Compound superhard honing oilstone containing zirconium oxide and preparation method of compound superhard honing oilstone

A honing whetstone containing zirconia technology, which is applied in the direction of honing tools, grinding/polishing equipment, abrasives, etc., can solve the problems of unsatisfactory grinding effect, single grinding characteristic, short service life, etc., and achieve self-sharpening Excellent, long service life and short grinding time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

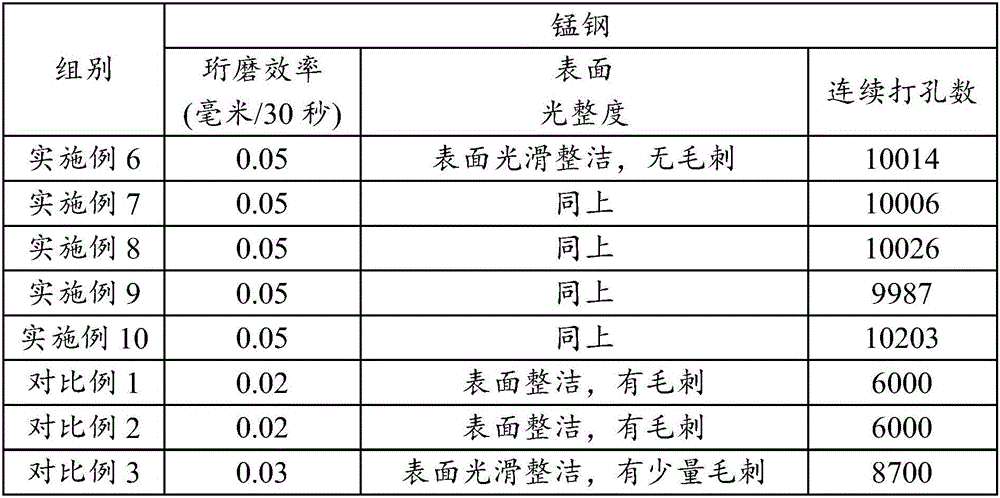

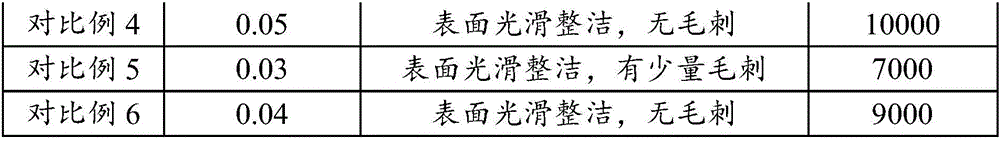

Examples

preparation example Construction

[0072] According to one aspect of the present invention, a method for preparing a zirconia-containing composite superhard honing stone comprises the following steps: weighing each raw material according to the weight percentage of the above-mentioned zirconia-containing composite superhard honing stone, each raw material After uniform mixing, pressing, and then sintering the pressed mixture to obtain the composite superhard honing oilstone containing zirconia.

[0073] In the present invention, the preparation method of the above-mentioned composite superhard honing oilstone containing zirconia is simple in process, and the composite superhard honing oilstone containing zirconia only needs to be mixed uniformly, pressed, and then sintered to obtain the composite superhard honing oilstone containing zirconia . The preparation method of the zirconia-containing composite superhard honing oil stone of the present invention is simple, has few steps in the preparation process, low p...

Embodiment 1

[0085] A composite superhard honing stone containing zirconia, said honing stone is mainly composed of the following raw materials in weight percentage: 0.1% zirconia, 50% copper, 2% silver, 4% aluminum, 2% zinc, 7.9% tin , 8% iron, 4% nickel, 4% cobalt, 4% lead, 4% paraffin and 10% synthetic diamond.

Embodiment 2

[0087] A composite superhard honing stone containing zirconia, said honing stone is mainly composed of the following raw materials in weight percentage: 2% zirconia, 50% copper, 2% silver, 4% aluminum, 2% zinc, 8% tin , iron 8%, nickel 3%, cobalt 3%, lead 4%, polyoxymethylene 4% and cubic boron nitride 10%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com