Cobalt-containing composite absorbing material and preparation method thereof

A composite wave-absorbing material and material liquid technology, which is applied in the field of cobalt-containing composite wave-absorbing materials and their preparation, can solve the problems of limiting the application of graphene wave-absorbing materials and narrow graphene absorption frequency bandwidth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The present invention also provides a preparation method of the composite wave absorbing material described in the above technical solution, which includes the following steps:

[0038] (1) Mixing ferric chloride, nano cobalt powder, surfactant, urea and ethylene glycol to obtain a mixed material liquid;

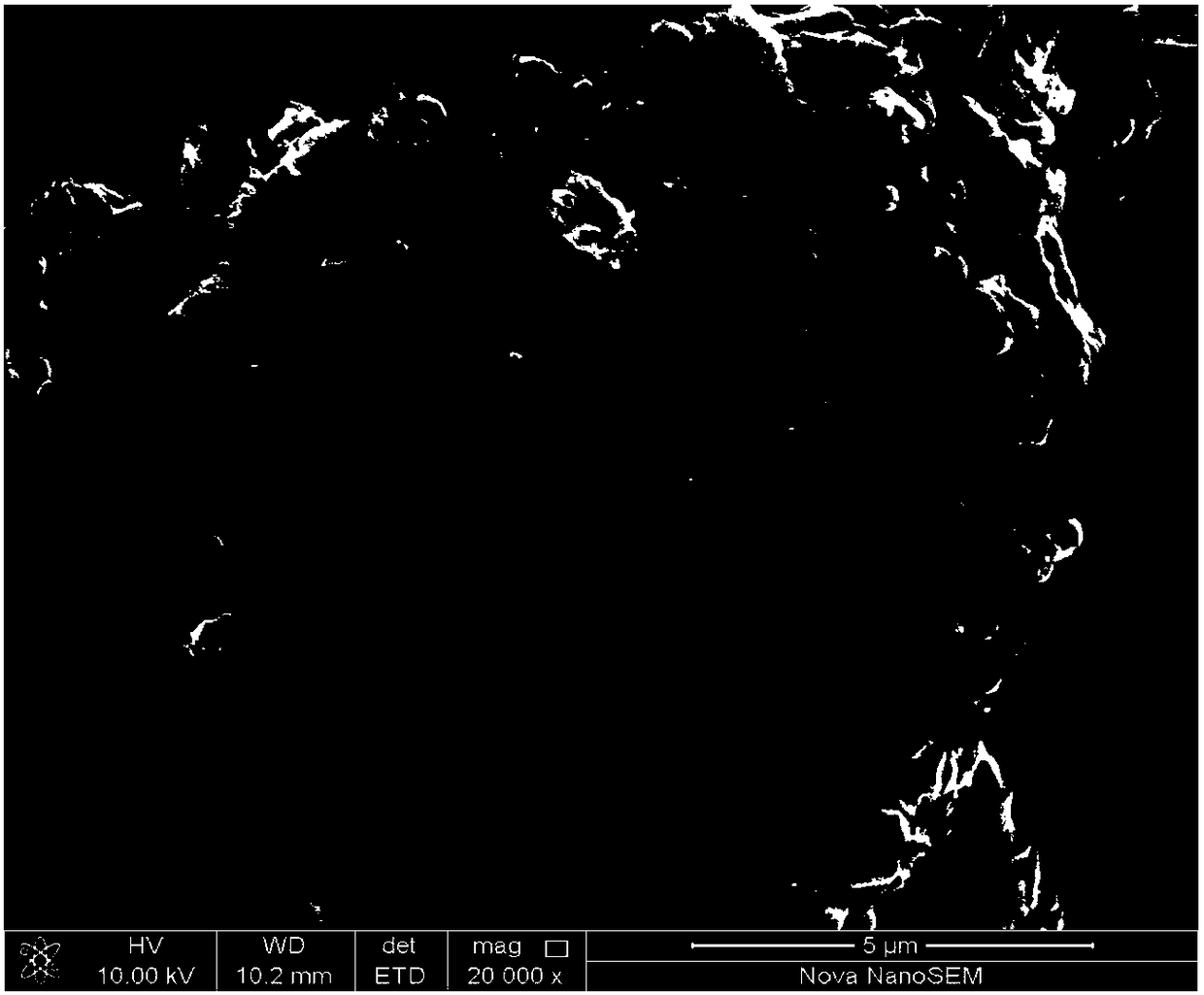

[0039] (2) Mix the mixed material liquid obtained in the step (1) with graphene oxide, and perform a hydrothermal reaction to obtain a hydrothermal reaction material liquid;

[0040] (3) Remove the supernatant of the hydrothermal reaction material liquid obtained in the step (2), and sequentially perform centrifugal washing and drying on the remaining material liquid to obtain a composite wave absorbing material.

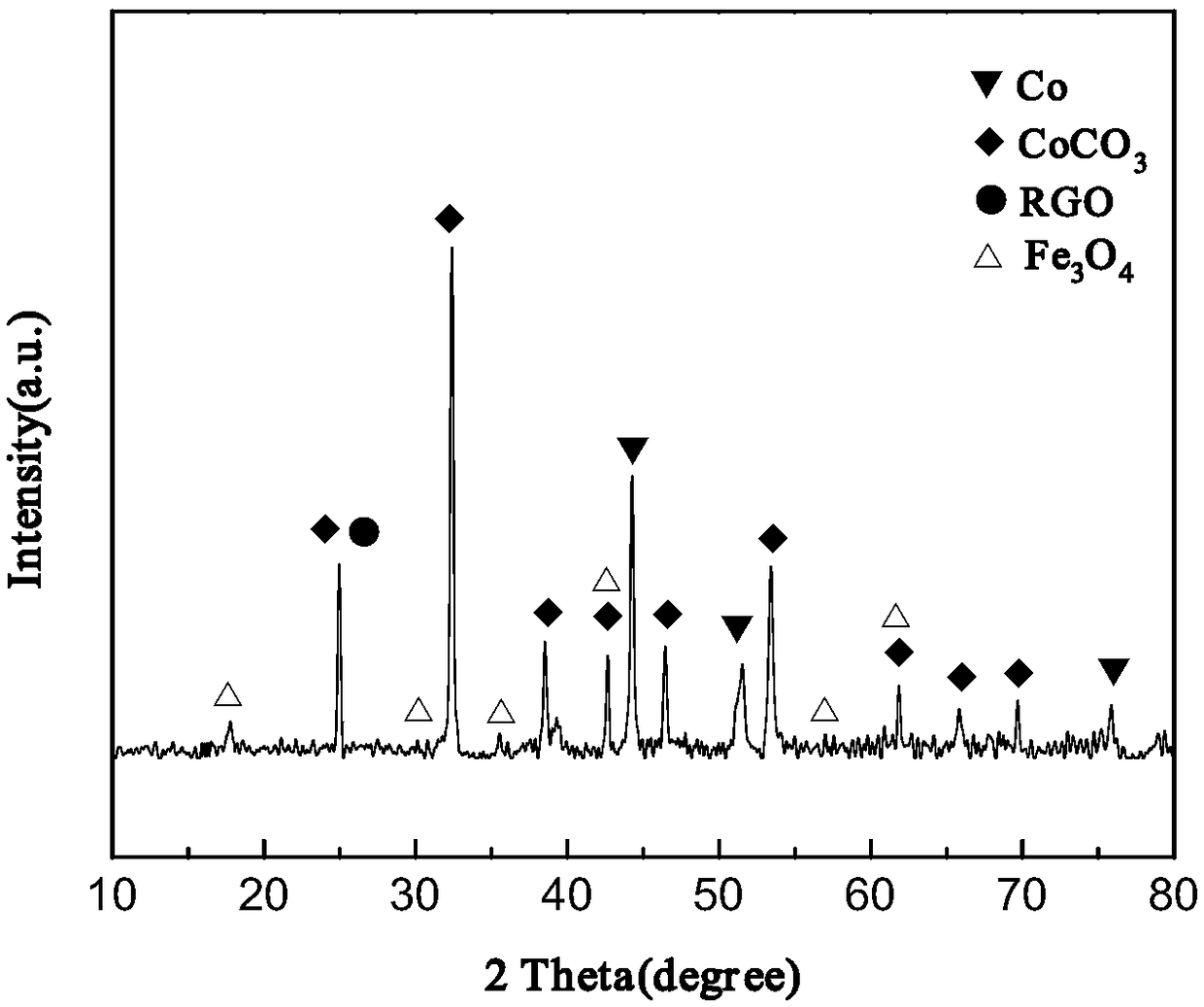

[0041] The invention mixes ferric chloride, nano cobalt powder, surfactant, urea and ethylene glycol to obtain a mixed material liquid. In the present invention, the particle size of the nano cobalt powder is consistent with the particle size of the nano cobalt in ...

Embodiment 1

[0061] According to the mass ratio of 1:3:2:110:18, weigh graphite powder, potassium permanganate, sodium nitrate, concentrated sulfuric acid and orthophosphoric acid. Among them, the mass of concentrated sulfuric acid is crushed to 98%, and the mass concentration of orthophosphoric acid is 1.685g / mL; Then, after ultrasonically mixing graphite powder, potassium permanganate, sodium nitrate, concentrated sulfuric acid and orthophosphoric acid to homogeneity, add the mixture to a polytetrafluoroethylene-lined autoclave, and keep it at 50℃ for 12h. . After the obtained product is cooled, hydrogen peroxide is slowly added to it at a rate of 10 mL / min (the mass fraction of hydrogen peroxide is 30%) according to the mass ratio of original graphite powder and hydrogen peroxide 1:2, and the liquid turns bright yellow. The mixed liquid after the reaction was washed with distilled water several times by centrifugation, the supernatant was discarded after each washing, and the remaining ...

Embodiment 2

[0068] According to the mass ratio of 1:2:1:90:10, weigh graphite powder, potassium permanganate, sodium nitrate, concentrated sulfuric acid and orthophosphoric acid. Among them, the mass of concentrated sulfuric acid is crushed to 98%, and the mass concentration of orthophosphoric acid is 1.685g / mL; Then, after ultrasonically mixing graphite powder, potassium permanganate, sodium nitrate, concentrated sulfuric acid and orthophosphoric acid to homogeneity, add the mixed solution to a polytetrafluoroethylene-lined autoclave, and keep it at 60℃ for 12h. . After the obtained product is cooled, hydrogen peroxide is slowly added to it at a rate of 10 mL / min (the mass fraction of hydrogen peroxide is 30%) according to the mass ratio of original graphite powder and hydrogen peroxide 1:2, and the liquid turns bright yellow. The mixed liquid after the reaction was washed with distilled water several times by centrifugation, the supernatant was discarded after each washing, and the rema...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

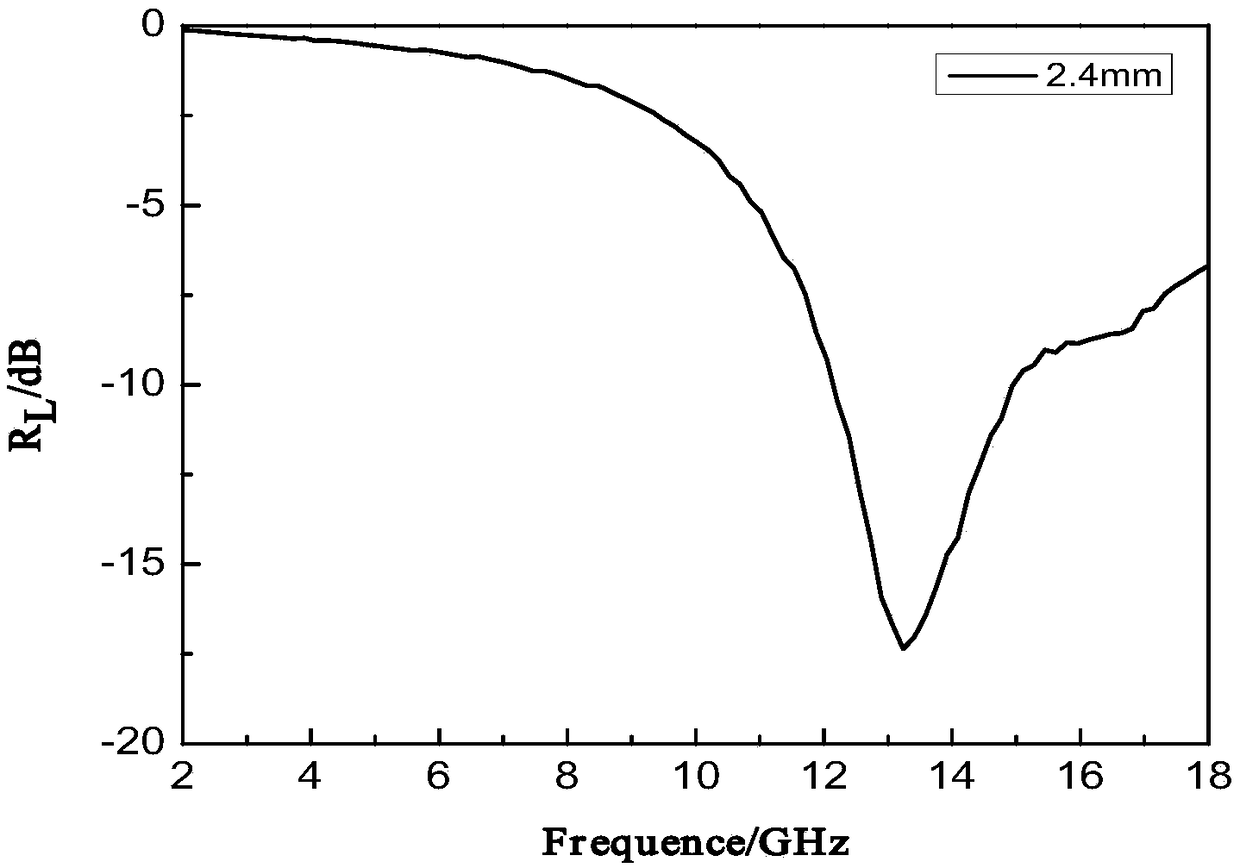

| Maximum reflection loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com