A kind of insulating powder technology for difficult passivation magnetic powder and the magnetic powder prepared therefrom

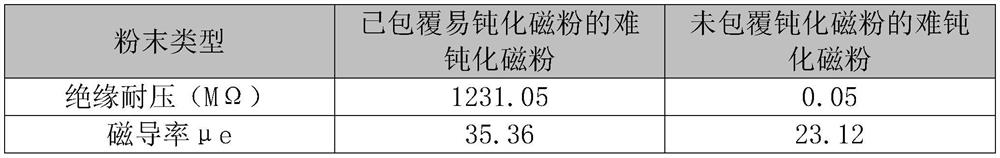

A technology of insulating powder and magnetic powder, applied in the manufacture of inductors/transformers/magnets, magnetic objects, magnetic materials, etc., can solve the problems of large eddy current loss, poor insulation performance, shrinkage, etc., to achieve improved reliability, high insulation performance, The effect of improving the pressing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

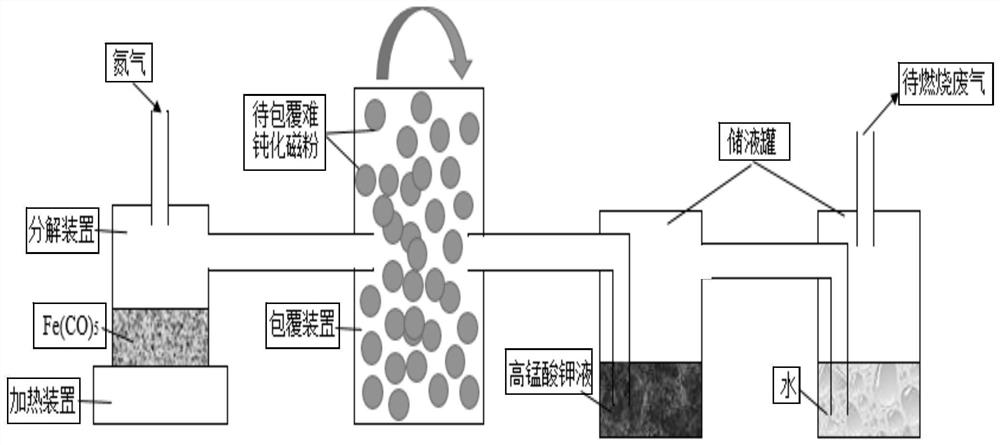

[0021] like figure 1 As shown, the present invention provides a device used in the carbonyl decomposition coating method, which includes a device for decomposing Fe(CO) 5 Decomposition device, for placing Fe(CO) 5 The heating device for heating the decomposition device, the coating device connected with the heating device for coating the hard-to-passivate magnetic powder, and the storage liquid for treating the tail gas connected with the coating device tank, the coating device can be rotated during the coating operation to improve the efficiency of coating; the liquid storage tank includes a first liquid storage tank stored with potassium permanganate solution and a storage tank for storing water The second liquid storage tank, the first liquid storage tank that described potassium permanganate solution is stored is used for intercepting unreacted complete Fe(CO) 5 and Fe(CO) 5 The carbon monoxide generated after decomposition is oxidized into harmless carbon dioxide to th...

Embodiment 2

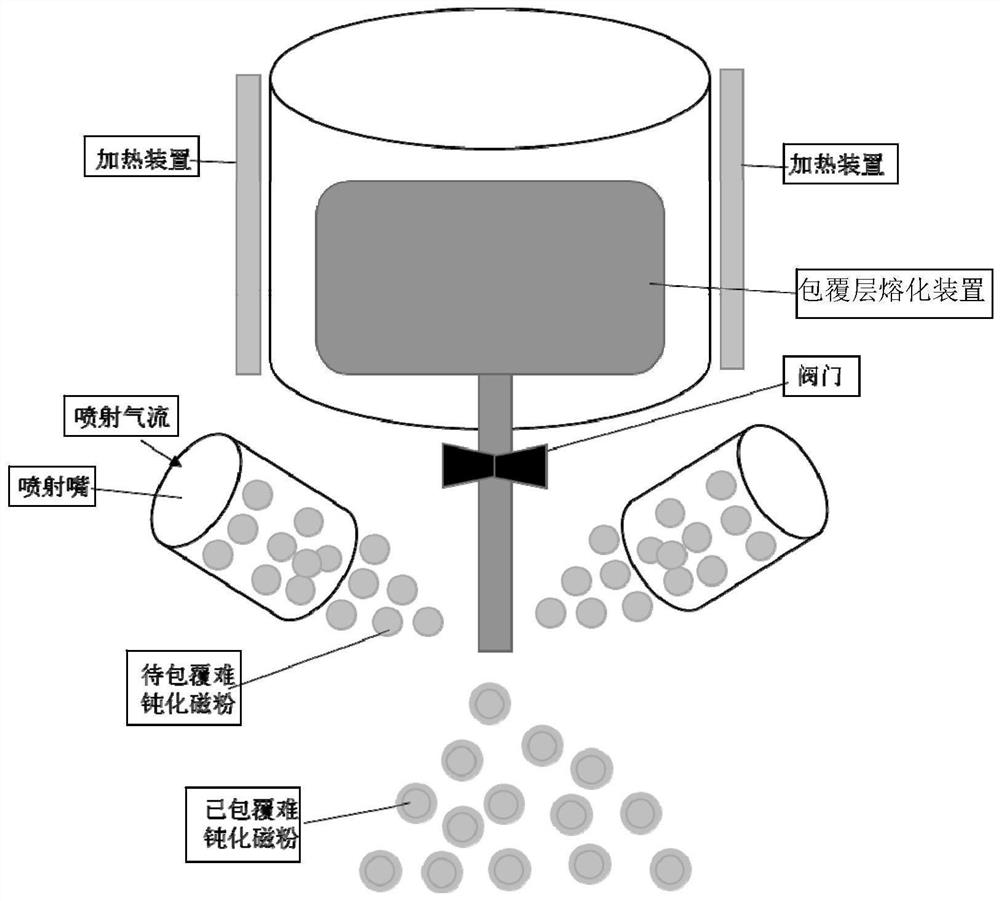

[0029] The application also provides a device used in the spray coating method, such as figure 2 As shown, the device includes a cladding layer melting device, a heating device for heating the cladding layer melting device and a hard-to-passivation magnetic powder spraying device located below the cladding layer melting device. The passivation magnetic powder spraying device sprays hard-to-passivate magnetic powder, and the coating layer melting device controls the outflow of molten easy-passivation magnetic powder through a valve, and the hard-to-passivation magnetic powder is coated by the easy-passivation magnetic powder.

[0030] How to use the device as figure 2 As shown, a. Turn on the heating device to melt the coating layer into a molten state; b. Put the hard-to-passivate magnetic powder to be coated into the related device of the injection nozzle; c. Open the valve to let the molten coating layer flow out, and open the Injection nozzle, so that the hard-to-passiva...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com