Preparation method of nitrogen-doped carbon nanotube supercapacitor

A technology of supercapacitors and carbon nanotubes, applied in the fields of electrochemistry and materials, can solve the problems of limited capacitance performance of CNTs, and achieve the effects of strictly controllable reaction parameters, uniform structure and low equipment requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Preparation of nitrogen-doped carbon nanotube supercapacitor:

[0036] (1) CVD preparation of carbon nanotubes (CNTs)

[0037] The size of 316L stainless steel sheet wire cutting is 10×10×0.5mm 3 . Use 1000#, 2000# sandpaper to polish on the metallographic sample polishing machine (roughness <Ra 10μm), then ultrasonically clean with absolute ethanol and distilled water for 10min respectively; dry it with a hair dryer and perform electrolytic polishing (the volume ratio of electrolyte , perchloric acid: ethylene glycol = 5:95), the working voltage is 20V, the reaction current is controlled to 0.02A, the reaction time is 20min, and the reaction temperature is controlled at about 2°C through the ice-water mixture.

[0038] (2) Vapor deposition of one-dimensional carbon nanotubes on stainless steel substrates

[0039] After the sample is processed, it is ultrasonically cleaned with absolute ethanol and distilled water for 10 minutes, dried with a hair dryer, placed in a ...

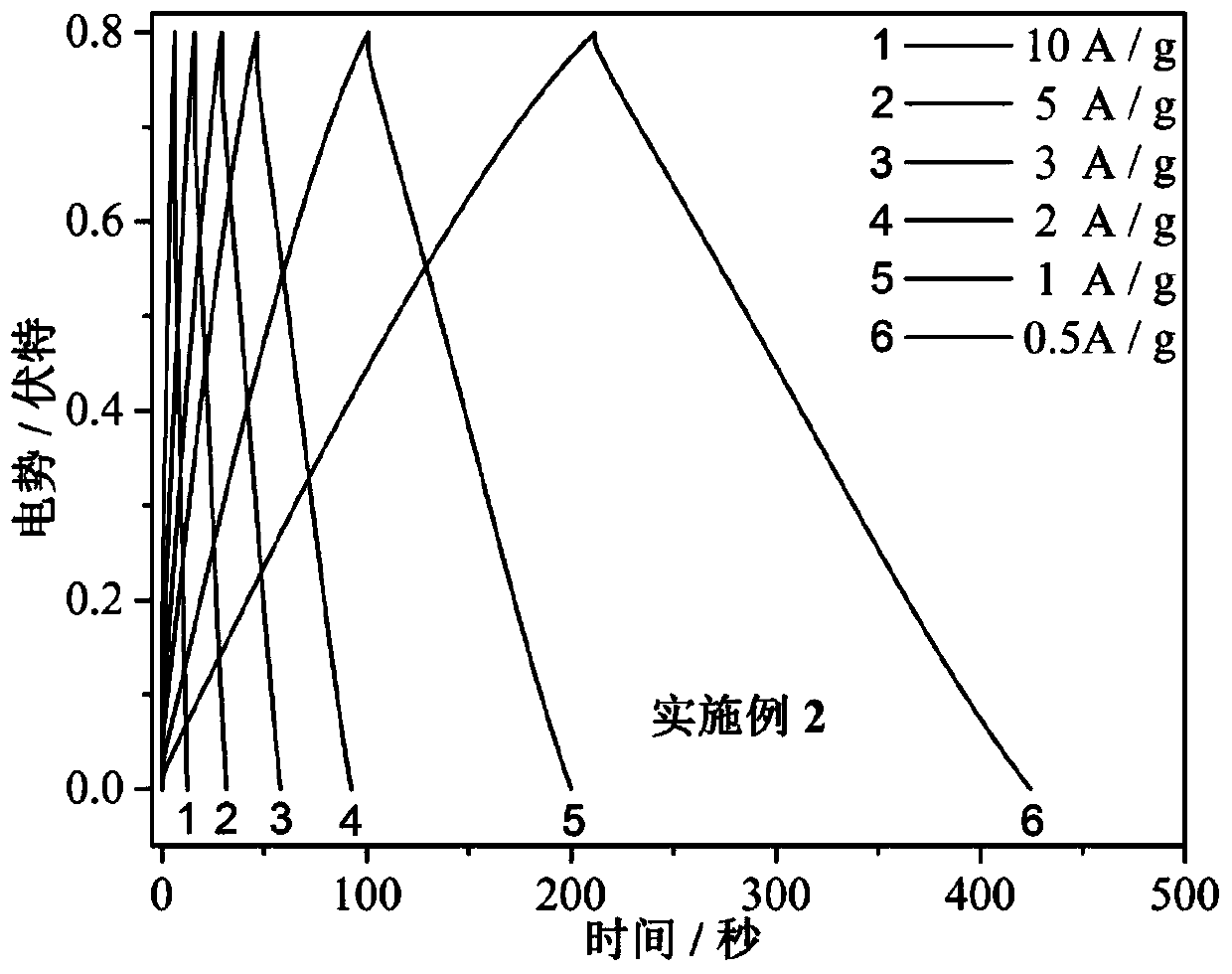

Embodiment 2

[0045] The preparation method is the same as in Example 1. The difference is that the concentration of urea solution is 0.3mol / L.

Embodiment 3

[0047] The preparation method is the same as in Example 1. The difference is that the concentration of urea solution is 0.5mol / L.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com