A preparation method of reduced graphene oxide/nickel oxide composite wave-absorbing material

A technology of composite materials and absorbing materials, applied in chemical instruments and methods, other chemical processes, etc., to achieve the effect of improving reflection loss, reducing quality, and achieving impedance matching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] 1. Preparation of graphene oxide

[0031] Graphene oxide was prepared by the modified Hummers method as the precursor of composite absorbing materials.

[0032] Concrete preparation method is: take the graphite of 3g, mix with the sodium nitrate of 1.5g, measure the sulfuric acid of 150mL and slowly add in the above-mentioned solid, ice bath and slowly add the potassium permanganate of 9.0g under magnetic stirring, this process Continue for about 2 hours; remove the ice bath, bathe in 35°C water for about 5 days, slowly add 140mL of water, then add 350mL of water after 30 minutes, slowly add 20mL of 30% hydrogen peroxide, the solution gradually turns dark yellow; centrifuge the above solution And washed several times with water, the lower layer was taken and ultrasonicated for 2 hours, then centrifuged at 8000 rpm to get the upper layer, dialyzed for 15 days, and freeze-dried.

[0033] 1. Preparation of graphene oxide / nickel acetate mixture

[0034] (1) Weigh 100mg of...

Embodiment 2

[0041] 1, the preparation of graphene oxide is the same as embodiment 1.

[0042] 2. Preparation of graphene oxide / nickel acetate mixture

[0043] (1) Weigh 100mg of graphene oxide, ultrasonically disperse it in 50mL of water, and prepare a 2mg / mL aqueous solution;

[0044] (2) Weigh 100 mg of nickel acetate tetrahydrate, add to the above solution under magnetic stirring and fully dissolve;

[0045] (3) After fully dissolving, sonicate for half an hour;

[0046] (4) The obtained mixed solution was frozen and then dried.

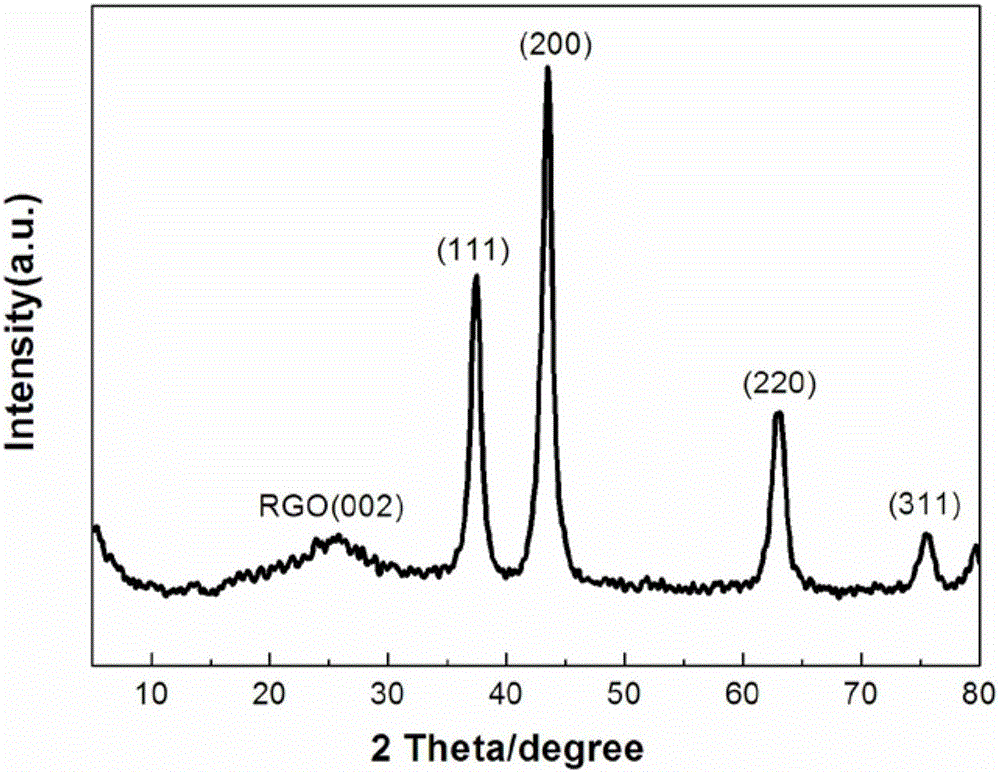

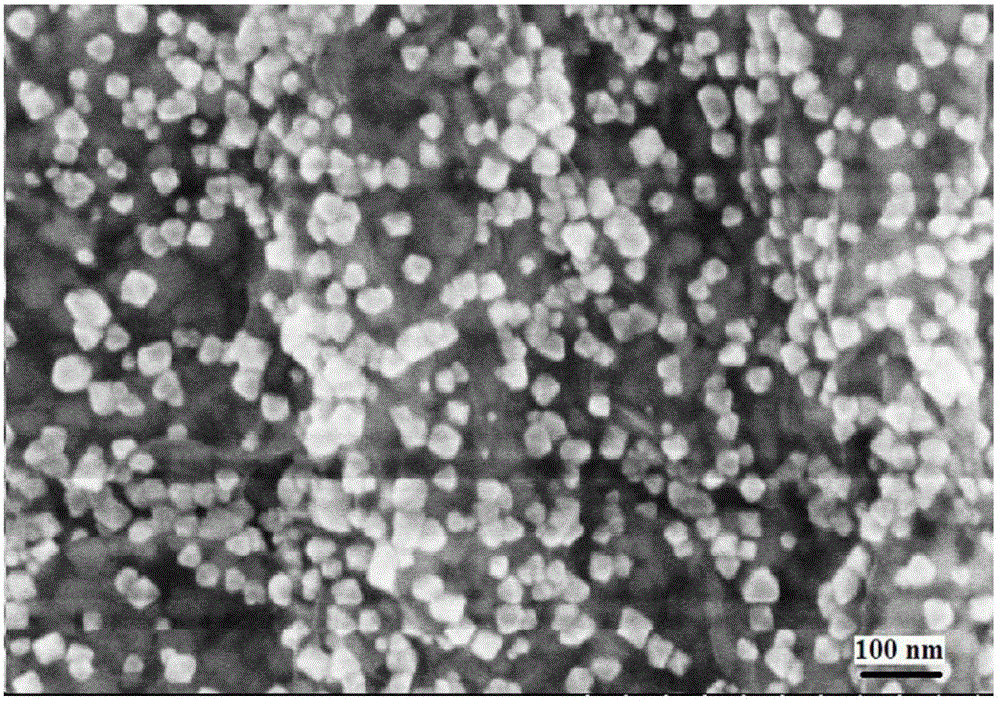

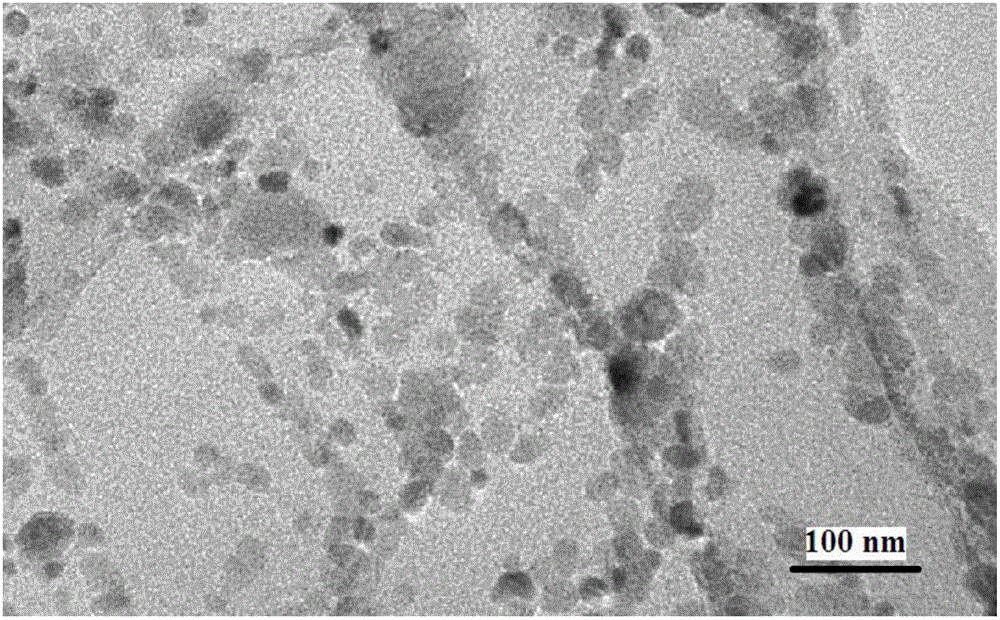

[0047] 3. Preparation of graphene oxide / nickel oxide composite absorbing material

[0048] The above freeze-dried graphene oxide / nickel acetate mixture was taken out, put into a porcelain boat, and heated in an argon atmosphere of a tube furnace. The heating rate was 5°C / min, and when the temperature was raised to 400°C, the temperature was kept for 2 hours, and then the temperature was lowered at a rate of 5°C / min. After cooling down to room temperature...

Embodiment 3

[0050] 1, the preparation of graphene oxide is the same as embodiment 1.

[0051] 2. Preparation of graphene oxide / nickel acetate mixture

[0052](1) Weigh 100mg of graphene oxide, ultrasonically disperse it in 50mL of water, and prepare a 2mg / mL aqueous solution;

[0053] (2) Weigh 50 mg of nickel acetate tetrahydrate, add to the above solution under magnetic stirring and fully dissolve;

[0054] (3) After fully dissolving, sonicate for half an hour;

[0055] (4) The obtained mixed solution was frozen and then dried.

[0056] 3. Preparation of graphene oxide / nickel oxide composite absorbing material

[0057] The above freeze-dried graphene oxide / nickel acetate mixture was taken out, put into a porcelain boat, and heated in an argon atmosphere of a tube furnace. The heating rate was 3°C / min, and when the temperature was raised to 600°C, the temperature was kept for 2 hours, and then the temperature was lowered at a rate of 3°C / min. After cooling down to room temperature, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com