Soft magnetic nanocrystalline metal or alloy sheet-shaped particles with internal grain orientation and microwave absorbing material

A technology of grain orientation and flake particles, applied in the direction of magnetic materials, magnetic objects, magnetic field/electric field shielding, etc., can solve the limitation of low-frequency magnetic permeability value of magnetic permeability value, decrease of magnetic substance content and magnetic properties, and easy pollution. Absorbers and other issues, to achieve the effect of improving magnetic loss, improving low-frequency and broadband absorption performance, and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Put 10 g of commercially available carbonyl iron powder into a tube furnace, heat-treat at 275° C. for 1 h under an argon atmosphere, and obtain carbonyl iron powder with an average grain size of 50 nm. Put the heat-treated spherical carbonyl iron powder into a 2.5L stainless steel ball mill jar, add 800g of zirconia balls with a diameter of 6mm and 100mL of absolute ethanol for ball milling, and the ball milling time is controlled at 14h. After ball milling, the resulting slurry was filtered and dried to obtain the final product. Such as figure 1 Shown is the SEM image of the flaky particles prepared in this example, and the results shown in the figure show that the product is a flaky particle with an average aspect ratio of about 84.

[0043] The obtained flake particles and paraffin were mixed evenly at a weight ratio of 3.3:1, placed in a rotatable heating plate with a uniform magnetic field at a temperature of 80°C, and the magnetic field strength was about 200Gau...

Embodiment 2

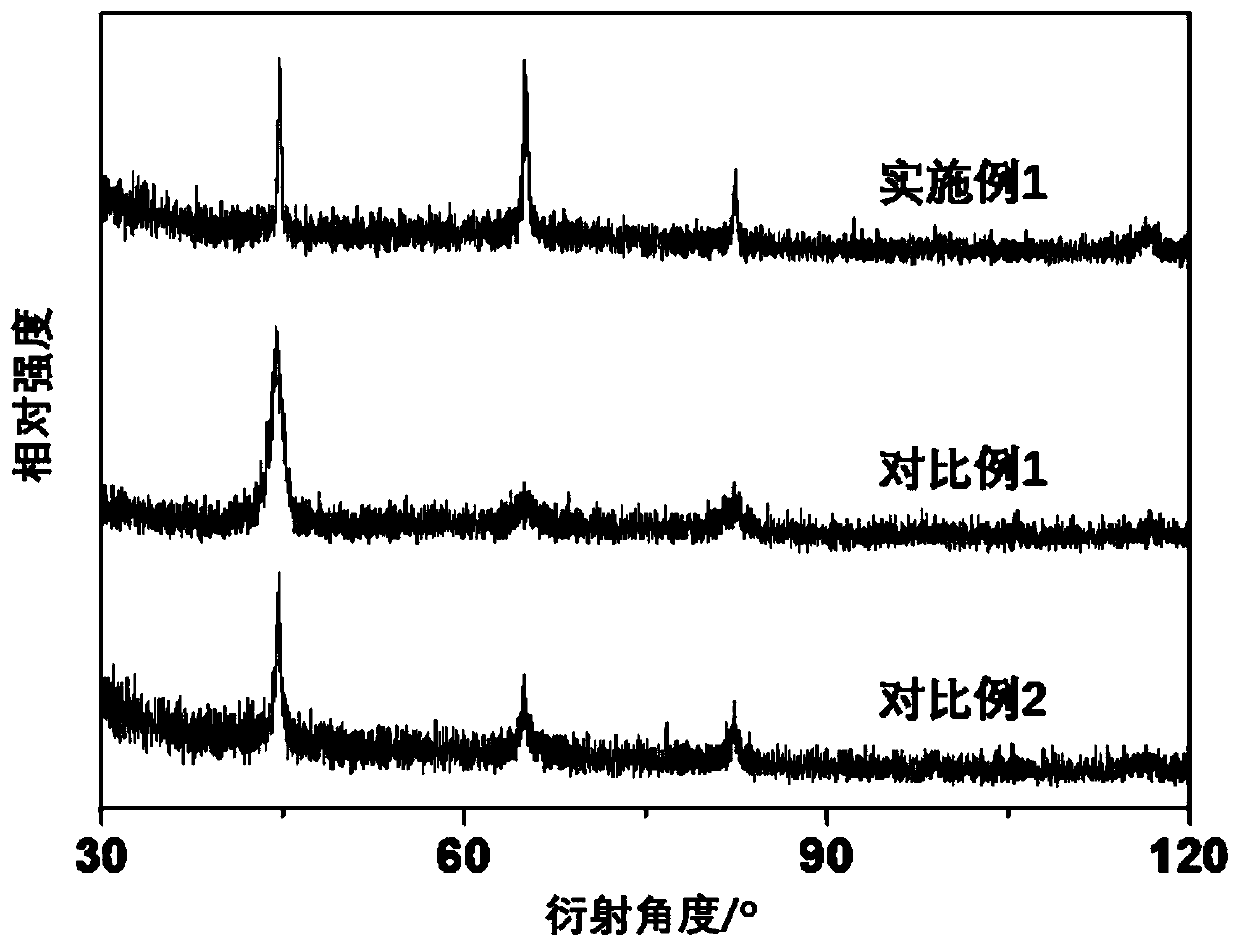

[0046] The preparation technology of flake particle is identical with embodiment 1, and the flake particle obtained is identical with embodiment 1, and its scanning electron microscope picture is as follows figure 1 As shown, the difference is that no magnetic field is applied for orientation when the flake particles are mixed with paraffin to prepare the absorbing material. The X-ray diffraction pattern of the composite wave-absorbing material gained in this comparative example is as follows figure 2 As shown, it can be seen from the figure that the absorbing material does not show grain orientation. The microwave-absorbing material of this comparative example is made into a coaxial ring with an inner diameter of 3mm and an outer diameter of 7mm for electromagnetic parameter testing. The electromagnetic parameters of the microwave-absorbing material of this embodiment are as follows: Figure 4 As shown, the results show that the absorbing material can obtain the imaginary p...

Embodiment 3

[0049] Put 10 g of commercially available carbonyl iron powder into a tube furnace, and heat-treat at 150° C. for 4 h, and at 270, 300, and 330° C. for 1 h under an argon atmosphere. Five samples of the original powder and the heat-treated spherical carbonyl iron powder were placed in a 2.5L stainless steel ball milling tank, and 800g of zirconia balls with a diameter of 6mm and 100mL of absolute ethanol were added for ball milling. The ball milling time was controlled at 18 , 16, 12, 16, 20h, the flake particles with the largest aspect ratio were obtained. After ball milling, the resulting slurry was filtered and dried to obtain the final product.

[0050] Mix the obtained five flake particles with paraffin at a weight ratio of 3.3:1, place them in a rotatable heating plate with a uniform magnetic field at a temperature of 80°C, and the magnetic field strength is about 200Gauss, stir evenly and perform rotational orientation at the same time. After mixing evenly, stop the ro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com