Composite microwave absorber and preparation method thereof

A microwave absorber and carbon nanofiber technology, which is applied in chemical instruments and methods, other chemical processes, textiles and papermaking, etc., can solve the problems of high energy consumption in the preparation process, unsatisfactory microwave performance, and low output, and achieve process performance. Low energy consumption, light weight, and improved absorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] On the other hand, the embodiment of the present invention also provides a preparation method of the composite microwave absorber, comprising the following steps:

[0042] S1. The carbon nanofibers are collected by centrifugation after acidification treatment, washed repeatedly and then dried; in specific implementation, during the acidification treatment process of the carbon nanofibers, the concentration of the carbon nanofibers in the acid is 2-6 mg / mL;

[0043] S2. Disperse the acidified carbon nanofibers in methanol solution, add methanol solution of cobalt nitrate, and magnetically stir; in the specific implementation process, the above dispersion process can be combined with ultrasonic action to promote dispersion;

[0044] S3. Under the condition of magnetic stirring, add a methanol solution of 2-methylimidazole to the mixed solution in step S2, centrifuge after the reaction is completed, and then use methanol to wash repeatedly and then dry; in the process of sp...

Embodiment 1

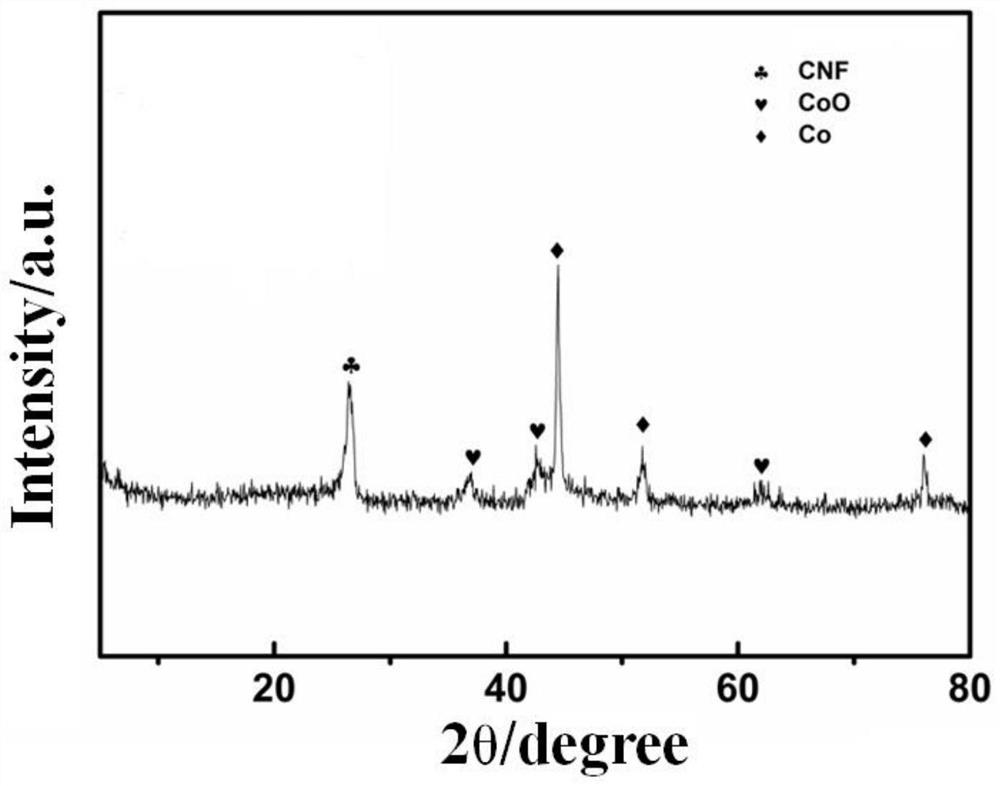

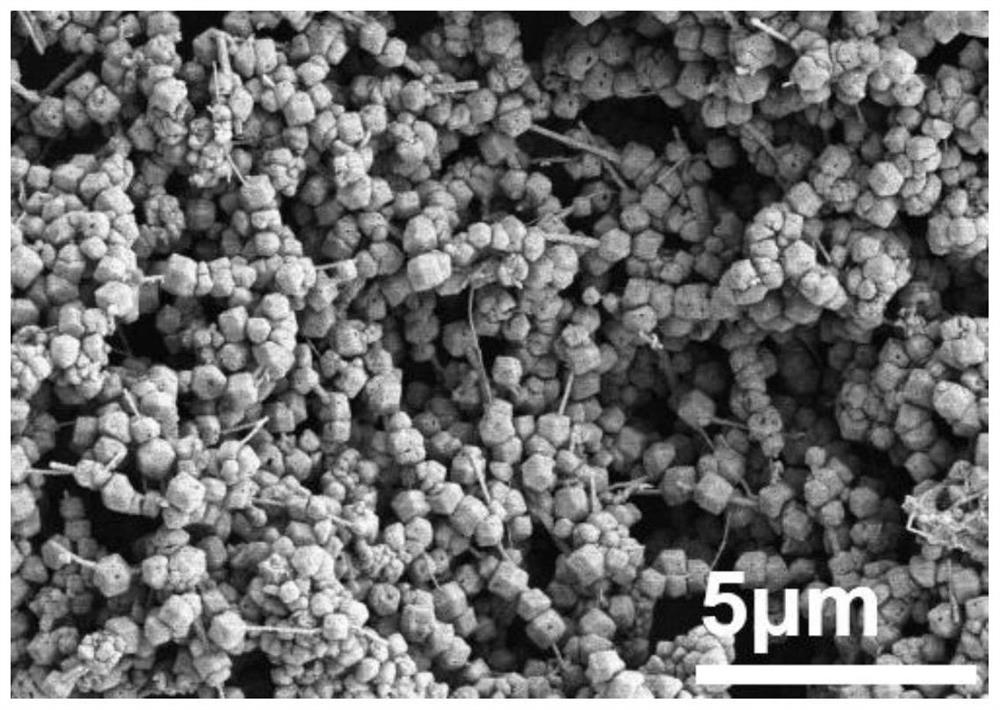

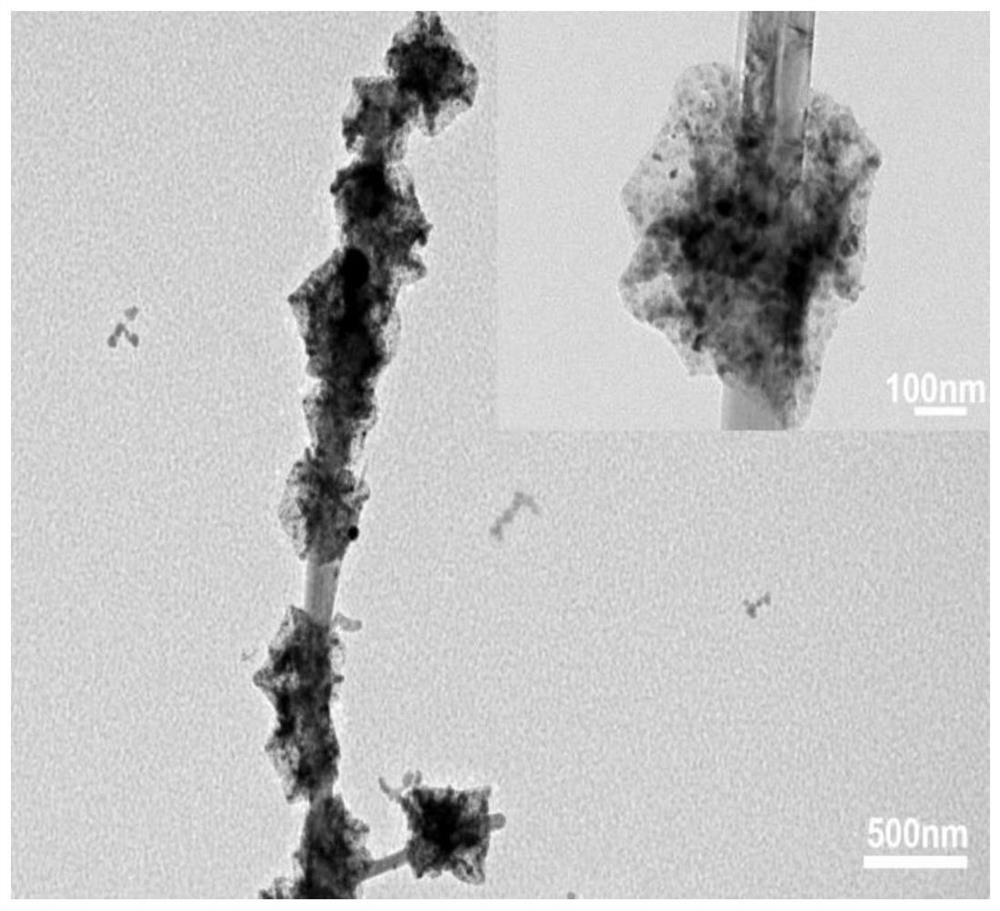

[0060] Example 1: Weigh 5g of carbon nanofibers, measure 1250mL of concentrated nitric acid and slowly add to the above solid, stir magnetically in a water bath at 90°C for 0.5h, cool and stir at room temperature for 2 hours; collect by centrifugation and vacuum dry to obtain acidified carbon Nanofibers. Weigh the acidified carbon nanofibers, and ultrasonically disperse them in methanol to obtain a methanol solution of carbon nanofibers with a concentration of 1mg / mL; configure 75mL of methanol solution of 70mM cobalt nitrate, and add to the methanol solution of carbon nanofibers under magnetic stirring The above solution was stirred for 1 hour; 50 mL of a methanol solution of 2-methylimidazole with a concentration of 300 mM was added under magnetic stirring conditions, and then reacted for 24 hours; the solid was collected by centrifugation, washed with methanol several times and then dried in vacuum to obtain carbon nanofibers @ZIF- 67. Put the above vacuum-dried carbon nan...

Embodiment 2

[0063] Example 2: Weigh 5g of carbon nanofibers, measure 1000mL of concentrated nitric acid and slowly add to the above solid, stir magnetically in a water bath at 85°C for 1 hour, and cool and stir at room temperature for 2 hours; collect by centrifugation and vacuum-dry to obtain acidified carbon nanofibers fiber. Weigh the carbon nanofibers after acidification, and ultrasonically disperse them in methanol to obtain a methanol solution of carbon nanofibers with a concentration of 2 mg / mL; 75 mL of a methanol solution of 100 mM cobalt nitrate is added to the methanol solution of carbon nanofibers under magnetic stirring. solution and stirred for 1 hour; under magnetic stirring conditions, add 50 mL of 2-methylimidazole methanol solution with a concentration of 200 mM, and react for 20 hours; collect samples by centrifugation, wash with methanol several times, and freeze-dry to obtain carbon nanofibers @ZIF-67 . The above freeze-dried carbon nanofibers @ZIF-67 were put into a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com