Preparation method of nanoparticle bionic enzyme sensitive element, product and application of product

A technology of nanoparticles and sensitive components, applied in the field of materials, can solve the problems of elusive electronic structure and hinder understanding, and achieve the effect of detecting multiple active sites, enhancing selectivity, and improving electron transfer performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

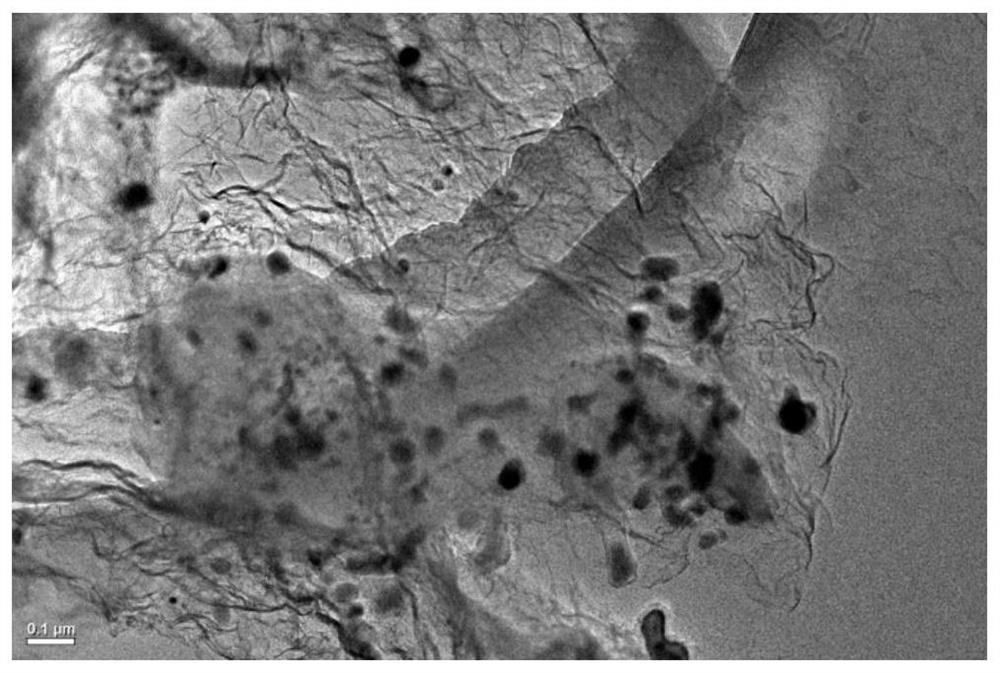

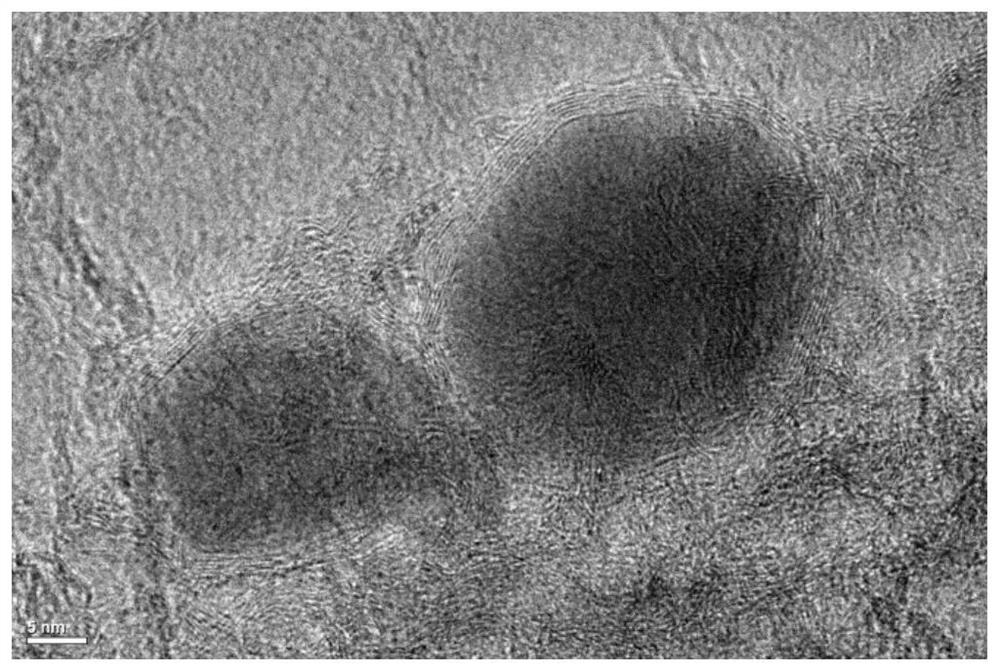

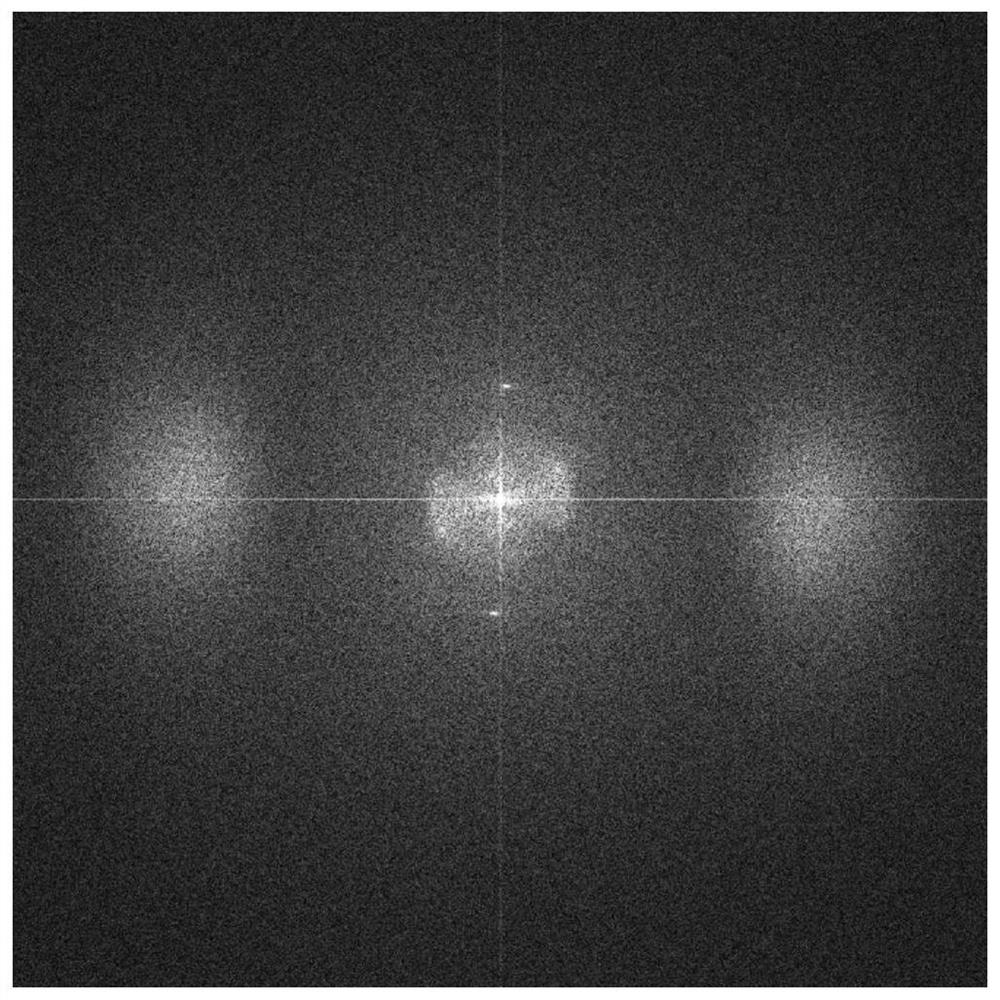

[0040] In the synthesis of nanoparticle biomimetic enzyme material (Co-NSG), the specific steps are as follows:

[0041] (1) First, 100 mg of graphite oxide (GO) was dispersed in 30 mL of deionized water (DIW) by ultrasound, and 2.5 mg of C 4 h 6 CoO 4 4(H 2 O); the mixture was stirred in a water bath at 80 °C for 2 hours, and then freeze-dried for 24 hours to remove DIW. Subsequently, the resulting product was mixed with 500 mg C 3 h 6 N 6 and 3g·L -1 C 3 h 7 NO 2 S were ground together to form a homogeneous mixture, then pyrolyzed at 900 °C for 2 h in an argon atmosphere. After cooling to room temperature, the biomimetic enzyme material (abbreviated as Co-NSG nanoparticle biomimetic enzyme material) is obtained.

[0042] Working electrode coated with biomimetic enzyme sensitive element:

[0043] The Co-NSG nanoparticle biomimetic enzyme material prepared above was dispersed in water at a concentration of 1 mg / mL to obtain an electrode modification solution, and 4...

Embodiment 2

[0052] Superoxide dismutase biomimetic enzyme material, the specific steps are as follows:

[0053] Mix 100mg GO with 500mg C 3 h 6 N 6 and 3g·L -1 C 3 h 7 NO 2 S were ground together into a homogeneous mixture and pyrolyzed at 1000 °C for 2 h in an argon atmosphere. After cooling to room temperature, the biomimetic enzyme material (abbreviated as NSG biomimetic enzyme material) is obtained;

[0054] Working electrode coated with NSG biomimetic enzyme material:

[0055] The prepared NSG biomimetic enzyme material was dispersed in water at a concentration of 1 mg / mL to obtain an electrode modification solution, which was coated on a glassy carbon electrode, dried at 26°C for 5 hours, and then coated with Nafion mass fraction 0.1 wt% Nafion solution, and dried again at 26° C. for 5 h to prepare a working electrode coated with superoxide dismutase biomimetic material.

[0056] Construction of superoxide anion radical electrochemical sensor:

[0057] The working electrod...

Embodiment 3

[0061] Superoxide dismutase biomimetic enzyme material, the specific steps are as follows:

[0062] Prepare 45mL of phosphate buffer solution, then add 0.1014g of manganese sulfate into 2mL of deionized water, mix the two solutions evenly, stir and react at 26°C for 8h, centrifuge at 5000r / min for 10min, and take the precipitate. After washing with water, vacuum-dry at 80° C. for 12 hours to prepare superoxide dismutase biomimetic enzyme material.

[0063] Working electrode coated with biomimetic enzyme sensitive element:

[0064] Disperse the prepared superoxide dismutase biomimetic material in water at a concentration of 1.5 mg / mL to obtain an electrode modification solution, apply the electrode modification solution to a glassy carbon electrode, dry at 26°C for 5 hours, and then apply Cover with a Nafion solution with a mass fraction of Nafion of 0.1 wt%, and dry it again at 26° C. for 5 hours to prepare a working electrode whose surface is coated with a superoxide dismuta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com