Asphalt pavement material rapidly restored through microwave heating

A technology of asphalt pavement and microwave heating, which is applied in the direction of sustainable waste treatment, solid waste management, climate sustainability, etc. It can solve the problems of low microwave absorption rate of asphalt mixture, expensive microwave absorber, and low efficiency of asphalt pavement , to achieve the effects of shortening microwave heating time, enhancing microwave absorption efficiency, and reducing microwave power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

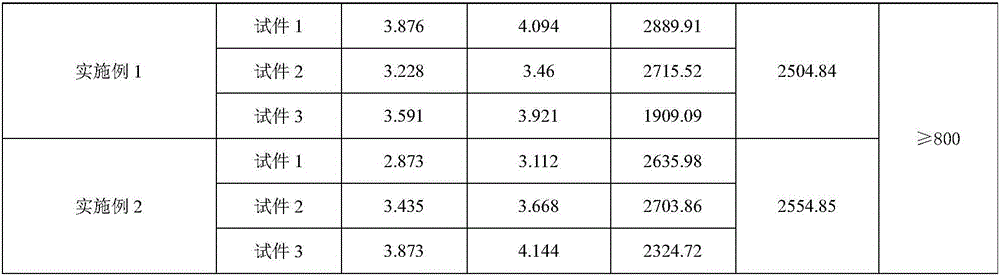

Embodiment 1

[0026] In the first step, ordinary steel slag is converted into modified steel slag by co-precipitation method.

[0027] ① Weigh Fe with an electronic balance 2 o 3 Mass fraction is 20 parts of common steel slag of 20%, pours in the beaker;

[0028] 2. measure a certain amount of concentrated hydrochloric acid (hydrochloric acid concentration is 12mol / L) according to the steel slag amount taken by weighing; then hydrochloric acid is poured in the beaker that steel slag is housed;

[0029] ③According to the amount of concentrated hydrochloric acid, weigh the corresponding amount of FeCl 2 , the solid FeCl 2 Prepared into a 5mol / L solution;

[0030] ④The prepared FeCl 2 The solution is poured into a beaker containing steel slag and hydrochloric acid;

[0031] ⑤According to the amount of hydrochloric acid added, determine the amount of ammonia water, taking into account the resulting Fe 3 o 4 As much as possible, so the amount of ammonia water is between 1.5-2 times the t...

Embodiment 2

[0036] The first step is to convert ordinary steel slag into modified steel slag by carbon reduction method.

[0037] ① Select Fe 2 o 3 Ordinary steel slag with a mass fraction of 20%, according to the above reaction equation, the mass ratio of activated carbon and steel slag in the reaction process is 1:200. Weigh activated carbon and steel slag of appropriate quality according to the mass ratio of activated carbon and steel slag, and place them in a vacuum high-temperature electric furnace;

[0038] ②Pass nitrogen to isolate oxygen or air, heat the raw materials, and the reaction time is 30 minutes to make them fully react;

[0039] ③Repeat the above steps to convert enough steel slag fine aggregate.

[0040] In the second step, the obtained steel slag fine aggregates are screened to obtain fine aggregates that meet the gradation requirements. Select 90# matrix asphalt, basalt coarse aggregate, limestone powder and modified steel slag fine aggregate, and form asphalt mix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com