Bull ring of food waste disposer

A technology of food waste treatment and grinding ring, which is applied in the direction of grain treatment, etc., can solve the problems of easy rounding of grinding grooves and crushing convex teeth, reduced grinding effect, long grinding time, etc., and achieves excellent wear resistance and corrosion resistance, The effect of long service life and short grinding time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to make the content of the present invention more clearly understood, the present invention will be further described in detail below based on specific embodiments and in conjunction with the accompanying drawings.

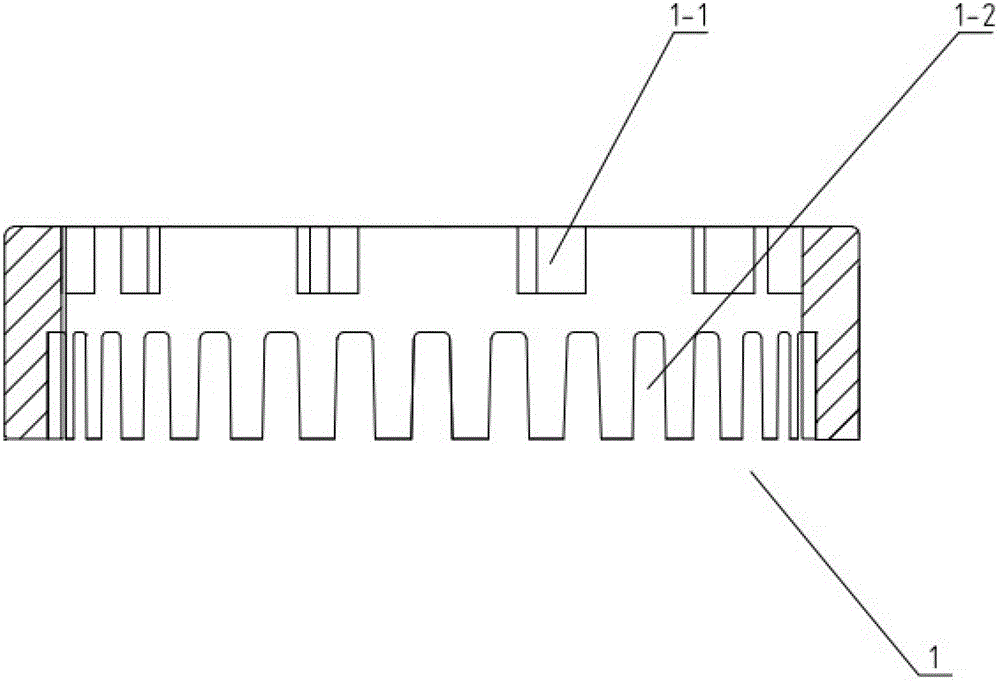

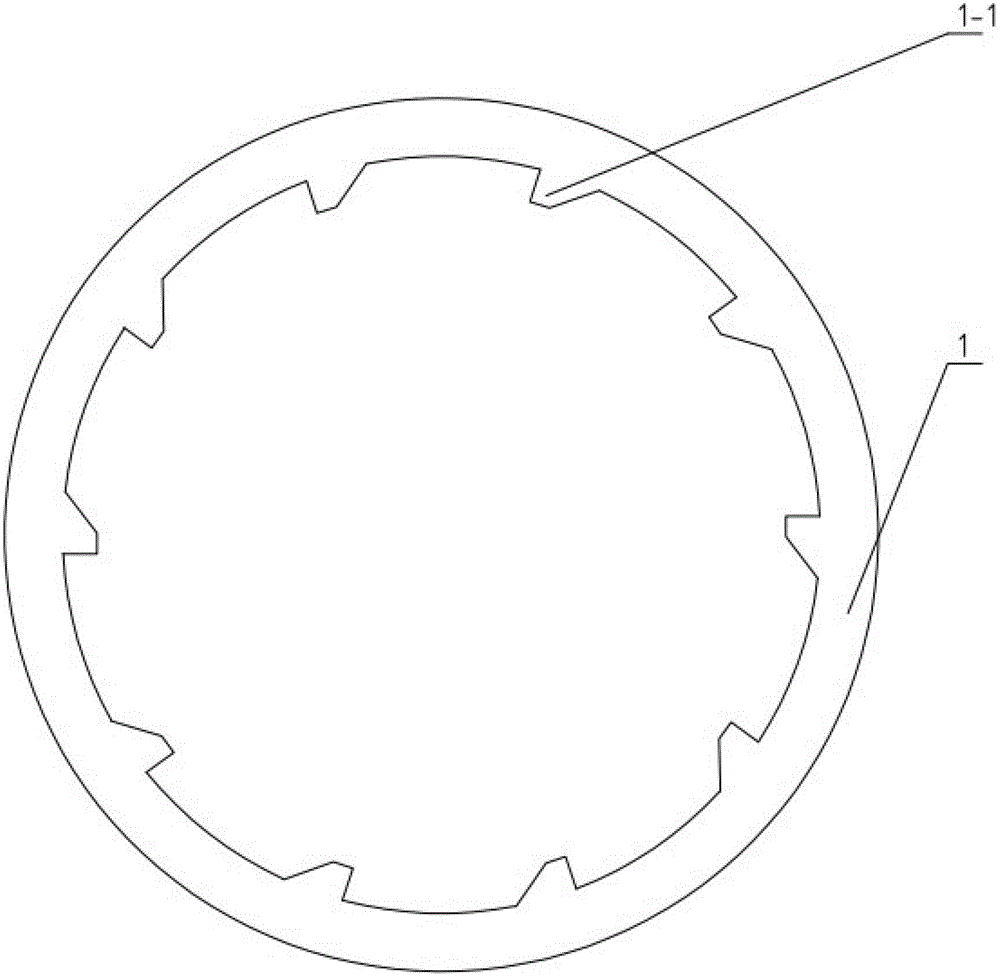

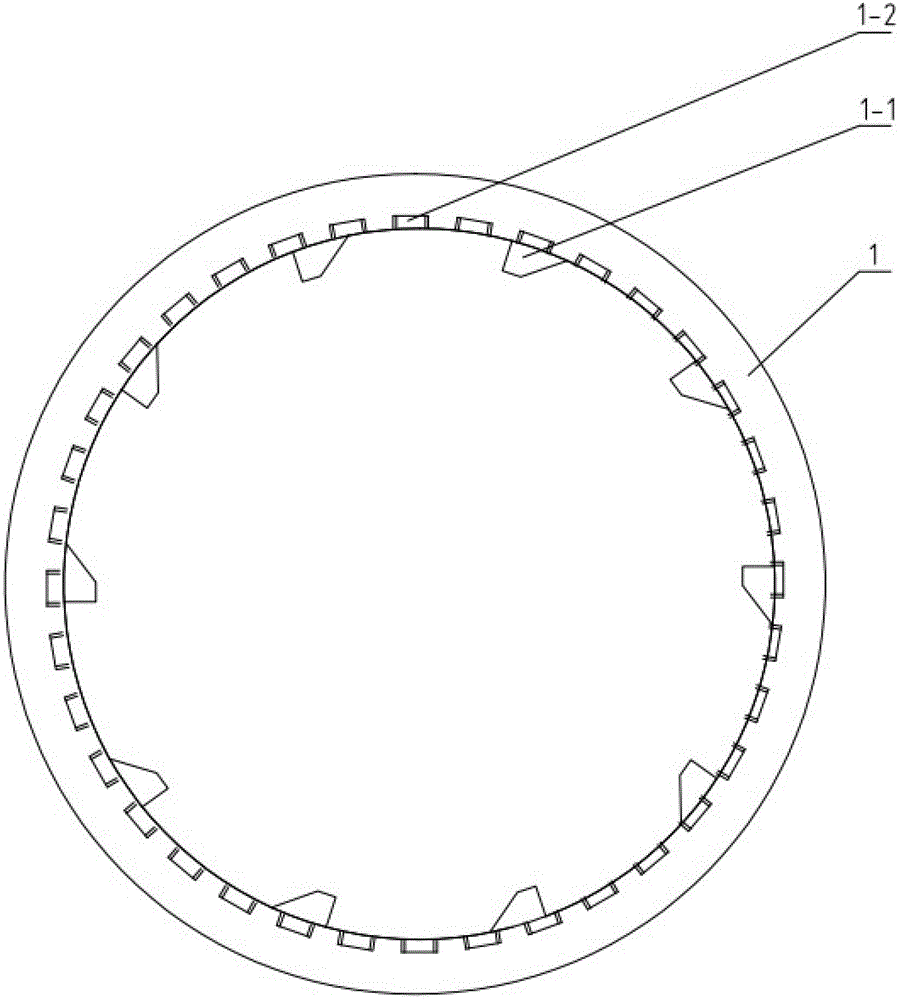

[0014] Such as Figure 1~3 As shown, a grinding ring of a food waste disposer includes a grinding ring body 1, and the inner wall of the upper part of the grinding ring body 1 is circumferentially provided with several inwardly protruding crushing teeth 1-1, and the grinding ring body 1 The inner wall of the lower part is provided with several grinding grooves 1-2 in the circumferential direction, and the grinding grooves 1-2 do not penetrate the side wall to prevent the rubbish abrasives from flowing out into the garbage disposer, and the grinding ring body 1 is made of high-alumina porcelain material. Garbage, especially garbage with relatively high hardness, such as bones and high-tenacity plant fibers, is initially crushed by the upper crushing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com