Multi-window silicon steel sheet structure and electronic equipment

A silicon steel sheet, multi-window technology, used in circuits, electrical components, transformer/inductor cooling, etc., can solve problems such as equipment efficiency decline, material loss, heat generation, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] There are two assembly forms of the existing silicon steel sheet structure, including single window and double window. However, for the two existing silicon steel sheet structures, it is obviously unreasonable to uniformly use one iron core structure regardless of high-power or low-power applications. Under the existing silicon steel sheet structure, the electric power continues to increase, which is equivalent to the continuous improvement of the electrical parameters, and the electric field strength, current strength, and magnetic field strength are all doubled or hundreds of times improved. The consequence of continuous improvement of parameters is that the tolerance limit of the material is continuously overdrawn, resulting in severe heat generation, serious loss of materials, and a continuous decline in the efficiency of the entire equipment.

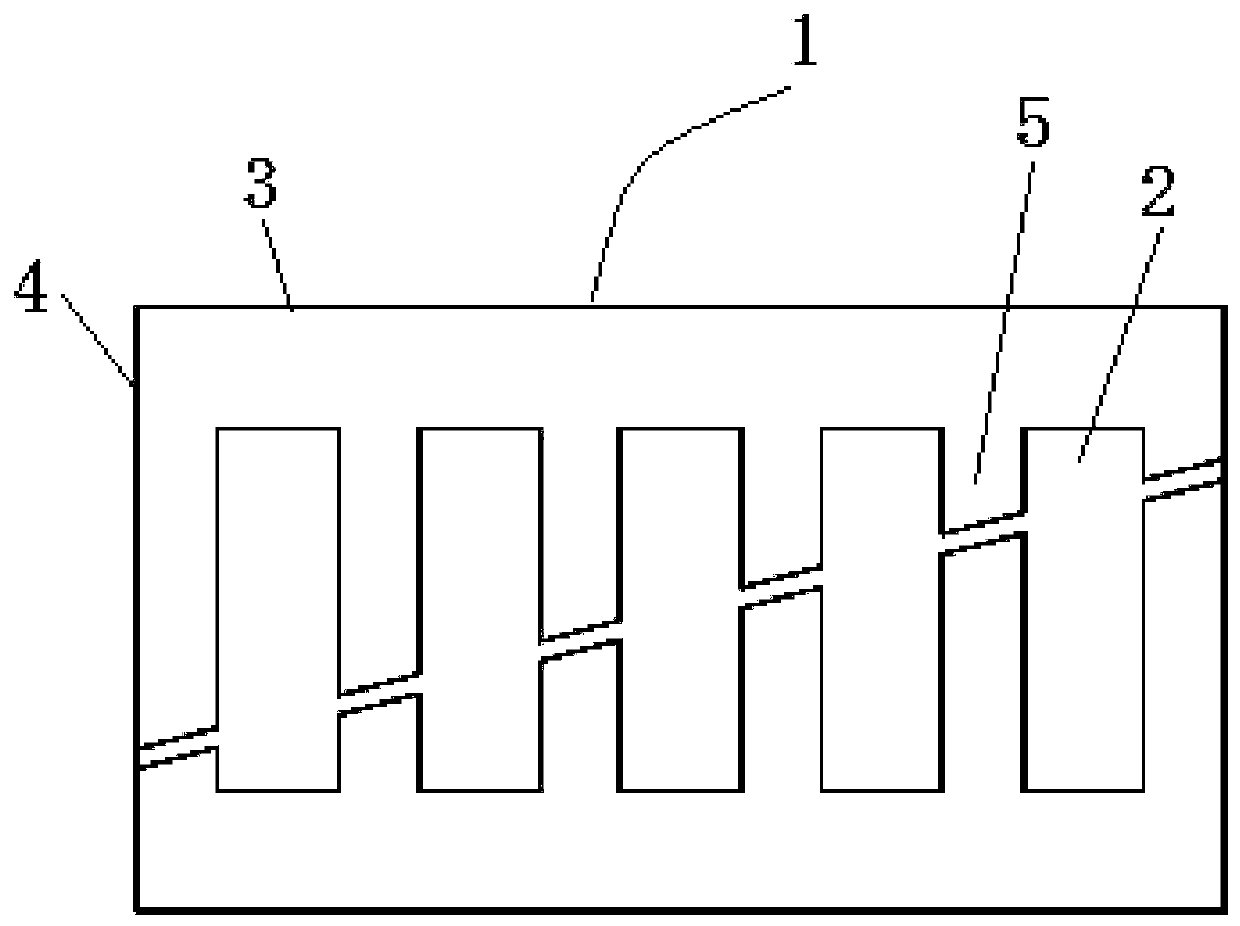

[0031] In order to solve the above technical problems, this embodiment provides a multi-window type silicon steel sheet st...

Embodiment 2

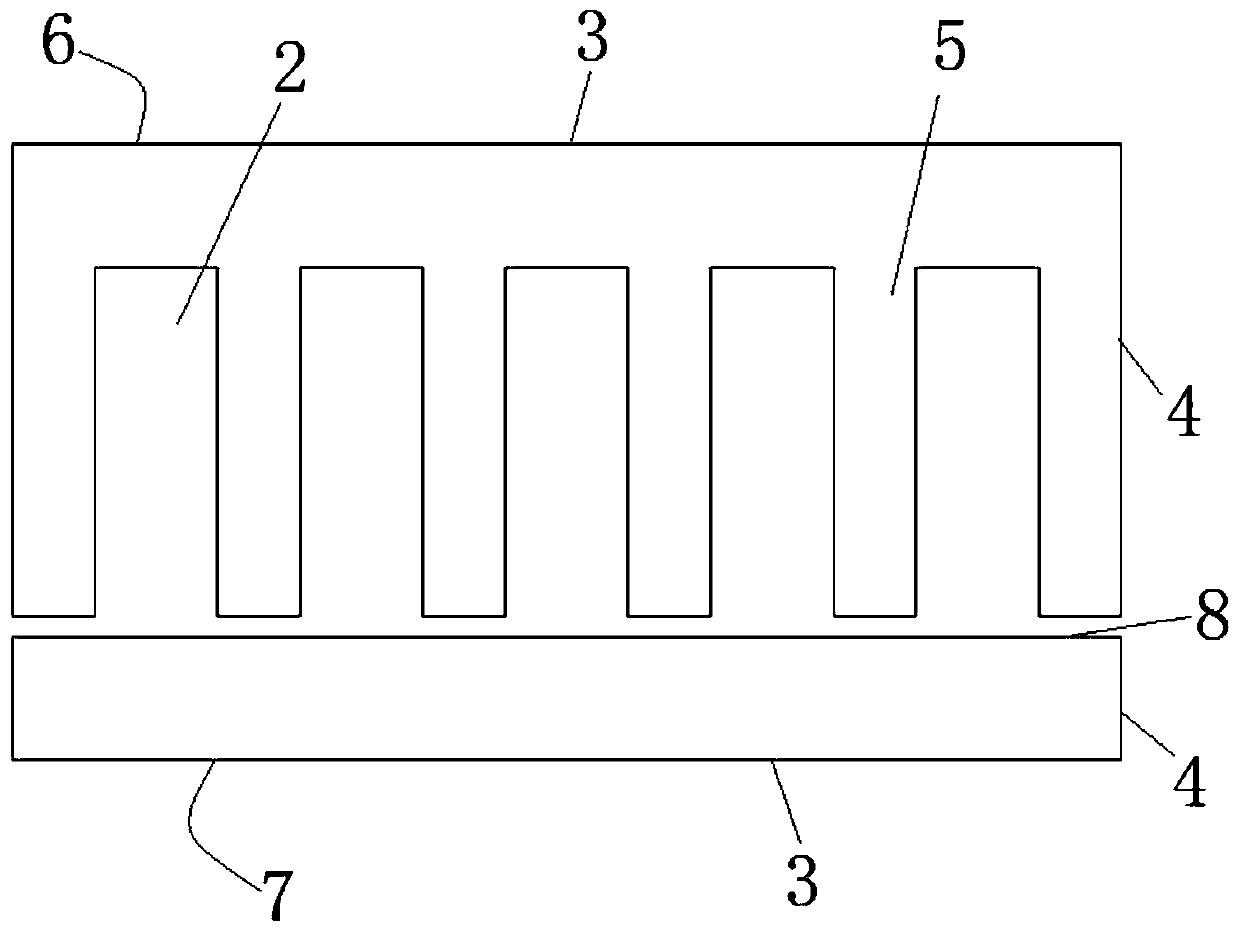

[0038] figure 2 It is a structural diagram of the multi-window type silicon steel sheet structure involved in this embodiment. like figure 2 As shown, the structure of the multi-window type silicon steel sheet is rectangular and consists of a first rectangular fixing piece 6, a second rectangular fixing piece 7 and five iron cores 2. The first rectangular fixing piece 6 and the second rectangular fixing piece 7 are arranged oppositely, the first rectangular fixing piece 6 is composed of the bottom piece 3, the side columns 4 located at both ends of the bottom piece 3 and the four center columns 5 on the bottom piece, and the second rectangular fixing piece 7 is made up of the bottom piece 3. The side columns 4 located at both ends of the bottom sheet 3 and the top sheet 8 located on the front side of the bottom sheet 3 close to the center column, the five iron cores 2 are sequentially located on the side columns 4, the center column 5 and the top Between the sheets 8, betw...

Embodiment 3

[0045] This embodiment provides an electronic device, which includes a multi-window silicon steel sheet structure.

[0046] Wherein, for the specific structure of the multi-window silicon steel sheet structure in this embodiment, please refer to the relevant description of the previous embodiments, and details are not repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com