Double-layer cement-based wave-absorbing material with adjustable wave-absorbing performance and its application method

A technology of wave absorbing material and wave absorbing performance, which is applied in the field of double-layer cement-based wave absorbing material, can solve the problems that the wave absorbing performance of cement-based material can not meet the actual needs, the electromagnetic environment is complicated and fixed, and the application field can be broadened. and value, improving the absorbing frequency band, and the effect of flexible regulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

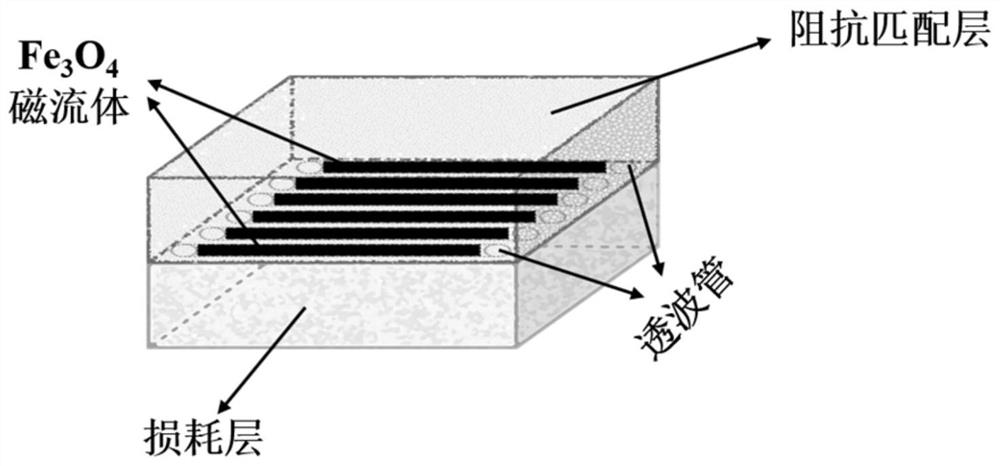

[0025] The present embodiment uses a cementitious material, a glass fiber tube and a nano Fe 3 O 4 As the main raw material, the specific preparation methods include:

[0026] (1) Will be nano Fe 3 O 4 Magnetic fluid is injected into a fiberglass tube and then sealed with resin for backup;

[0027] (2) Vitrified beads and cement dry mixed for 3min; Then add water to stir to get an impedance matching layer; Among them, the amount of vitrified beads is 10%, and the water-to-ash ratio is 0.35;

[0028](3) First dry mix cement and toner for 3min; Then prepare the absorption layer according to the preparation process of standard mortar, where the single-stage sand distribution (1.5~2.5mm) dosage is 300%, the toner dosage is 3%, and the water-ash ratio is 0.4;

[0029] (4) Using the method of layered pouring, first pouring the absorption layer 20mm, and then pouring the impedance matching layer 10mm to obtain a double-layer cement-based absorbing material; Wherein the upper and lower la...

Embodiment 2

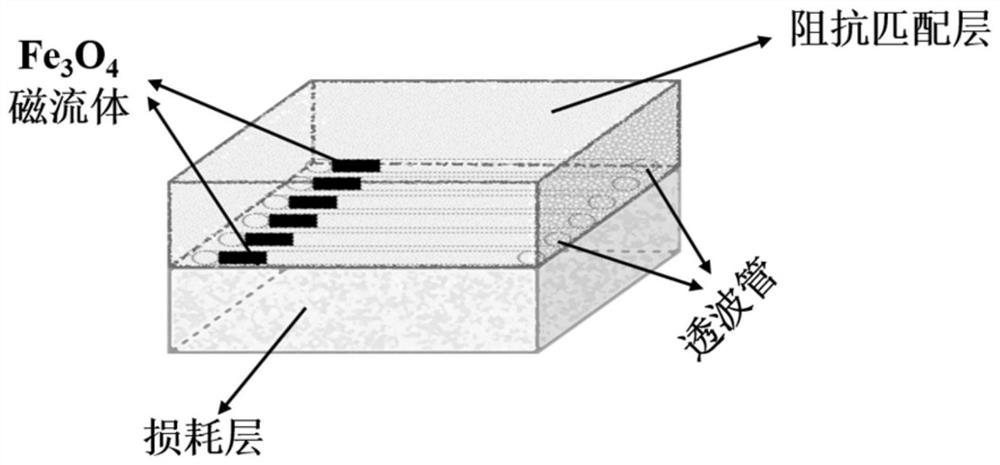

[0031] The present embodiment uses a cementitious material, a glass fiber tube and a nano Fe 3 O 4 As the main raw material, the specific preparation methods include:

[0032] (1) Will be nano Fe 3 O 4 Magnetic fluid is injected into a fiberglass tube and then sealed with resin for backup;

[0033] (2) Vitrified beads and cement dry mixed for 3min; Then add water to stir to get an impedance matching layer; Among them, the amount of vitrified beads is 10%, and the water-to-ash ratio is 0.35;

[0034] (3) First dry mix cement and toner for 3min; Then prepare the absorption layer according to the preparation process of standard mortar, where the single-stage sand distribution (1.5~2.5mm) dosage is 300%, the toner dosage is 3%, and the water-ash ratio is 0.4;

[0035] (4) Using the method of layered pouring, first pour the absorption layer 10mm, and then pour the impedance matching layer 20mm to obtain a double-layer cement-based absorbing material; Where the upper and lower layers ar...

Embodiment 3

[0037] The present embodiment uses a cementitious material, a glass fiber tube and a nano Fe 3 O 4 As the main raw material, the specific preparation methods include:

[0038] (1) Will be nano Fe 3 O 4 Magnetic fluid is injected into a fiberglass tube and then sealed with resin for backup;

[0039] (2) Vitrified beads and cement dry mixed for 3min; Then add water to stir to get an impedance matching layer; Among them, the amount of vitrified microbeads is 5%, and the water-ash ratio is 0.35;

[0040] (3) First dry mix cement and toner for 3min; Then prepare the absorption layer according to the preparation process of standard mortar, where the single-stage sand distribution (1.5~2.5mm) dosage is 300%, the toner dosage is 3%, and the water-ash ratio is 0.4;

[0041] (4) Using the method of layered pouring, first pour the absorption layer 10mm, and then pour the impedance matching layer 20mm to obtain a double-layer cement-based absorbing material; Where the upper and lower layers a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com