NdFeB magnet with low eddy current loss

A NdFeB magnet technology, applied in the direction of magnetic objects, magnetic materials, permanent magnets, etc., can solve the problems that hinder the reduction of the remanence cost of NdFeB magnets, demagnetization of NdFeB magnet materials, irreversible demagnetization of permanent magnets, etc. , to achieve the effect of improving the temperature rise of the rotor, improving the magnetic performance, and the slotting position is flexible and changeable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

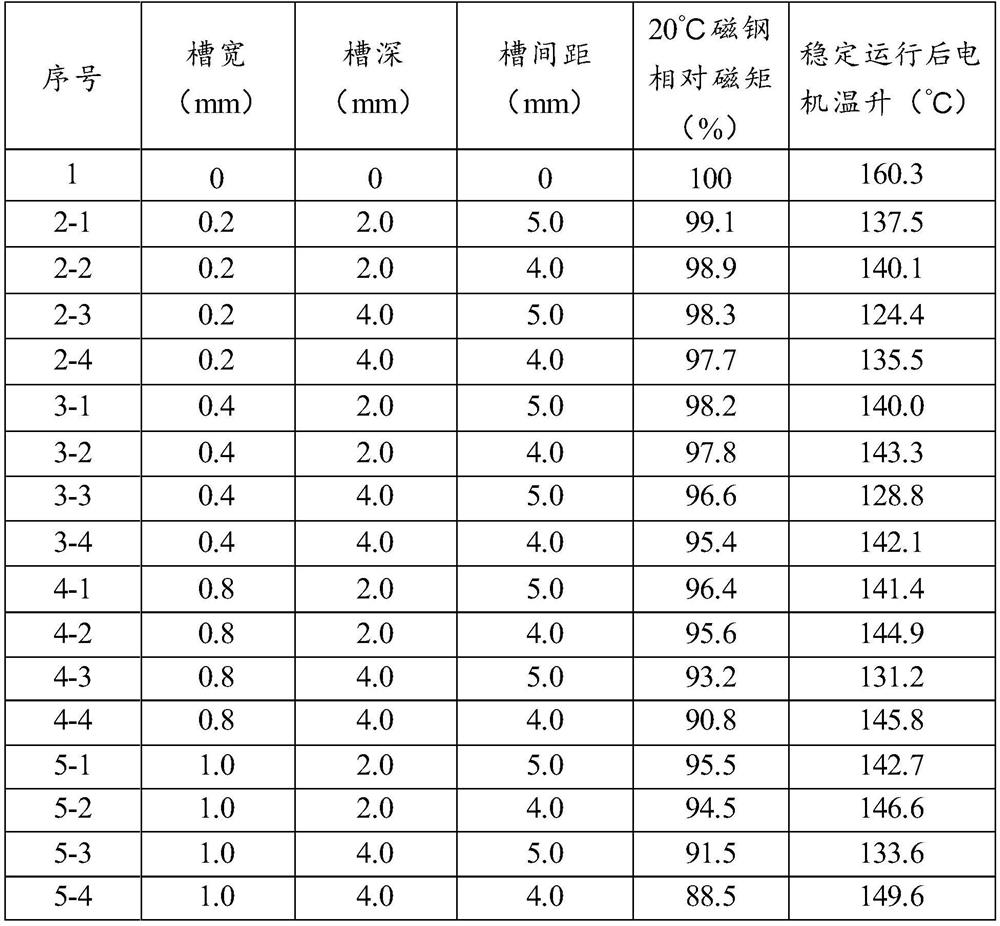

[0061] The present invention is to complete and refine the overall technical scheme, better ensure the performance of the NdFeB magnet, and improve its performance of reducing eddy current loss. The above NdFeB magnet and its preparation method preferably include the following contents:

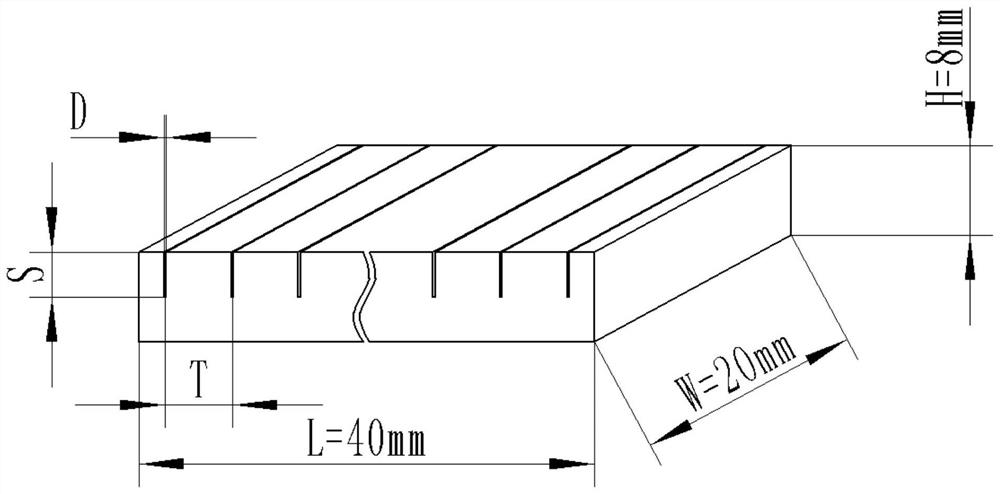

[0062] The present invention provides a method for preparing a slotted NdFeB magnet, comprising: slotting the surface of a NdFeB magnet square magnet that has not been infiltrated or a NdFeB square magnet that has been infiltrated; The number of surfaces is at least 1 and the number of slots is greater than zero, preferably the width of the slot is 0.05~1.0mm, the diameter of the opening is not zero, and the depth is (1 / 100~80 / 100)*H mm; (plane can pass through or not).

[0063] Specifically, the grooved surface may be on any one surface or multiple surfaces of the magnet, preferably one or two surfaces perpendicular to the orientation direction.

[0064] Specifically, the depth of the opene...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com