Metal-carbon composite particle and preparation method and application thereof

A carbon composite and particle technology, which is applied in metal processing equipment, carbon preparation/purification, nano-carbon, etc., can solve problems such as difficulty in meeting practical application requirements, impossibility of large-scale promotion and application, poor impedance matching performance, etc., and achieve excellent microwave Good absorption performance, weight reduction, and good impedance matching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A kind of Ni-C composite particle, its preparation method comprises the following steps:

[0037] 1) Disperse 3mmol of nickel chloride hexahydrate and 0.3g (1.428mmol) of trimesic acid in 60mL of solvent (by N,N-dimethylformamide, ethanol and water in a volume ratio of 1:1:1 composition), stir until the solids are completely dissolved, then transfer the material to a high-pressure reactor, react at 150°C for 10h, centrifuge, and wash the solid obtained by centrifugation with methanol for 3 times, and then dry it under vacuum at 70°C for 12h to obtain Ni base MOF;

[0038] 2) The Ni-based MOF was calcined at 500° C. for 3 h in a nitrogen atmosphere to obtain Ni-C composite particles.

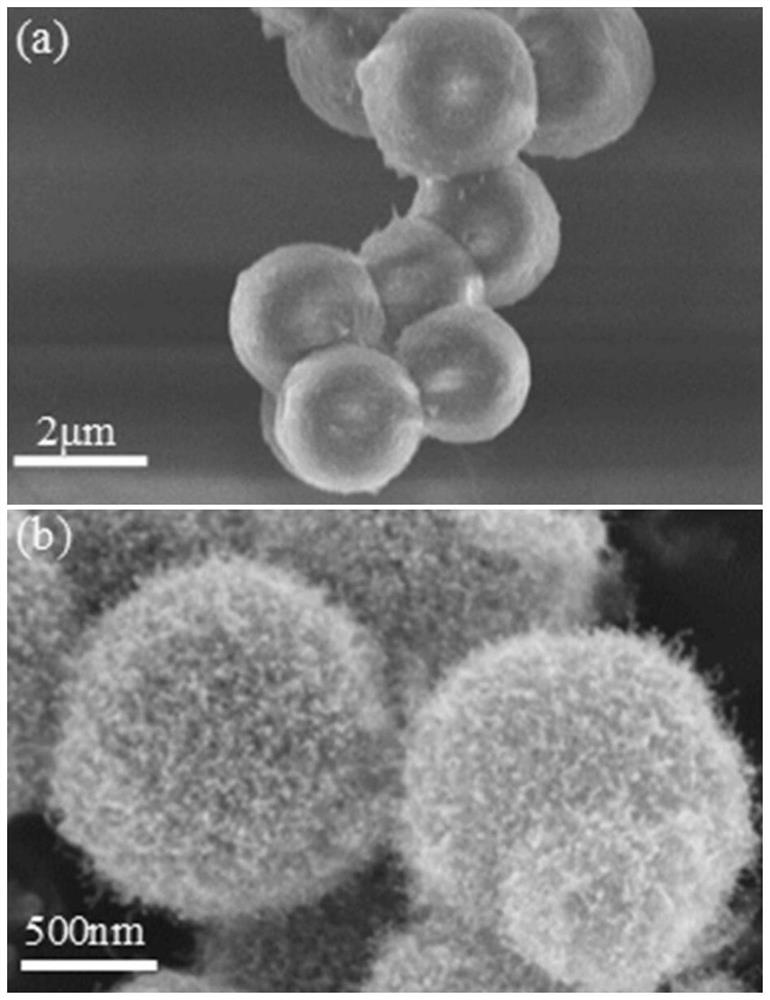

[0039] The scanning electron microscope (SEM) figure of Ni-based MOF and Ni-C composite particle in the present embodiment is as follows figure 1 (a is Ni-based MOF, b is Ni-C composite particles).

[0040] Depend on figure 1 It can be seen that the Ni-based MOF presents a smooth and c...

Embodiment 2

[0042] A kind of Ni-Co-C composite particle, its preparation method comprises the following steps:

[0043] 1) Disperse 2mmol of nickel chloride hexahydrate, 1mmol of cobalt chloride hexahydrate and 0.3g (1.428mmol) of trimesic acid in 60mL of solvent (made of N,N-dimethylformamide, ethanol and water According to the volume ratio of 1:1:1), stir until the solid is completely dissolved, then transfer the material to a high-pressure reactor, react at 150°C for 10h, centrifuge, and wash the solid obtained by centrifugation with methanol for 3 times, and then in a 70°C Drying under vacuum condition for 12h, to obtain Ni-Co-based MOF;

[0044] 2) The Ni-Co-based MOF was calcined at 500° C. for 3 h in a nitrogen atmosphere to obtain Ni-Co-C composite particles.

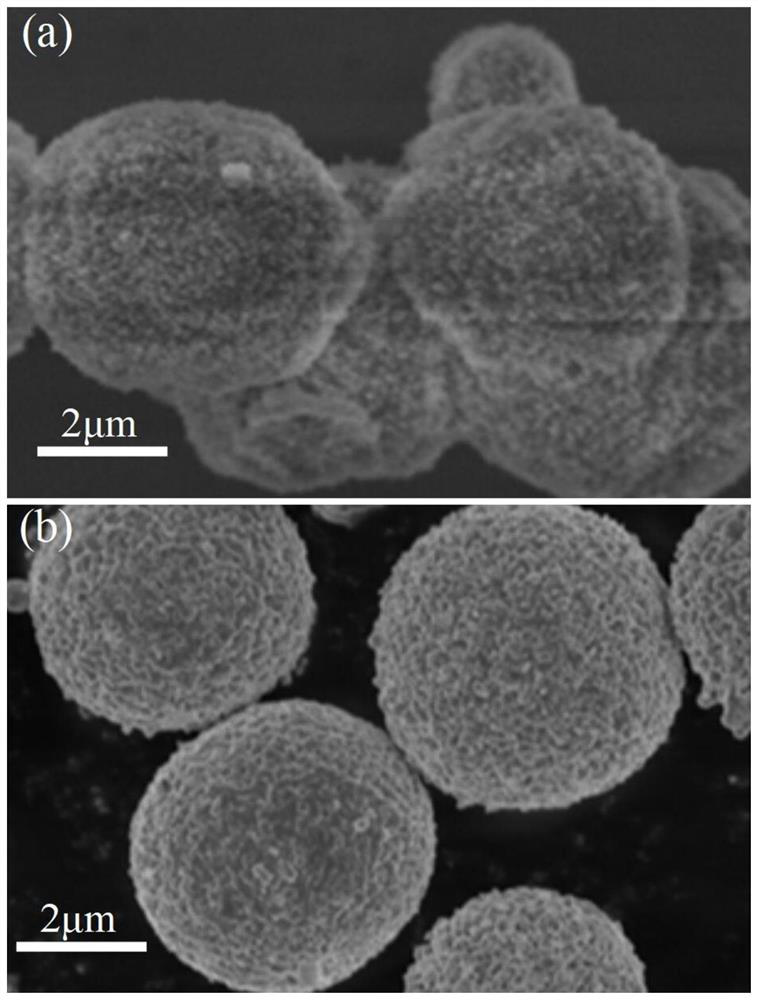

[0045] The SEM images of Ni-Co-based MOF and Ni-Co-C composite particles in this example are as follows figure 2 (a is Ni-Co-based MOF, b is Ni-Co-C composite particles).

[0046] Depend on figure 2 It can be seen tha...

Embodiment 3

[0048] A kind of Ni-Co-C composite particle, its preparation method comprises the following steps:

[0049] 1) Disperse 1.5mmol of nickel chloride hexahydrate, 1.5mmol of cobalt chloride hexahydrate and 0.3g (1.428mmol) of trimesic acid in 60mL of solvent (from N,N-dimethylformamide, ethanol and water according to the volume ratio of 1:1:1), stir until the solid is completely dissolved, then transfer the material to a high-pressure reactor, react at 150°C for 10h, centrifuge, and wash the solid obtained by centrifugation with methanol for 3 times, and then at 70 Dry under vacuum condition at ℃ for 12h to obtain Ni-Co-based MOF;

[0050] 2) The Ni-Co-based MOF was calcined at 500° C. for 3 h in a nitrogen atmosphere to obtain Ni-Co-C composite particles.

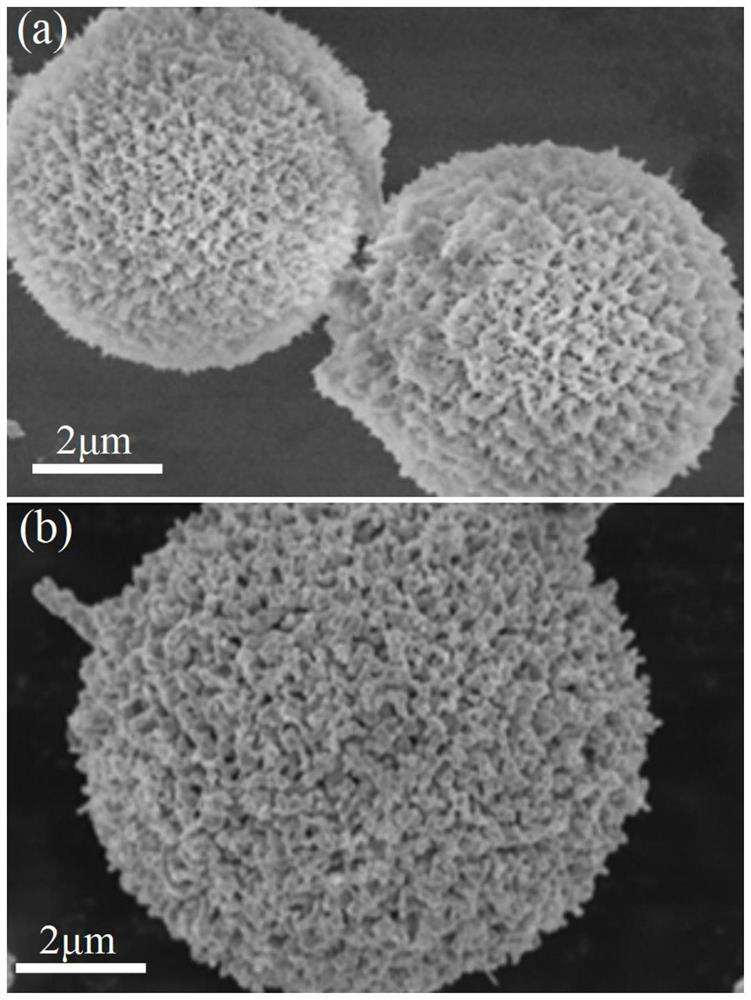

[0051] The SEM images of Ni-Co-based MOF and Ni-Co-C composite particles in this example are as follows image 3 (a is Ni-Co-based MOF, b is Ni-Co-C composite particles).

[0052] Depend on image 3 It can be seen that the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com