Electromagnetic shielding material for electroless cobalt plating of modified carbon nanotubes and preparation method of electromagnetic shielding material

An electromagnetic shielding material, multi-wall carbon nanotube technology, applied in liquid chemical plating, metal material coating process, coating and other directions, can solve the problems of easy agglomeration, large specific surface area, poor dispersion of carbon nanotubes, etc. The effect of improving magnetic properties and increasing magnetic loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

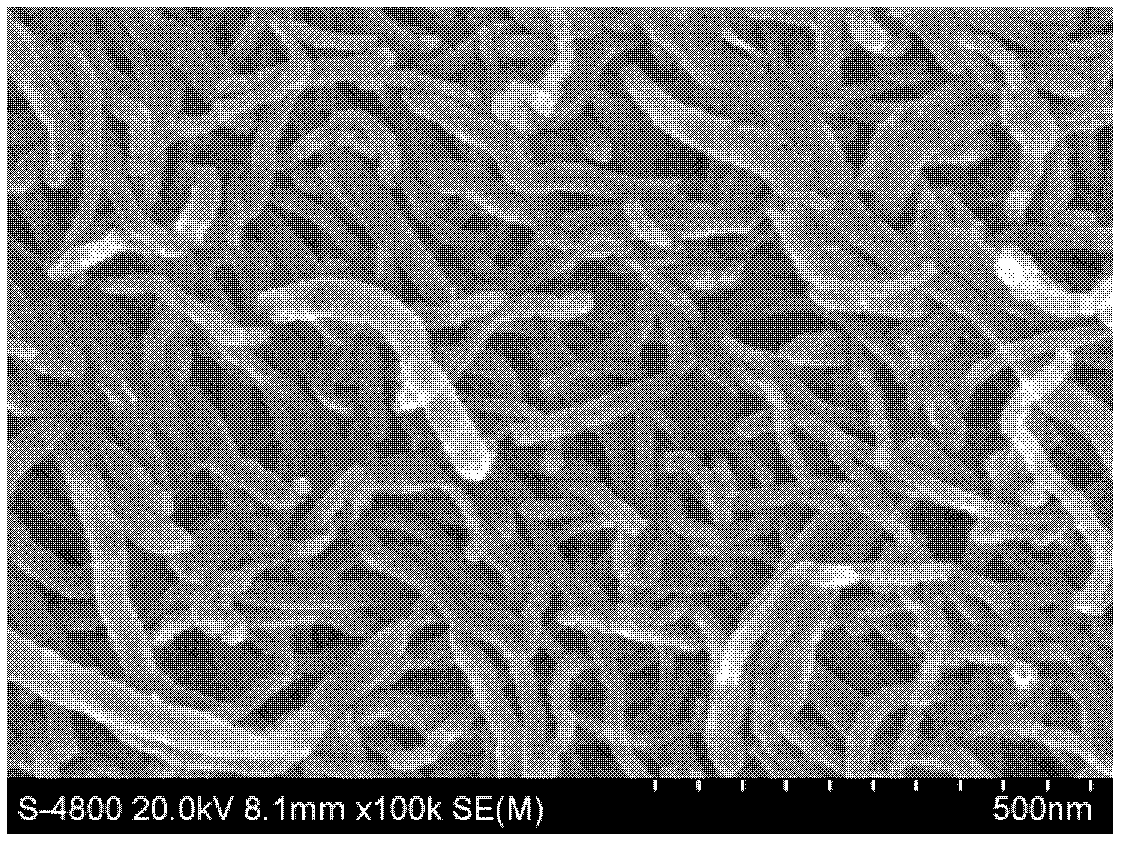

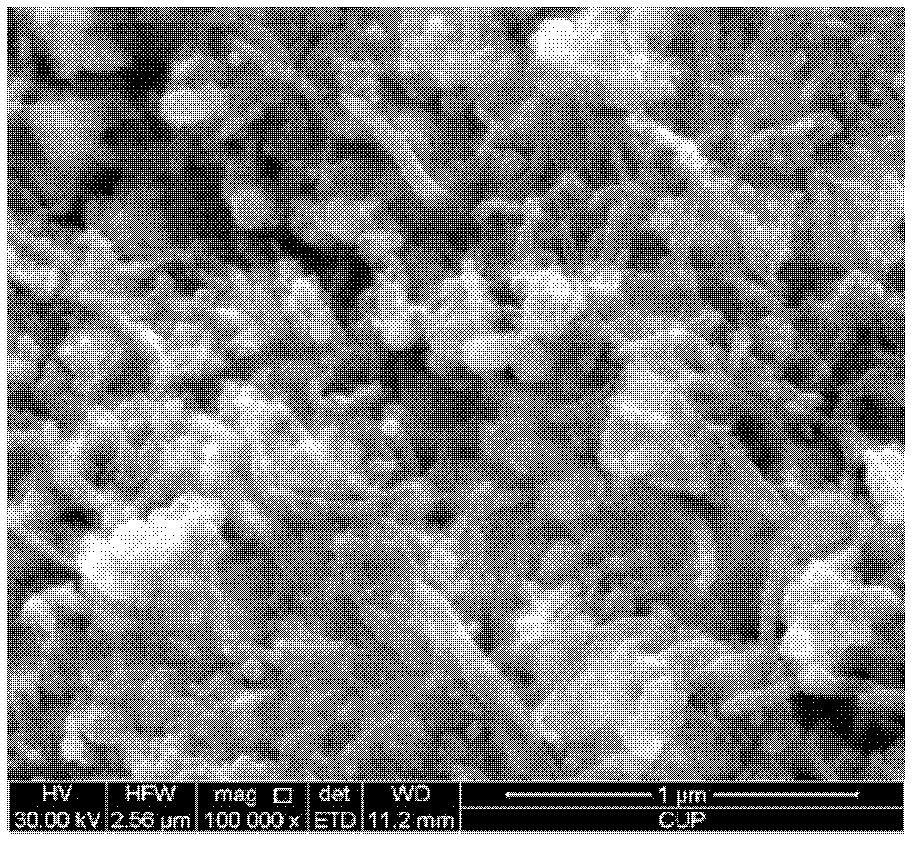

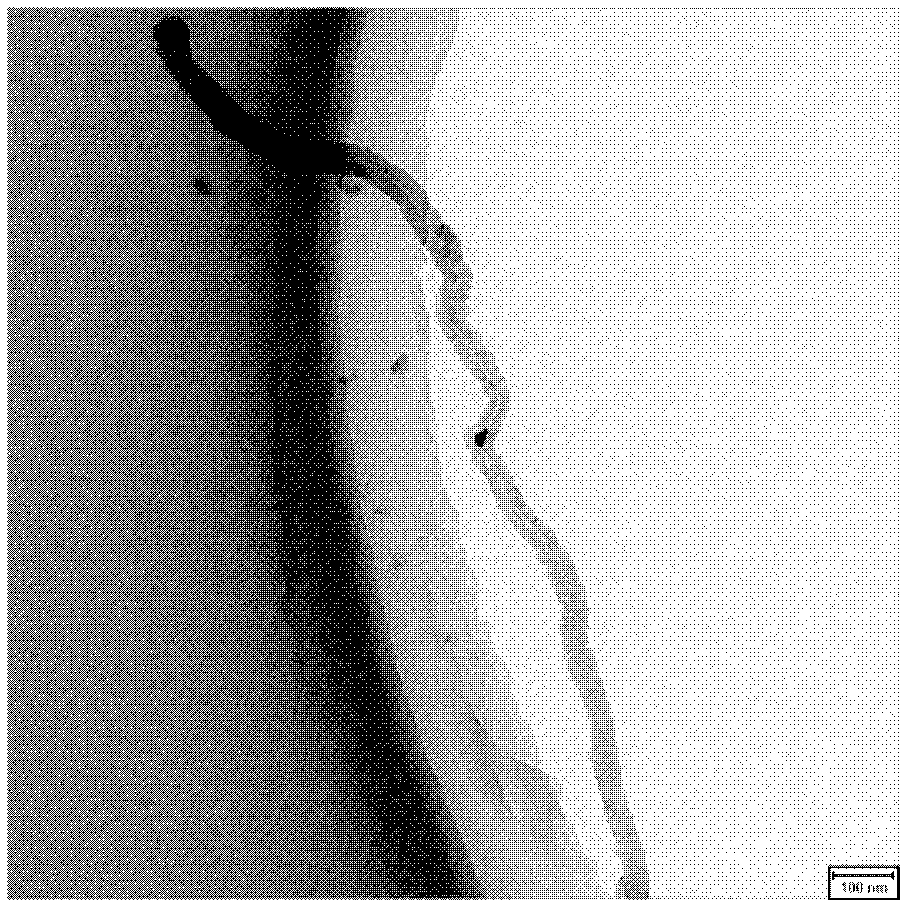

[0034] The electroless cobalt-plated modified carbon nanotube electromagnetic shielding material provided by the present invention will be further described in detail below with reference to the accompanying drawings and examples.

[0035] Apply the preparation method provided by the invention to prepare the electromagnetic shielding material of electroless cobalt-modified carbon nanotubes, and the specific steps are as follows:

[0036] Step 1: Acidification pretreatment of multi-walled carbon nanotubes:

[0037] 1. Mix 45ml of concentrated sulfuric acid and 15ml of concentrated nitric acid, add 0.6g of multi-walled carbon nanotubes at 60~65℃, ultrasonically stir and reflux for 4 hours to form a mixture; then slowly add the mixture into deionized water, -0.03MPa~- 0.06MPa vacuum filtration, and repeated washing with deionized water until the solution is neutral.

[0038] 2. Drying the multi-walled carbon nanotubes after suction filtration and washing at a vacuum degree of -0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| lattice spacing | aaaaa | aaaaa |

| lattice spacing | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com