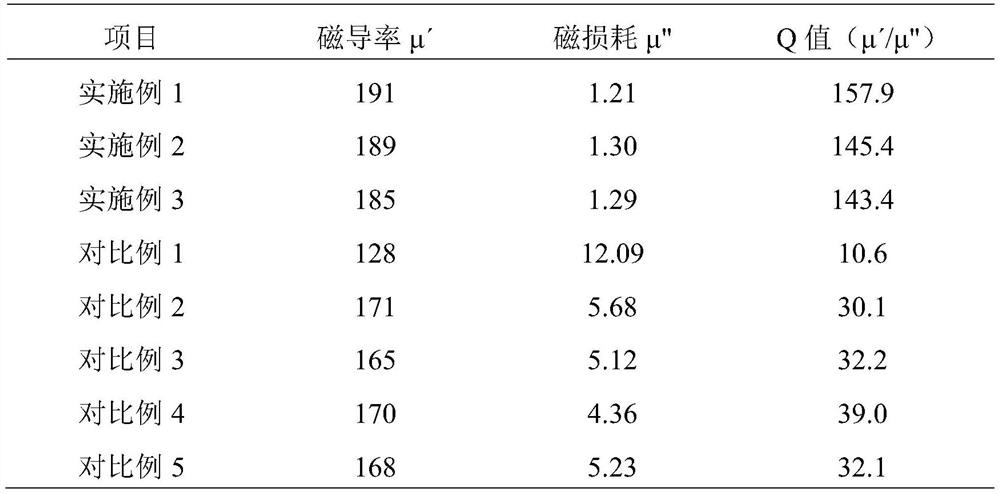

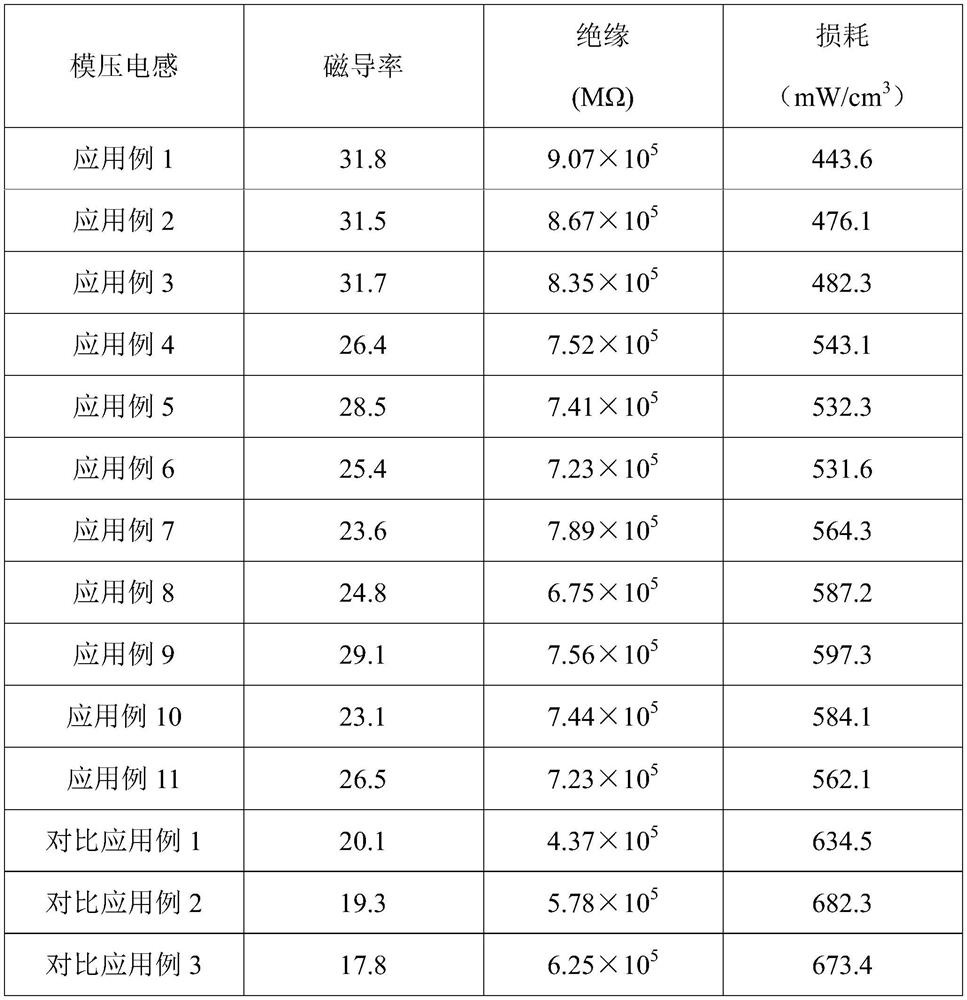

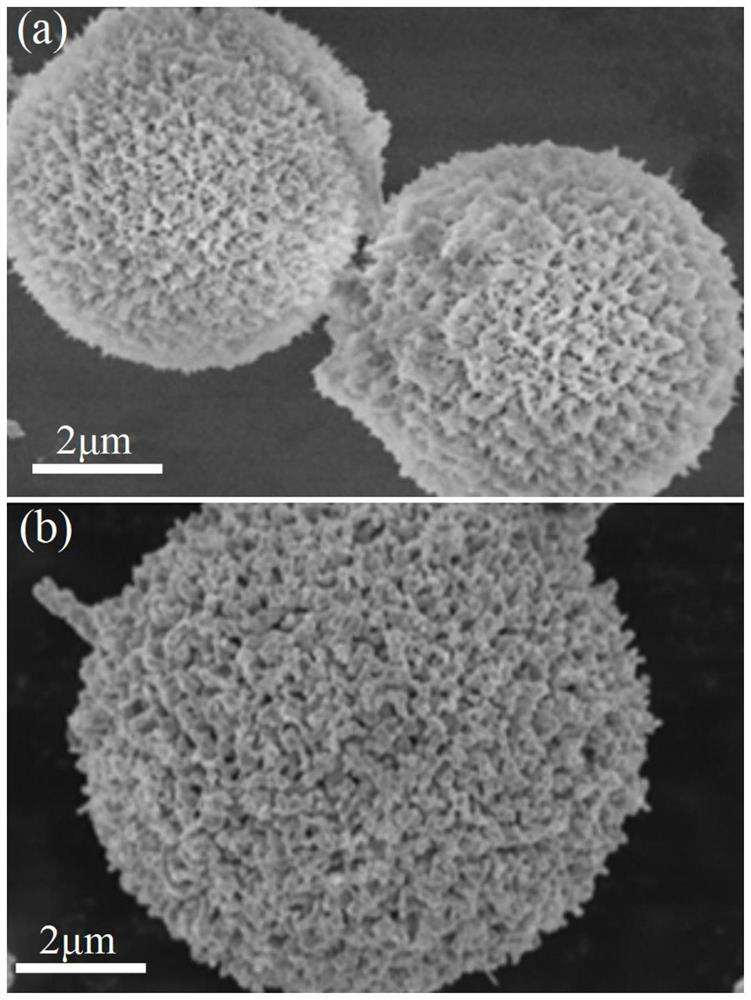

Magnetic core material, and preparation method and application thereof

ActiveCN112768166AReduce permeabilityImprove permeabilityInductances/transformers/magnets manufactureMagnetic materialsComposite materialMagnetic core

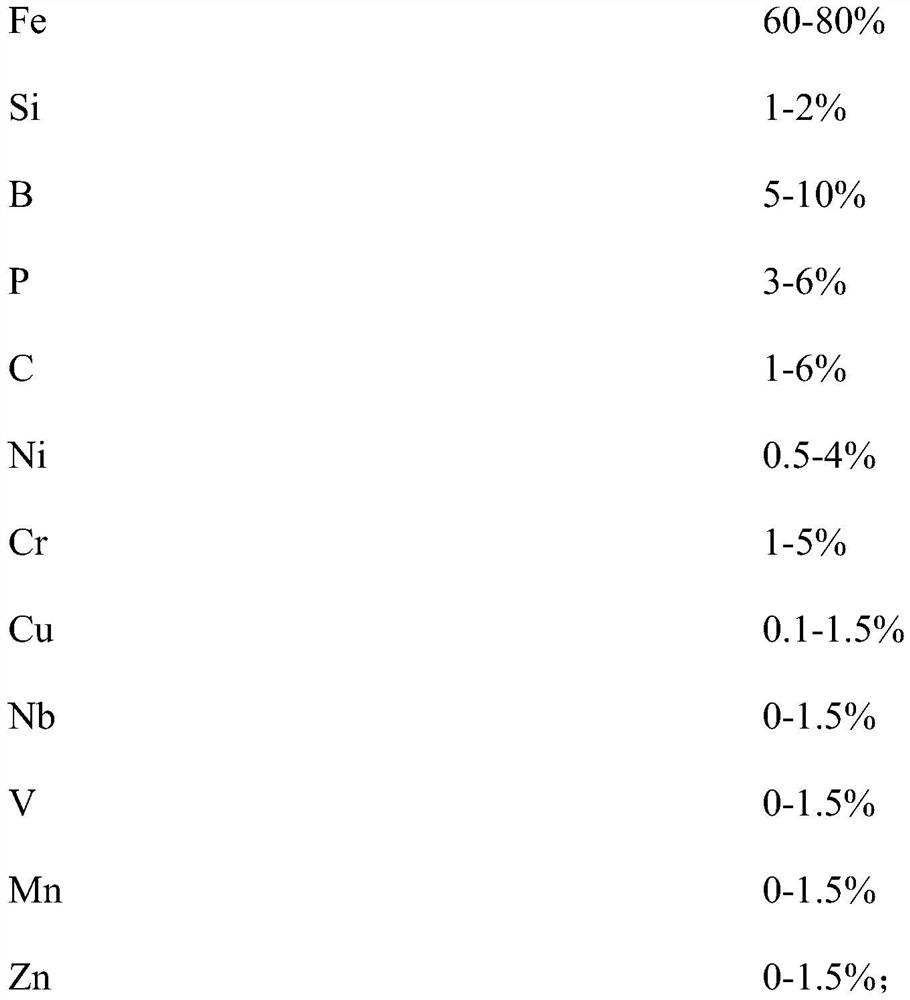

The invention provides a magnetic core material, and a preparation method and an application thereof. The magnetic core material comprises a first magnetic powder, a second magnetic powder and a third magnetic powder which are bonded and mixed by a binder. The preparation method comprises the following steps: (1) mixing the first magnetic powder, the second magnetic powder and the third magnetic powder to obtain a ternary magnetic powder; (2) passivating the ternary magnetic powder obtained in the step (1) to obtain a passivated magnetic powder; (3) coating the passivated magnetic powder obtained in the step (2) to obtain a coated magnetic powder; (4) bonding and granulating the coated magnetic powder obtained in the step (3) to obtain magnetic particles; and (5) carrying out compression molding on the magnetic particles obtained in the step (4) to obtain the magnetic core material. The magnetic core material provided by the invention has the characteristics of low forming pressure, high magnetic conductivity and low loss, and the short-circuit risk of a molded inductor is reduced.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

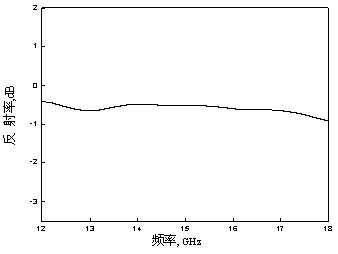

Preparation method of foam aluminium alloy wave-absorbing material

InactiveCN102002300AImprove absorbing performanceLow resistivityPretreated surfacesRadiation-absorbing paintsEpoxyDry mixing

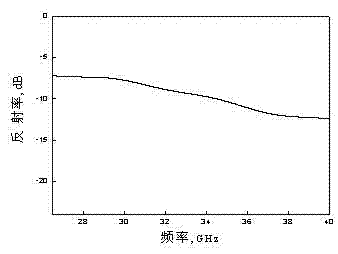

The invention relates to a preparation method of a foam aluminium alloy wave-absorbing material, comprising surface pretreatment of foam aluminium alloy substrates, preparation of wave-absorbing coating and spraying of the wave-absorbing coating. The preparation method of the wave-absorbing material comprises the following steps of: (1) adding a coupling agent to polyaniline, adding a rare earth oxide after ball milling wet mixing, drying after ball milling wet mixing, and dry mixing to prepare a composite filler; (2) adding the coupling agent to the composite filler to prepare a coupling filler; (3) uniformly mixing a dispersing agent and a diluent, and adding the mixture to the coupling filler to prepare a dispersed filler; and (4) mixing epoxide resin with polyamide to prepare a film forming matter, grinding the film forming matter together with the dispersed filler, mixing, stirring, carrying out sonic oscillation, stirring and sieving, wherein the screenings are used as wave-absorbing coating. The wave-absorbing agent foam aluminium alloy-based wave-absorbing material doped with rare earth oxide has excellent wave-absorbing performance, and the bandwidth lower than -10dB can reach 13.5GHz in the frequency range of 26.5GHz to 40.0GHz.

Owner:NORTHEASTERN UNIV

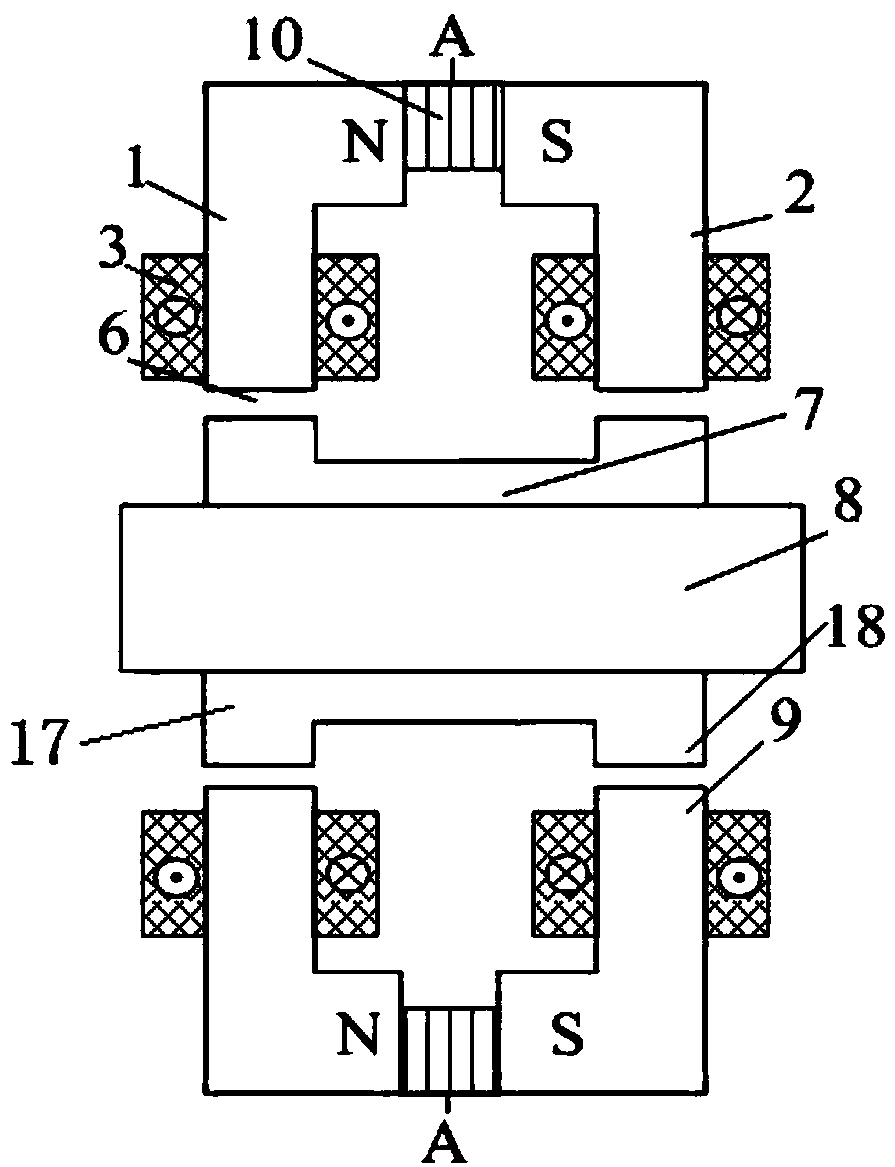

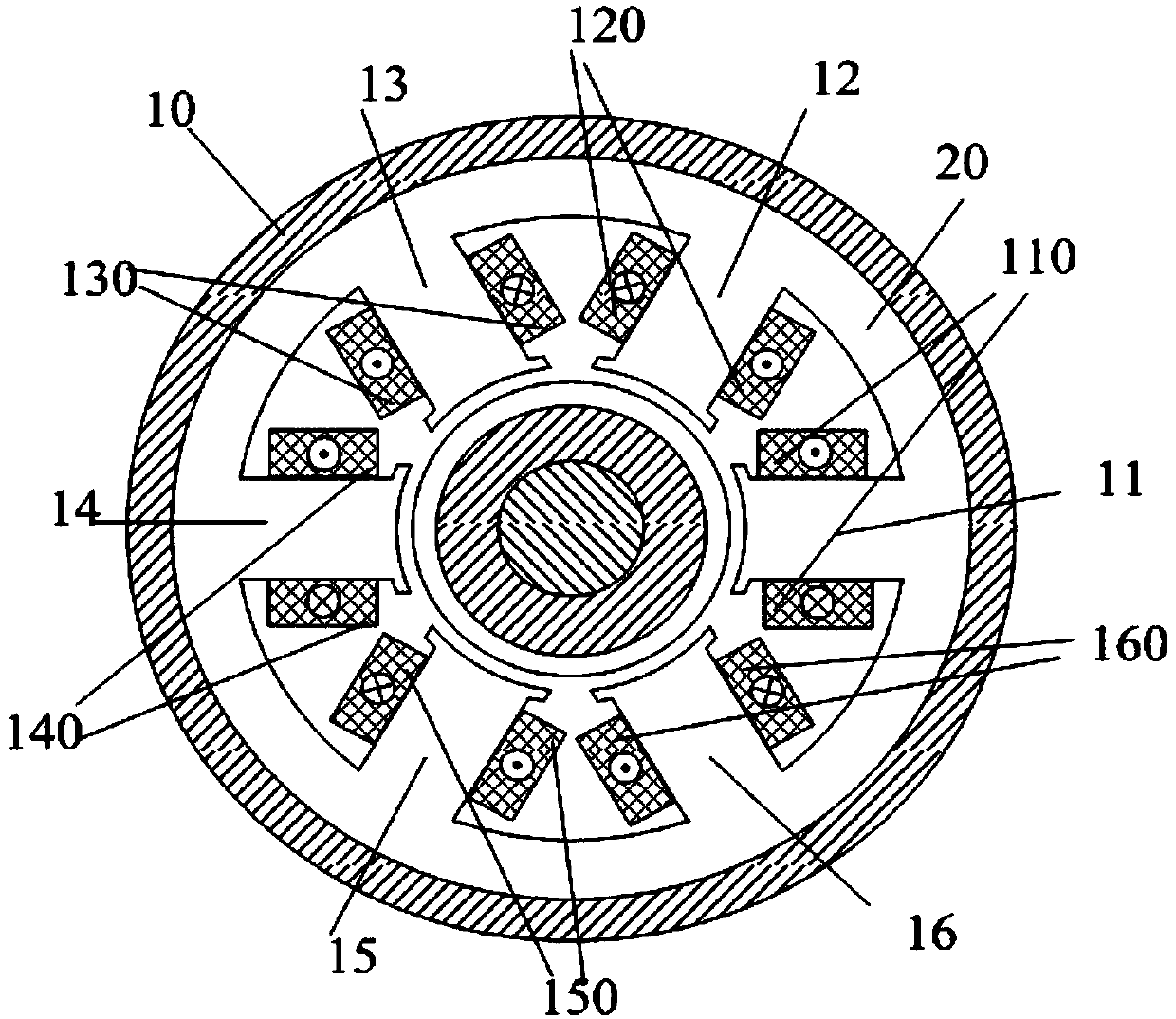

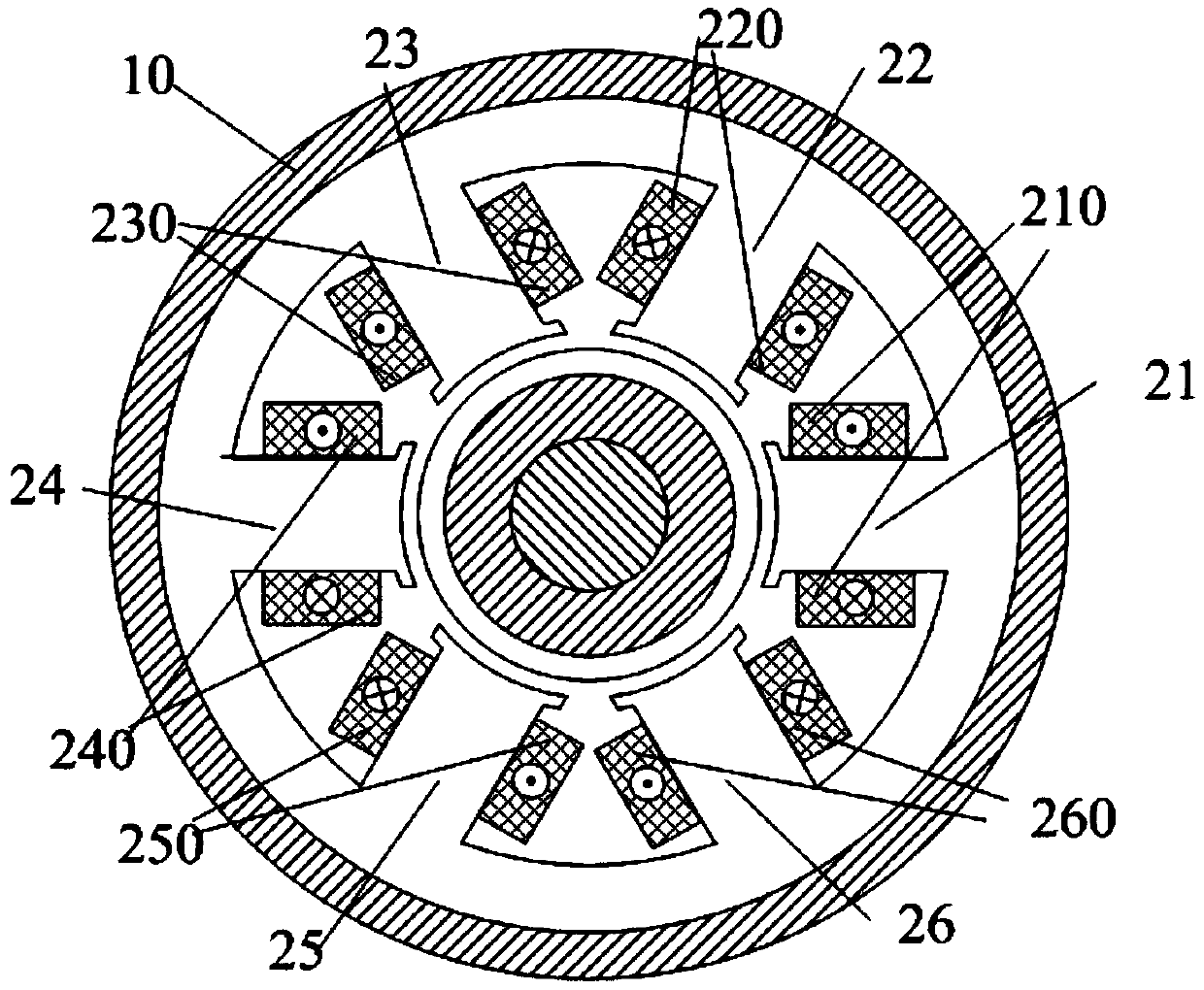

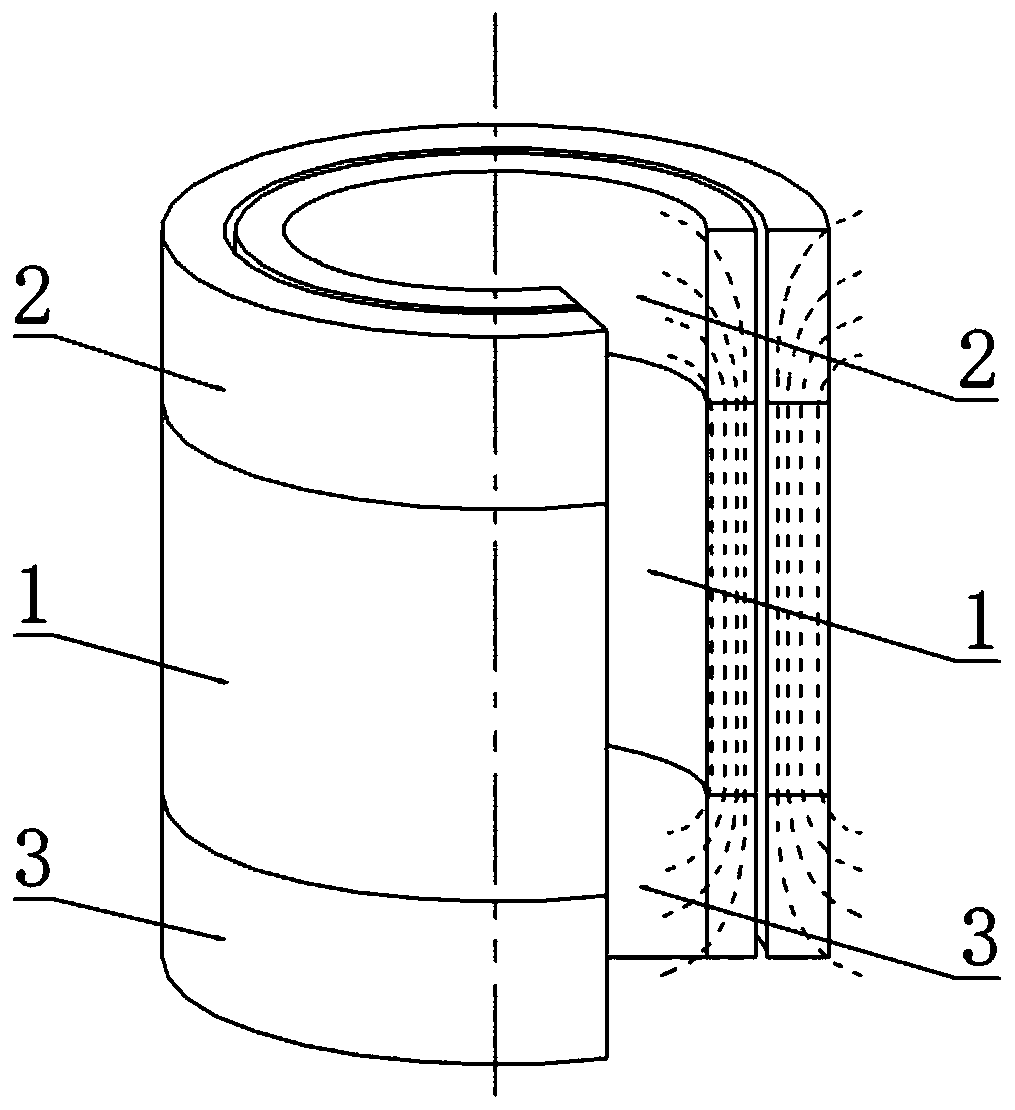

Six-pole mixed magnetic bearing

InactiveCN108050156AIncrease the number of ampere turnsIncrease layout spaceBearingsMagnetic bearingMagnetic poles

The invention discloses a six-pole mixed magnetic bearing. The rotors are coaxially sleeved with left stator iron cores and right stator iron cores which are symmetrically arranged in the axial direction, left stress discs are arranged at the left ends of the rotors, and right stress discs are arranged at the right ends of the rotors, and circular ring-shaped permanent magnets are laminated between yoke portions of the left stator iron cores and the right stator iron cores; the permanent magnets are axially magnetized, six stator magnetic poles are uniformly distributed in each of the left stator iron cores and the right stator iron cores in the circumferential direction, the six stator magnetic poles of each left stator iron core are aligned with the corresponding left stress disc in theradial direction, and the six stator magnetic poles of each right stator iron core are aligned with the corresponding right stress disc in the radial direction; and the two radial control coils whichare in face-to-face and radial direction on the same stator iron core in the left stator iron core and the right stator iron core are connected in series with a same winding direction, and the two radial control coils which are in axial-facing direction on the left stator iron core and the right stator iron core are connected in series with an opposite winding direction. According to the six-polemixed magnetic bearing, suspension force and displacement characteristics and suspension force and current characteristics tend to be linear, and coupling between two radial degrees of freedom is reduced.

Owner:JIANGSU UNIV

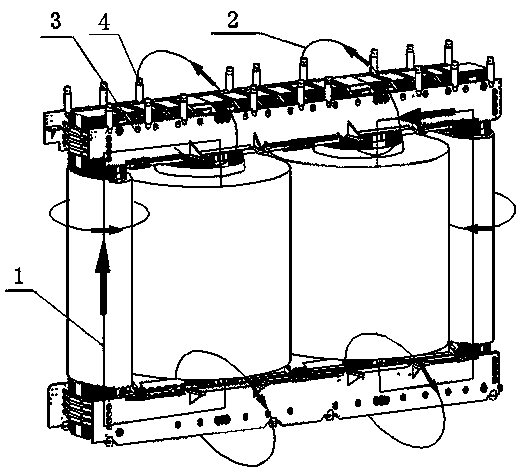

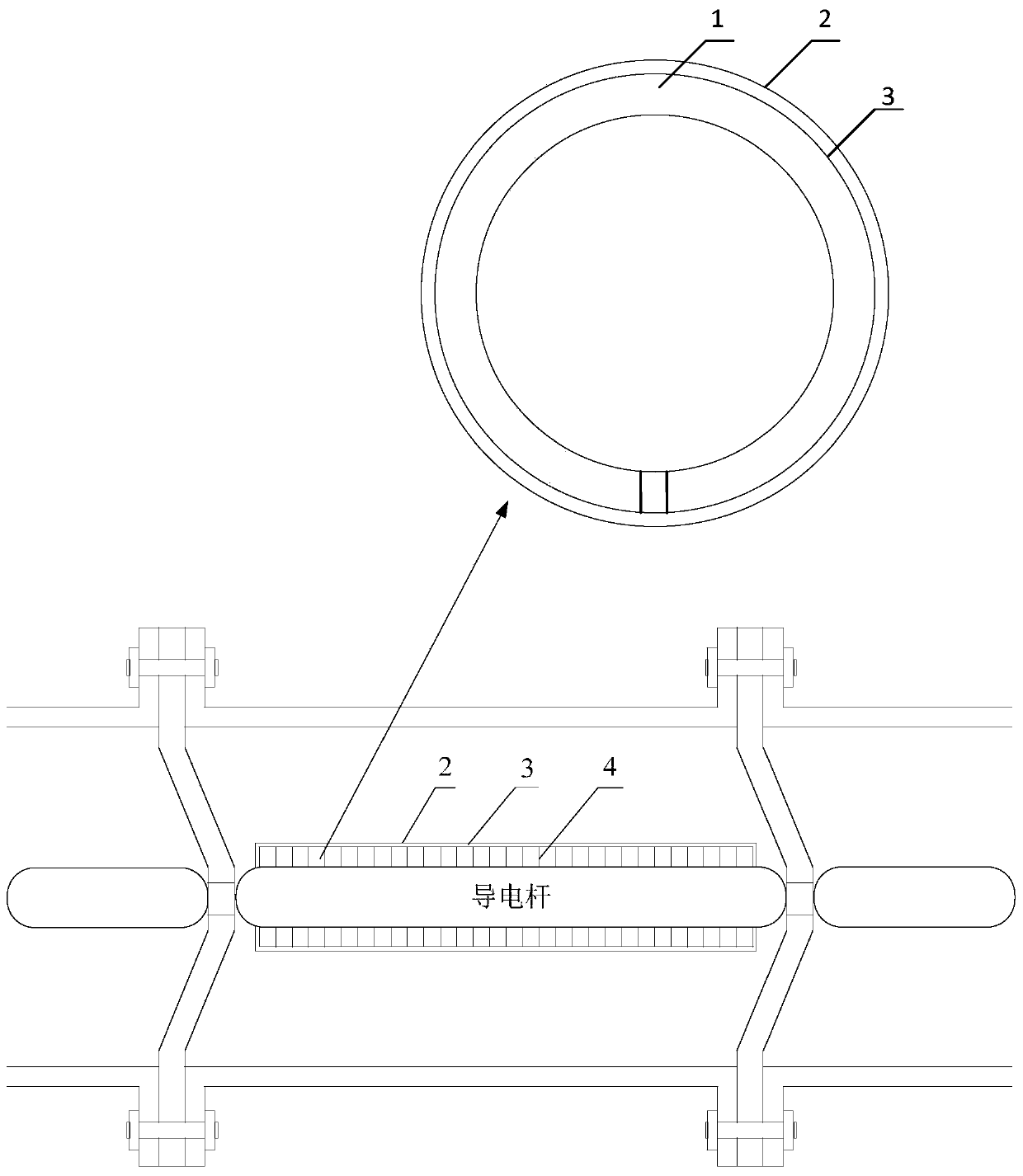

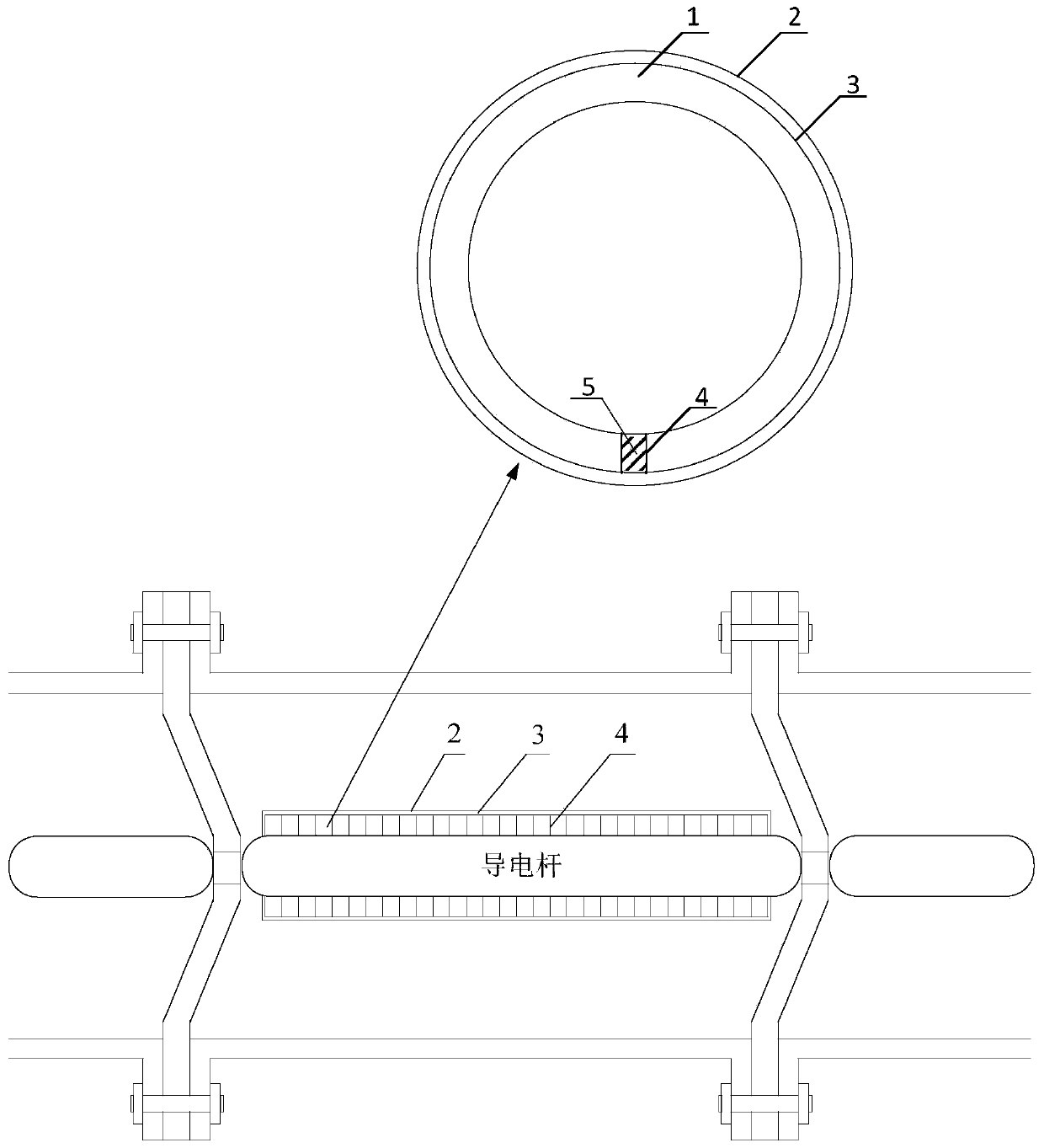

External circulation bypass structure between converter transformer core pulling plate columns

InactiveCN103745813AReduce lossImprove eddy current lossTransformers/inductances coils/windings/connectionsUnwanted magnetic/electric effect reduction/preventionTransformerPlate column

The invention relates to an external circulation bypass structure between converter transformer core pulling plate columns, in particular to a circulation bypass structure between large-capacity converter transformer core pulling plate columns, and belongs to the technical field of transformer manufacturing. According to the technical scheme, a plurality of copper cables (4) are arranged in a conductor grip frame (3), the copper cables are connected with coil outgoing wires and then connected with an upper clamp and a lower clamp, and the copper cables, the upper clamp, the lower clamp and core main column pulling plates form short circuit rings (2) along core windows. The external circulation bypass structure has the advantages that on the premise that the structure and the strength of the pulling plates are not changed, losses of the pulling plates are reduced, eddy current losses of cores are greatly reduced, leakage flux is restrained, the structure is simple, and layout is reasonable.

Owner:BAODING TIANWEI BAOBIAN ELECTRICAL

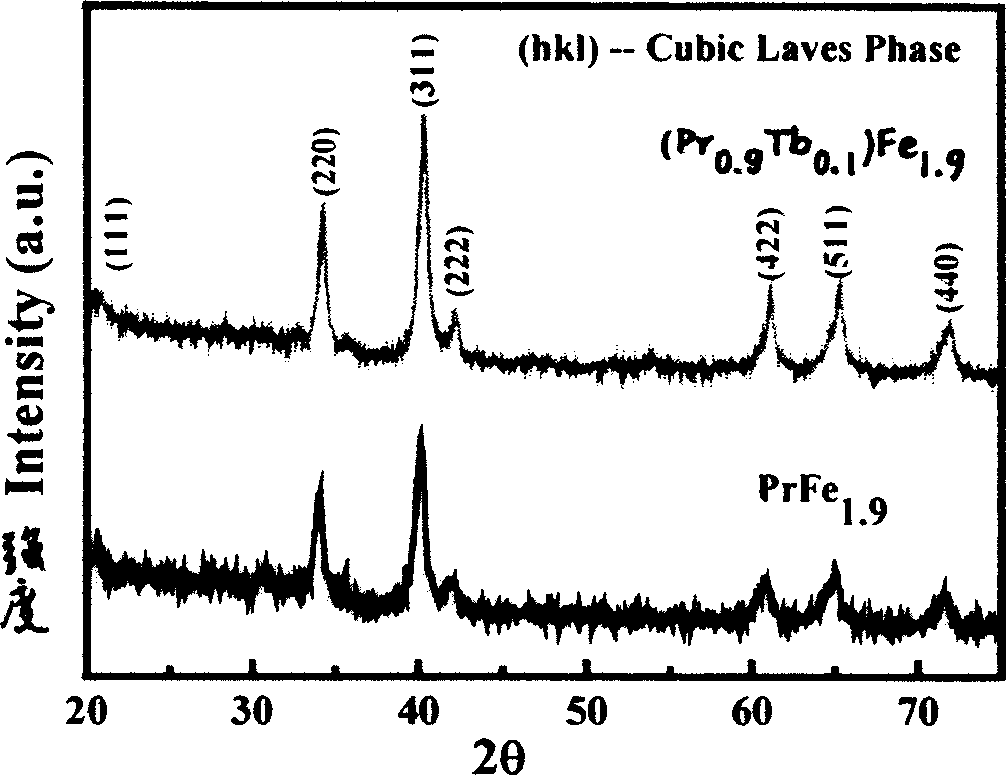

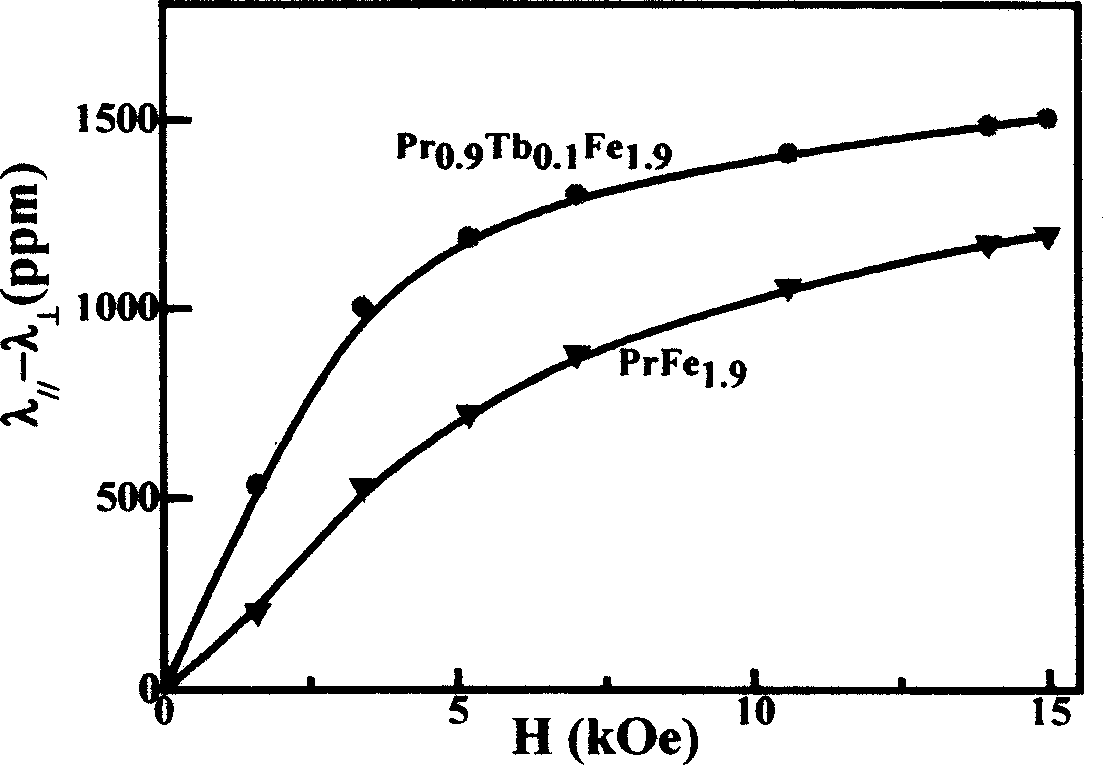

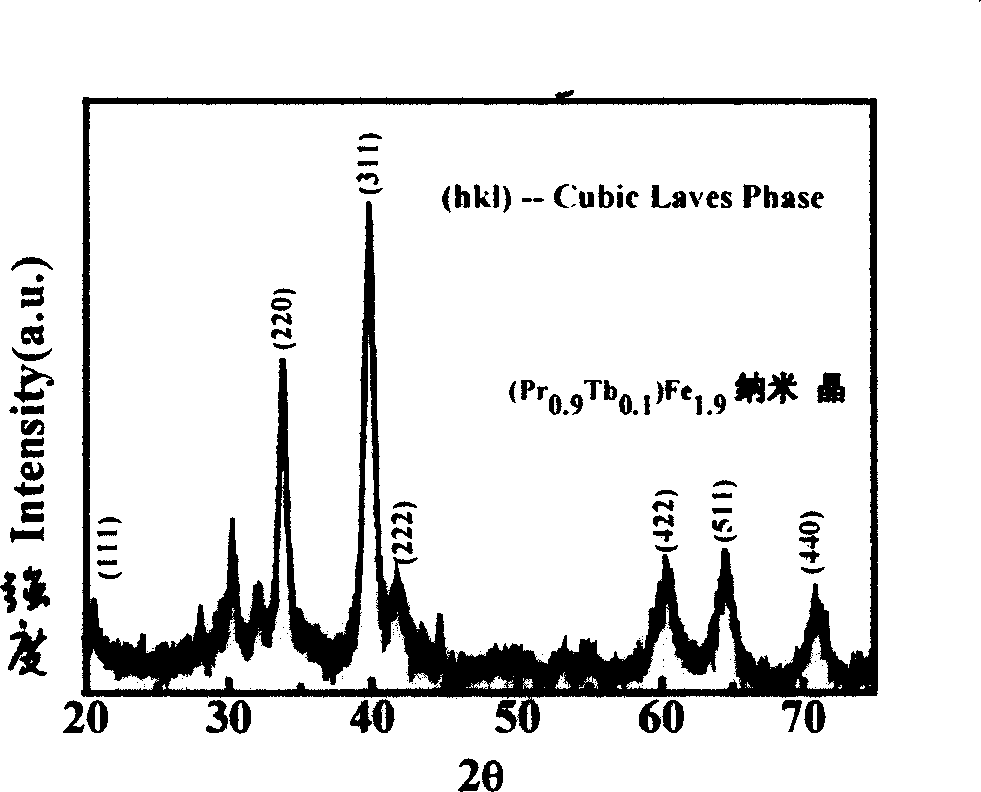

Pr series rare earth super magnetostric tive material and its preparing method

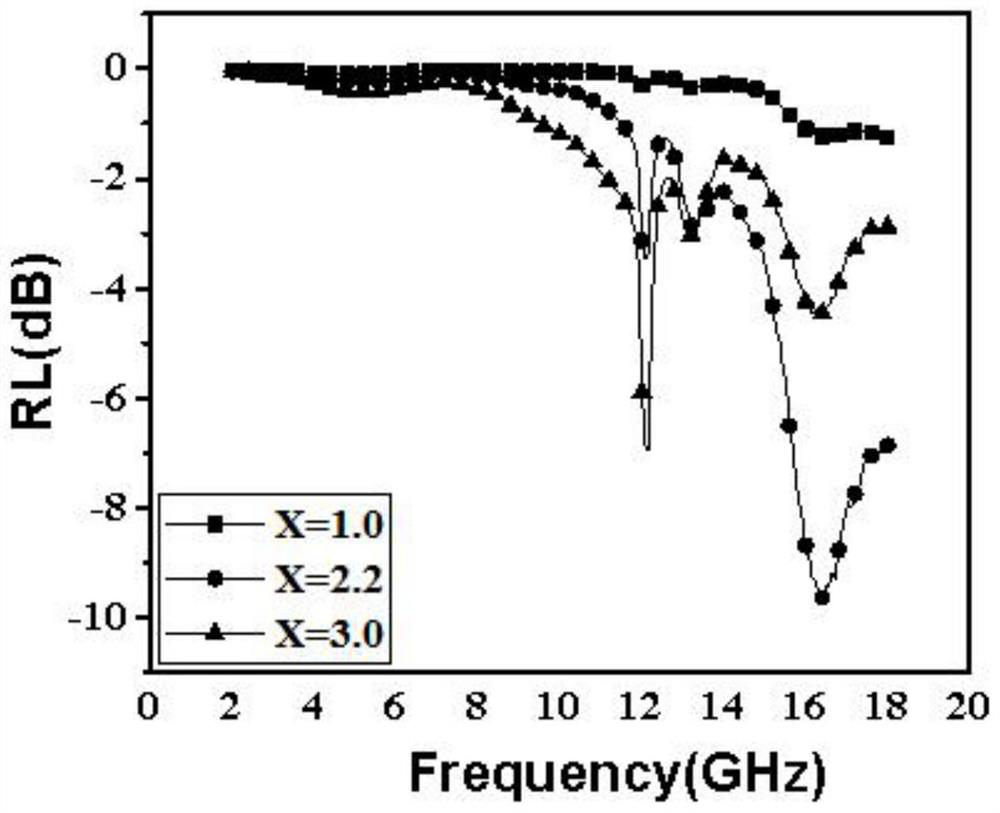

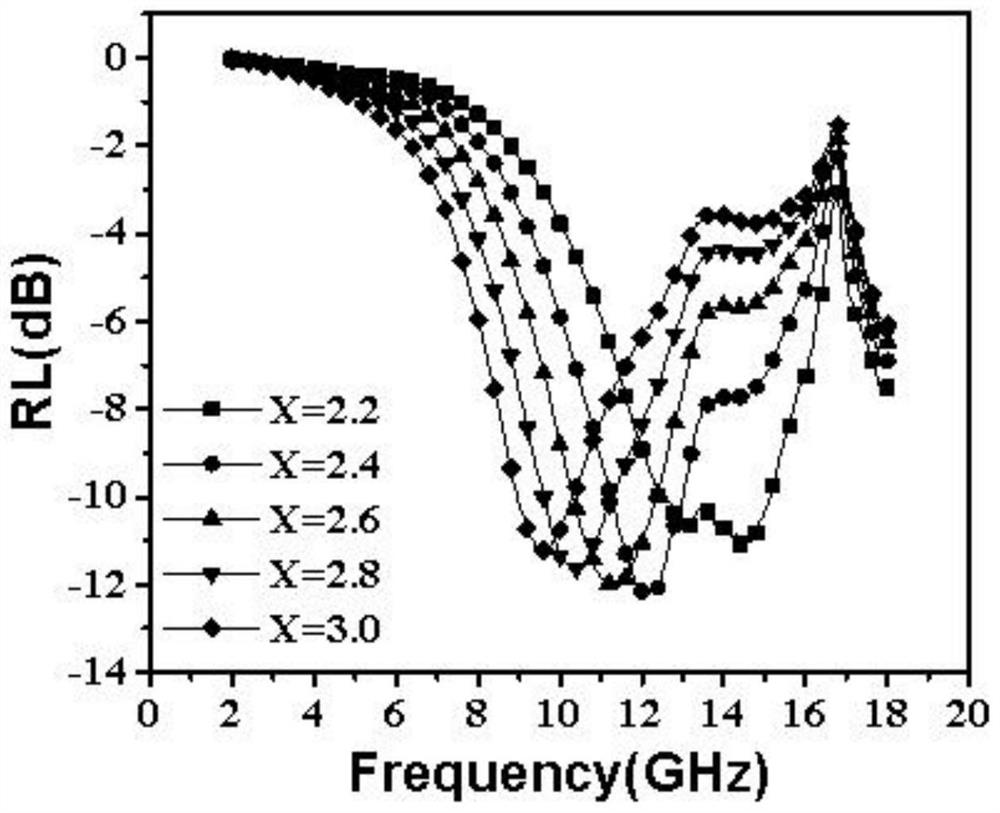

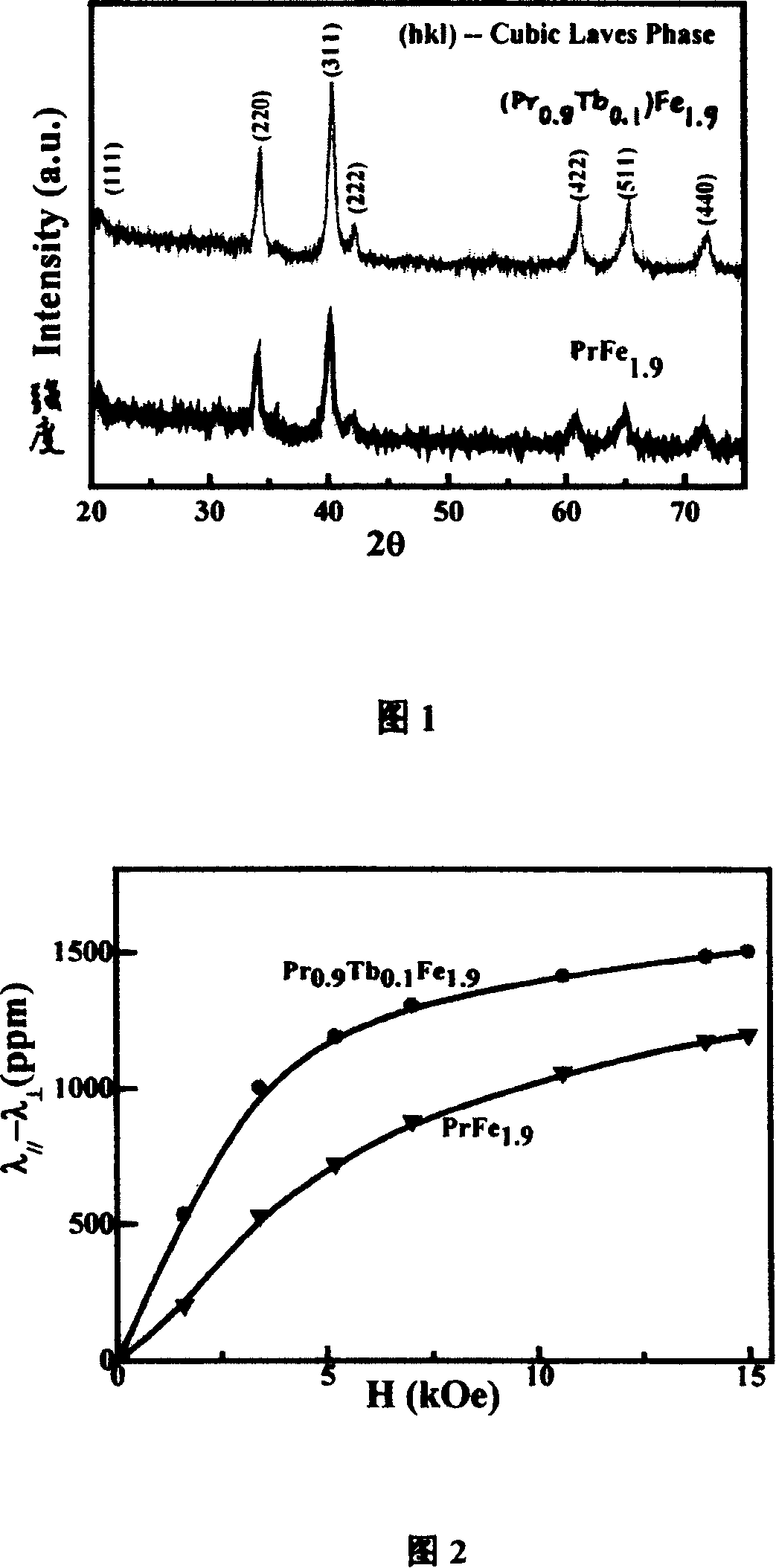

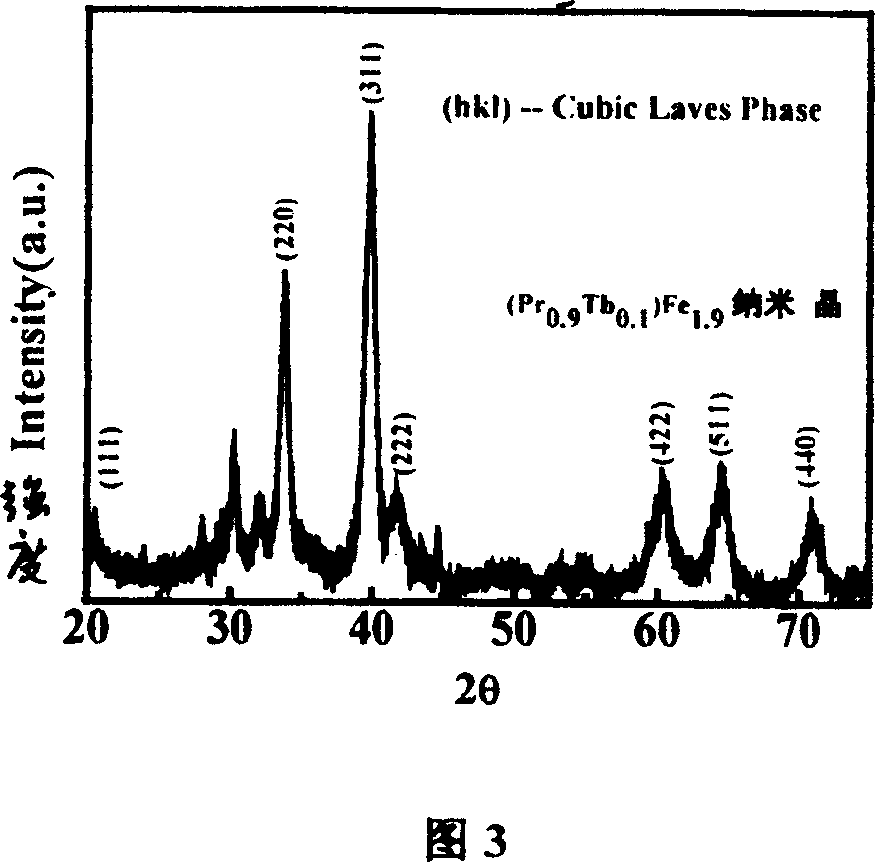

This invention provides a Pr series rare earth super magnetostriction material and its preparation method, and the chemical components (atomic ratios) are: Pr1-x(Tb1-yREy)x(FelMz)RE represents for Dy, Sm, Ho, Er, Ce, Nd and etc rare earth elements; M represents one or several kinds of B, Si, C, Zr, Nb, Cu, Mn, V, Ti, Cr, Ga, Co, Ni, w, Hf, Ta, Mg. (0 is less than or equal to x is less than or equal to 0.6, 0 is less than or equal to y is less than or equal to 1, 0 is less than or equal to z is less than or equal to 0.4, 0 is less than or equal to t is less than or equal to 4.) The preparation method is : use high-pressing technology to compose the Pr series rare earth super magnetostriction material with high Pr content that the usual pressure cannot realize. This invention greatly lowers the cost of the present material and maintains high magnetostriction performance.

Owner:NANJING UNIV

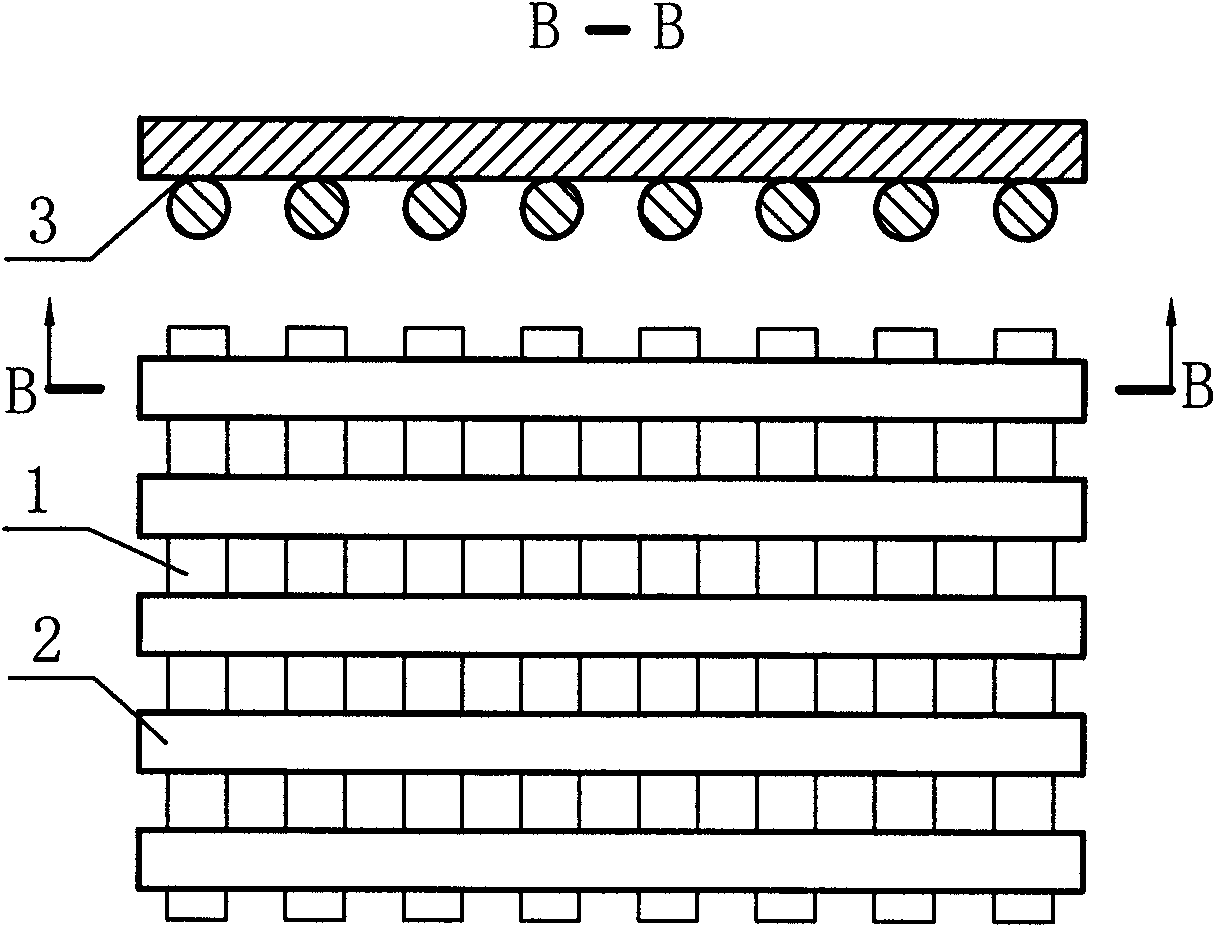

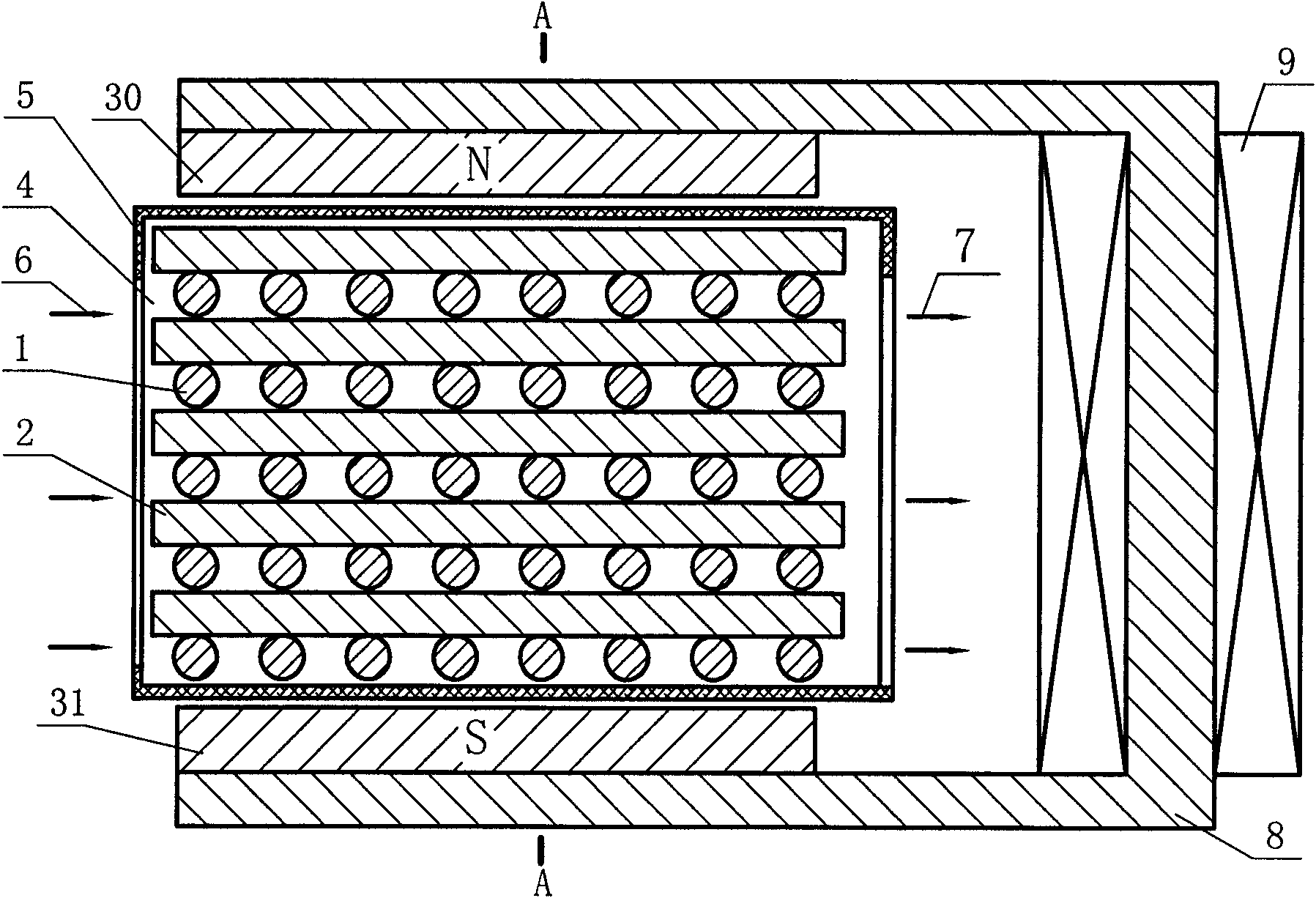

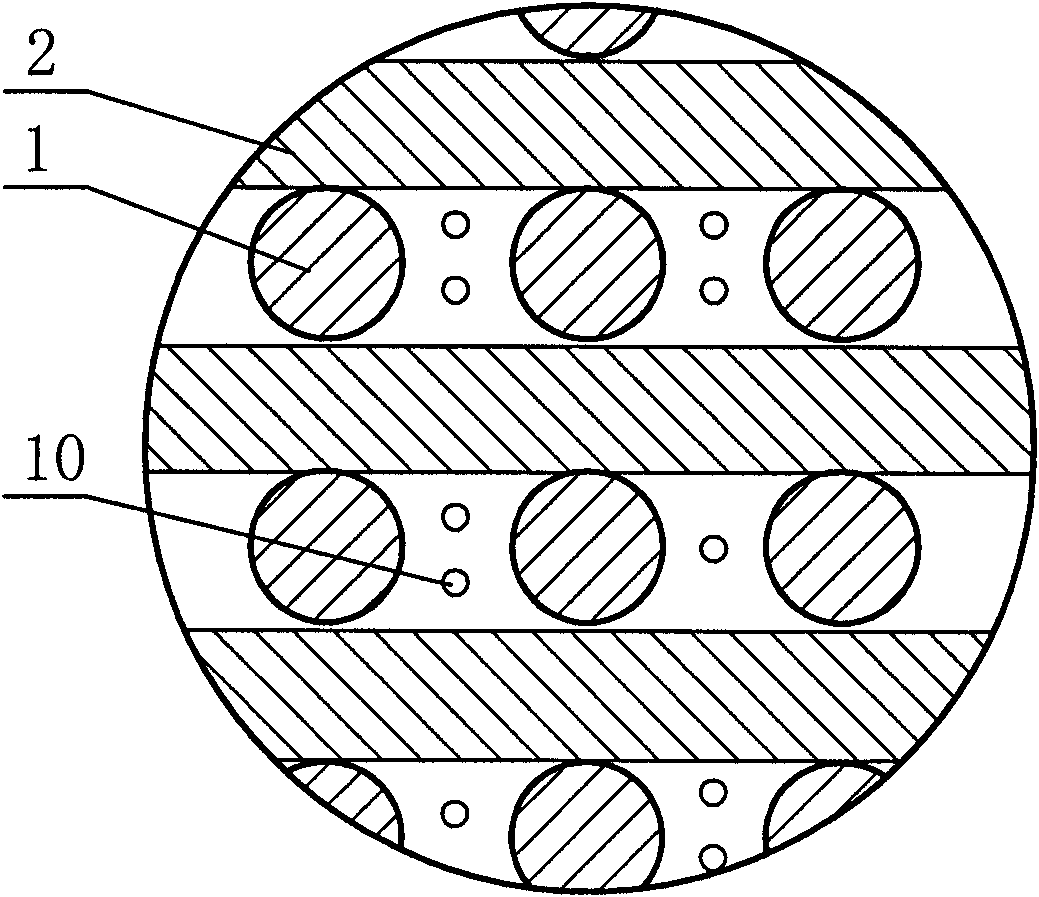

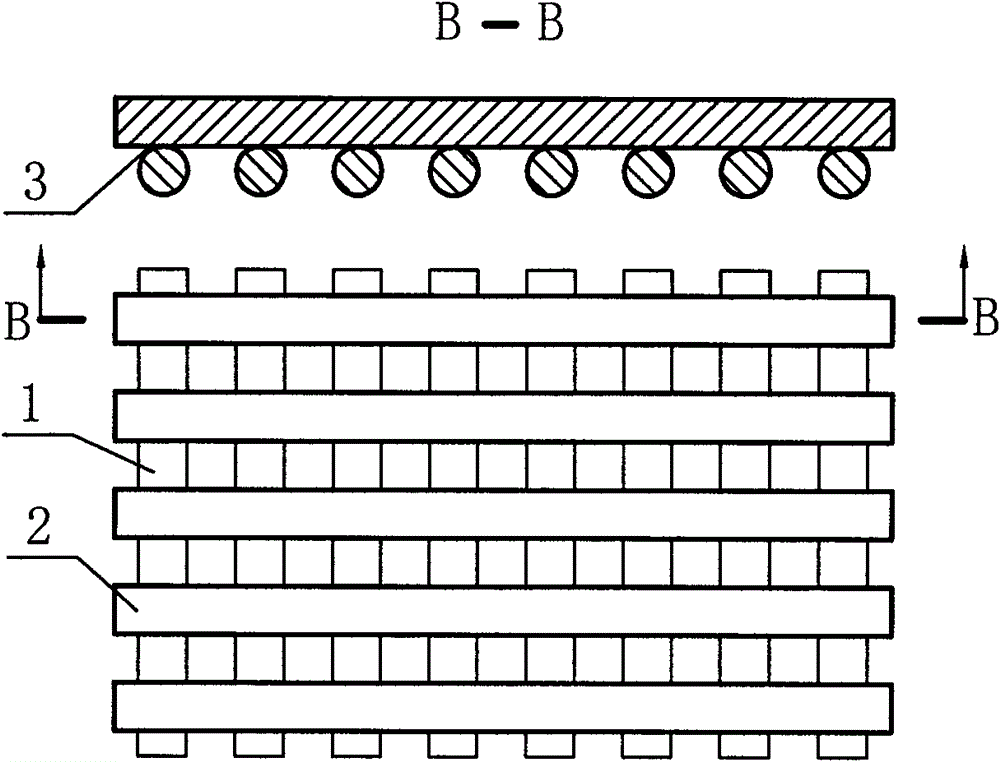

Magnetic fluid sieving device

InactiveCN102728463APromote circulationPass smoothlyHigh gradient magnetic separatorsMagnetic tension forceMagnetic poles

The invention relates to a magnetic fluid sieving device, which mainly comprises a fluid separation sieve and a magnetic loop. The device is characterized in that magnetic wires and nonmagnetic wires in the fluid separation sieve formed by multiple layers of screen meshes in a plurality of independent fluid separation cavities under magnetic poles divide a magnetic field space into several minimal spaces of high gradient magnetic potentials and an equal magnetic potential; magnetic particles in a fluid are enriched in the high gradient magnetic field spaces under the action of magnetic force when the fluid flows through the fluid separation sieve; and when the magnetic poles relatively move along the direction of the nonmagnetic wires, the magnetic particles are acted by the magnetic force of the magnetic poles, move with the magnetic poles along a direction nearly orthogonal to a fluid flow channel, and are separated out. The magnetic fluid sieving device of the invention has the advantages of realization of continuous and efficient separation of the magnetic particles from the fluid, low operation energy consumption, and simple maintenance, and can be used for environmental protection, magnetic metal recovery, and magnetic mineral sorting.

Owner:邹吉武

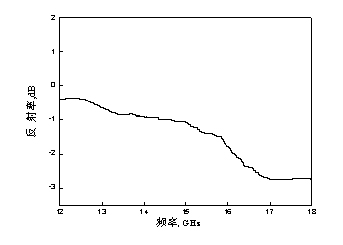

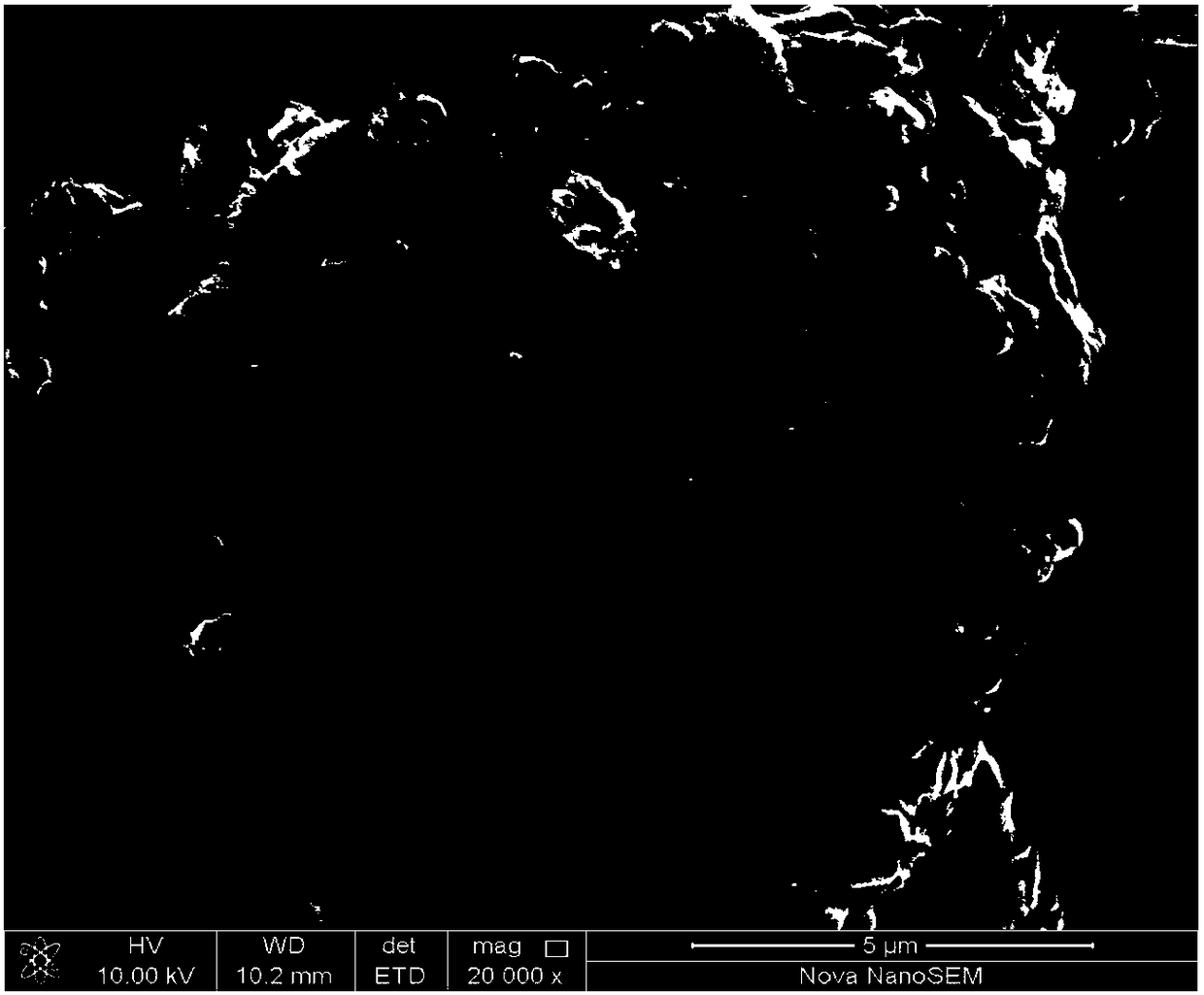

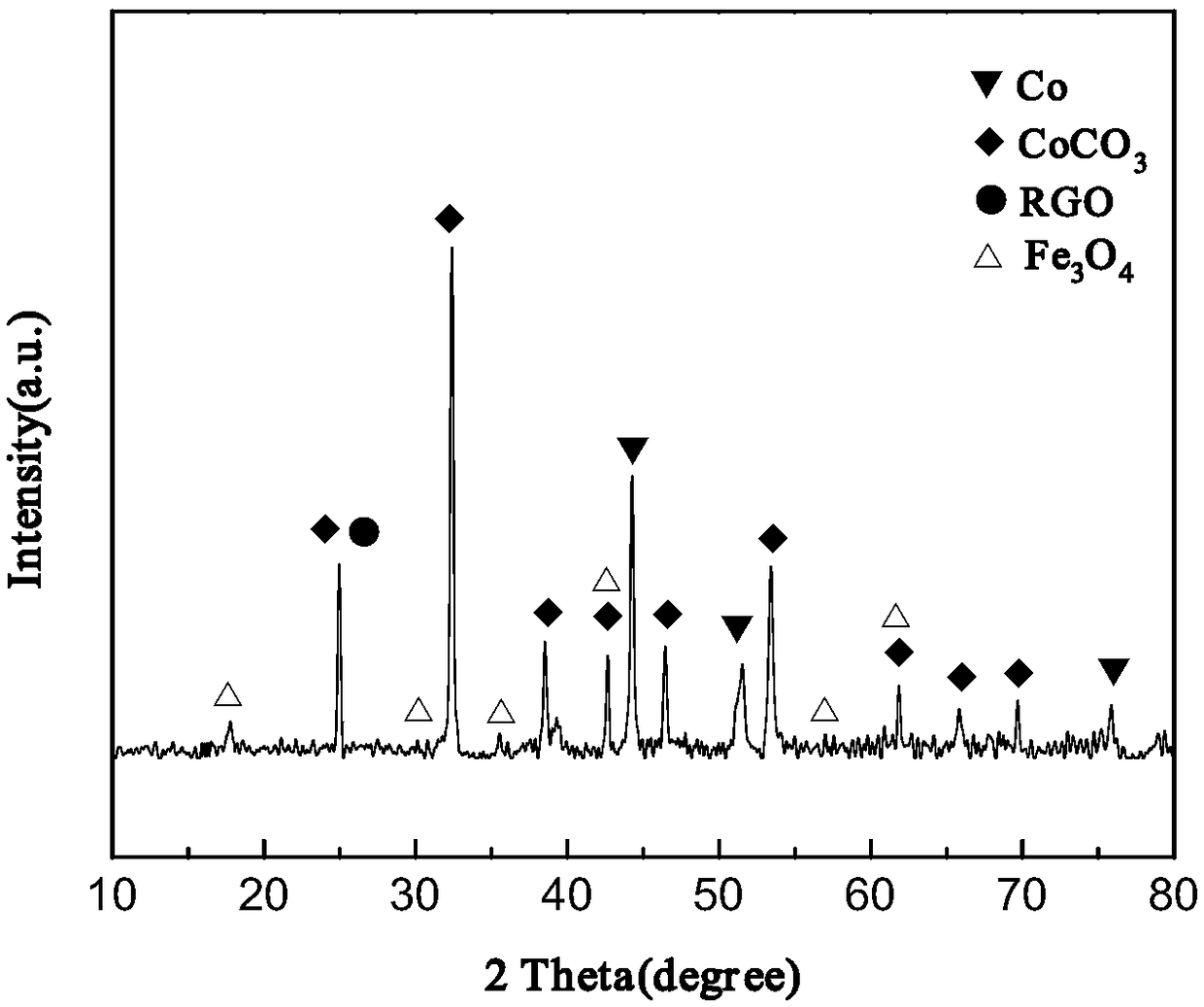

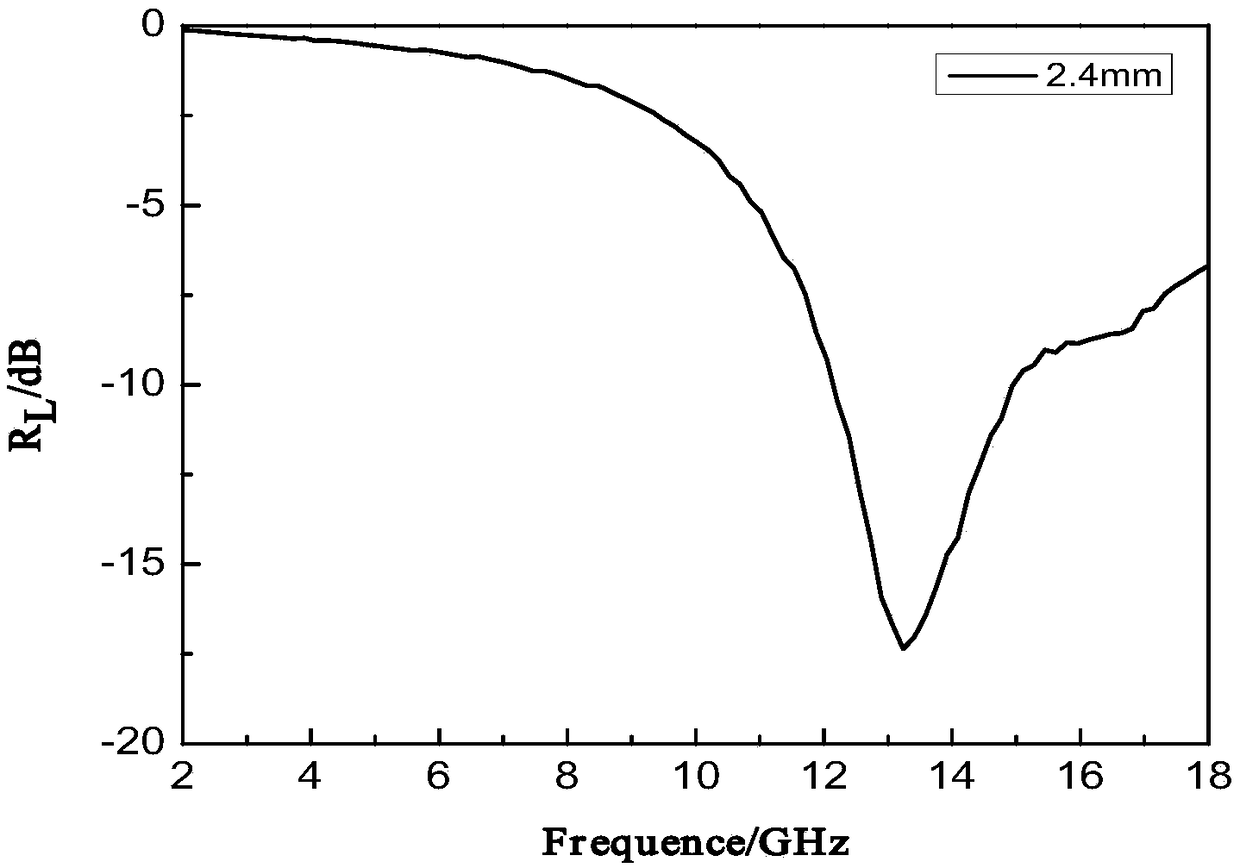

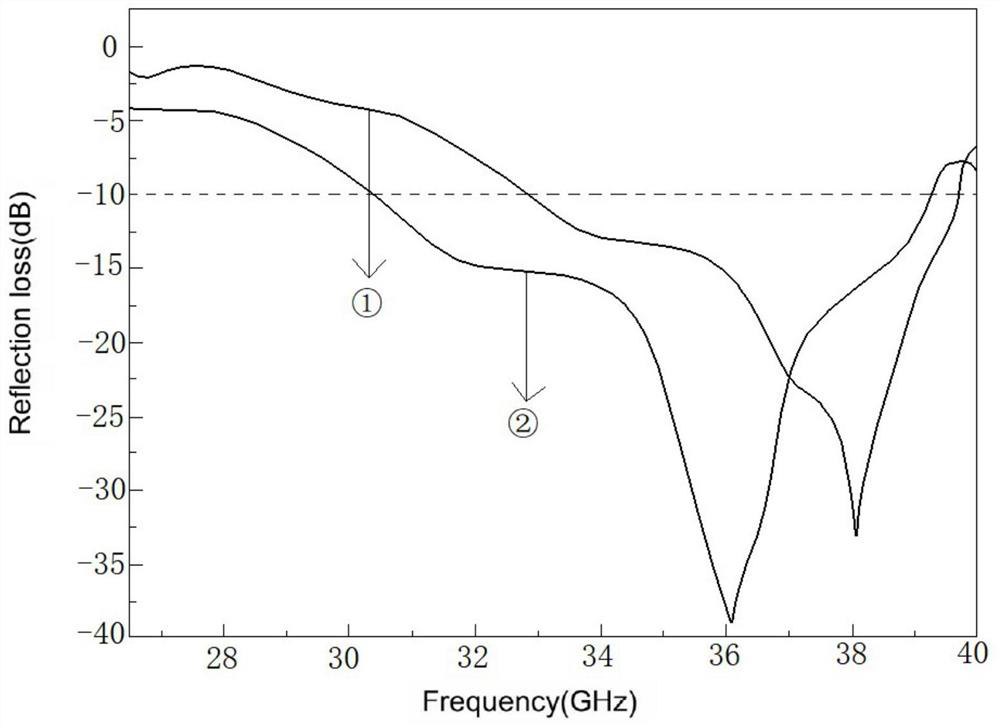

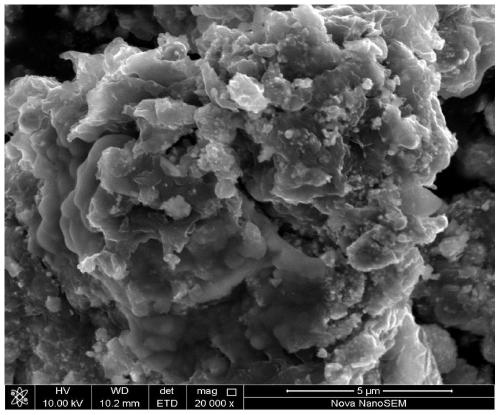

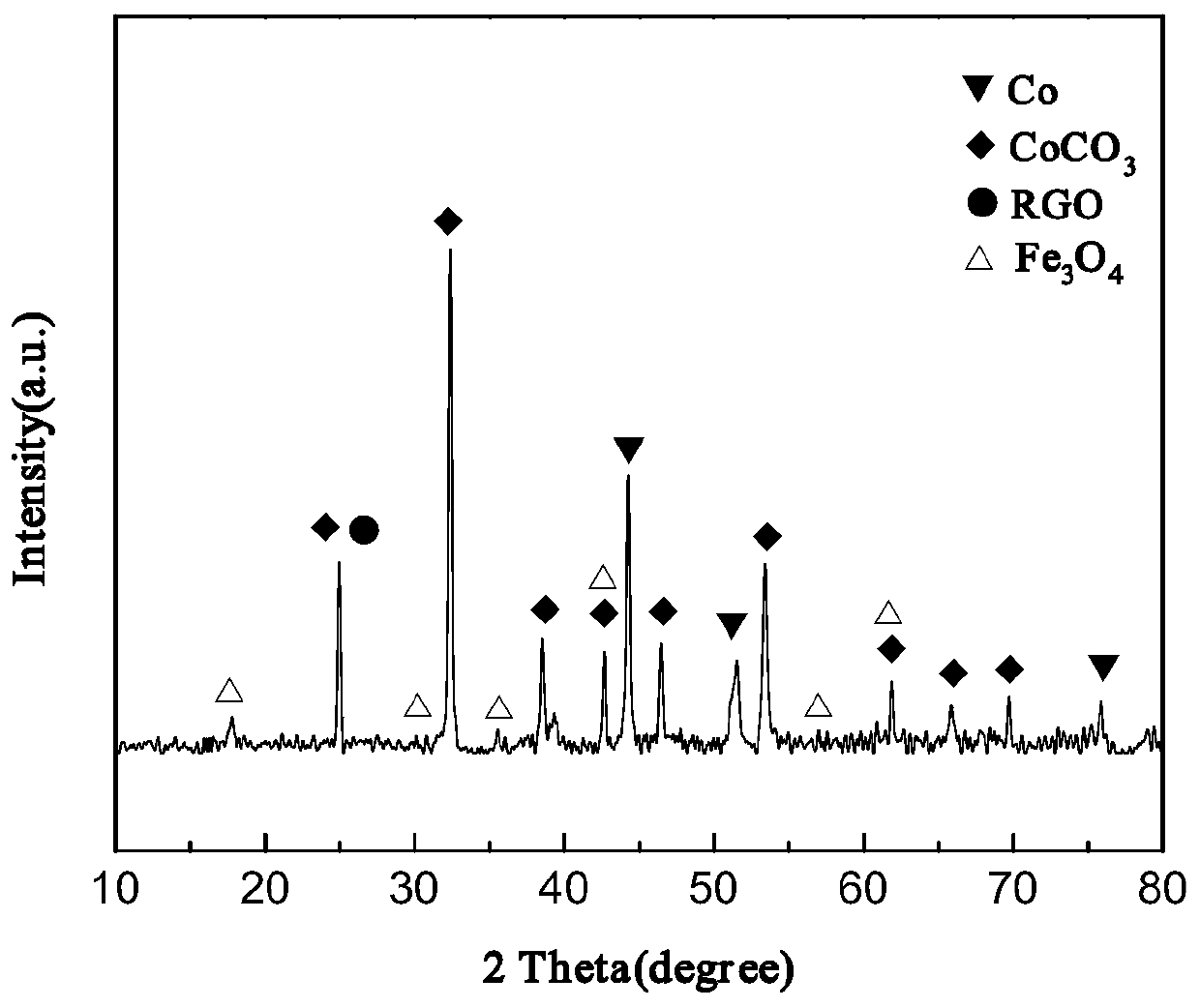

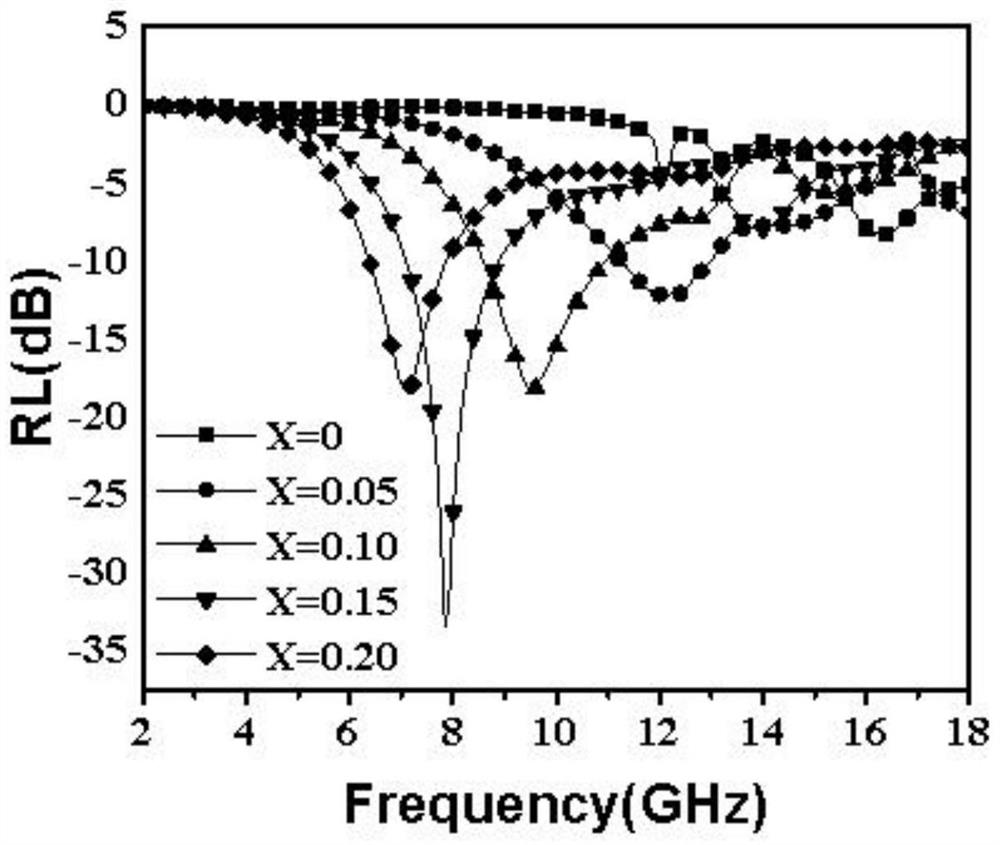

Cobalt-containing composite absorbing material and preparation method thereof

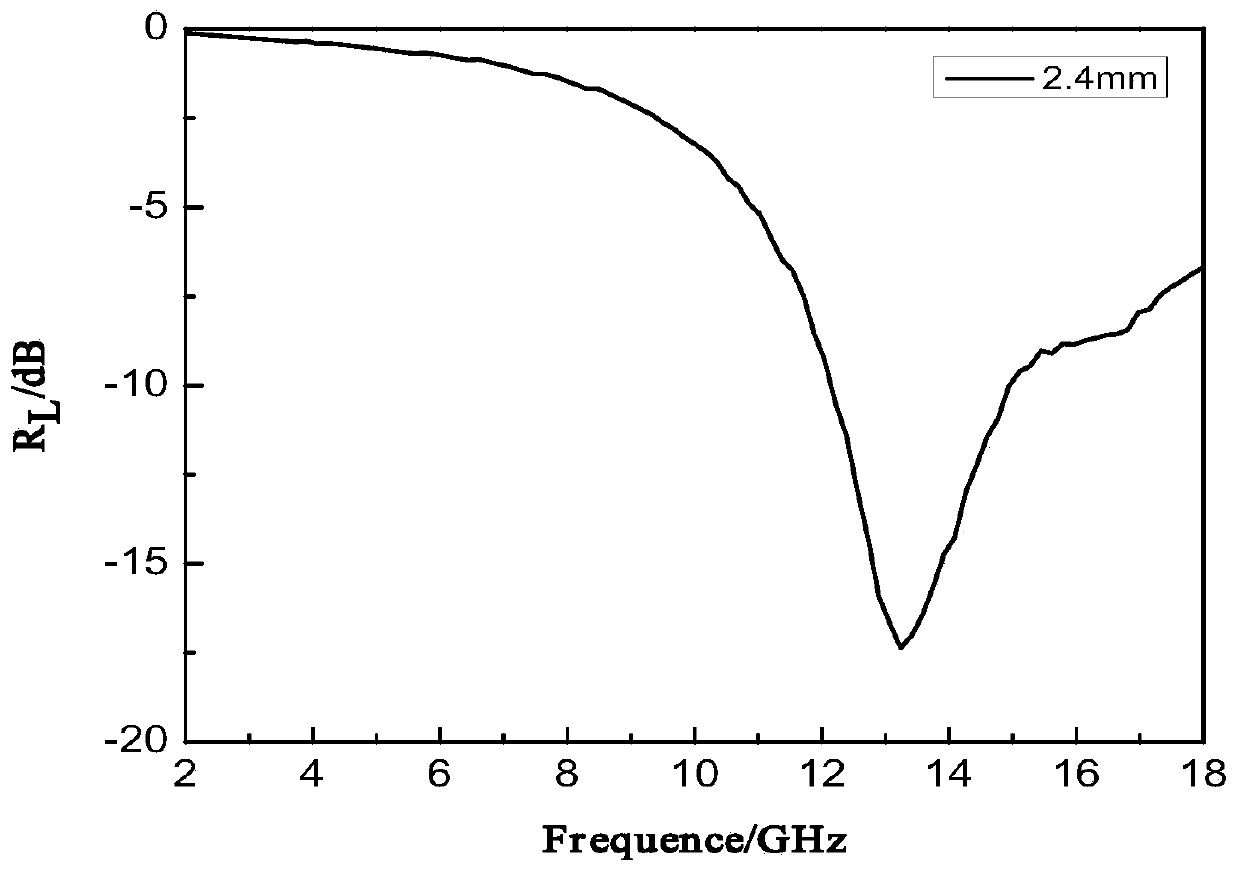

ActiveCN108307614APromote absorptionImprove eddy current lossCarbon compoundsOther chemical processesReflection lossOxide matrix

The invention provides a cobalt-containing composite absorbing material and a preparation method thereof. The composite absorbing material comprises a graphene oxide matrix, ferrite, nanometer cobaltand cobaltous carbonate, and the ferrite, the nanometer cobalt and the cobaltous carbonate are loaded on the surface of the graphene oxide matrix. Results of the embodiment show that according to theobtained composite absorbing material, when the matching thickness is 2.44 mm, the maximum absorption -19.13dB is achieved during 12.32 GHz, and the effective absorption frequency band whose reflection loss is lower than -10dB reaches 4.10 GHz; and when the matching thickness is 2.40 mm, the maximum absorption -17.36dB is achieved during 13.34 GHz, the effective absorption frequency band whose reflection loss is lower than -10dB reaches 2.74 GHz, the visible absorbing frequency band is substantially widened, and the absorbing capability is enhanced.

Owner:ARMOR ACADEMY OF CHINESE PEOPLES LIBERATION ARMY

Ferrite magnetic material and manufacturing method thereof

InactiveCN112430075AImprove magnetic propertiesReduce lattice distortionFerrite (magnet)Materials science

The invention belongs to the technical field of ferrites, and particularly relates to a ferrite magnetic material which comprises main components, auxiliary components and additives, the main components comprise Fe2O3, Mo2O3, Yb2O3, NiO and ZnO, and the auxiliary components comprise WO3 and Nd2O3. Based on the main component amount, the content of Fe2O3 in the main components is 48-52 mol%, the content of Mo2O3 in the main components is 16-24 mol%, the content of Yb2O3 in the main components is 12-20 mol%, the content of NiO in the main components is 9-15 mol%, and the content of ZnO in the main components is 6-10 mol%. Based on the weight of the main components, the content of WO3 is 0.1-1wt%, and the content of Nd2O3 is 0.1-1wt%. The additives are composed of V2O5, SiO2 and CuO. The ferrite material disclosed by the invention has higher magnetic conductivity and lower magnetic loss at the same time under 13.56 MHz, and meets the application requirements of NFC.

Owner:江西耀润磁电科技有限公司

Preparation method of foam aluminium alloy wave-absorbing material

InactiveCN102002300BImprove absorbing performanceLow resistivityPretreated surfacesRadiation-absorbing paintsEpoxyDry mixing

The invention relates to a preparation method of a foam aluminium alloy wave-absorbing material, comprising surface pretreatment of foam aluminium alloy substrates, preparation of wave-absorbing coating and spraying of the wave-absorbing coating. The preparation method of the wave-absorbing material comprises the following steps of: (1) adding a coupling agent to polyaniline, adding a rare earth oxide after ball milling wet mixing, drying after ball milling wet mixing, and dry mixing to prepare a composite filler; (2) adding the coupling agent to the composite filler to prepare a coupling filler; (3) uniformly mixing a dispersing agent and a diluent, and adding the mixture to the coupling filler to prepare a dispersed filler; and (4) mixing epoxide resin with polyamide to prepare a film forming matter, grinding the film forming matter together with the dispersed filler, mixing, stirring, carrying out sonic oscillation, stirring and sieving, wherein the screenings are used as wave-absorbing coating. The wave-absorbing agent foam aluminium alloy-based wave-absorbing material doped with rare earth oxide has excellent wave-absorbing performance, and the bandwidth lower than -10dB can reach 13.5GHz in the frequency range of 26.5GHz to 40.0GHz.

Owner:NORTHEASTERN UNIV LIAONING

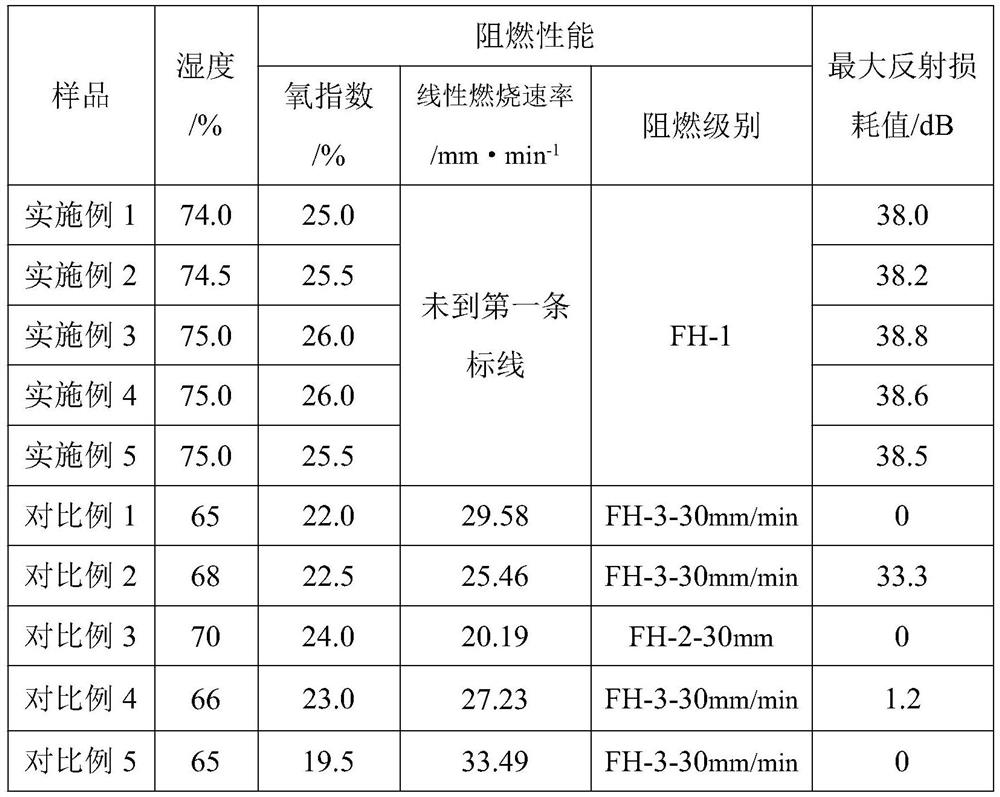

Epoxy resin glass fiber composite isolation protection material and application thereof in isolation protection of relay protection wiring terminal

PendingCN114752184AImprove anti-corrosion performanceImprove absorption efficiencyCoupling device detailsEpoxyGlass fiber

The invention discloses an epoxy resin glass fiber composite isolation protection material which is prepared from the following raw materials in parts by weight: 100-150 parts of epoxy resin, 10-15 parts of glass fiber, 10-20 parts of a polyaniline-silicon carbide compound, 35-50 parts of an inorganic flame retardant, 5-10 parts of nano calcium carbonate, 20-55 parts of a rare earth coupling agent and 5-10 parts of a dispersing agent. The inorganic flame retardant is composed of magnesium hydroxide and calcium hydroxide. The invention also discloses an application of the epoxy resin glass fiber composite isolation protection material in isolation protection of a relay protection wiring terminal. The epoxy resin glass fiber composite isolation protection material has good moisture resistance, flame retardance and wave-absorbing anti-interference performance, isolation protection can be better carried out on a wiring terminal, and the safety is improved.

Owner:华润电力(贺州)有限公司

Preparation method of glass ceramic with good thermal conductivity

PendingCN110436785AHigh thermal conductivityLow thermal conductivityGlass shaping apparatusEpoxyFiber

The invention relates to a preparation method of glass ceramic with good thermal conductivity, and belongs to the technical field of glass ceramic materials. According to the invention, waste glass powder and silicon dioxide are used as raw materials, alumina fiber toughening-modified epoxy resin is used as a binder, and aluminum nitride, diamond, copper powder and waste ceramic powder with high thermal conductivity are used as fillers, and the glass ceramic with good thermal conductivity is prepared by doping rare earth lanthanum oxide through low-temperature co-firing. The diamond has high thermal conductivity, low dielectric constant, high resistivity and high breakdown field intensity; the aluminum nitride has excellent electrical properties and thermal properties, is a good thermal shock resistant material, has strong molten metal erosion resistance, is also an electrical insulator, and has good dielectric properties. By means of the low-temperature co-firing process, the preparation method is low in sintering temperature, low in dielectric constant and short in signal delay time; the glass serves as a fluxing agent to promote densification of the glass-ceramic composite material; in addition, the ceramic filler is used for improving the mechanical strength and insulativity of the substrate and preventing warping caused by the surface tension of the glass during sintering.

Owner:黄兰英

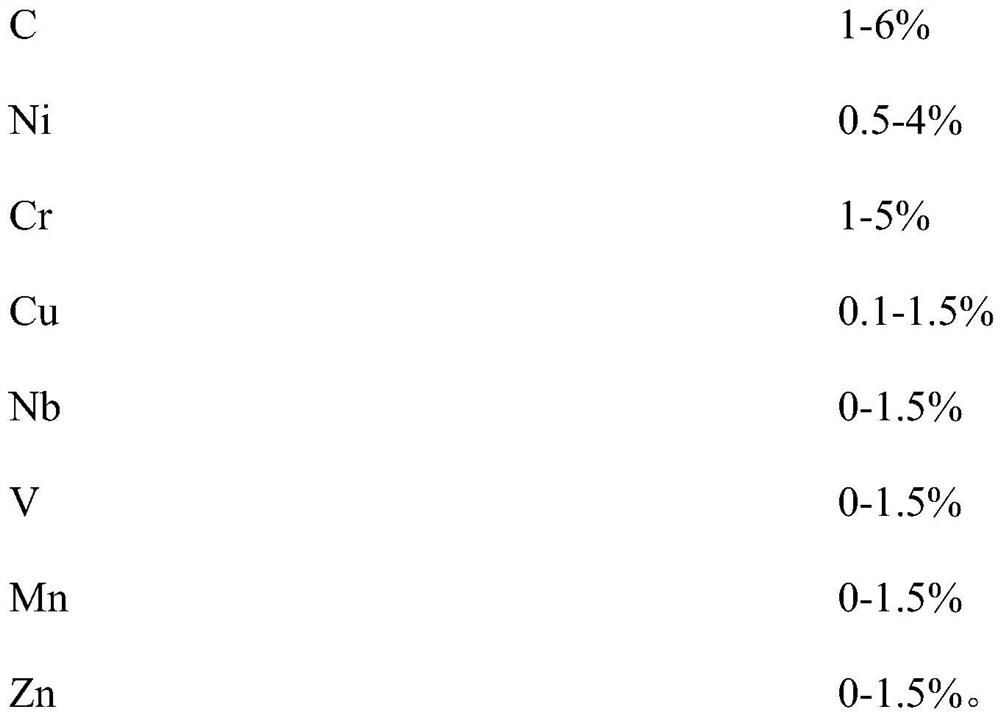

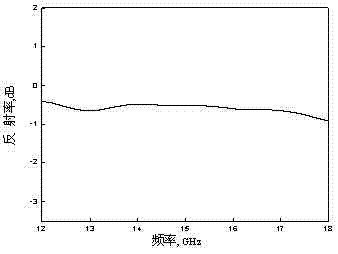

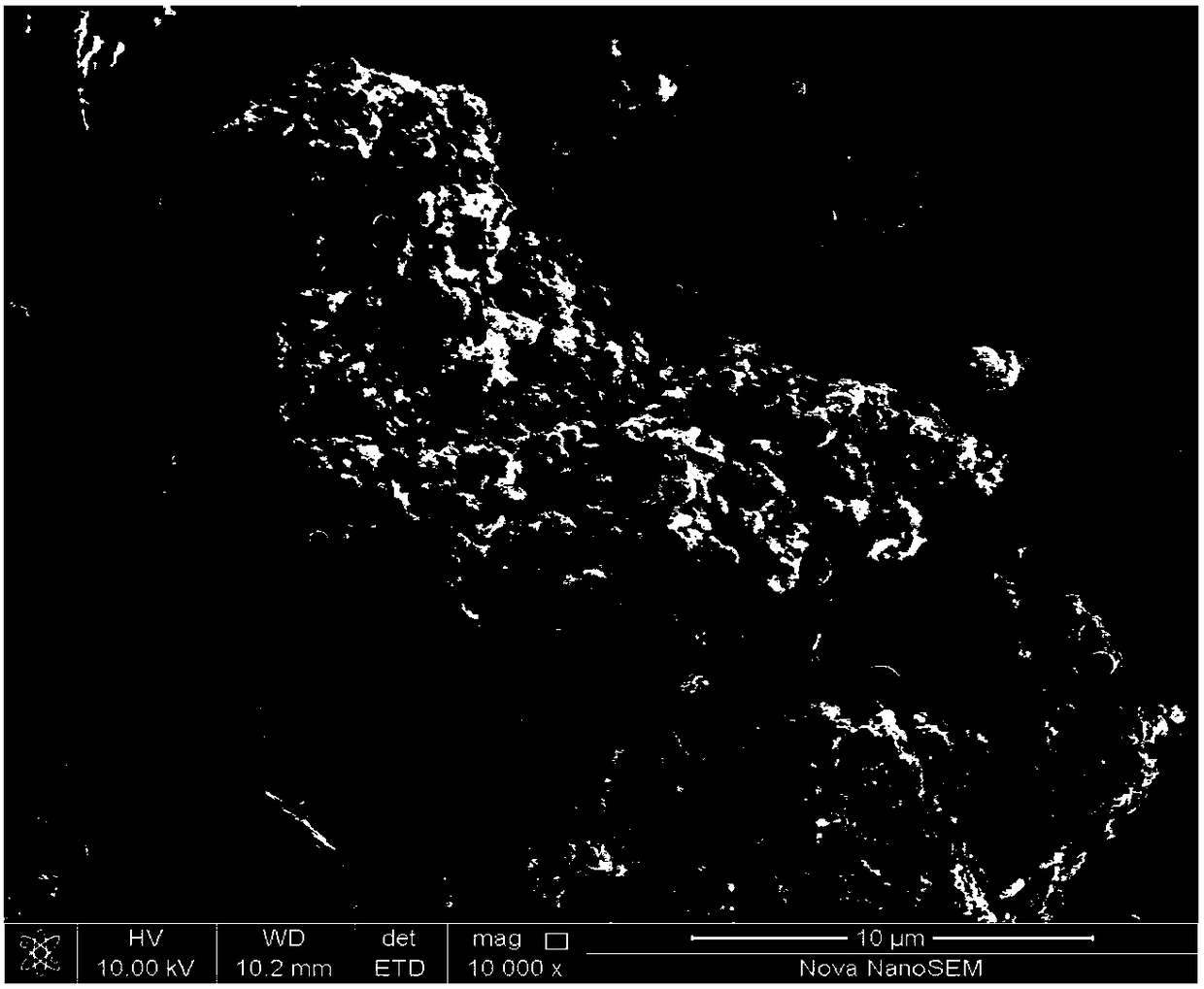

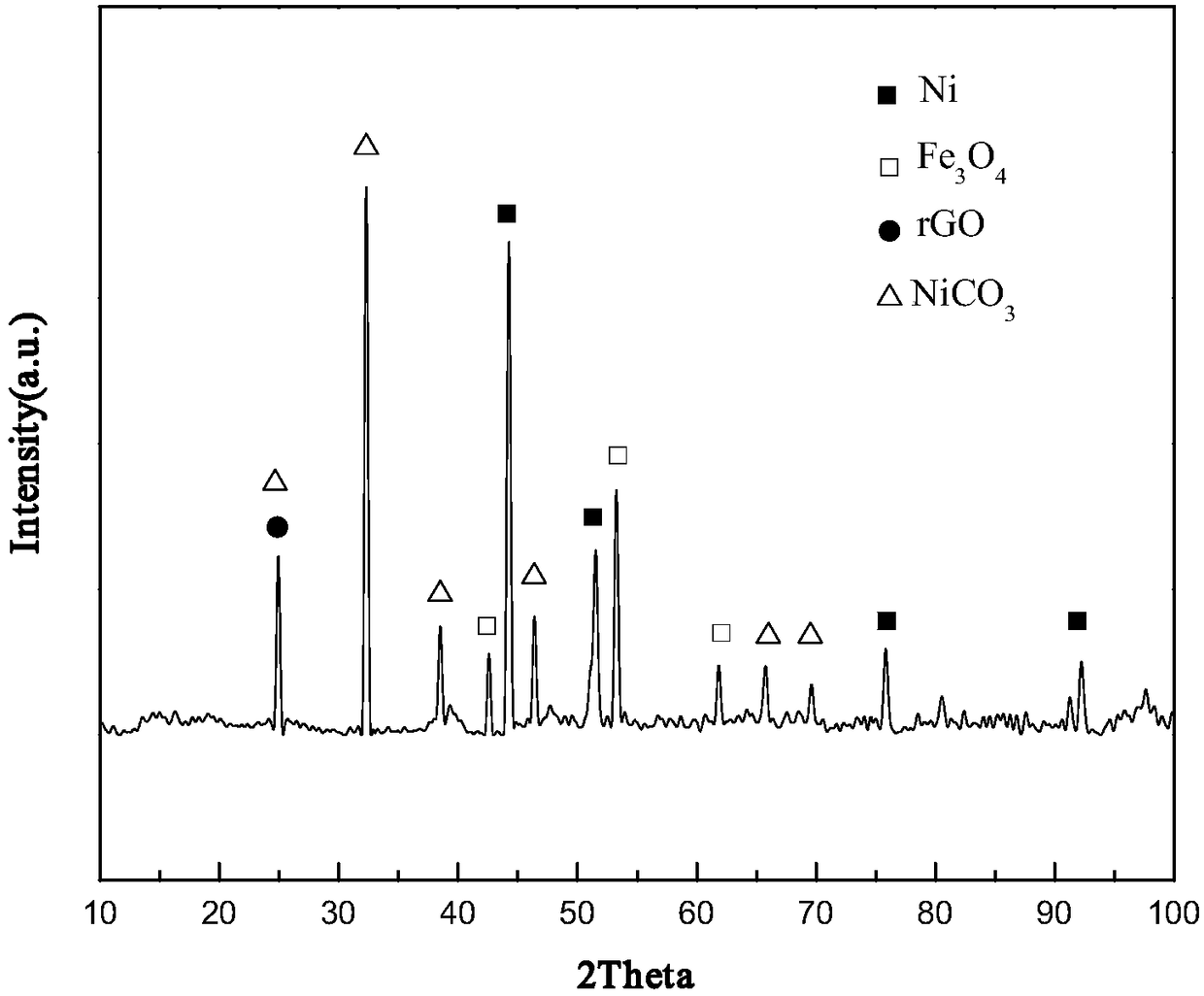

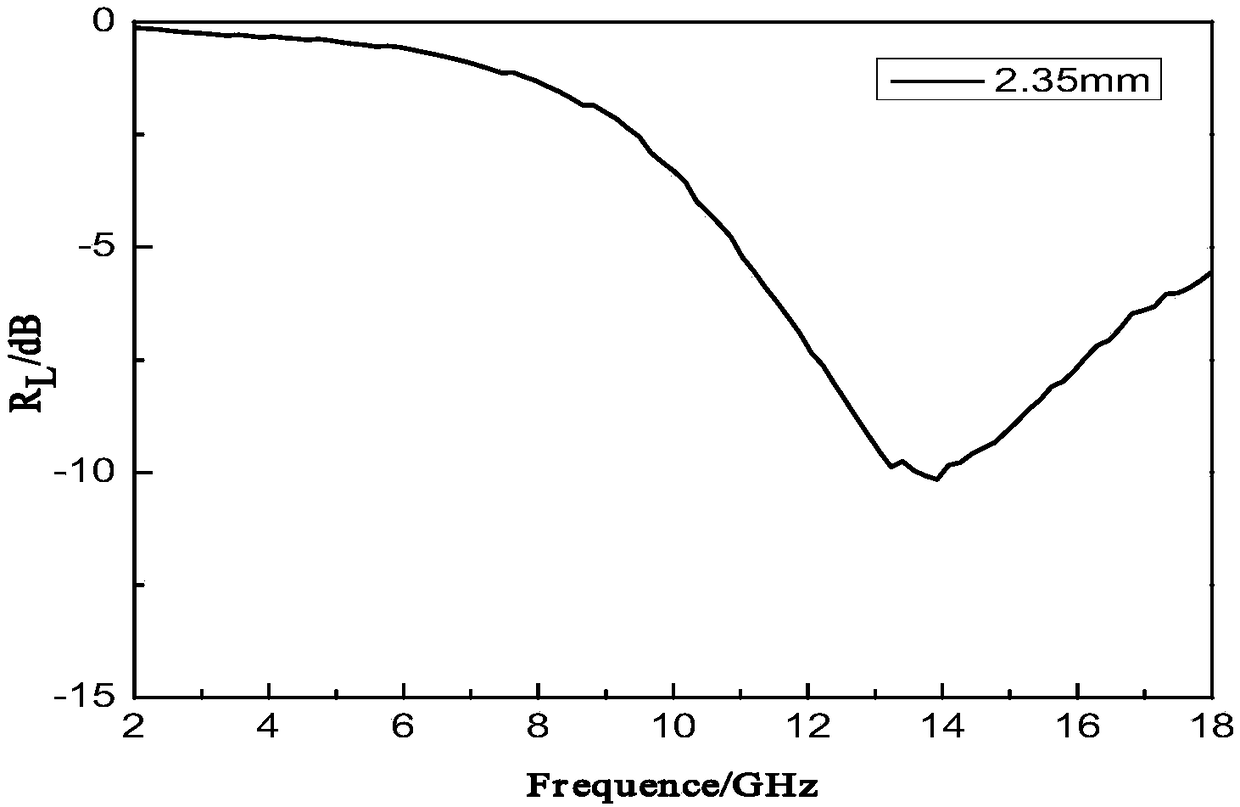

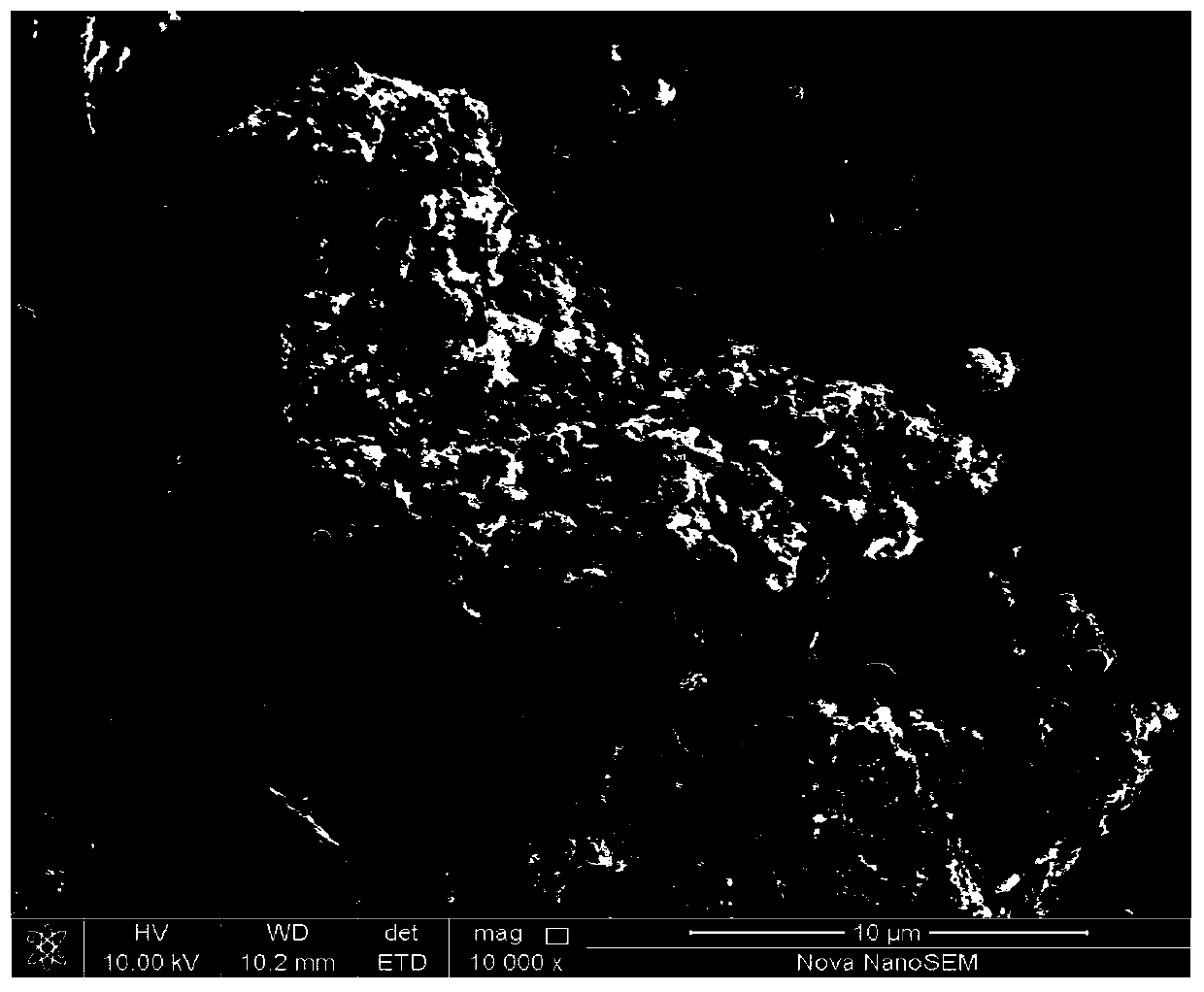

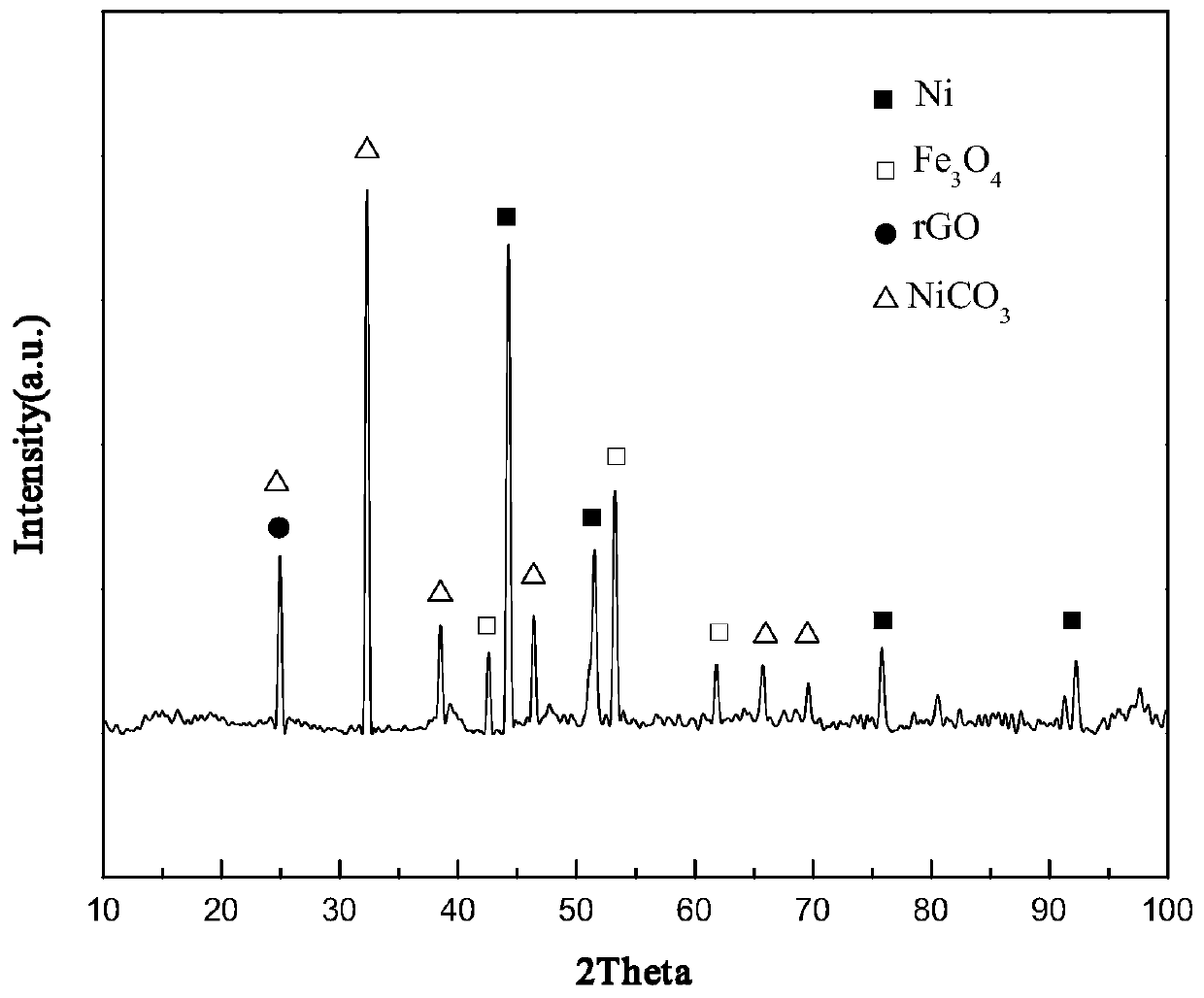

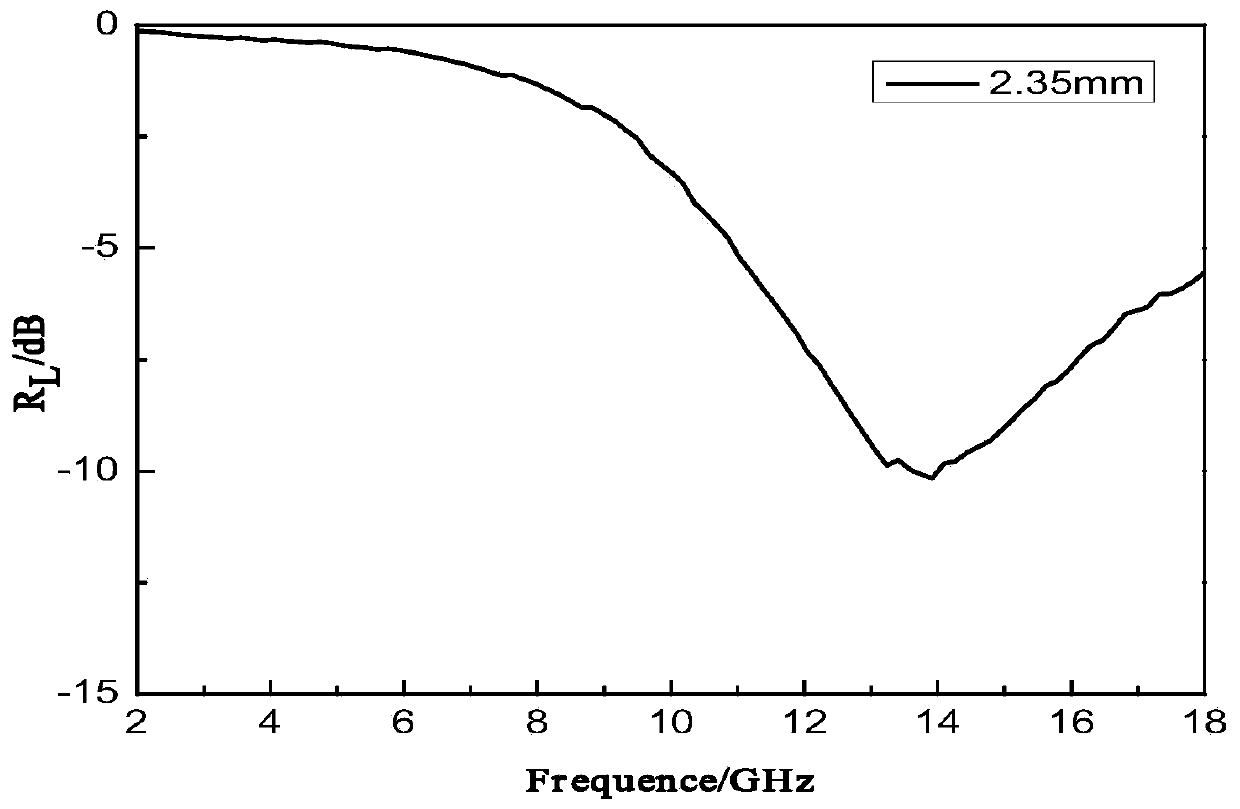

Nickel-containing composite absorbing material and preparation method thereof

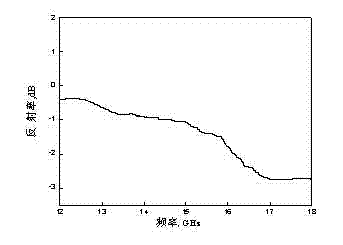

ActiveCN108342183APromote absorptionImprove eddy current lossOther chemical processesReflection lossGraphene

The invention provides a nickel-containing composite absorbing material and a preparation method thereof. The composite absorbing material comprises graphene oxide substrate, ferrite, nano nickel andnickelous carbonate; the ferrite, the nano nickel and the nickelous carbonate are loaded on the surface of the graphene oxide substrate. The result of the embodiment reveals that when the matching thickness of the composite absorbing material is 2.25 mm, -15.16 dB is absorbed to the maximum when the frequency reaches 14.88 GHz, the effective absorbing frequency band reaches 4 GHz when the reflection loss is lower than -10 dB, the absorbing frequency band is significantly broadened, and the absorbing capability is enhanced.

Owner:ARMOR ACADEMY OF CHINESE PEOPLES LIBERATION ARMY

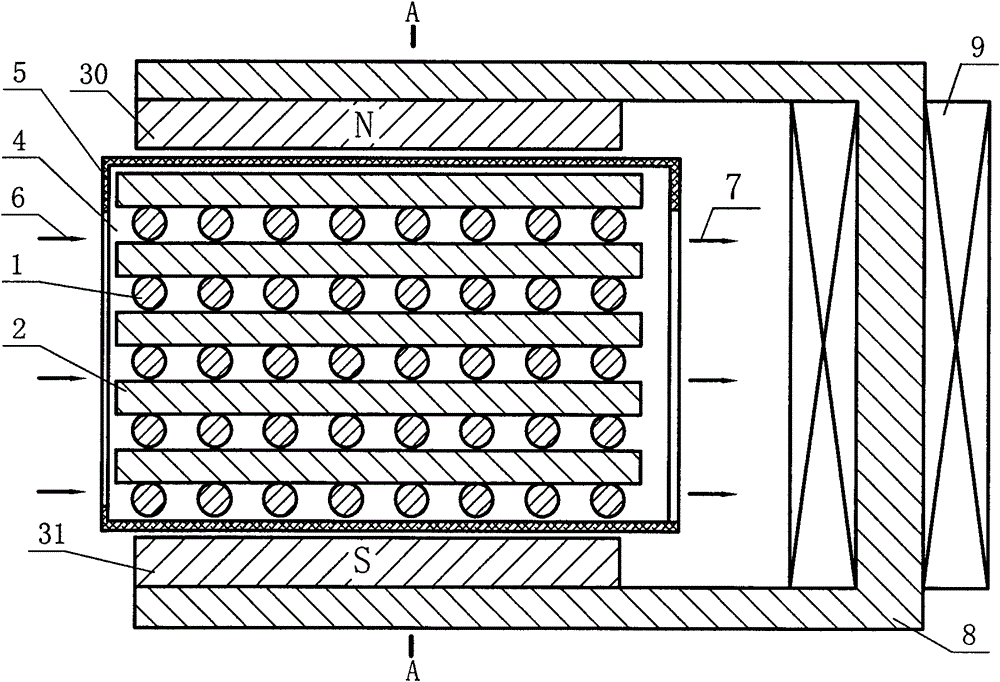

Magnetic ring device for suppressing very fast transient overvoltage in gas-insulated switchgear

ActiveCN106992510BReduce magnetic field strengthImprove saturation characteristicsPermanent magnetsEmergency protective arrangements for limiting excess voltage/currentOvervoltageAdhesive

The present invention provides a magnet ring device for inhibiting very fast transient overvoltage in a gas insulated switchgear. The magnet ring device comprises a magnet ring string, a copper foil adhesive tape and a fixed housing. The magnet ring string is formed by a plurality of open-loop anti-saturation magnet rings, and each two adjacent open-loop anti-saturation magnet rings are tightly connected through adhesives; each open-loop anti-saturation magnet ring is provided with an air gap; and the outer surface of the magnet ring string is coated with the copper foil adhesive tape, and the fixed housing is fixed at the outer portion of the magnet ring string. The magnet ring is provided with the air gap with the appropriate length to effectively improve the saturation characteristic of the device, cause more energy consumption for the traveling wave and reduce the VFTO (Very Fast Transient Overvoltage) value caused by operating a disconnecting switch in GIS (Gas Insulated Switchgear); the copper foil adhesive tape can effectively avoid leakage of a magnetic line, enhance the eddy current loss of the magnet ring device, reduce the influence of the VFTO on the device, improve the distribution of the electric field at the surface of the magnet ring string and avoid the partial discharge phenomenon caused by too high local field intensity. The fixed housing can improve the intensity and the rigidity of the whole magnet ring device.

Owner:YUNNAN POWER GRID CO LTD ELECTRIC POWER RES INST

Magnetic fluid sieving device

InactiveCN102728463BPromote circulationPass smoothlyHigh gradient magnetic separatorsMagnetic tension forceWire rod

The invention relates to a magnetic fluid sieving device, which mainly comprises a fluid separation sieve and a magnetic loop. The device is characterized in that magnetic wires and nonmagnetic wires in the fluid separation sieve formed by multiple layers of screen meshes in a plurality of independent fluid separation cavities under magnetic poles divide a magnetic field space into several minimal spaces of high gradient magnetic potentials and an equal magnetic potential; magnetic particles in a fluid are enriched in the high gradient magnetic field spaces under the action of magnetic force when the fluid flows through the fluid separation sieve; and when the magnetic poles relatively move along the direction of the nonmagnetic wires, the magnetic particles are acted by the magnetic force of the magnetic poles, move with the magnetic poles along a direction nearly orthogonal to a fluid flow channel, and are separated out. The magnetic fluid sieving device of the invention has the advantages of realization of continuous and efficient separation of the magnetic particles from the fluid, low operation energy consumption, and simple maintenance, and can be used for environmental protection, magnetic metal recovery, and magnetic mineral sorting.

Owner:邹吉武

A kind of magnetic core material and its preparation method and application

ActiveCN112768166BReduce permeabilityImprove permeabilityInductances/transformers/magnets manufactureMagnetic materialsCompression moldingInductor

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

A kind of cobalt-containing composite wave-absorbing material and preparation method thereof

ActiveCN108307614BPromote absorptionImprove eddy current lossCarbon compoundsOther chemical processesReflection lossOxide matrix

The invention provides a cobalt-containing composite absorbing material and a preparation method thereof. The composite absorbing material comprises a graphene oxide matrix, ferrite, nanometer cobaltand cobaltous carbonate, and the ferrite, the nanometer cobalt and the cobaltous carbonate are loaded on the surface of the graphene oxide matrix. Results of the embodiment show that according to theobtained composite absorbing material, when the matching thickness is 2.44 mm, the maximum absorption -19.13dB is achieved during 12.32 GHz, and the effective absorption frequency band whose reflection loss is lower than -10dB reaches 4.10 GHz; and when the matching thickness is 2.40 mm, the maximum absorption -17.36dB is achieved during 13.34 GHz, the effective absorption frequency band whose reflection loss is lower than -10dB reaches 2.74 GHz, the visible absorbing frequency band is substantially widened, and the absorbing capability is enhanced.

Owner:ARMOR ACADEMY OF CHINESE PEOPLES LIBERATION ARMY

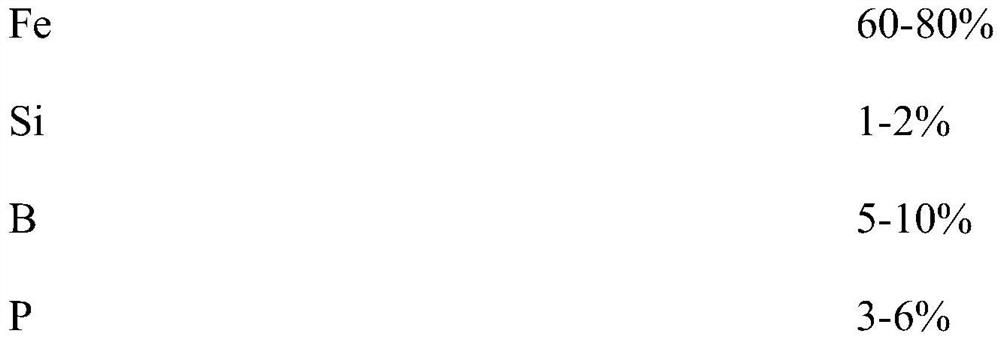

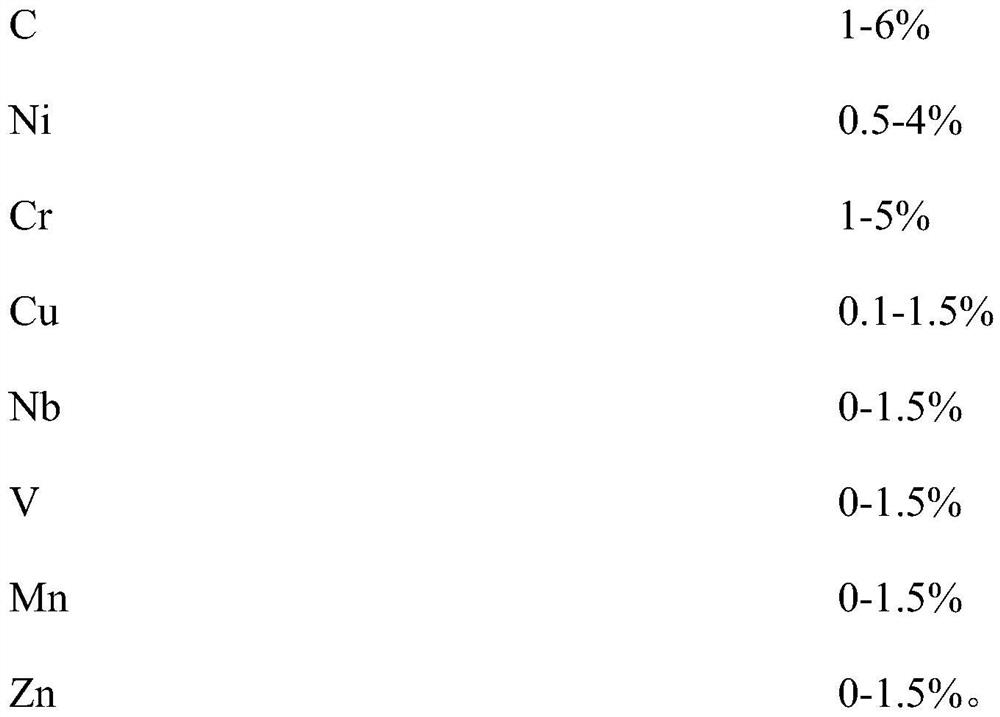

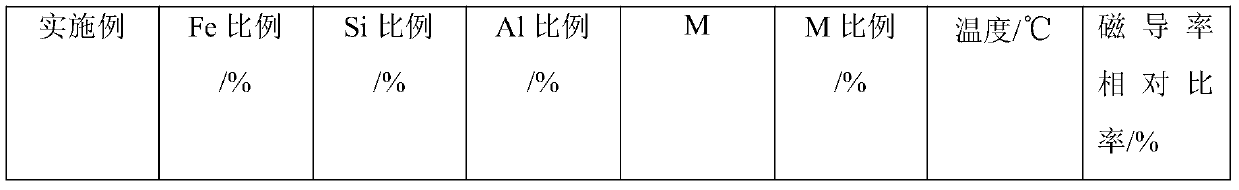

Preparation method of high magnetic permeability wave-absorbing material

ActiveCN107507689BImprove processing plasticityImprove eddy current lossMagnetic materialsSurface roughnessIron based alloy

Owner:GRIREM ADVANCED MATERIALS CO LTD

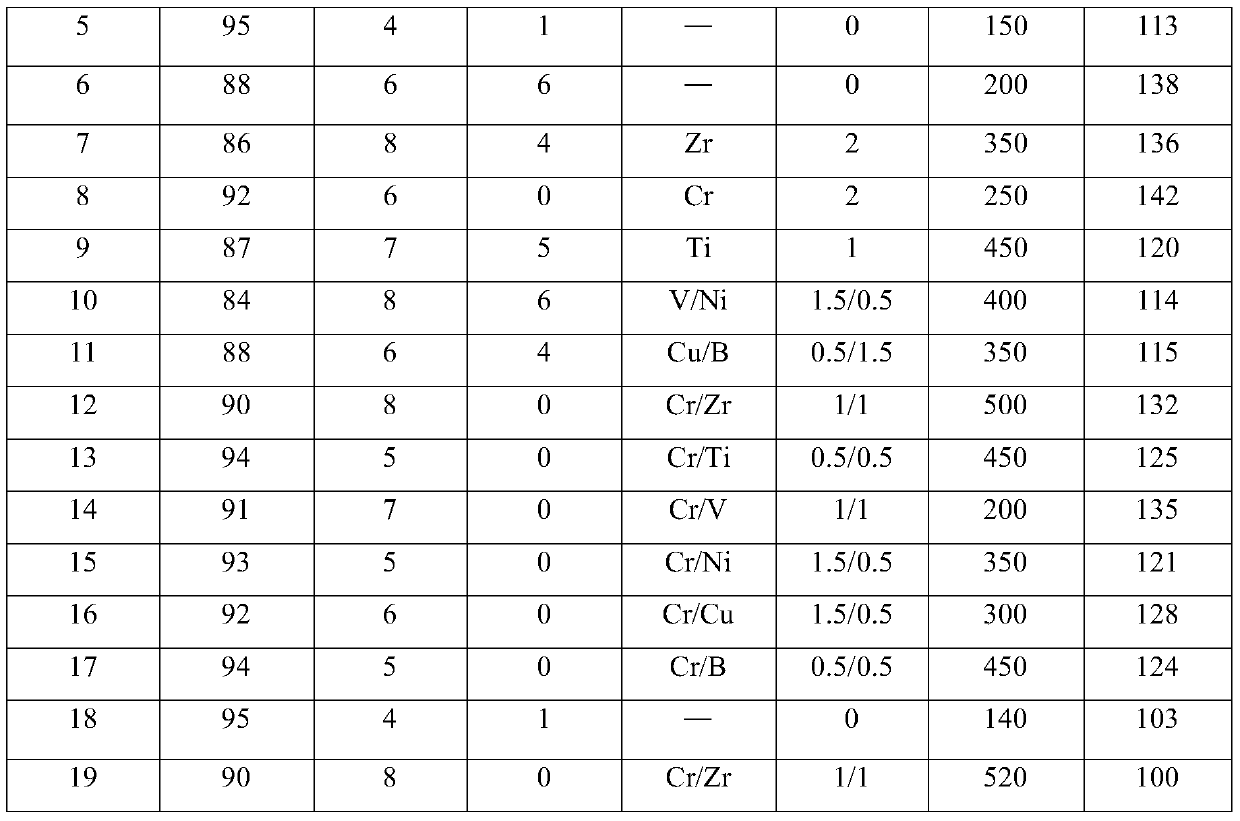

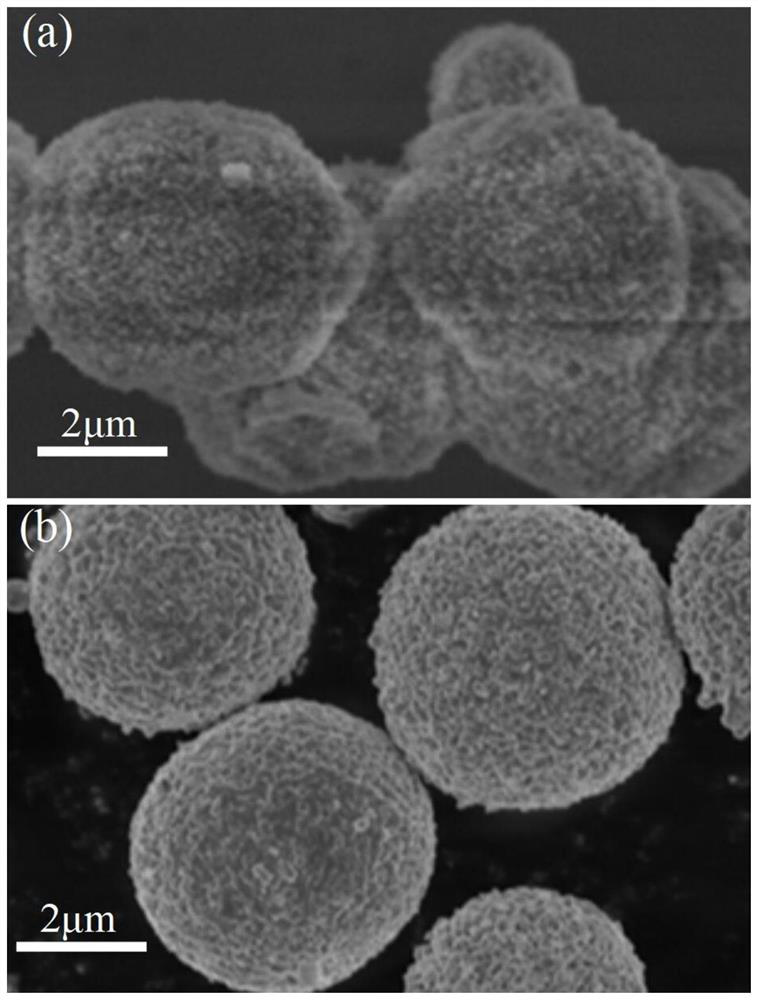

Metal-carbon composite particle and preparation method and application thereof

PendingCN114346250AImprove microwave absorption performanceWide absorption bandwidthMagnetic/electric field screeningTransportation and packagingCarbon compositesNickel salt

The invention discloses a metal-carbon composite particle and a preparation method and application thereof. The preparation method of the metal-carbon composite particles comprises the following steps: 1) dispersing cobalt salt or / and nickel salt and trimesic acid in a solvent, and reacting to obtain cobalt or / and nickel-based MOF (Metal Organic Framework); and 2) calcining the cobalt or / and nickel-based MOF in a protective atmosphere to obtain the metal-carbon composite particles. The metal-carbon composite particle has the advantages of excellent microwave absorption performance, wide absorption bandwidth, good impedance matching performance, light weight and simple preparation method, can be used in electromagnetic wave absorption materials, and has a very wide application prospect.

Owner:GUANGDONG POLYTECHNIC NORMAL UNIV

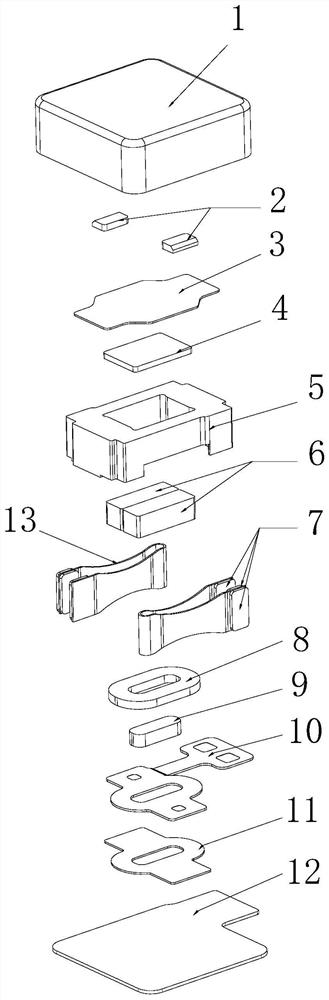

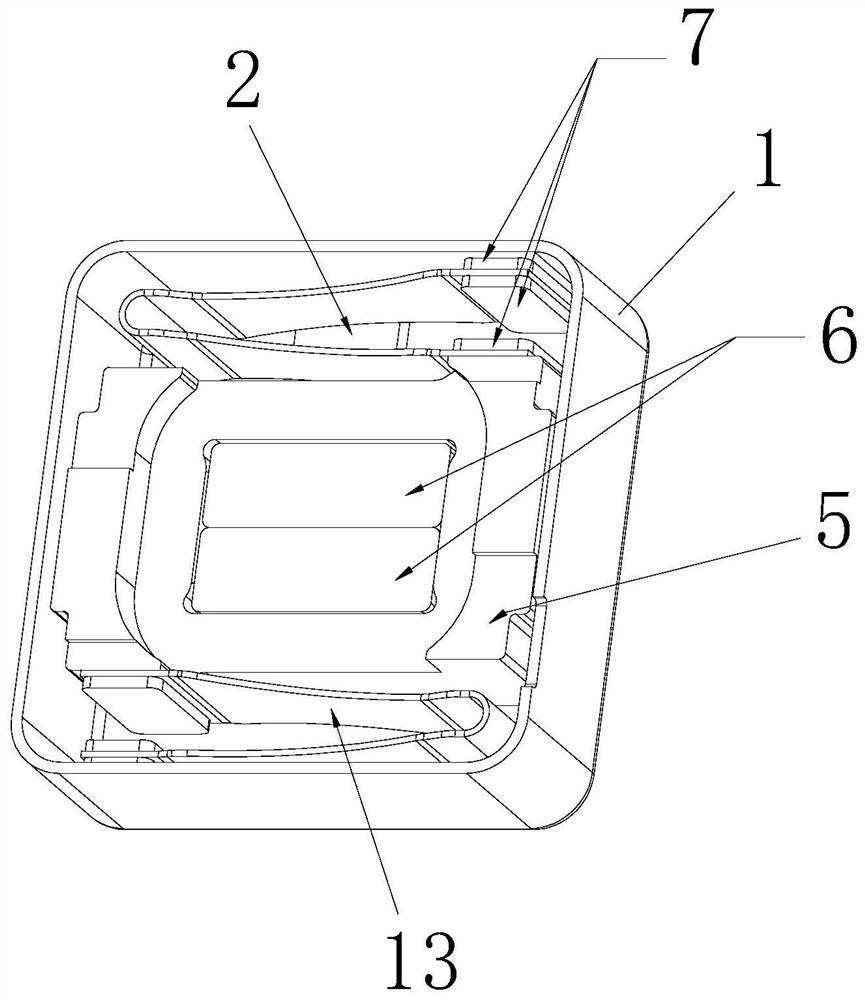

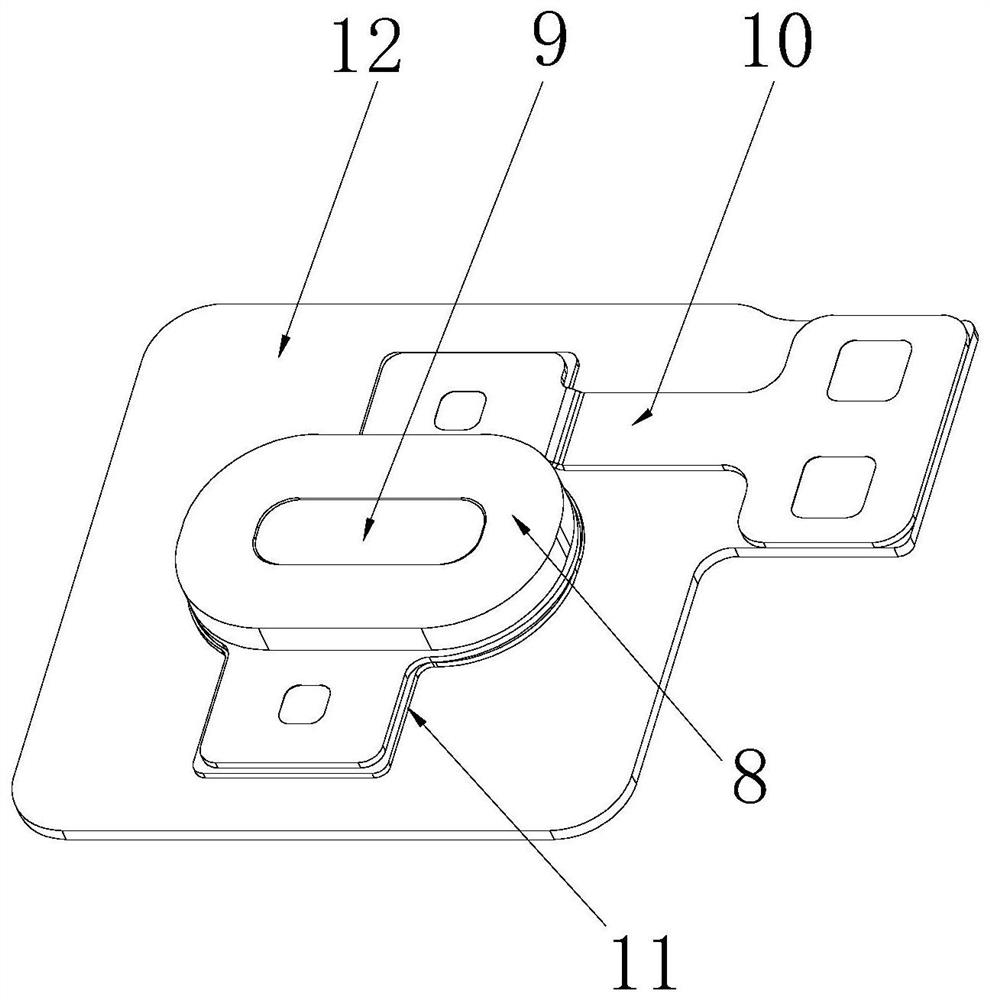

A horizontal linear vibration motor and its realization method

ActiveCN111463989BEasy to assembleImprove manufacturabilityDynamo-electric machinesElectric machineWorking environment

The invention discloses a horizontal linear vibration motor, which comprises a casing, a lower cover plate is connected to the lower part of the casing, a stator assembly is connected above the lower cover plate, a vibrator assembly is arranged above the stator assembly, and the two sides of the vibrator assembly pass through The spring piece is connected to the casing, and the stator assembly includes a coil, an iron core, an FPC circuit board and a damping plate, wherein the damping plate, the FPC circuit board and the coil are stacked on top of the lower cover in sequence from bottom to top, and the iron core is set through the damping plate 1. Inside the FPC circuit board and the coil, the vibrator assembly includes a counterweight, and the interior of the counterweight is provided with two magnetic steels arranged side by side; the invention also discloses a method for realizing a horizontal linear vibration motor. The electromagnetic characteristics of the damping plate of the present invention lead to a large eddy current loss generated on the vibrator assembly when it moves, which generates reliable energy consumption for the motor to stop, and because its electromagnetic characteristics change little within the working temperature range, the motor damping does not change with the working environment temperature And obviously changed.

Owner:ZHEJIANG DONGYANG CHENGJI ELECTRO MECHANICS CO LTD

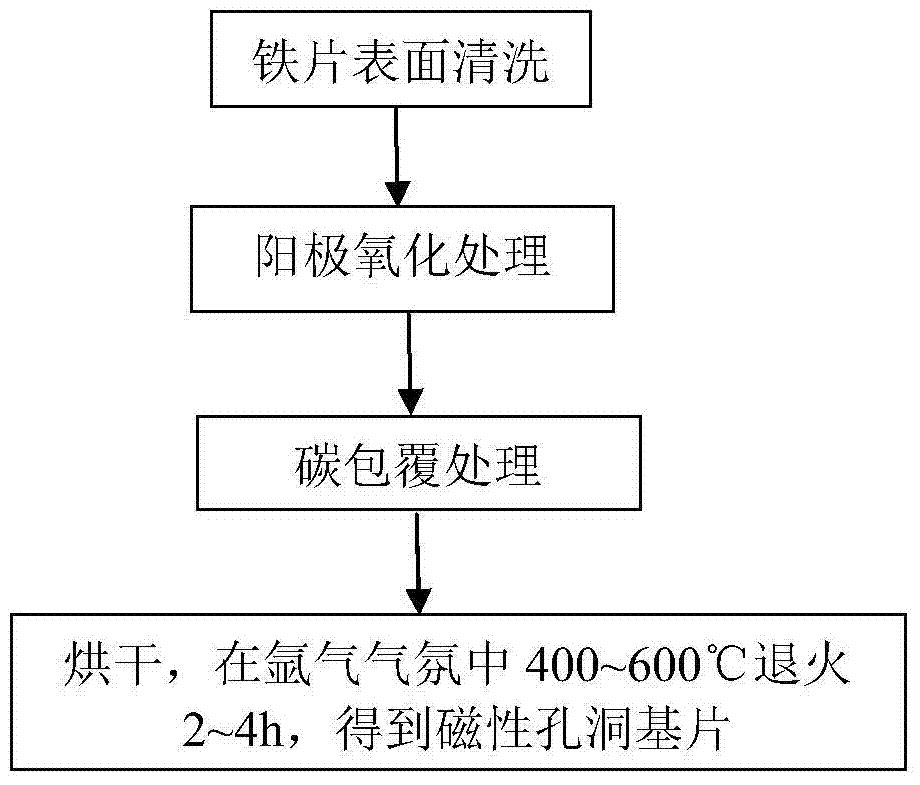

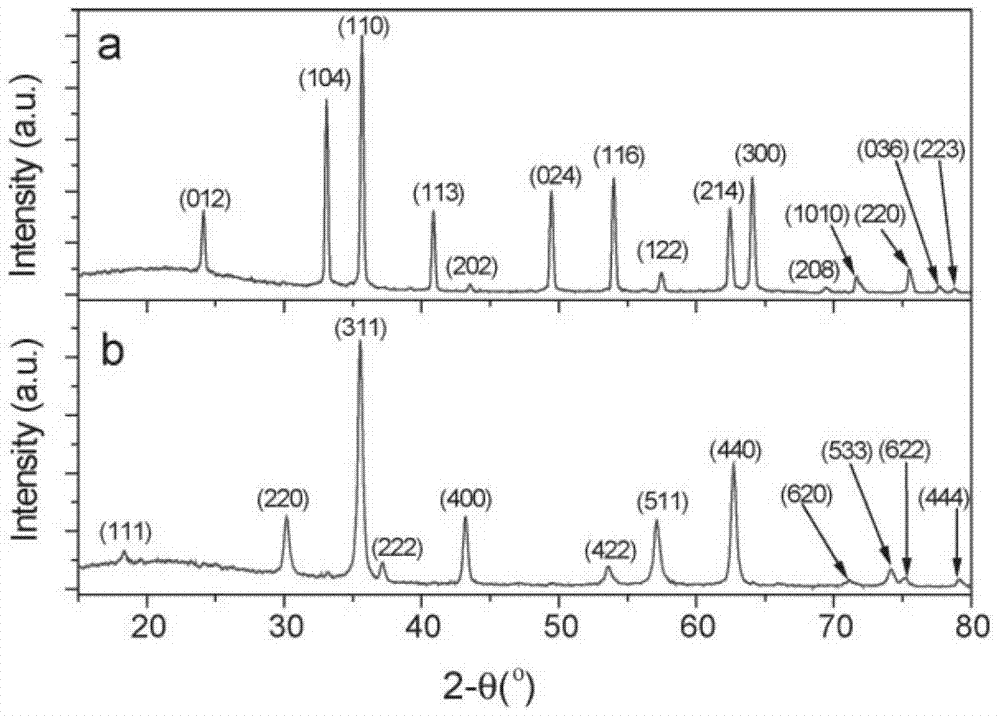

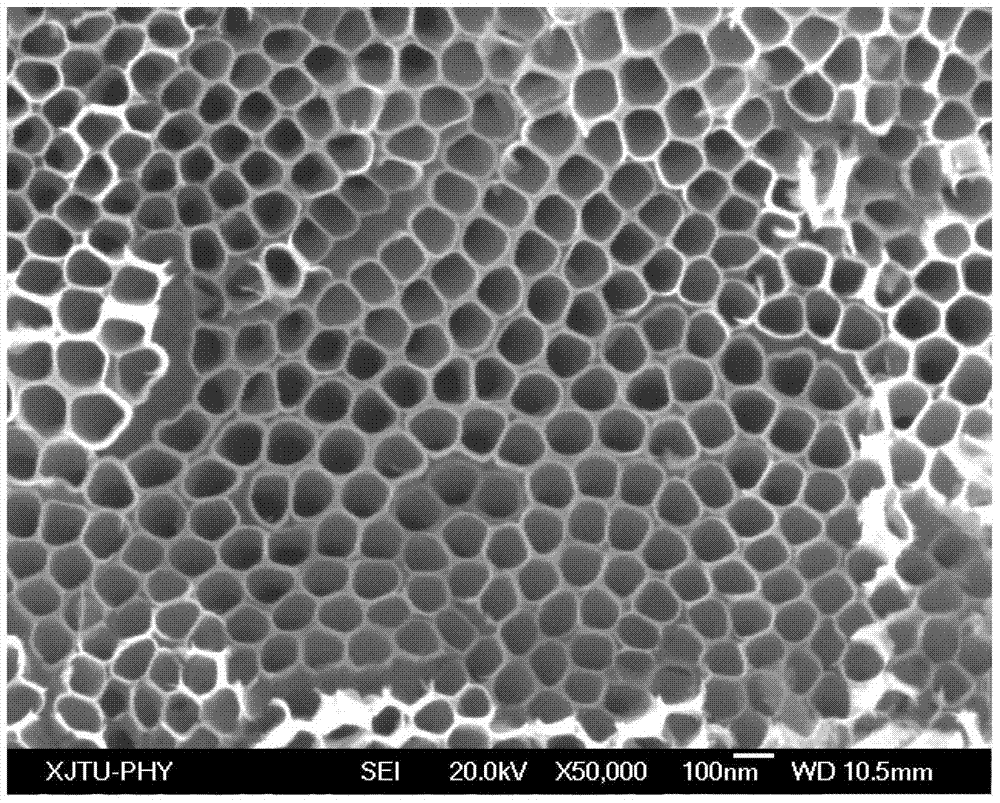

A magnetic hole substrate for preparing sheet-shaped electromagnetic noise suppression material

InactiveCN105112982BImprove conductivitySimple manufacturing processAnodisationMagnetic/electric field screeningMaterials preparationPorous layer

The invention provides a magnetic hole substrate for preparing a sheet-shaped electromagnetic noise suppression material and a preparation method thereof. The magnetic hole substrate includes an iron substrate and a porous layer on the iron substrate, and the porous layer is a nanoscale hole. The carbon-coated ferroferric oxide has a pore size of 50-150nm, and ferromagnetic nanowires can be deposited in the holes by an electroplating process as a sheet-shaped electromagnetic noise suppression material. The preparation method is as follows: first, the clean iron sheet is anodized, then soaked in glucose ethanol solution for 8-12 hours, dried, and finally annealed at 400-600 DEG C for 2-4 hours in an argon atmosphere. The present invention adopts magnetic material as hole substrate material, which enhances the ferromagnetic coupling effect between the magnetic nanowires deposited in the holes, has good noise absorption performance, and the absorption frequency can reach above 10 GHz; and it is easy to realize miniaturization and integration It can meet the demand for electromagnetic noise suppression in high frequency and wide frequency range.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

A nickel-containing composite wave-absorbing material and its preparation method

ActiveCN108342183BPromote absorptionImprove eddy current lossOther chemical processesMagnetic/electric field screeningReflection lossGraphite oxide

The invention provides a nickel-containing composite absorbing material and a preparation method thereof. The composite absorbing material comprises graphene oxide substrate, ferrite, nano nickel andnickelous carbonate; the ferrite, the nano nickel and the nickelous carbonate are loaded on the surface of the graphene oxide substrate. The result of the embodiment reveals that when the matching thickness of the composite absorbing material is 2.25 mm, -15.16 dB is absorbed to the maximum when the frequency reaches 14.88 GHz, the effective absorbing frequency band reaches 4 GHz when the reflection loss is lower than -10 dB, the absorbing frequency band is significantly broadened, and the absorbing capability is enhanced.

Owner:ARMOR ACADEMY OF CHINESE PEOPLES LIBERATION ARMY

SrNdMnO wave-absorbing material and preparation method thereof

PendingCN114715947AChanging the magnetocrystalline anisotropy fieldChange activityOther chemical processesMagnetic/electric field screeningPhysical chemistryWave band

The invention provides a SrNdMnO wave-absorbing material and a preparation method thereof, and relates to the technical field of microwave absorbing materials. The molecular formula of the SrNdMnO wave-absorbing material is Sr1-xNdxMnO3, x is more than 0 and less than or equal to 0.2, and the wave-absorbing material is obtained by adopting gelation reaction, pre-sintering and calcining. The invention overcomes the defects in the prior art, and the wave-absorbing material can absorb electromagnetic waves in the microwave band of 2-18GHz, and has the advantages of wide absorption frequency band, high absorption efficiency (greater than 90%), low absorption frequency, simple preparation process and suitability for large-scale production.

Owner:GUILIN UNIV OF ELECTRONIC TECH

Production method of electromagnetic wave-absorbing gypsum composite material

The invention relates to a production method of an electromagnetic wave-absorbing gypsum composite material, and belongs to the technical field of wave-absorbing materials. According to the productionmethod of the electromagnetic wave-absorbing gypsum composite material, antimonous oxide and carbon fibers are mechanically mixed, rare earth is adopted for doping to modify an obtained mixture, an obtained modified mixture is used as filler, through a sol-gel method, ferrous titanate is produced, and is used as an absorbent, gypsum is used as a matrix, and the matrix and the absorbent are subjected to composition to produce the electromagnetic wave-absorbing gypsum composite material; the antimonous oxide not only has wave transmittance, but also has certain absorbing capability, after rareearth doping modification is conducted, the magnetic performance and the wave absorbing performance are effectively improved, the ferrous titanate is an inorganic functional material with microwave absorbing performance, and has good wave absorbing performance, and the carbon fibers can effectively improve the mechanical performance of the material; and an ilmenite structure has a large electricalloss tangent angle, by means of electronic polarization, ionic polarization, molecular polarization or interfacial polarization of a medium, electromagnetic waves are attenuated and absorbed, and theferrous titanate compound has an excellent impedance matching property.

Owner:黄梅龙源石膏有限公司

Pr series rare earth super magnetostric tive material and its preparing method

This invention provides a Pr series rare earth super magnetostriction material and its preparation method, and the chemical components (atomic ratios) are: Pr1-x(Tb1-yREy)x(FelMz)RE represents for Dy, Sm, Ho, Er, Ce, Nd and etc rare earth elements; M represents one or several kinds of B, Si, C, Zr, Nb, Cu, Mn, V, Ti, Cr, Ga, Co, Ni, w, Hf, Ta, Mg. (0 is less than or equal to x is less than or equal to 0.6, 0 is less than or equal to y is less than or equal to 1, 0 is less than or equal to z is less than or equal to 0.4, 0 is less than or equal to t is less than or equal to 4.) The preparation method is : use high-pressing technology to compose the Pr series rare earth super magnetostriction material with high Pr content that the usual pressure cannot realize. This invention greatly lowers the cost of the present material and maintains high magnetostriction performance.

Owner:NANJING UNIV

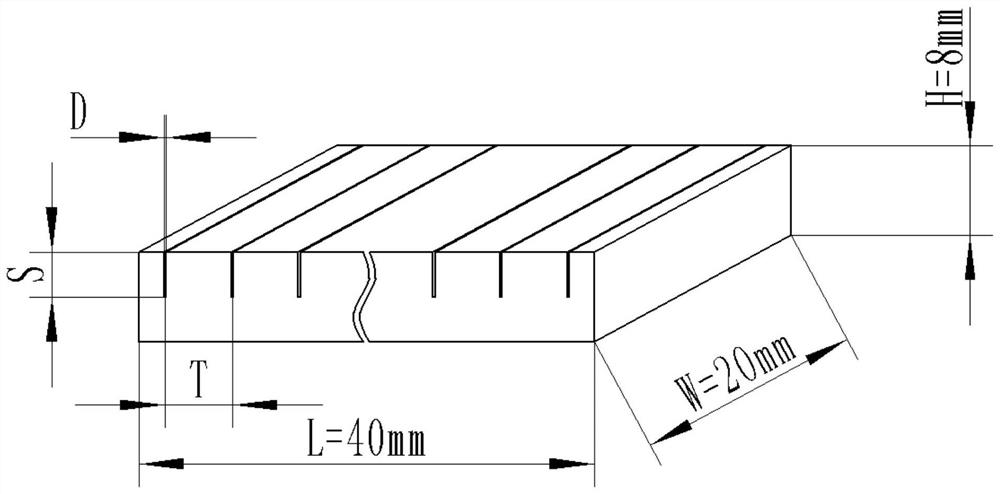

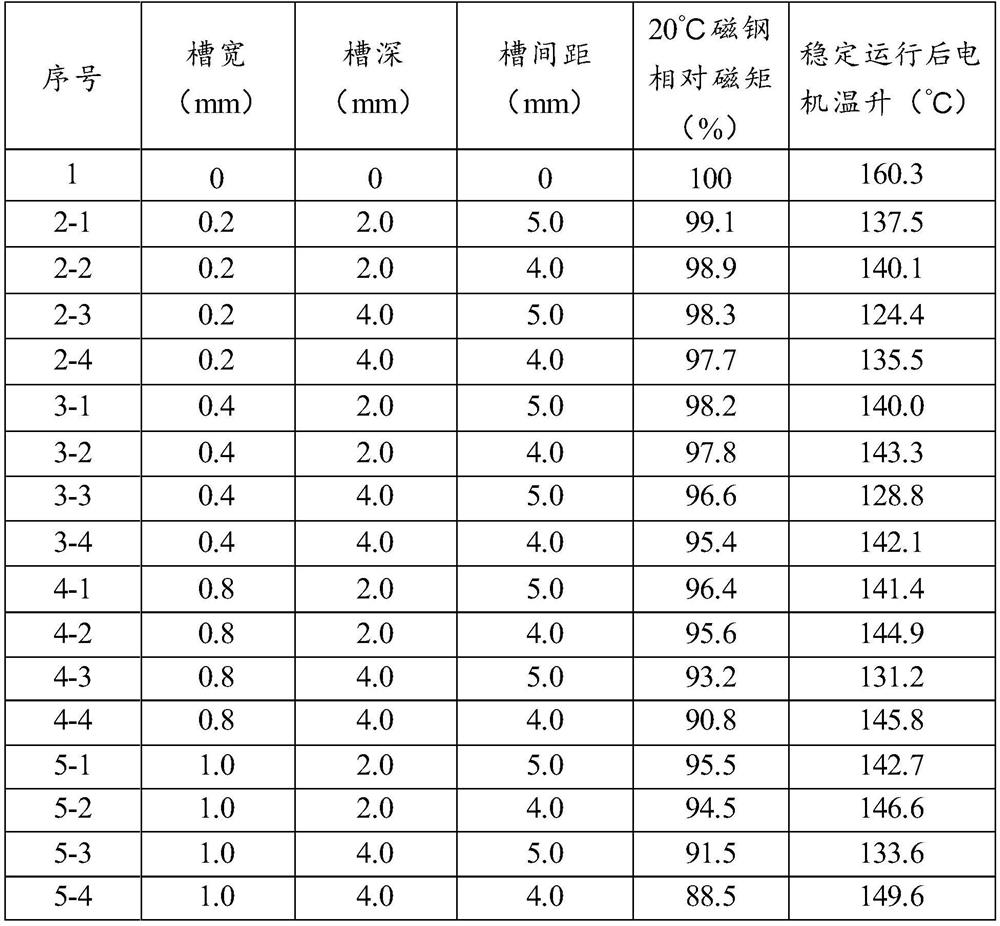

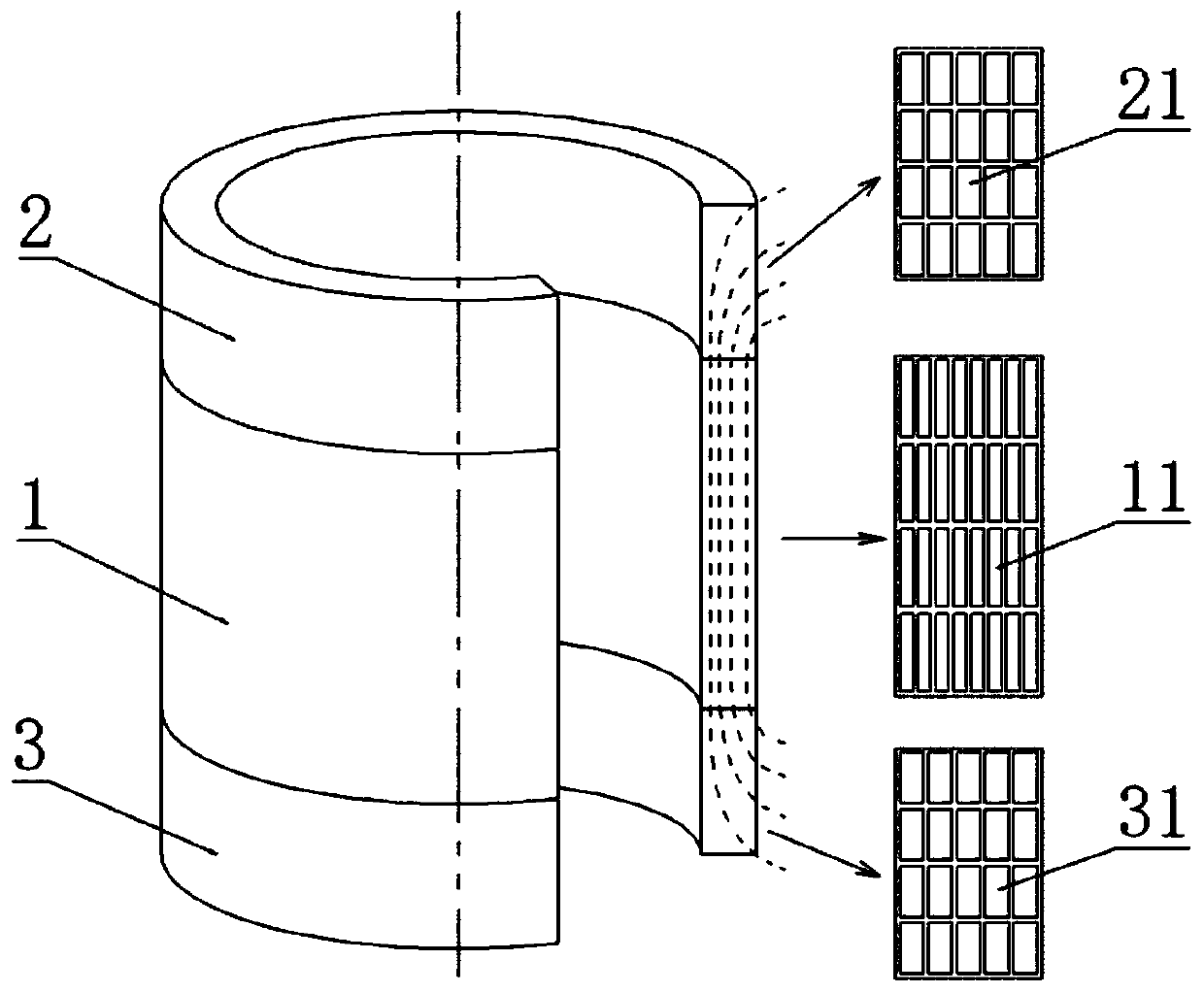

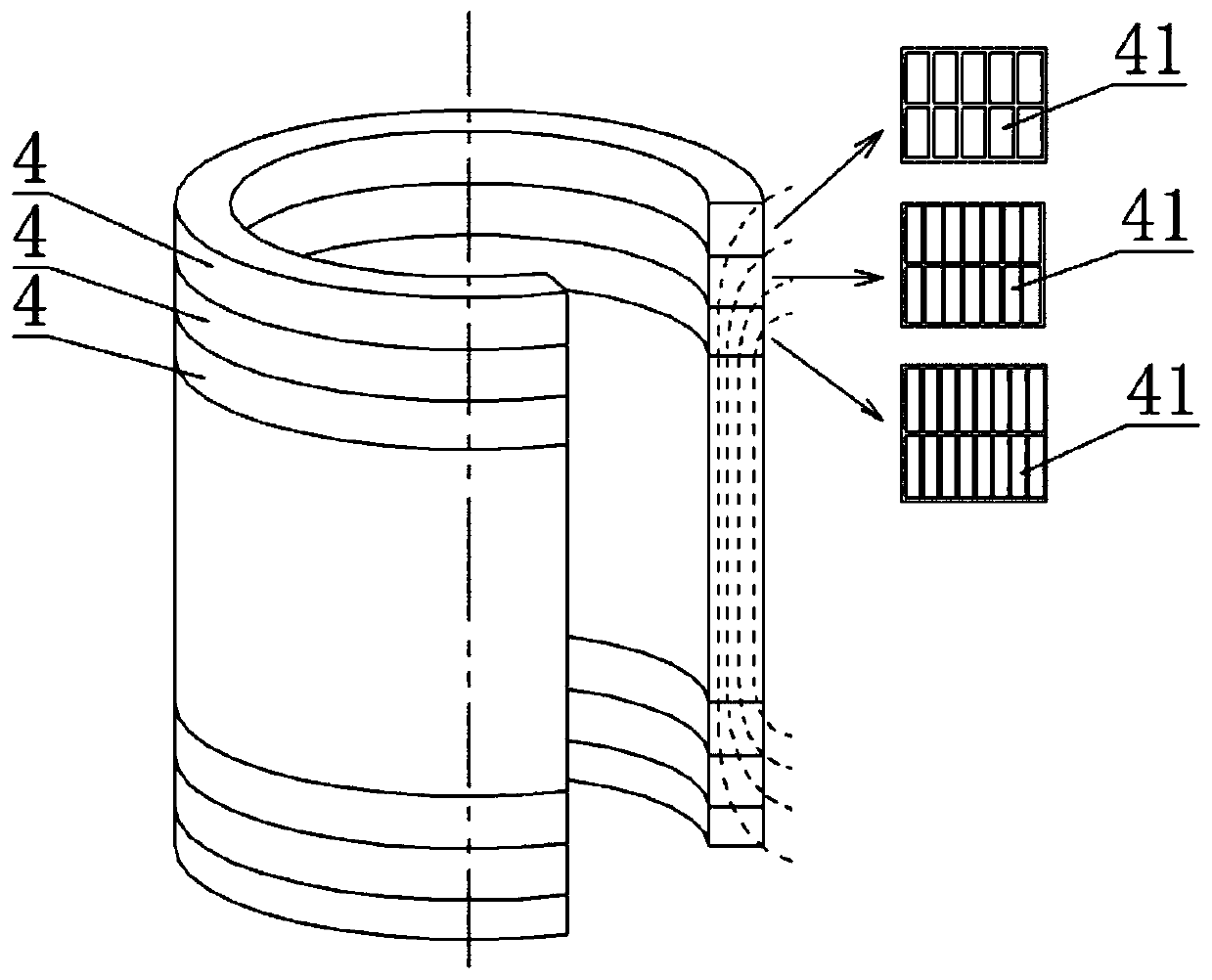

NdFeB magnet with low eddy current loss

PendingCN114743748AImprove eddy current lossImprove temperature riseElectric machinesPermanent magnetsMetallurgyElectric machine

The invention provides a slotted neodymium-iron-boron magnet. The slotted neodymium-iron-boron magnet comprises a neodymium-iron-boron square magnet which is subjected to permeation treatment or not subjected to permeation treatment; and the groove is arranged on the surface of the neodymium iron boron square magnet. The neodymium-iron-boron square magnet with the slotting structure is flexible and changeable in slotting position and easy to operate, can be applied to different products by meeting the performance requirements of all parts, can reasonably select the slotting position according to the requirements, improves the magnetic performance of different positions, and improves the production efficiency. The motor is greatly helpful for improving torque output capability and reducing loss in high-speed operation, magnetic steel eddy-current loss is reduced, motor efficiency is improved, temperature rise of the rotor is improved, usage amount of heavy rare earth diffusion sources is reduced, and motor cost is reduced.

Owner:JIANGXI JLMAG RARE EARTH

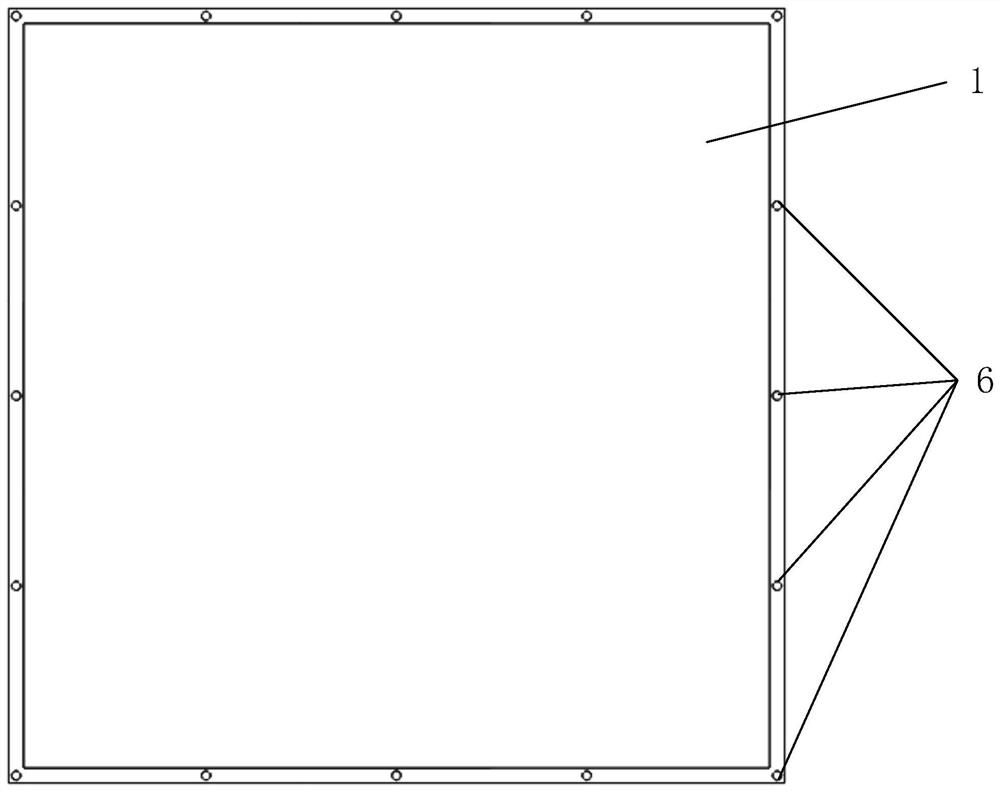

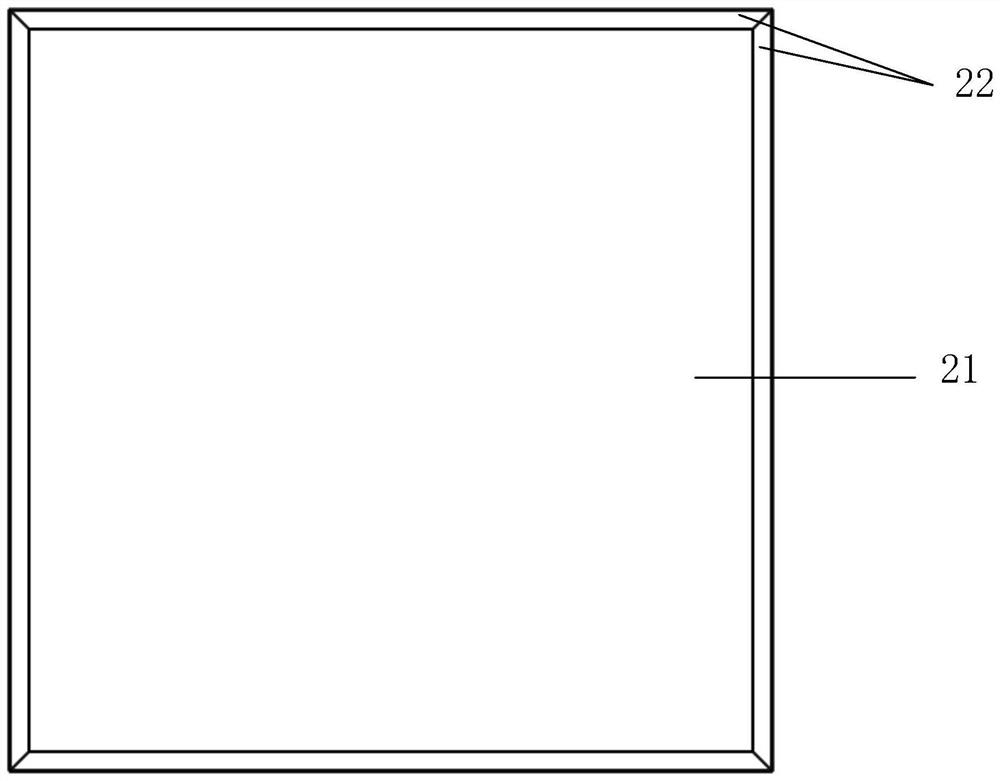

Transformer coil with low eddy current loss

ActiveCN111128528AReduce widthReduce thicknessTransformers/inductances coils/windings/connectionsUnwanted magnetic/electric effect reduction/preventionTransformerEddy current

The invention provides a transformer coil with low eddy current loss, and belongs to the field of transformers. The low eddy current loss transformer coil includes a coil body section, a coil first end section, and a coil second end section. The coil main body section is formed by winding a main wire. The coil first end section is located at one end of the coil main body section and is formed by winding a first wire, and the first wire is conductively connected with the main wire. The coil second end section is located at one end, far away from the coil first end section, of the coil main bodysection, the coil second end section is formed by winding a second wire, and the second wire is conductively connected with the main wire. The ratio of the axial width to the radial thickness of thefirst wire section and the ratio of the axial width to the radial thickness of the second wire section are both smaller than the ratio of the axial width to the radial thickness of the main wire section. According to the low-eddy-current-loss transformer coil, the ratios of the axial width to the radial thickness of the cross section of the first wire to the cross section of the second wire are reduced, so that the overall eddy current loss is reduced.

Owner:BAODING TIANWEI GROUP TEBIAN ELECTRIC

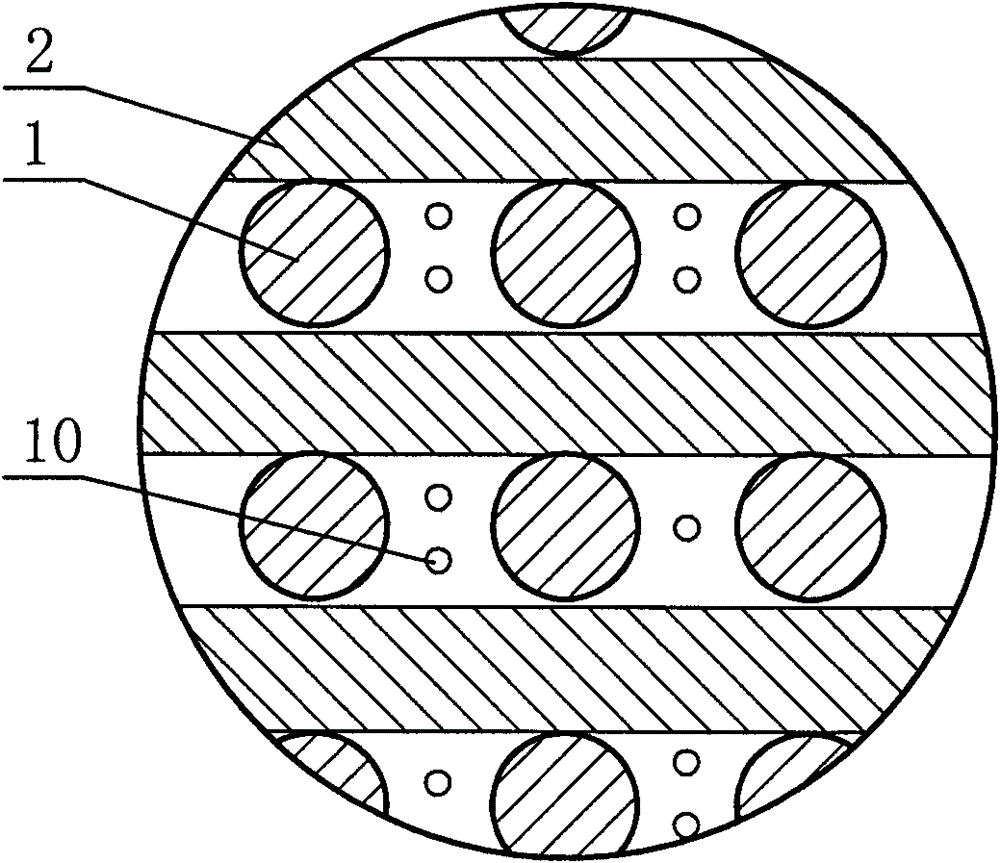

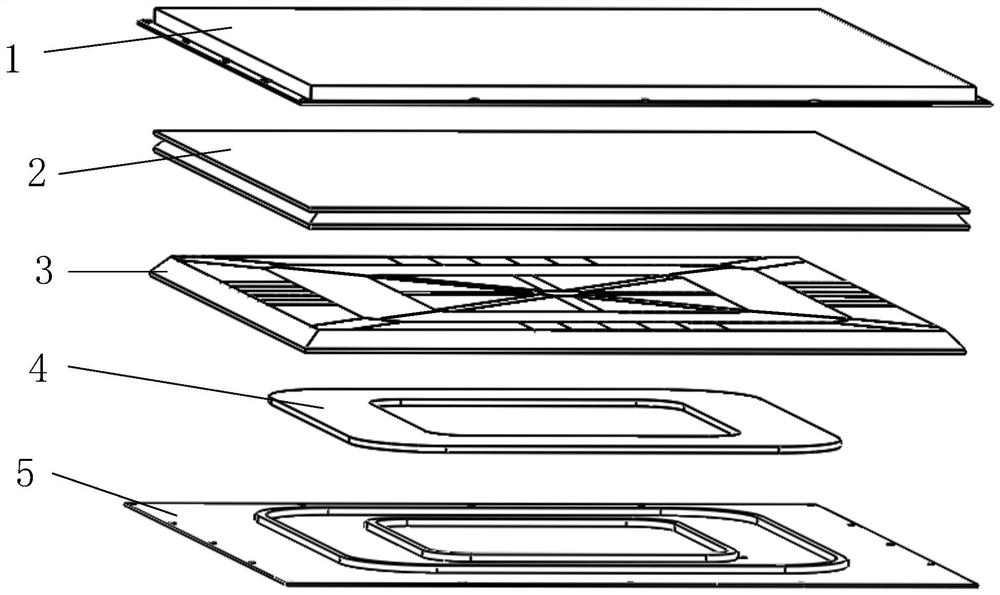

A composite shielding structure suitable for electric vehicle wireless power supply system

ActiveCN111463000BReduce sizeImprove magnetic permeabilityCharging stationsTransformersManganeseEngineering

The invention is a composite shielding structure suitable for a wireless power supply system of an electric vehicle. The structure includes an aluminum cover, an alumina ceramic heat-conducting plate, a magnetic material shielding plate, a receiving coil and a bakelite substrate; the magnetic material shielding plate includes a shielding plate chamfer and a split plate; the split plate is made of manganese-zinc power iron Oxygen and iron-based nanocrystalline alloy two kinds of magnetic materials are spliced into plate structures of various shapes. The receiving coil is set between the inner frame boundary of the bakelite substrate and the outer frame boundary of the substrate, the magnetic material shielding plate is covered on the receiving coil, the alumina ceramic heat conduction plate is covered on the magnetic material shielding plate, and the aluminum cover is covered on the oxide Above the aluminum ceramic heat conduction plate, it is fixed as a whole by screws and the Bakelite substrate. The invention not only can rationally utilize the magnetic material to shield electromagnetic radiation, but also can conduct the heat generated in the charging process to ensure the effective operation of the system.

Owner:HEBEI UNIV OF TECH

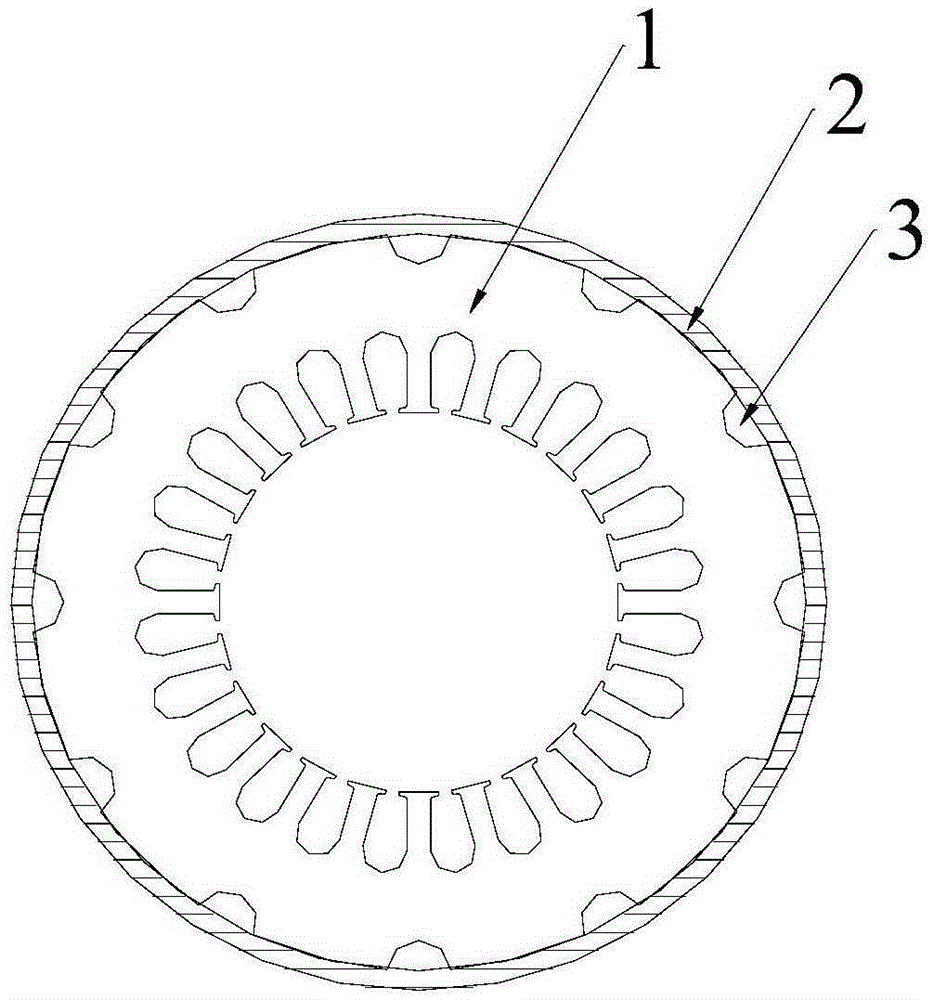

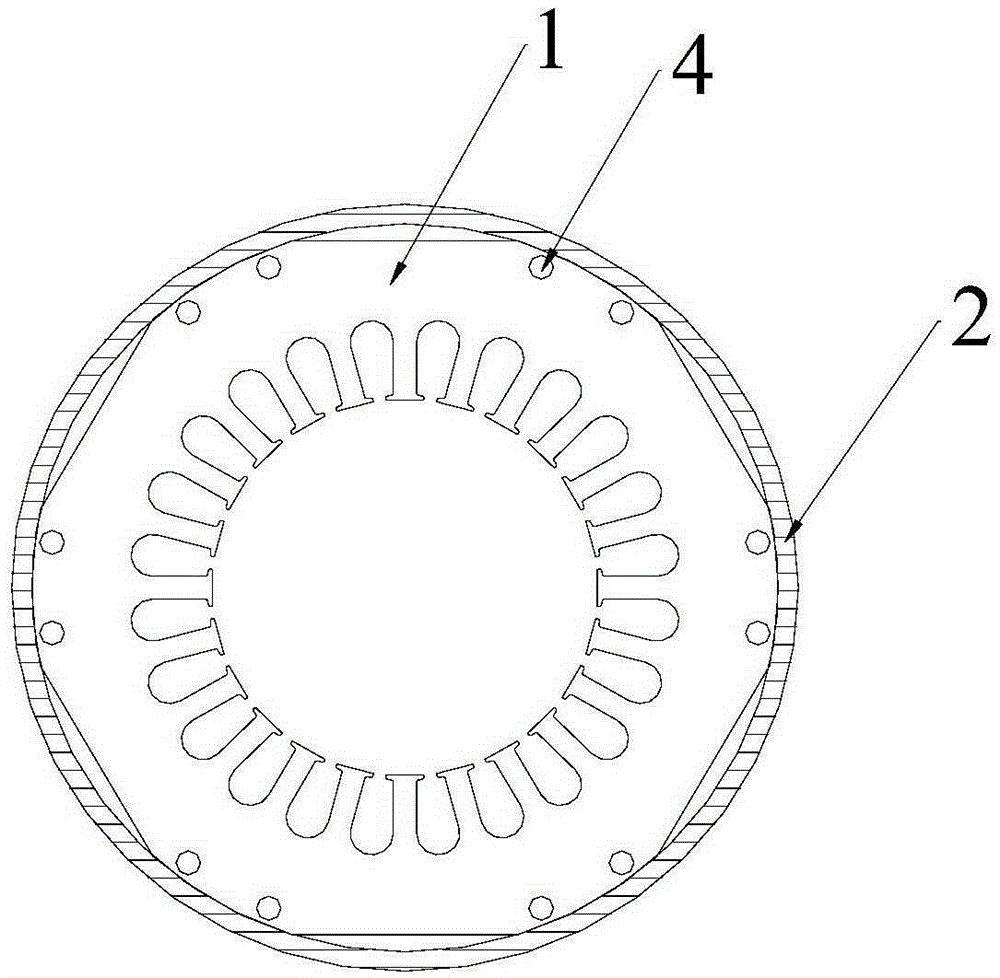

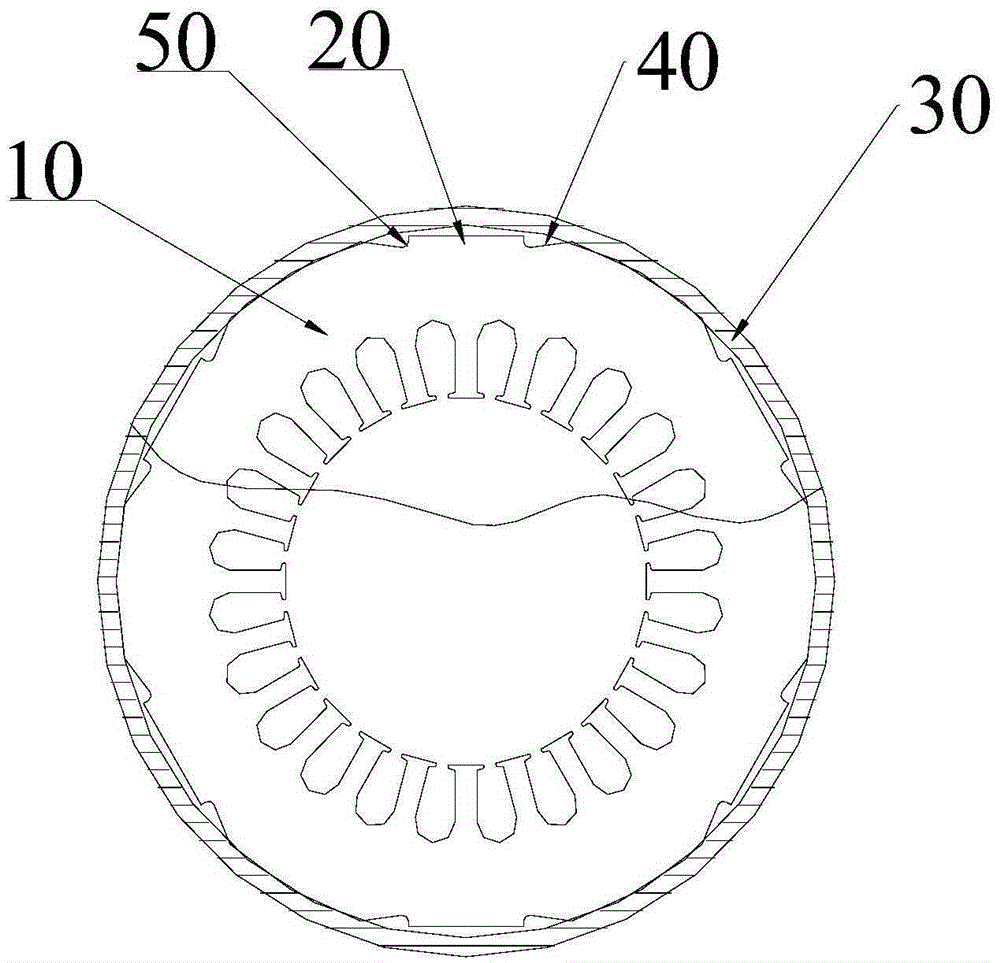

Motor core structure and air-conditioning compressor with same

ActiveCN105406617AImprove magnetic permeabilityReduce feverMagnetic circuit stationary partsEngineeringEddy current

The invention provides a motor core structure and an air-conditioning compressor with the same. The motor core structure comprises a main iron core body, a plurality of concave parts and lug bosses, wherein the concave parts are arranged on the outer peripheral surface of the main iron core body; the plurality of concave parts sink towards the center of the main iron core body along the radial direction respectively; the lug bosses are located in the concave parts; and a clearance is formed between the top surface of each lug boss and a shell of a motor. According to the motor core structure employing the technical scheme provided by the invention, the stress on the contact surface of the main iron core body and a main shell can be absorbed and guided; the stress is transferred to the lug bosses for accumulation; and the stress is eliminated on the outer peripheral edge of the motor core, so that the influence on magnetic domain distortion in a steel sheet of the motor core caused by the stress is reduced to the maximal extent; the eddy current loss caused by magnetic field turbulence is improved; the magnetic property of the motor is improved; motor heating is comprehensively lowered; and the power consumption is lowered.

Owner:GREE ELECTRIC APPLIANCES INC +1

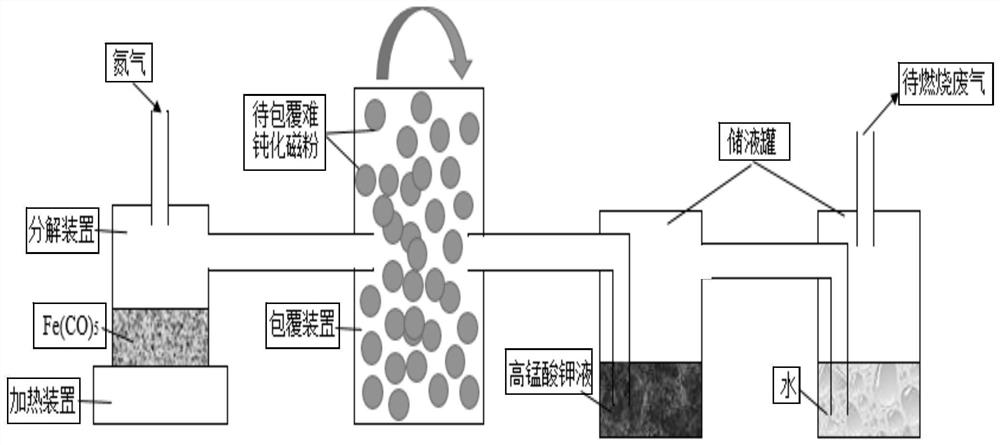

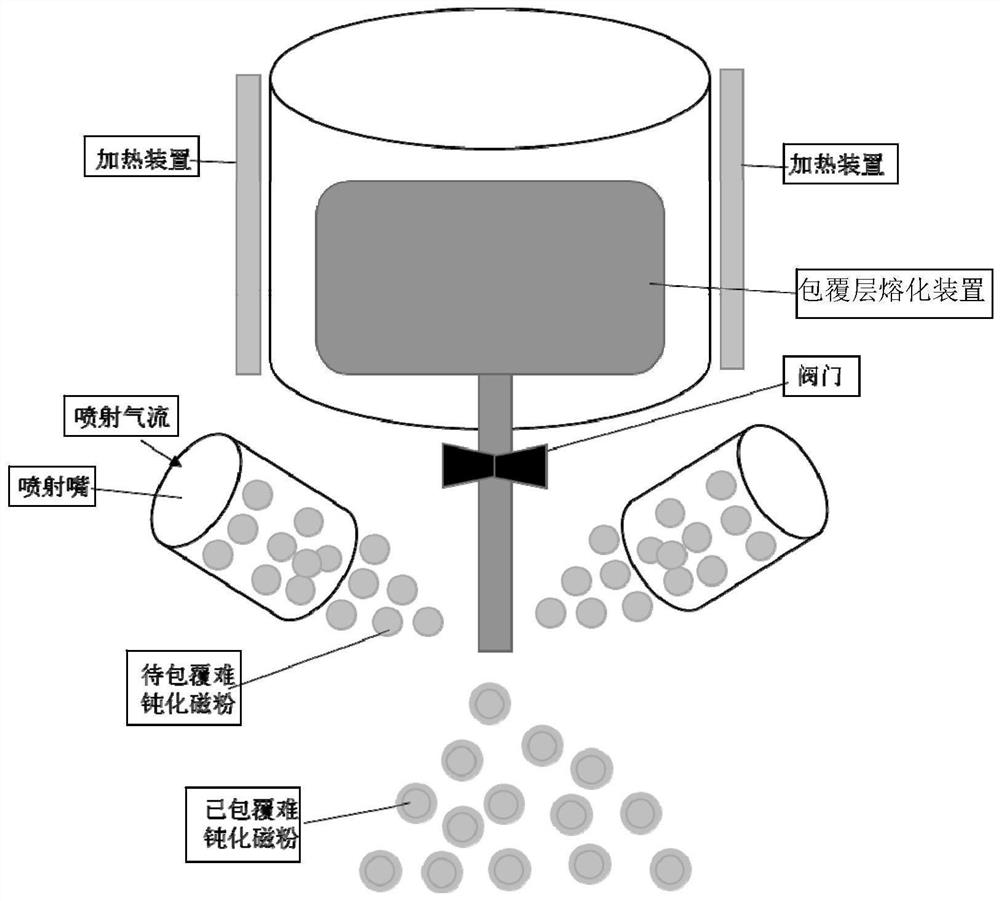

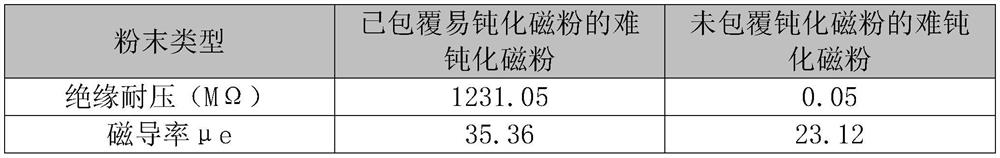

A kind of insulating powder technology for difficult passivation magnetic powder and the magnetic powder prepared therefrom

ActiveCN110197752BImprove reliabilityImprove insulation performanceInductances/transformers/magnets manufactureMagnetic materialsEddy currentElectronic component

Owner:SHENZHEN MICROGATE TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com