Oriented honeycomb wave-absorbing material and preparation method thereof

A technology of wave-absorbing materials and honeycomb materials, which is applied in antennas, electrical components, magnetic field/electric field shielding, etc., can solve problems such as unsuitable honeycomb materials, achieve easy control of wave-absorbing performance, good absorption effect, and improve wave-absorbing frequency bands Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

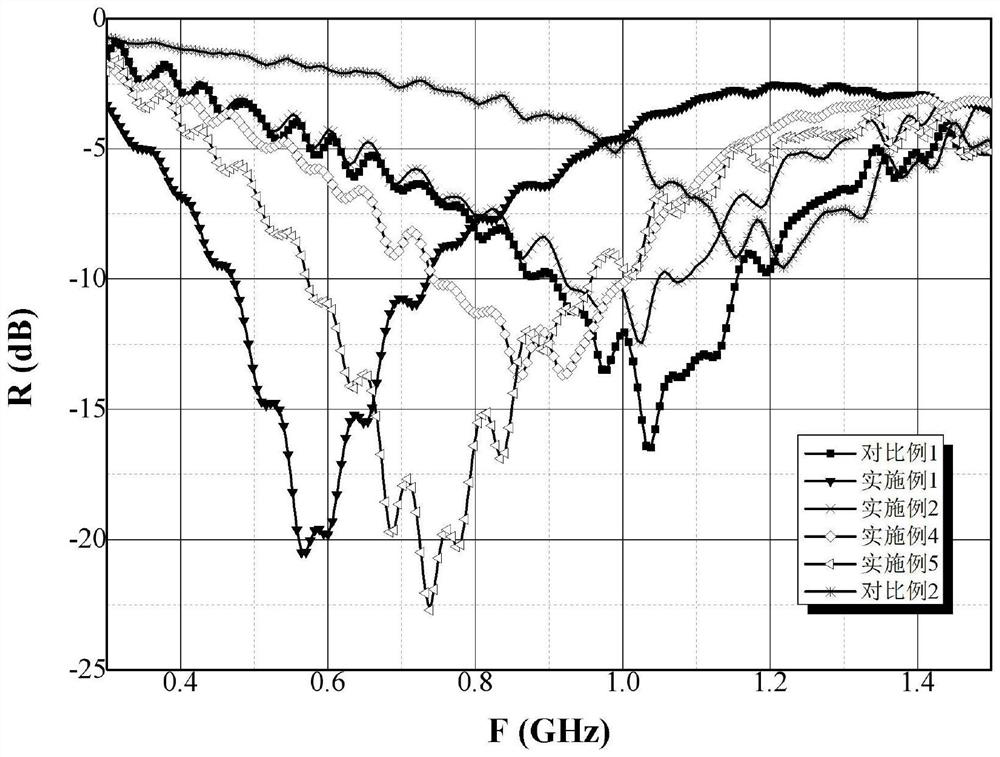

Embodiment 1

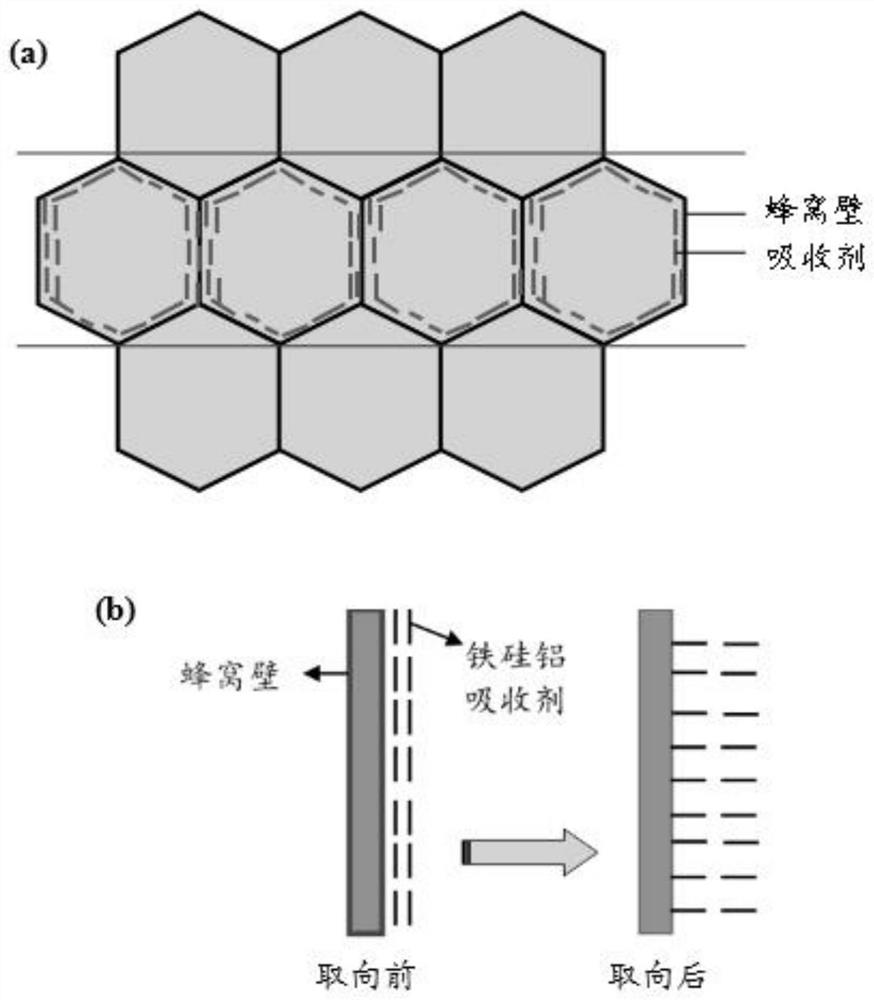

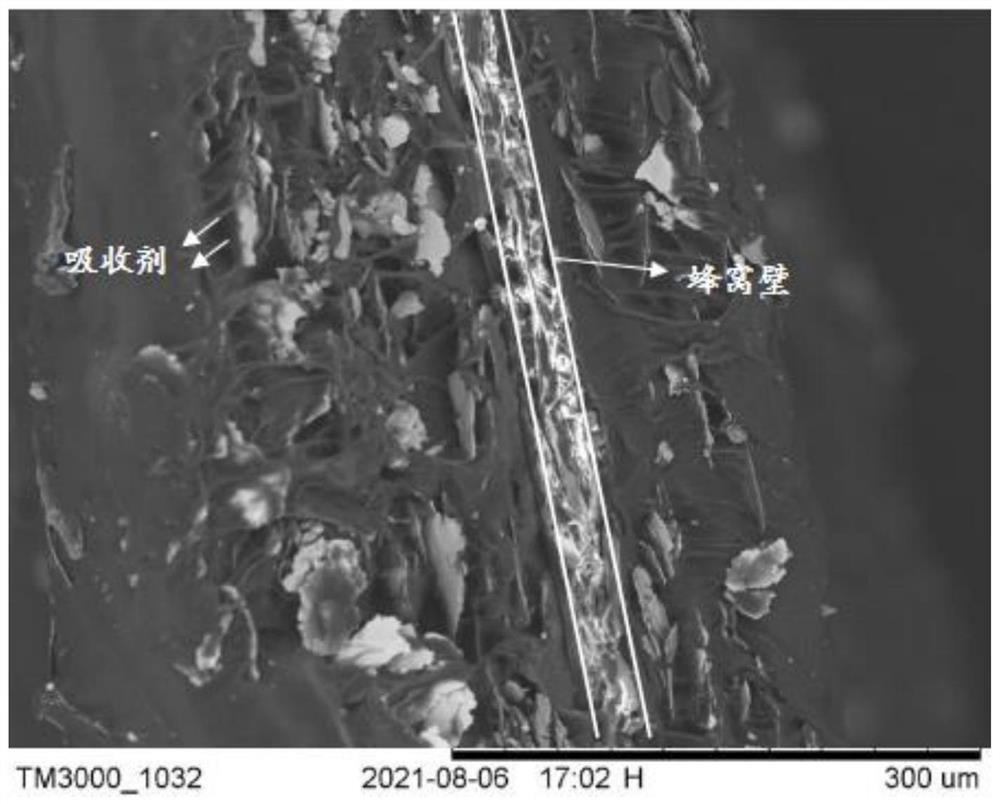

[0041] In this embodiment, aramid honeycomb material with a cell side length of 2.75 mm (the thickness of the flat plate is 20 mm), and flake sendust powder (with a particle size of 50 μm and a thickness of about 1 μm, the contents of each element are: silicon 9.0 to 10.0 wt%, aluminum 5.0~6.0wt%, iron balance) and water-based acrylic resin as the main raw materials, the specific preparation methods include:

[0042] (1) Preparation of magnetic absorbent slurry: Add 100 parts of sendust powder to 62.5 parts of water-based acrylic resin, add 112.5 parts of water and 1 part of dispersing thickener to adjust the viscosity of the slurry; use a disperser to disperse , the rotating speed is set to 1000rpm, and dispersed for 1h to prepare sendust magnetic wave-absorbing slurry;

[0043] (2) Honeycomb impregnation: Place the honeycomb base material horizontally in the wave-absorbing slurry, lift it up after the slurry is completely submerged, turn the honeycomb over and impregnate it ...

Embodiment 2

[0048] In this embodiment, aramid honeycomb material with a cell side length of 2.75 mm (the thickness of the flat plate is 20 mm), and flake sendust powder (with a particle size of 50 μm and a thickness of about 1 μm, the contents of each element are: silicon 9.0 to 10.0 wt%, aluminum 5.0~6.0wt%, iron balance) and water-based acrylic resin as the main raw materials, the specific preparation methods include:

[0049] (1) Preparation of magnetic absorbent slurry: Add 100 parts of sendust powder to 210 parts of water-based acrylic resin, add 100 parts of water and 1 part of dispersing thickener to adjust the viscosity of the slurry; use a disperser to disperse, Set the rotation speed to 1000rpm, disperse for 1h, and prepare sendust magnetic wave-absorbing slurry;

[0050] (2) Honeycomb impregnation: Place the honeycomb base material horizontally in the wave-absorbing slurry, lift it up after the slurry is completely submerged, turn the honeycomb over and impregnate it again; pla...

Embodiment 3

[0055] In this embodiment, the aramid honeycomb material with a cell side length of 2.75mm (the thickness of the plate is 20mm), carbonyl iron powder and water-based acrylic resin are used as the main raw materials. The specific preparation methods include:

[0056] (1) Preparation of magnetic absorbent slurry: Add 100 parts of iron powder to 62.5 parts of water-based acrylic resin, add 112.5 parts of water and 1 part of dispersive thickener to adjust the viscosity of the slurry; Set at 1000rpm, disperse for 1h, and prepare ferromagnetic wave-absorbing slurry;

[0057] (2) Honeycomb impregnation: Place the honeycomb base material horizontally in the wave-absorbing slurry, lift it up after the slurry is completely submerged, turn the honeycomb over and impregnate it again; place the honeycomb in another clean container, and remove it by vibration control. Excess paint, once on the front and back;

[0058] (3) Orientation of the honeycomb absorbing material: place the honeycomb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com