Preparation method of CNTs/Ni-Fe3O4 functional material

A ni-fe3o4, cnts-fe3o4 technology, applied in the field of functional nanocomposite materials and environmental biology, can solve the problems of difficult control of coating coating amount, incapable of industrial mass production, cumbersome manufacturing process, etc., to increase the virtual permeability of magnetic permeability Department, functional diversity, wide-ranging effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

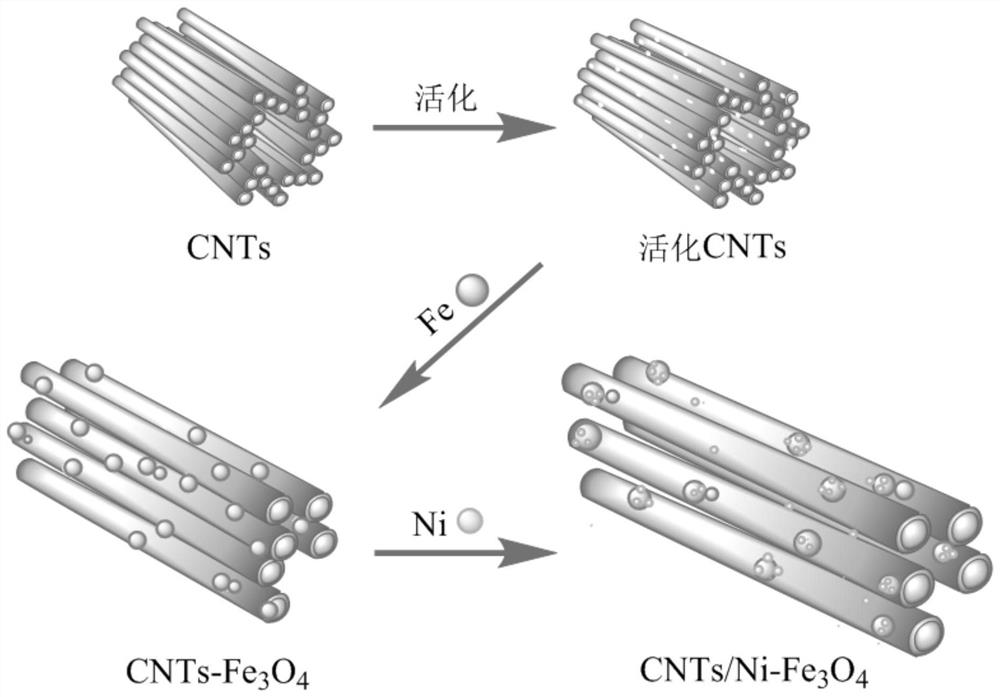

[0038] Such as figure 1 As shown, the CNTs / Ni-Fe 3 o 4 The preparation method of functional material, its concrete steps comprise:

[0039] Step 1. Purification and activation of multi-walled carbon nanotubes:

[0040] Step 1.1, mixing concentrated nitric acid and concentrated sulfuric acid at a volume ratio of 3:1 to obtain a mixed acid, adding multi-walled carbon nanotubes to the mixed acid according to a solid-to-liquid ratio of 1:20 g / mL for purification and activation for 12 hours;

[0041] Step 1.2, filtering after purification and activation in step 1.1, washing the multi-walled carbon nanotubes with ammonia water and ionized water with a concentration of 30wt% to neutrality, and then drying to obtain multi-walled carbon nanotubes;

[0042] Step 1.3, the multi-walled carbon nanotubes purified and activated in step 1.2 are ball-milled in a planetary ball mill for 5 hours under the conditions of a ball-to-material ratio of 50:1 and a rotating speed of 500 r / min, and dr...

Embodiment 2

[0054] Such as figure 1 As shown, the CNTs / Ni-Fe 3 o 4 The preparation method of functional material, its concrete steps comprise:

[0055] Step 1. Purification and activation of multi-walled carbon nanotubes:

[0056] Step 1.1, mixing concentrated nitric acid and concentrated sulfuric acid at a volume ratio of 3:1 to obtain a mixed acid, adding multi-walled carbon nanotubes to the mixed acid according to a solid-to-liquid ratio of 1:20 g / mL for purification and activation for 12 hours;

[0057] Step 1.2, filtering after purification and activation in step 1.1, washing the multi-walled carbon nanotubes with ammonia water and ionized water with a concentration of 30wt% to neutrality, and then drying to obtain multi-walled carbon nanotubes;

[0058] Step 1.3, the multi-walled carbon nanotubes purified and activated in step 1.2 are ball-milled in a planetary ball mill for 5 hours under the conditions of a ball-to-material ratio of 50:1 and a rotating speed of 500 r / min, and dr...

Embodiment 3

[0069] Such as figure 1 As shown, the CNTs / Ni-Fe 3 o 4 The preparation method of functional material, its concrete steps comprise:

[0070] Step 1. Purification and activation of multi-walled carbon nanotubes:

[0071] Step 1.1, mixing concentrated nitric acid and concentrated sulfuric acid at a volume ratio of 3:1 to obtain a mixed acid, adding multi-walled carbon nanotubes to the mixed acid according to a solid-to-liquid ratio of 1:20 g / mL for purification and activation for 12 hours;

[0072] Step 1.2, filtering after purification and activation in step 1.1, washing the multi-walled carbon nanotubes with ammonia water and ionized water with a concentration of 30wt% to neutrality, and then drying to obtain multi-walled carbon nanotubes;

[0073] Step 1.3, the multi-walled carbon nanotubes purified and activated in step 1.2 are ball-milled in a planetary ball mill for 5 hours under the conditions of a ball-to-material ratio of 50:1 and a rotating speed of 500 r / min, and dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com