Magnetic fluid sieving device

A screening device and magneto-fluid technology, applied in high-gradient magnetic separators and other directions, can solve the problems of poor separation effect and high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

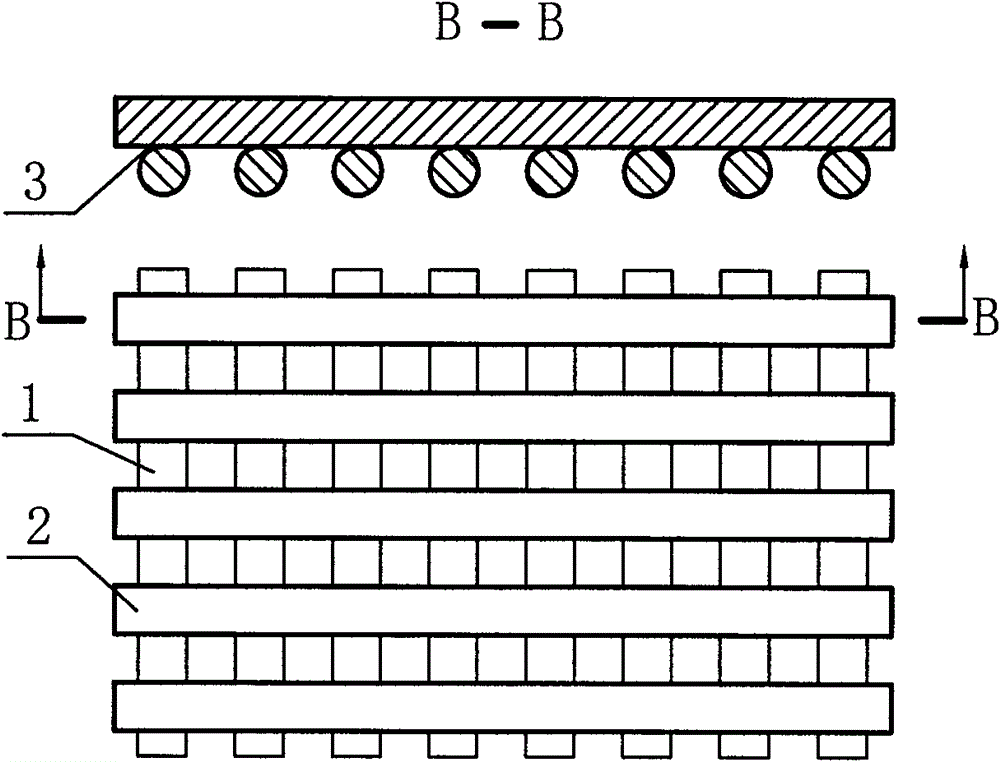

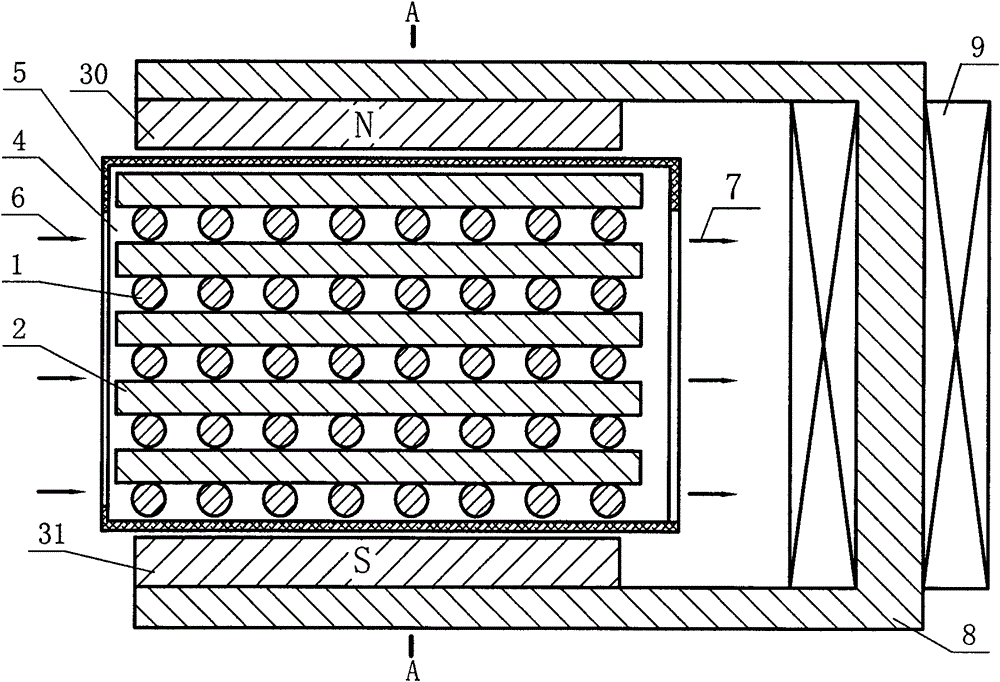

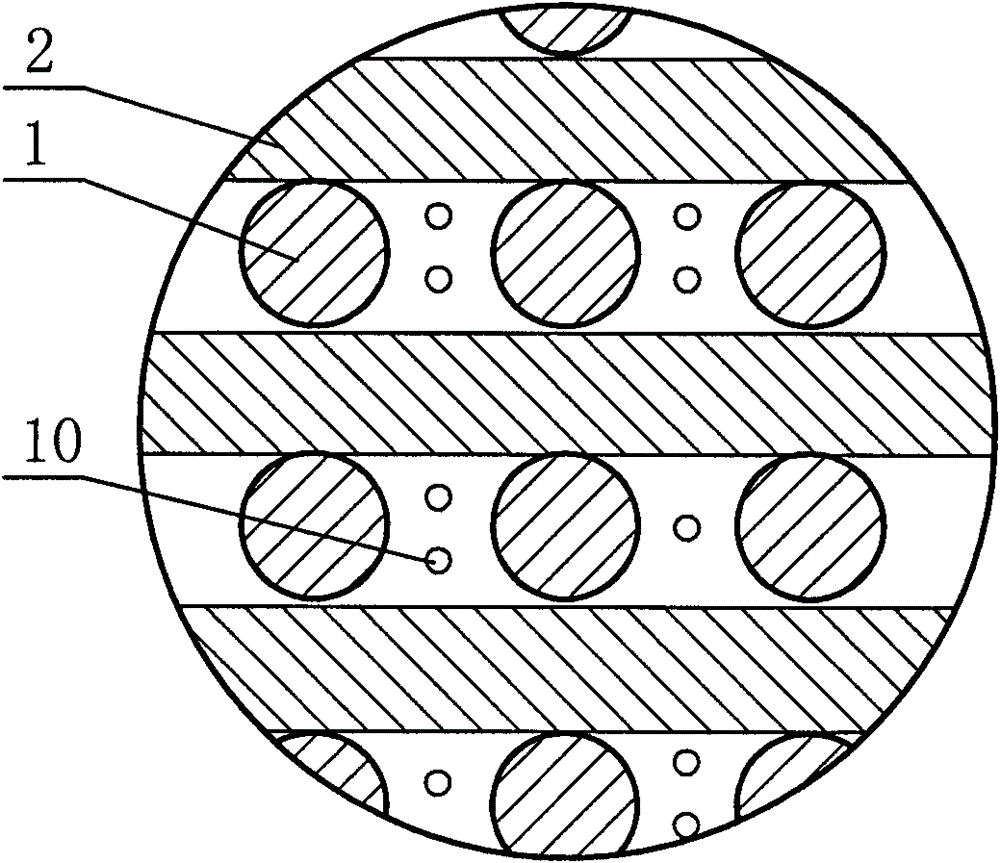

[0018] combine figure 1 , the non-magnetic conductive wire 1 and the magnetic conductive wire 2 are nearly orthogonally stacked, and the screen mesh of the fluid separation screen is formed after welding or bonding at the intersection point 3 . The magnetically conductive wires and the non-magnetically conductive wires in the screen are in their respective planes. The magnetically conductive wires are made of magnetically conductive metal materials, and the nonmagnetically conductive wires can be made of nonmagnetic metal materials or non-metallic materials, such as fiber reinforced plastics. When selecting metal materials, materials with high resistivity should be selected, otherwise large eddy current losses will occur. exist figure 2 , image 3 , Figure 4 , Figure 5 Among them, the magnetic circuit of the magnetically conductive material 8 provides a magnetic potential by the exciting coil 9, and the multi-sheet screens stacked in the non-magnetically conductive she...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com