Epoxy resin glass fiber composite isolation protection material and application thereof in isolation protection of relay protection wiring terminal

A glass fiber and epoxy resin technology, which is applied to the components, circuits and connections of the connecting device, can solve the problems of heating contact resistance and affecting the safe operation of the terminals.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

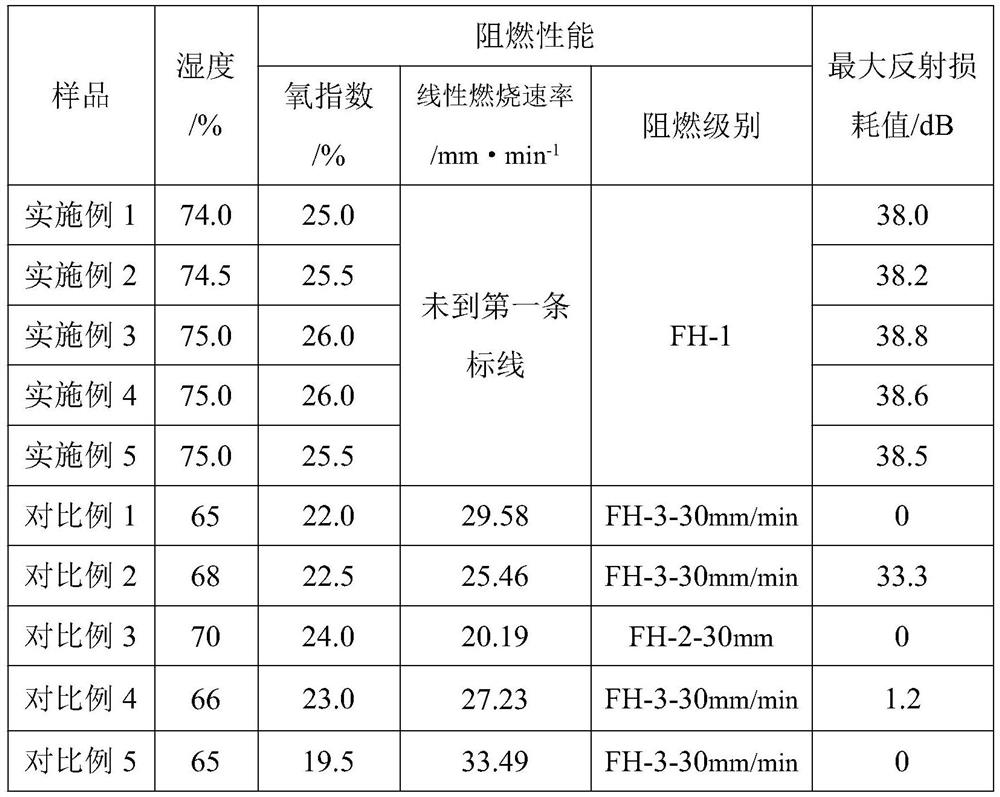

Embodiment 1

[0029] An epoxy resin glass fiber composite isolation and protection material is prepared from raw materials including the following parts by weight: 100 parts of epoxy resin, 10 parts of glass fiber, 12 parts of polyaniline-silicon carbide, 10 parts of magnesium hydroxide, 10 parts of hydroxide 25 parts of calcium, 5 parts of nano calcium carbonate, 20 parts of rare earth coupling agent, 7 parts of sodium dodecylbenzene sulfonate.

[0030] A preparation method of epoxy resin glass fiber composite isolation protection material, comprising the following steps:

[0031] (1) Mix and stir glass fiber, magnesium hydroxide, calcium hydroxide, and nano-calcium carbonate evenly, and then mix with rare earth coupling agent at 100 ° C for 10 minutes to carry out surface modification to obtain a modified mixture;

[0032](2) The sodium dodecylbenzene sulfonate and the aqueous hydrochloric acid solution are uniformly mixed and stirred for half an hour, then the aniline monomer is added an...

Embodiment 2

[0036] An epoxy resin glass fiber composite isolation and protection material is prepared from raw materials including the following parts by weight: 120 parts of epoxy resin, 11 parts of glass fiber, 10 parts of polyaniline-silicon carbide, 12 parts of magnesium hydroxide, 30 parts of calcium, 6 parts of nano calcium carbonate, 30 parts of rare earth coupling agent, 5 parts of sodium dodecylbenzene sulfonate.

[0037] A preparation method of epoxy resin glass fiber composite isolation protection material, comprising the following steps:

[0038] (1) Mix and stir glass fiber, magnesium hydroxide, calcium hydroxide, and nano-calcium carbonate evenly, and then mix with rare earth coupling agent at 105 ° C for 9 minutes to carry out surface modification to obtain a modified mixture;

[0039] (2) The sodium dodecylbenzene sulfonate and the aqueous hydrochloric acid solution are uniformly mixed and stirred for half an hour, then the aniline monomer is added and the stirring is cont...

Embodiment 3

[0043] An epoxy resin glass fiber composite isolation and protection material is prepared from raw materials including the following parts by weight: 130 parts of epoxy resin, 14 parts of glass fiber, 17 parts of polyaniline-silicon carbide, 21 parts of magnesium hydroxide, 28 parts of calcium, 8 parts of nano calcium carbonate, 40 parts of rare earth coupling agent, 6 parts of sodium dodecylbenzene sulfonate.

[0044] A preparation method of epoxy resin glass fiber composite isolation protection material, comprising the following steps:

[0045] (1) Mix and stir glass fiber, magnesium hydroxide, calcium hydroxide, and nano-calcium carbonate evenly, and then mix with rare earth coupling agent at 110 ° C for 8 minutes to carry out surface modification to obtain a modified mixture;

[0046] (2) The sodium dodecylbenzene sulfonate and the aqueous hydrochloric acid solution are uniformly mixed and stirred for half an hour, then the aniline monomer is added and the stirring is cont...

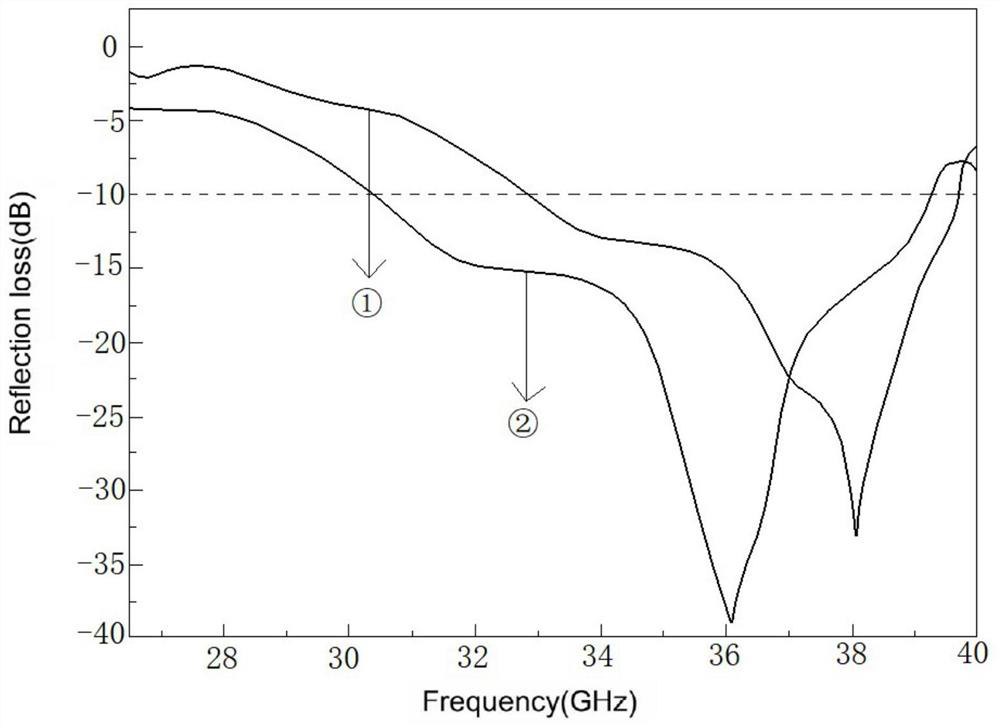

PUM

| Property | Measurement | Unit |

|---|---|---|

| Maximum reflection loss | aaaaa | aaaaa |

| Bandwidth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com