Method for enhancing electron transfer capability of humic acid to promote anaerobic fermentation and acid production of sludge

A sludge anaerobic fermentation and electron transfer technology, applied in chemical instruments and methods, fermentation, sludge treatment, etc., can solve the problems of low yield of volatile fatty acids, low conversion efficiency of organic matter, etc., achieve enhanced effect and improve electron transfer Efficiency, the effect of improving electron transfer ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Embodiment 1 Humic acid redox ability changes

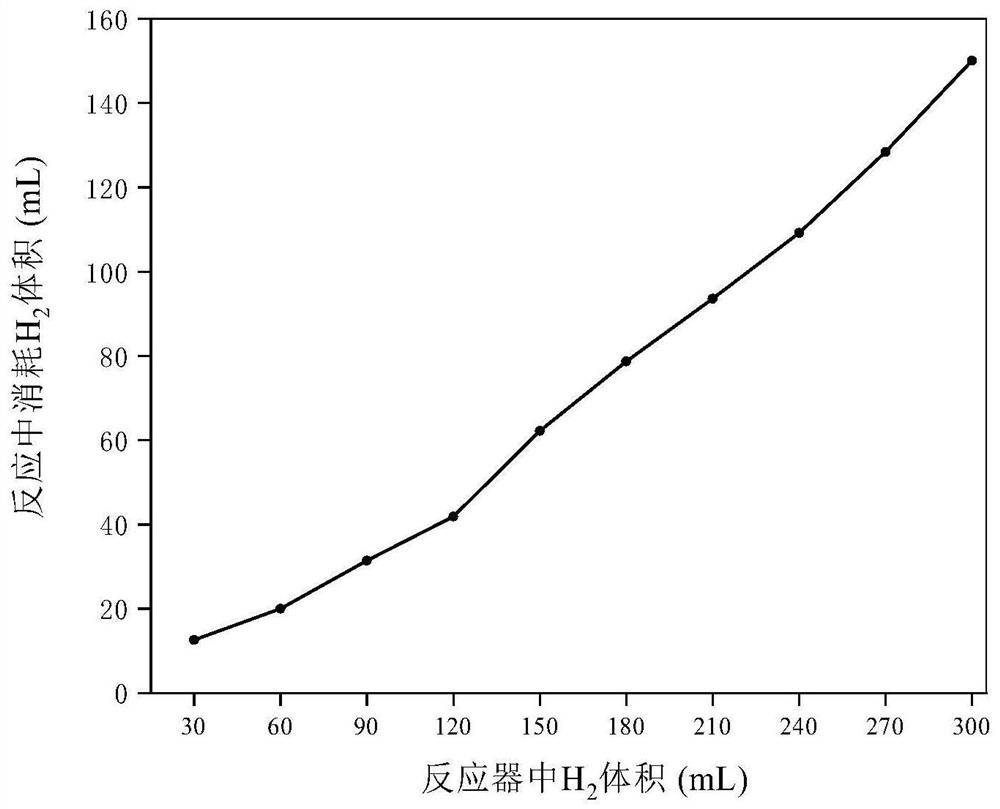

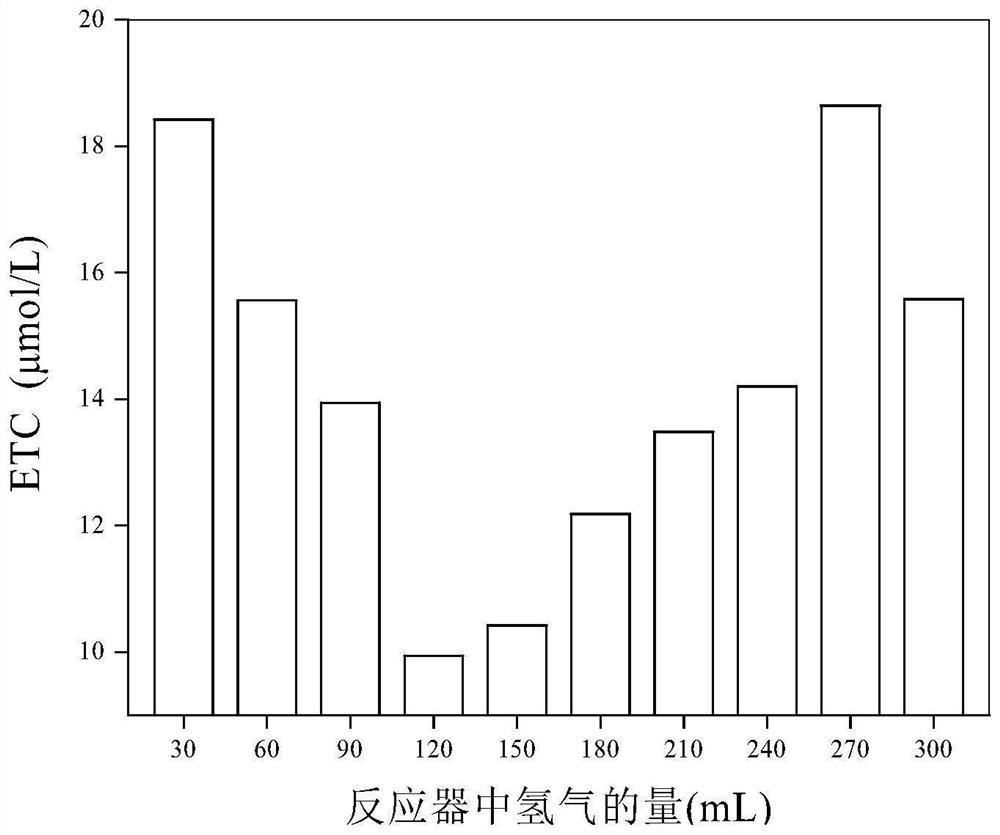

[0042] First, the municipal sludge is adjusted to a water content of 90%, thermally hydrolyzed at a temperature of 180°C for 30 minutes, the organic matter in the sludge is released into the liquid phase, and the solid phase in the thermal hydrolyzate is removed by solid-liquid separation Residue, obtain sludge hydrolyzate; The humic acid concentration of sludge hydrolyzate is 1.0g / L, the sludge hydrolyzate is adjusted to pH neutrality; Then, according to the mass ratio of humic acid and Pd-C catalyst is 1 : 1, add Pd-C catalyst (100% recoverable). Transfer the hydrolyzate (1000ml) together with the Pd-C catalyst to a serum bottle and seal it, then expose to N 2After 20 minutes, empty the oxygen in the serum bottle to ensure an anaerobic environment. Fill 30, 60, 90, 120, 150, 180, 210, 240, 300mLH into the aerated serum bottle respectively 2 , and placed in a shaker at 37°C for 24 hours.

[0043] Will go through Pd-C / ...

Embodiment 2

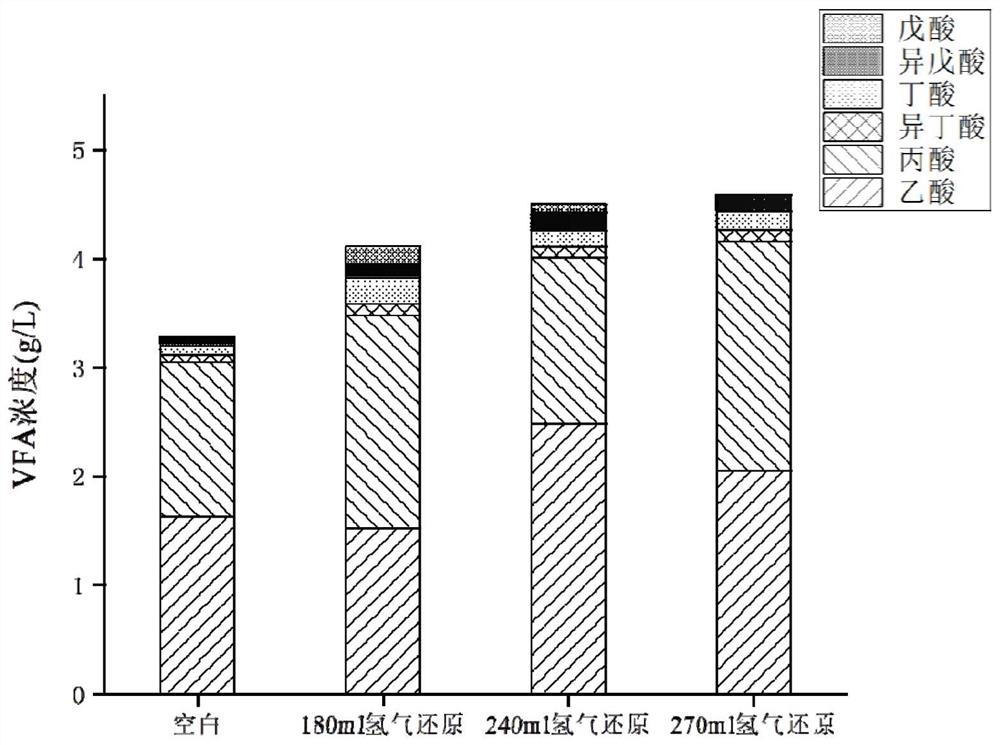

[0049] First, the municipal sludge is adjusted to a water content of 92%, thermally hydrolyzed at a temperature of 185°C for 35 minutes, the organic matter in the sludge is released into the liquid phase, and the solid phase in the thermal hydrolyzate is removed by solid-liquid separation Residue, obtain sludge hydrolyzate; The humic acid concentration of sludge hydrolyzate is 1.0g / L, sludge hydrolyzate is adjusted to pH=7; Then, be 1 according to the mass ratio of humic acid and Pd-C catalyst : 1, add Pd-C catalyst (100% recoverable). Transfer the humic acid and Pd-C catalyst together into a serum bottle and seal it, then expose to N 2 After 20 minutes, empty the oxygen in the serum bottle to ensure an anaerobic environment. Fill 240mLH into the serum bottle after aeration respectively 2 , and placed in a shaker at 37°C for 30 hours.

[0050] Will go through Pd-C / H 2 Sludge hydrolyzate after catalytic reduction system reaction and without Pd-C / H 2 The sludge hydrolyzate ...

Embodiment 3

[0053] First, the municipal sludge is adjusted to a water content of 92%, thermally hydrolyzed at a temperature of 185°C for 35 minutes, the organic matter in the sludge is released into the liquid phase, and the solid phase in the thermal hydrolyzate is removed by solid-liquid separation Residue, obtain sludge hydrolyzate; The humic acid concentration of sludge hydrolyzate is 1.0g / L, sludge hydrolyzate is adjusted to pH=7; Then, be 1 according to the mass ratio of humic acid and Pd-C catalyst : 1, add Pd-C catalyst (100% recoverable). Transfer the humic acid and Pd-C catalyst together into a serum bottle and seal it, then expose to N 2 After 20 minutes, empty the oxygen in the serum bottle to ensure an anaerobic environment. Fill 270mLH into the serum bottle after aeration respectively 2 , and placed in a shaker at 37°C for 30 hours.

[0054] Will go through Pd-C / H 2 Sludge hydrolyzate after catalytic reduction system reaction and without Pd-C / H 2 The sludge hydrolyzate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com