Patents

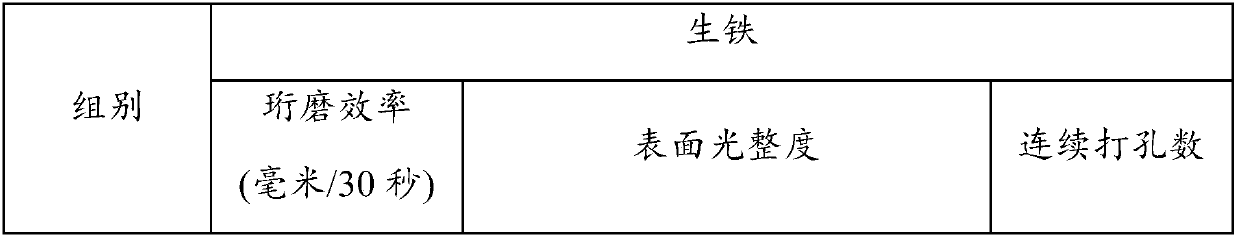

Literature

45 results about "Honing oil" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Honing oil is a liquid, solution or emulsion used to aid in the cutting or grinding of metal, typically by abrasive tools or stones, and may or may not contain oil. It can also be called machining oil, tool oil, cutting fluid, and cutting oil.

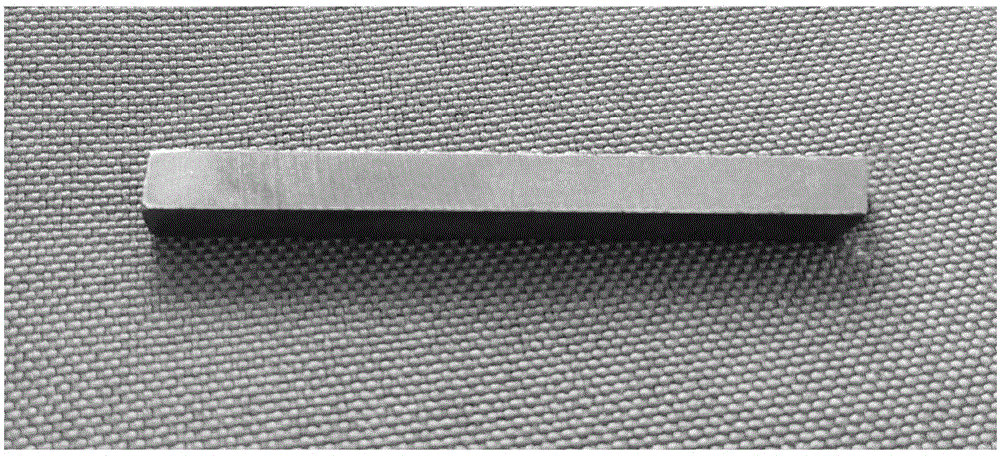

Mixed ultra-hard abrasive honing stone

InactiveCN104400614AReduce processing costsEasy to manufactureOther chemical processesAbrasion apparatusNickelHot press

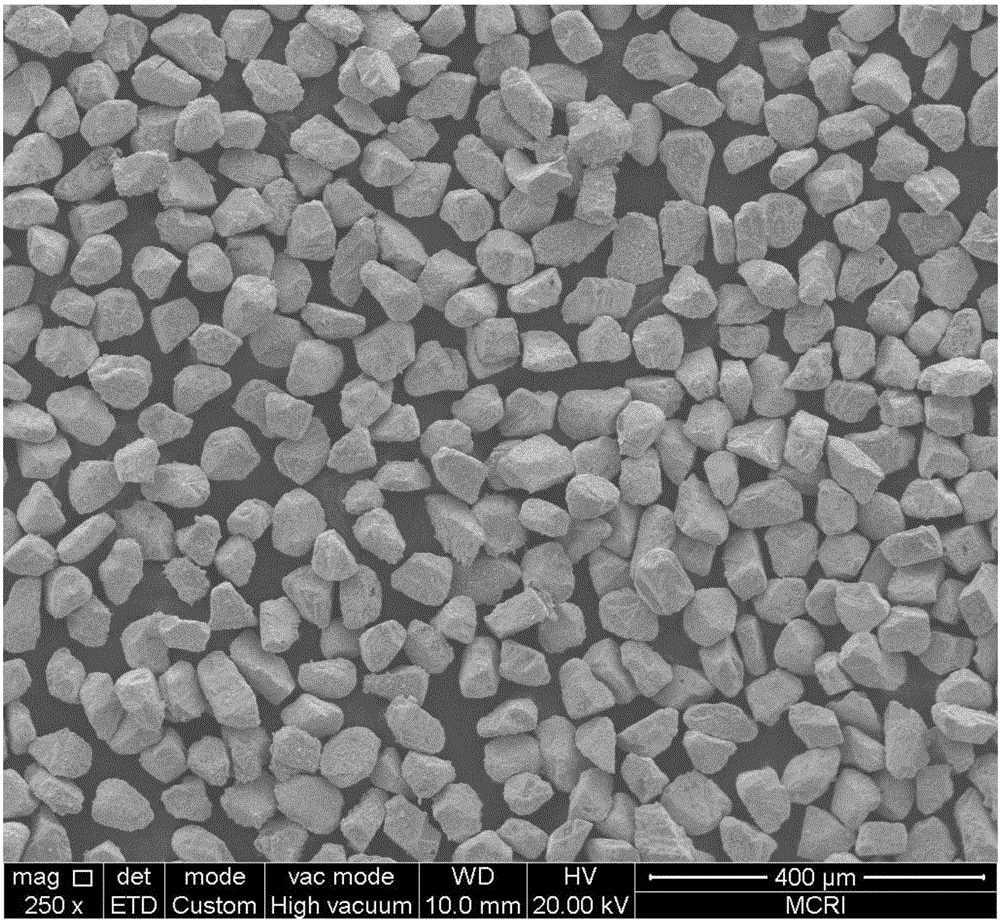

The invention discloses a mixed ultra-hard abrasive honing stone. The mixed ultra-hard abrasive honing stone is characterized by comprising the following components in percentage by weight: 20-40 percent of copper, 2-6 percent of silver, 1-10 percent of aluminum, 2-6 percent of zinc, 2-20 percent of tin, 10-20 percent of iron, 5-10 percent of nickel, 5-30 percent of cobalt, 1-9 percent of lead, 5-10 percent of a bonding agent and the balance of an ultra-hard material, wherein the volume ratio is 60-100 percent; the metal purity of the copper, the silver, the aluminum, the zinc, the tin, the iron, the nickel, the cobalt and the lead is over 99 percent; the granularity of the ultra-hard material is 200-1,000 meshes; the honing stone is prepared by performing mixing, cold press molding and vacuum hot press process on the raw materials according to the mixture ratio. The mixed ultra-hard abrasive honing stone disclosed by the invention has the advantages of sharp grinding, high grinding efficiency, large grinding weight, short grinding time, long service life, superior self-sharpening property, low process cost, easiness and convenience in preparation, and the like.

Owner:YINCHUAN HENGYIDA MACHINERY

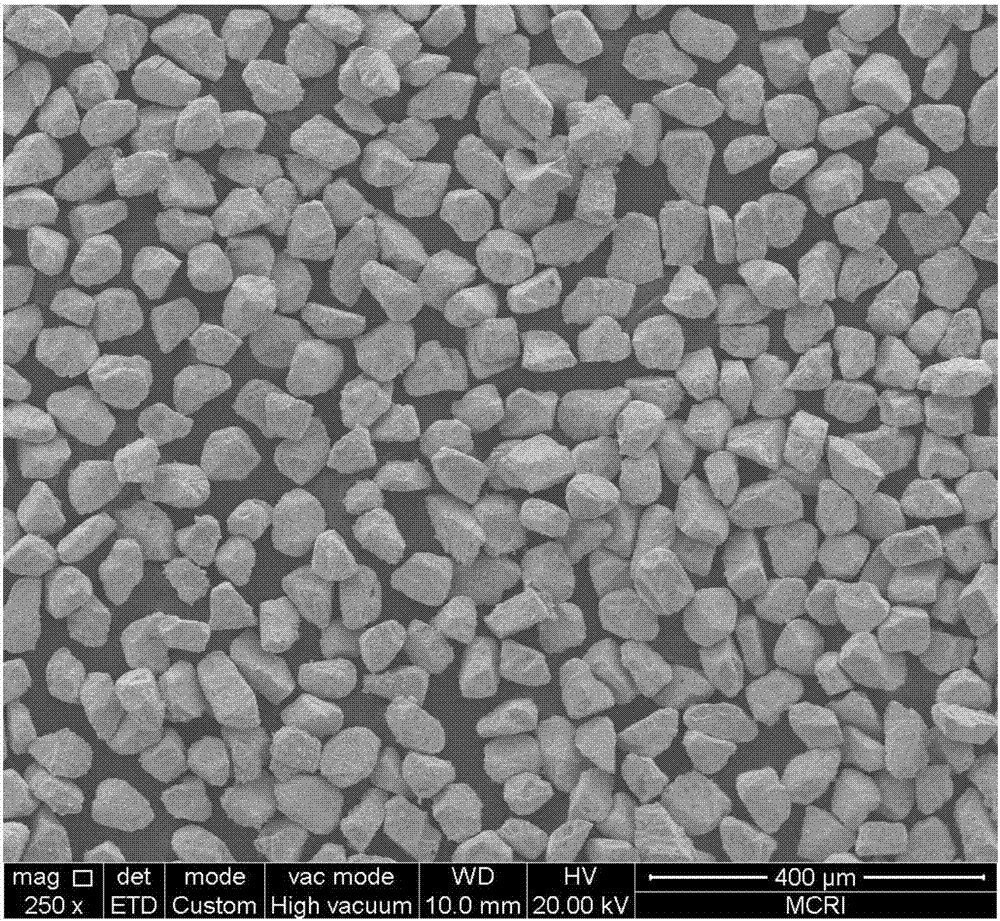

Preparation method of mixed ultra-hard honing oil stone

ActiveCN105803248AImprove cutting performanceImprove bindingTransportation and packagingAbrasion apparatusHoning oilSputtering

The invention relates to the technical field of ultra-hard honing, in particular to a preparation method of a mixed ultra-hard honing oil stone. The preparation method of the mixed ultra-hard honing oil stone is characterized in that diamond with the surface being subjected to tungsten-plating metallization and cubic boron nitride (CBN) with the surface being subjected to tungsten-plating metallization are used for preparing the honing oil stone as abrasive materials. The preparation method comprises the steps that firstly, the molten salt process and magnetron sputtering tungsten-plating pretreatment are conducted on diamond abrasive particles and CBN abrasive particles; secondly, the pretreated abrasive particles and metal bonding agent powder are subjected to ball milling after being mixed according to a certain proportion; and thirdly, mixed powder subjected to ball milling is placed in a graphite mold to be hot-pressed and sintered or is placed in a steel mold to be pressed into a blank, and non-pressure compacting sintering is conducted in the reducing atmosphere. The honing oil stone prepared through the preparation method has the advantages of being high in strength and hardness, high in honing efficiency, high in self-sharpness, long in service life and the like.

Owner:ZHENJIANG N E T DIAMOND

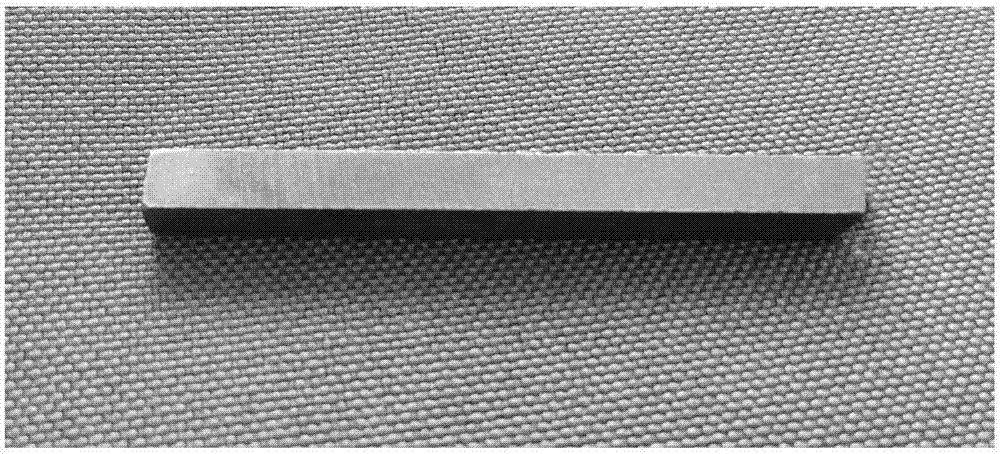

Diamond honing oilstone and preparation method thereof

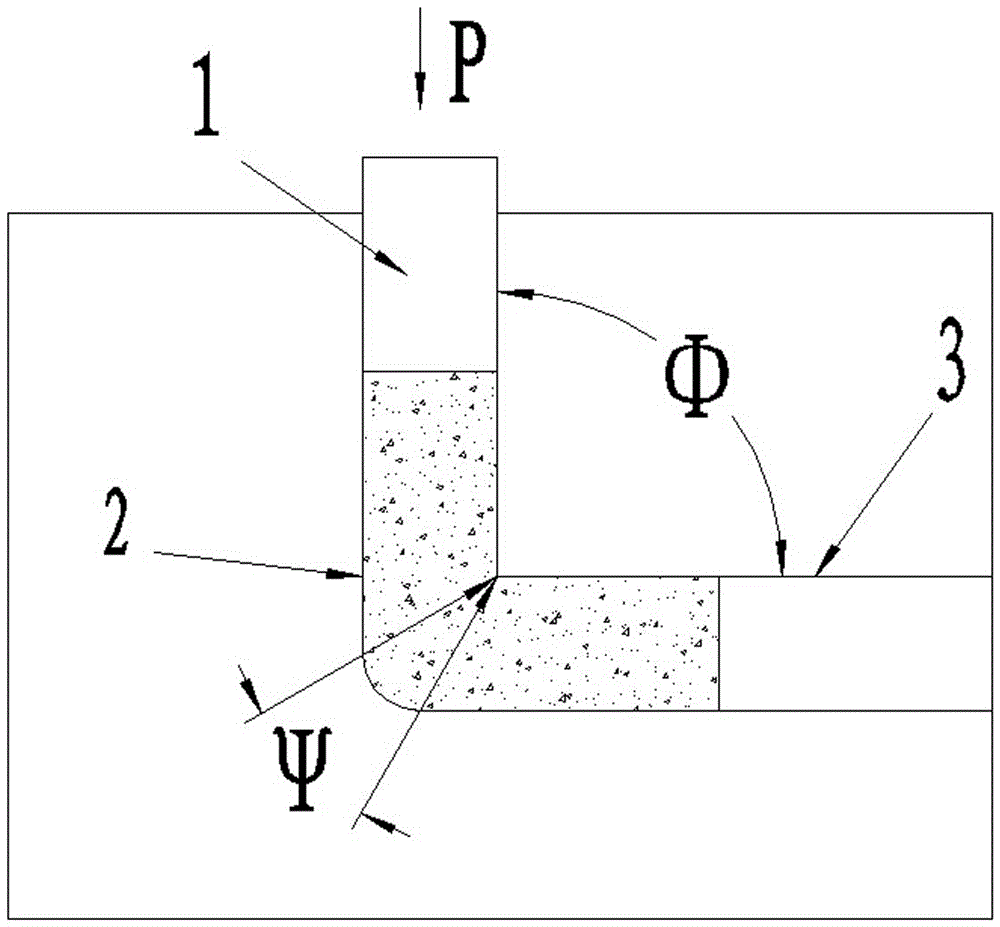

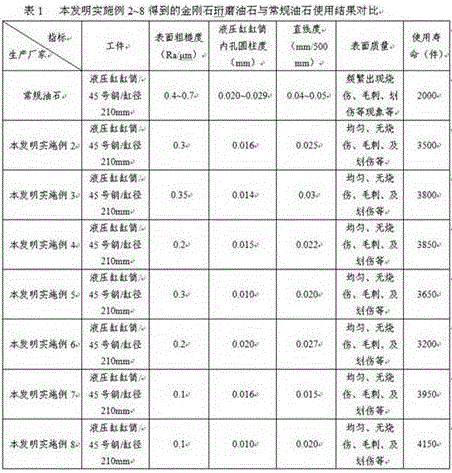

ActiveCN106217273AImprove cooling effectImprove plasticityAbrasion apparatusGrinding devicesHydraulic cylinderGranularity

The invention provides a diamond honing oilstone and a preparation method thereof. The diamond honing oilstone is prepared from, by weight percent, 5%-10% of diamond micro-powder with the granularity ranging from 400 meshes to 1000 meshes and 90%-95% of a metal bond. The metal bond is composed of 45%-55% of copper-tin pre-alloyed powder, 12%-20% of silver powder, 30%-33% of magnesium powder and 2%-5% of talcum powder with the granularity ranging from 200 meshes to 800 meshes. The specific preparation method includes the steps that an oilstone blank is prepared through the procedures such as material mixing, mold forming, sintering and equal channel angular extrusion; and finally, machining is conducted on the oilstone blank, and a finished product with the qualified size precision is obtained. The oilstone manufactured through the method solves the problems that at present, a hydraulic cylinder barrel honing oilstone machining hydraulic cylinder barrel is low in cylindricity and poor in straightness accuracy, the surface roughness does not reach the standard, and burns, burrs and hydraulic cylinder barrel inner hole surface scratches exist, meanwhile, hardness of the oilstone is improved, the shape retention is improved, and the service life is prolonged.

Owner:ZHENGZHOU RES INST FOR ABRASIVES & GRINDING CO LTD

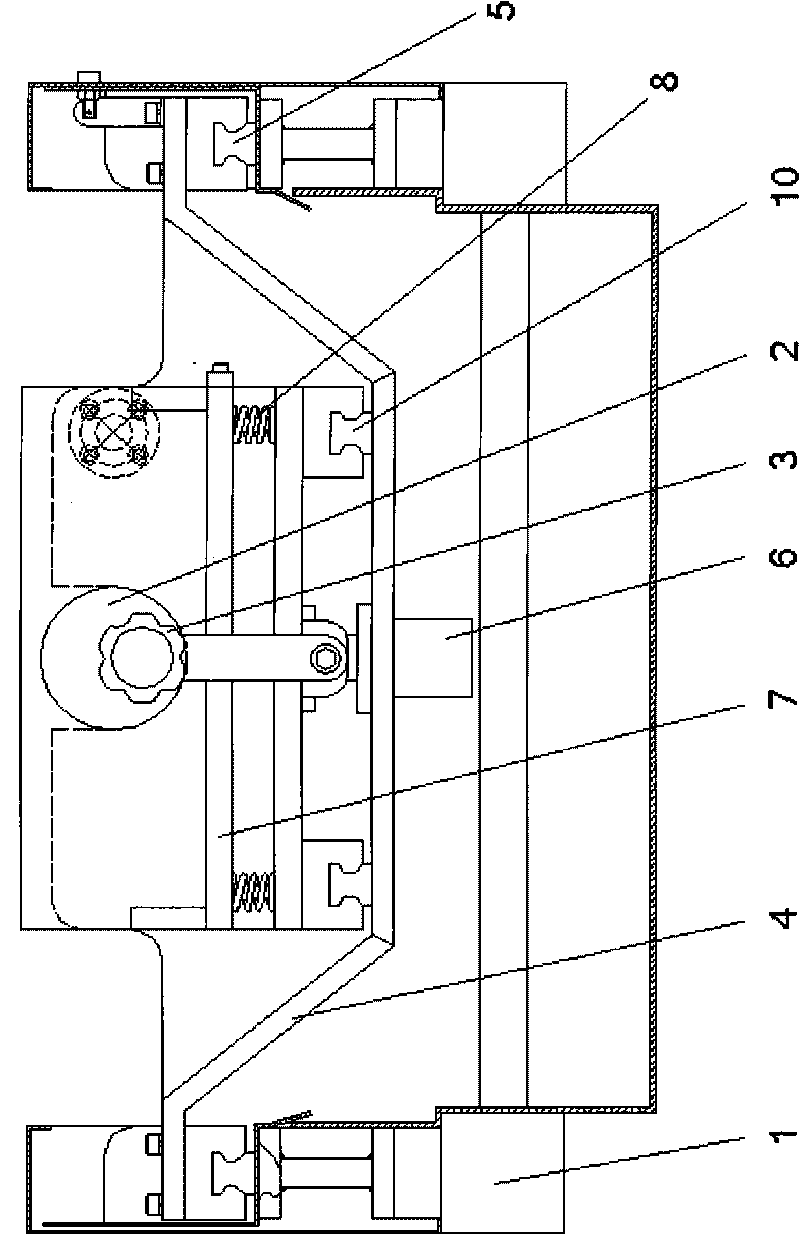

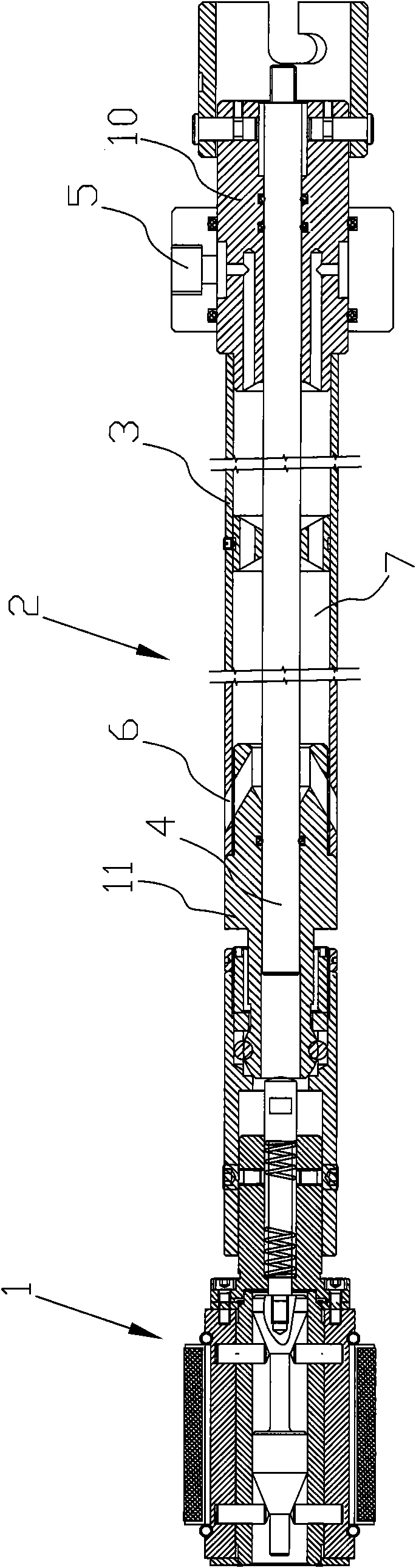

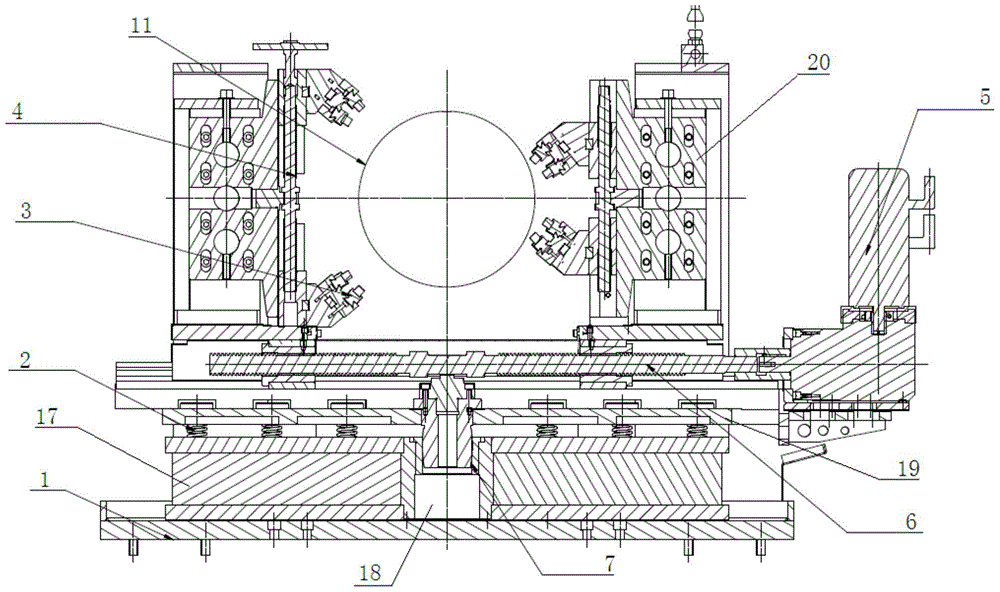

Inner bore honing machine

InactiveCN101758449AReduce gapImprove machining accuracyHoning machinesHoning oilReciprocating motion

The invention discloses an inner bore honing machine relating to the technical field of honing machines, and solving the technical problem of improving honing precision. The honing machine comprises a rack, a principal axis, a honing oil stone rod, a workpiece bench and a reciprocator, wherein the principal axis is arranged on the rack and can be driven to rotate, and the honing oil stone rod is axially and fixedly connected with the principal axis. The honing machine is characterized in that the reciprocator comprises a stroke planker and an I-shaped straight ball-guide, wherein the I-shaped straight ball-guide is arranged on the rack and has the same axial direction with the principal axis; and the stroke planker is arranged on the I-shaped straight ball-guide and can be driven to carry out reciprocating motion along the I-shaped straight ball-guide. The workpiece bench comprises a positioning cylinder and a positioning supporting plate, wherein the positioning supporting plate is arranged on the stroke planker and is used for holding and fixing workpieces, and the positioning cylinder is used for positioning the positioning supporting plate; and the rack is also provided with a magnetic switch for controlling the motion of the positioning cylinder and the movement of the stroke planker. The inner bore honing machine provided by the invention can improve the machining accuracy of the workpieces.

Owner:上海鸿宁精密机械有限公司

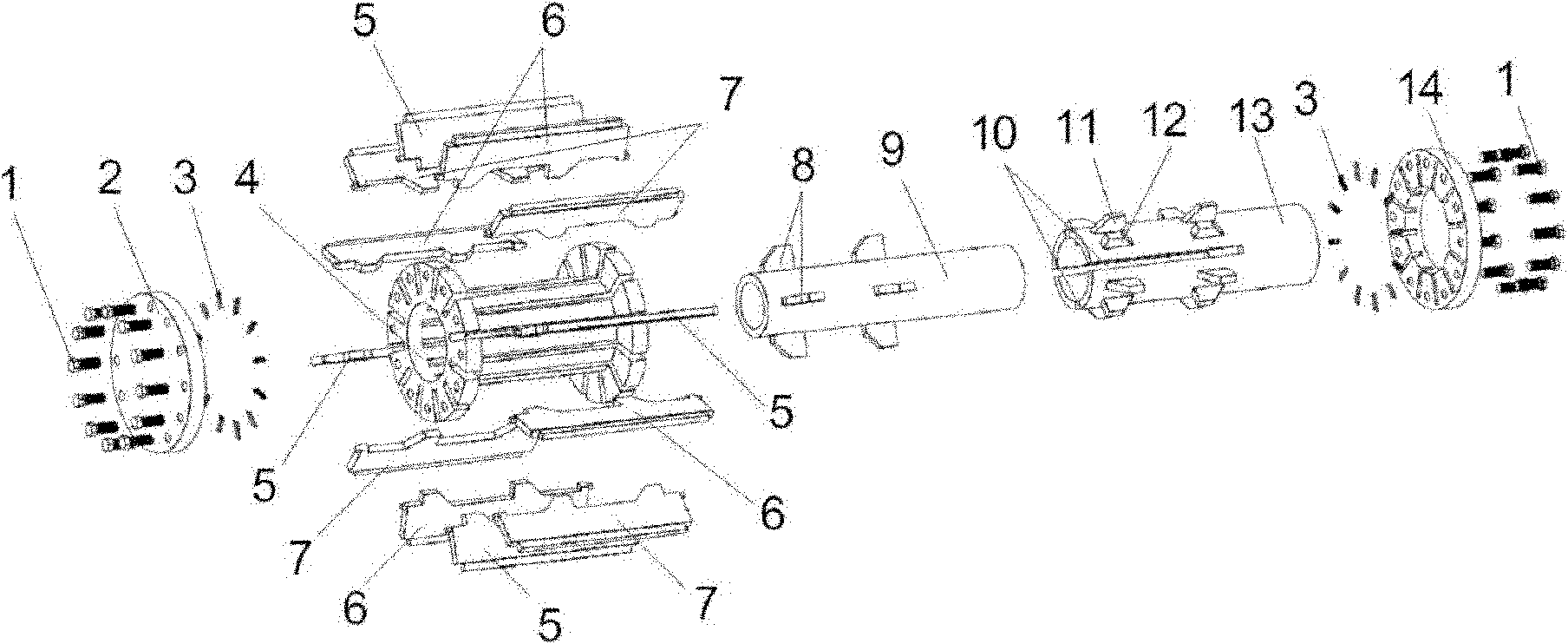

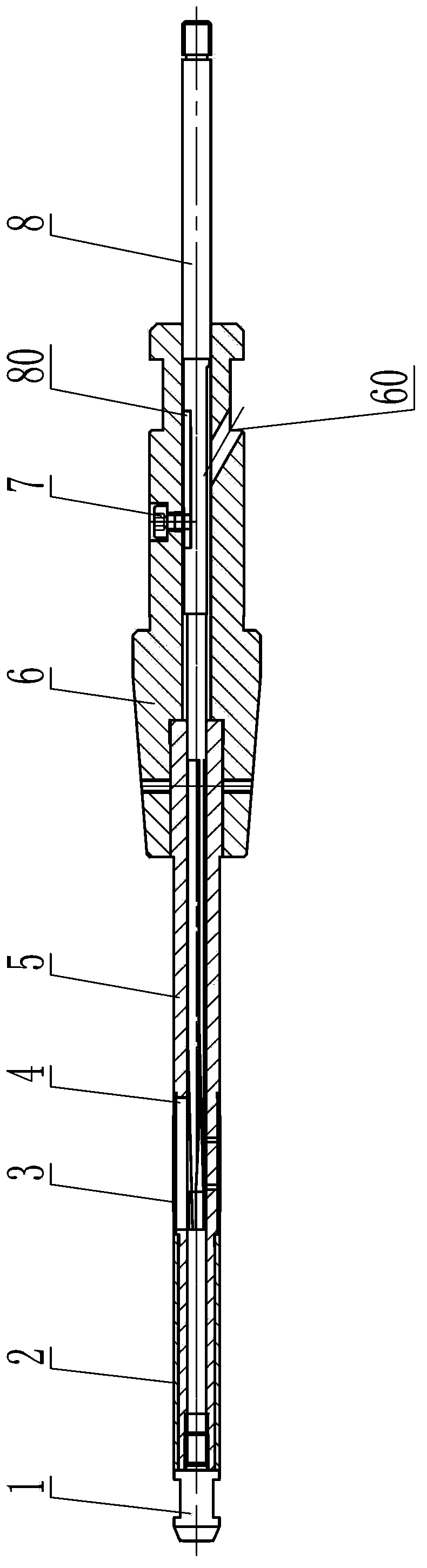

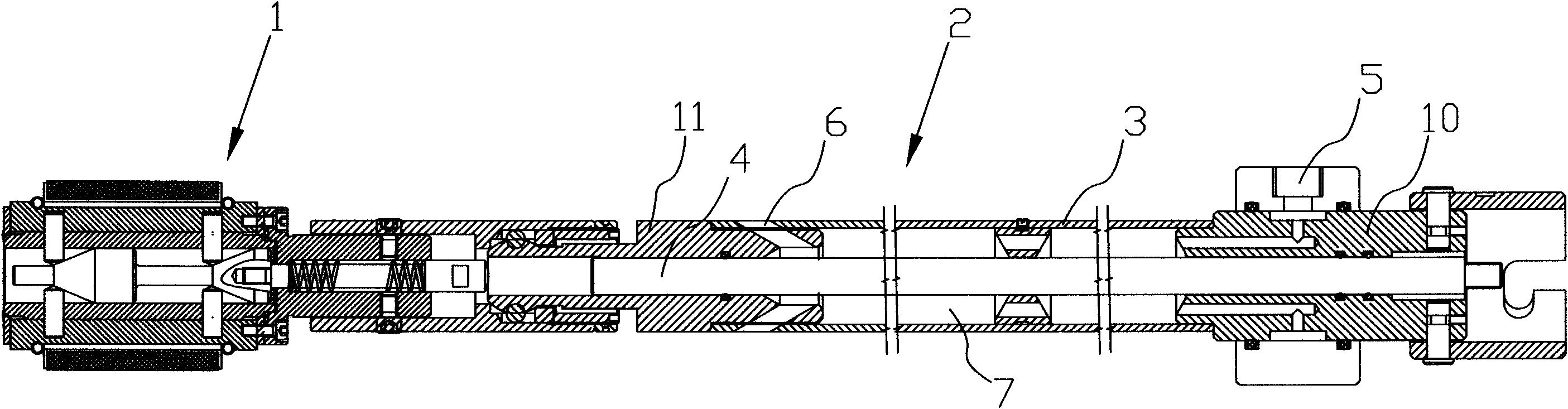

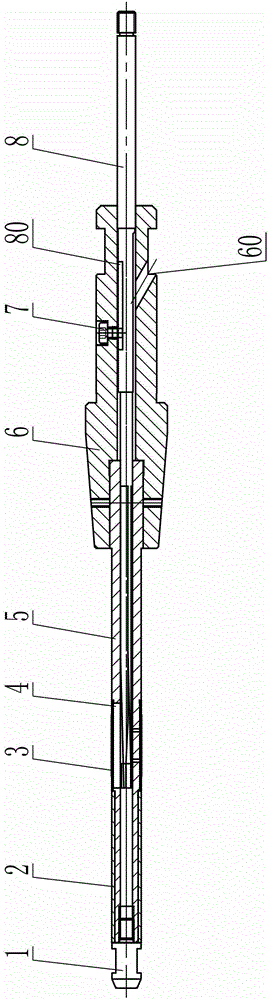

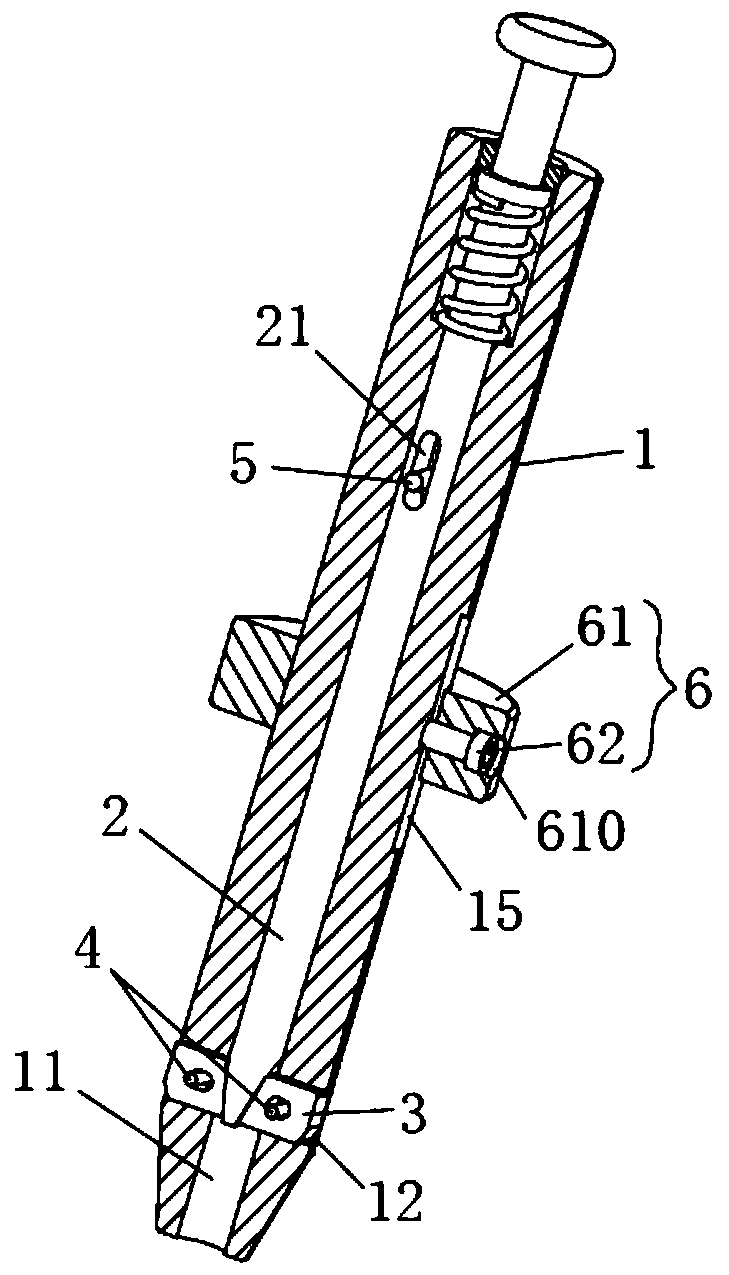

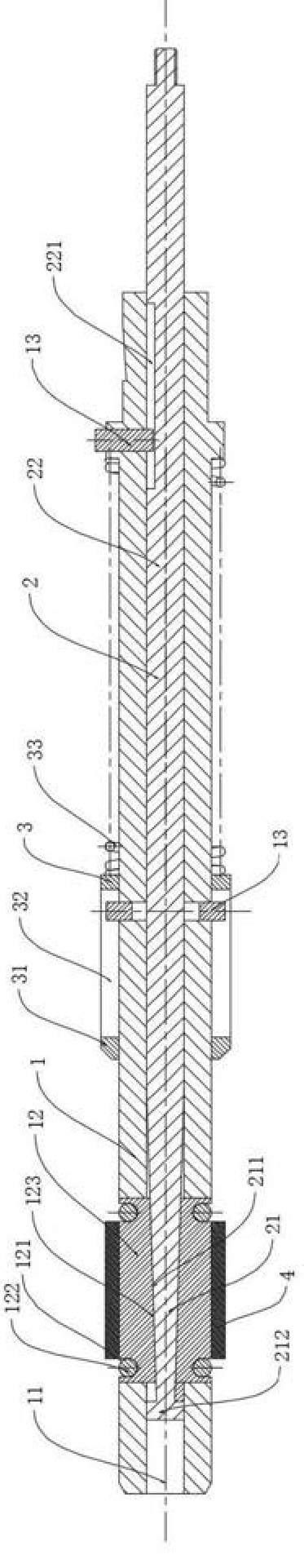

Novel automatic oil spout type honing lever

ActiveCN101549475AAvoid scratchesQuality improvementHoning toolsHoning machinesHoning oilPetroleum engineering

The scheme of the invention is that a novel automatic oil spout type honing lever includes an external tube and a push bar arranged in the external tube, the front end of the push bar is connected with a honing head, the honing lever is also provided with a honing oil inlet and a honing oil outlet, a space between the outer wall of the push bar and the inner wall of the external tube forms a oil piping, two ends of the oil piping are connected with the honing oil inlet and the honing oil outlet; after feeding the honing oil to the oil piping from the honing oil inlet, the honing oil will be injected from the honing oil outlet. The advantage of the invention is that the honing lever is provided with the honing oil inlet and the honing oil outlet, the honing oil outlet is arranged nearby the honing head, when honing, the honing oil is sprayed on an emery stick to wash away the abrasive dust, it is also capable of cooling honing parts rapidly, a great amount of cutting heat is carried off, a cutting burl which may scratch workpiece surface may be avoided, and the workpiece surface quality and honing efficiency is capable of being improved.

Owner:SUZHOU XINNENG PRECISE MACHINERY

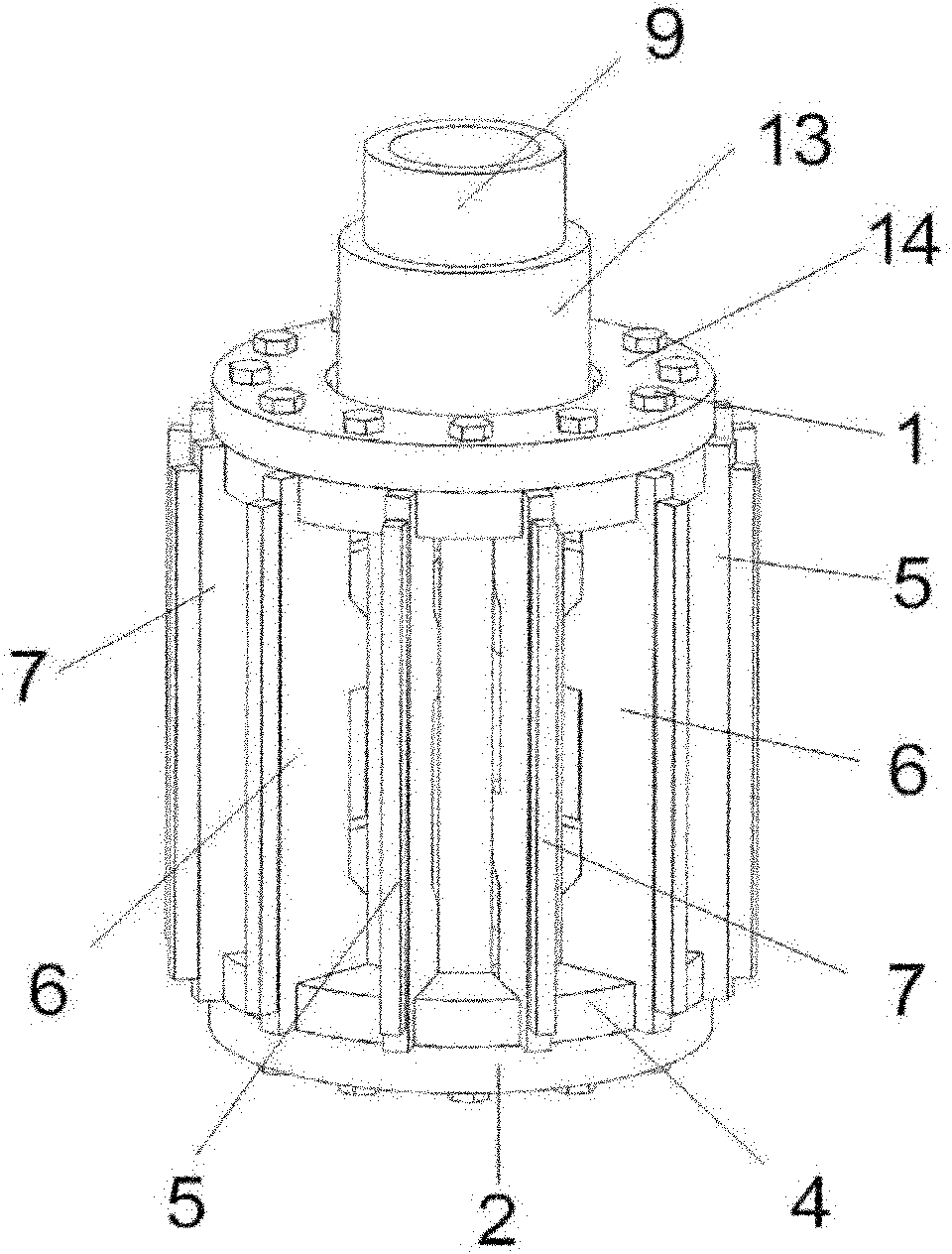

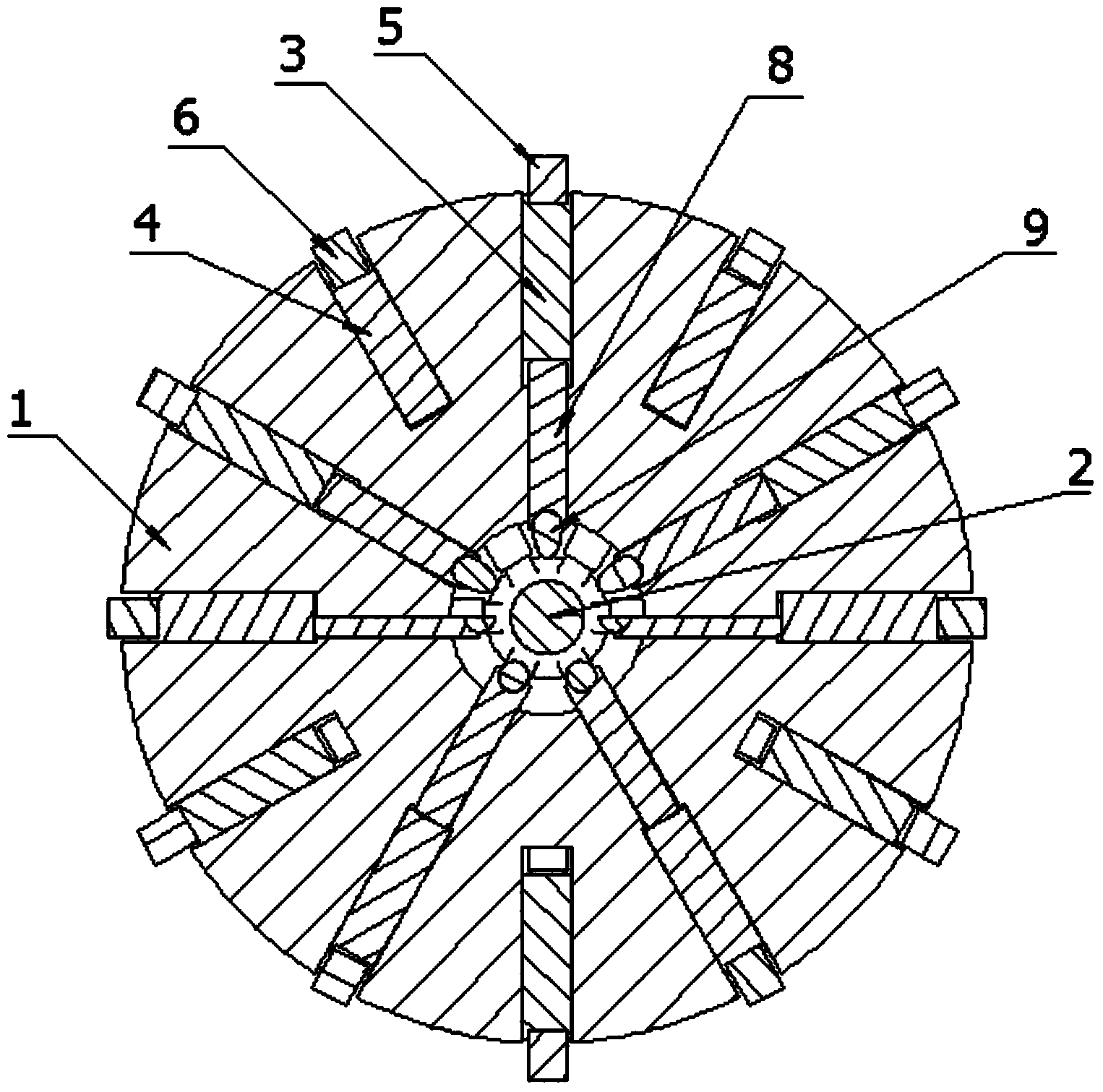

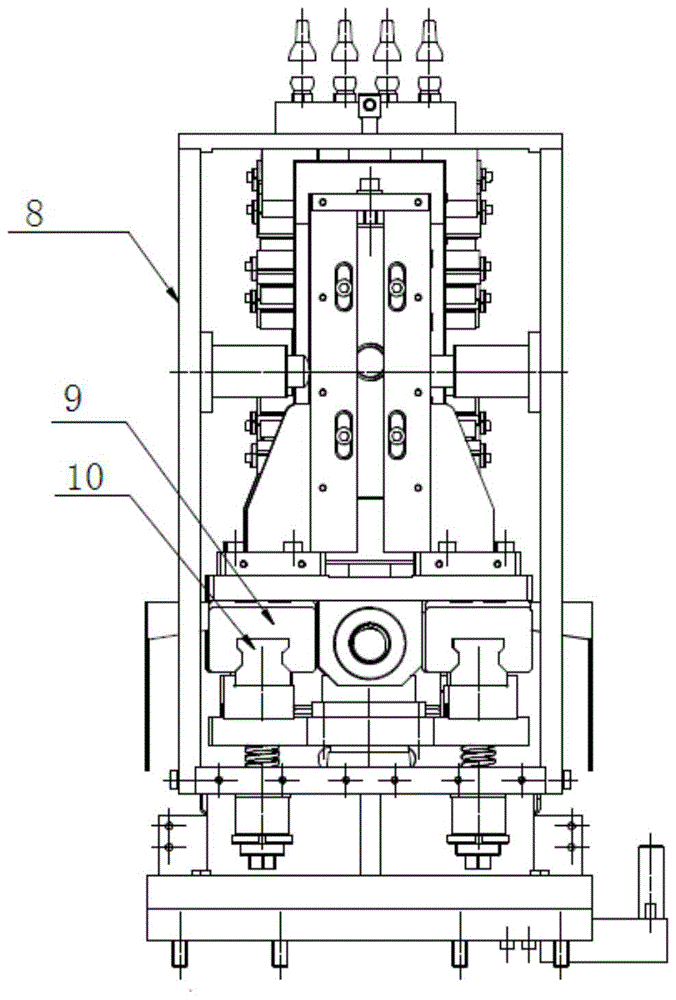

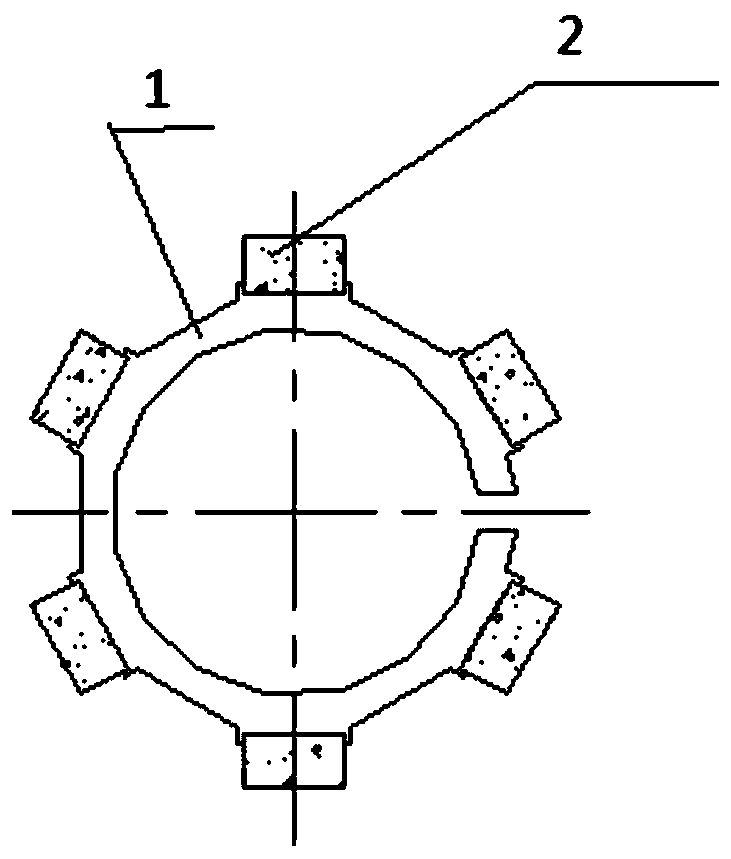

Honing head for platform screen

The invention discloses a honing head for a platform screen in the technical field of automobile part processing. The honing head comprises an upper end cover, a lower end cover, oil stone pressure springs, a support, coarse honing oil stones, refined honing oil stones, screen honing stones, an inner shaft and an outer shaft; the outer shaft is sleeved on the inner shaft; the inner shaft is arranged in a center hole of the support; the coarse honing oil stones, the refined honing oil stones, and the screen honing stones are uniformly and crosswise arranged on clamp grooves distributed on a circumference of the support uniformly; the oil stone pressure springs are arranged in clamp grooves radially distributed on the upper end cover and the lower end cover; and the edges of two sides of the coarse honing oil stones, the refined honing oil stones, and the screen honing stones are fixed in the clamp grooves of the upper end cover and the lower end cover and are connected with the oil stone pressure springs; and the upper end cover and the lower end cover are fixed at two ends of the support. The coarse honing oil stones, the refined honing oil stones, and the screen honing stones can be gathered on one honing head, the honing head or a honing machine tool is not needed to be replaced during conversion among coarse honing, refined honing and screen honing, the processing quality and efficiency of the platform screen can be effectively improved and the requirement of high-precision platform screen honing can be met.

Owner:SHANGHAI JIAO TONG UNIV

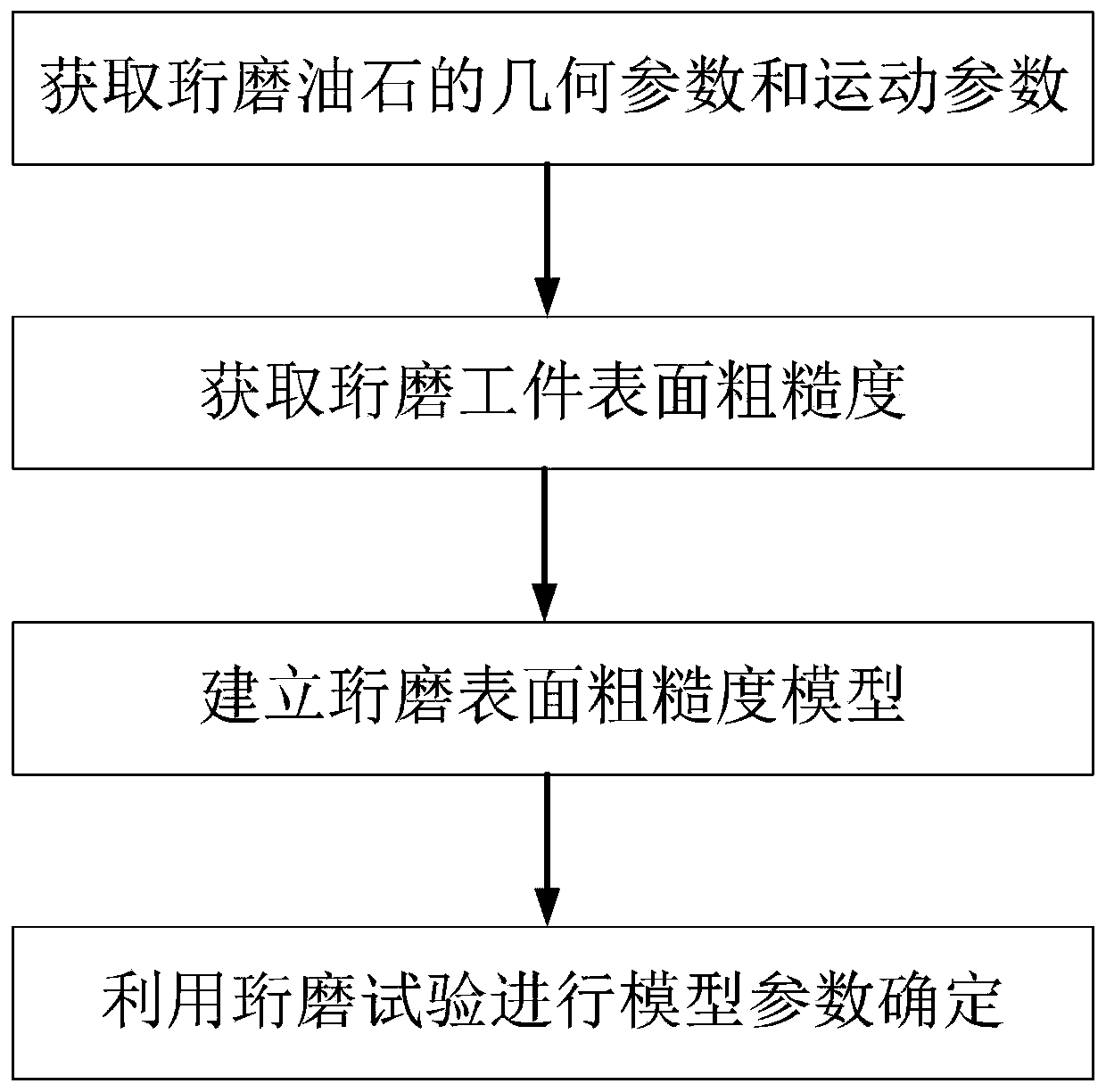

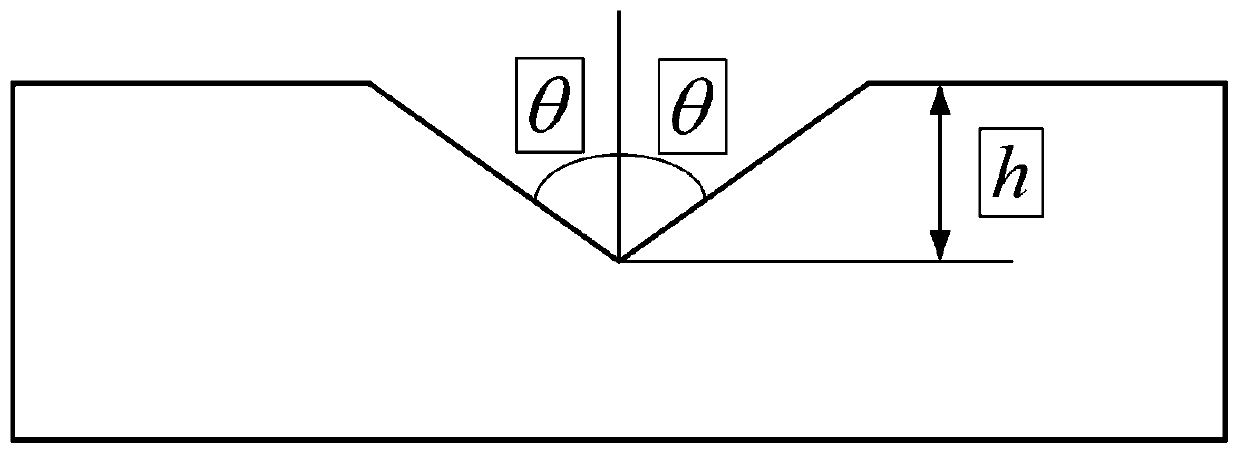

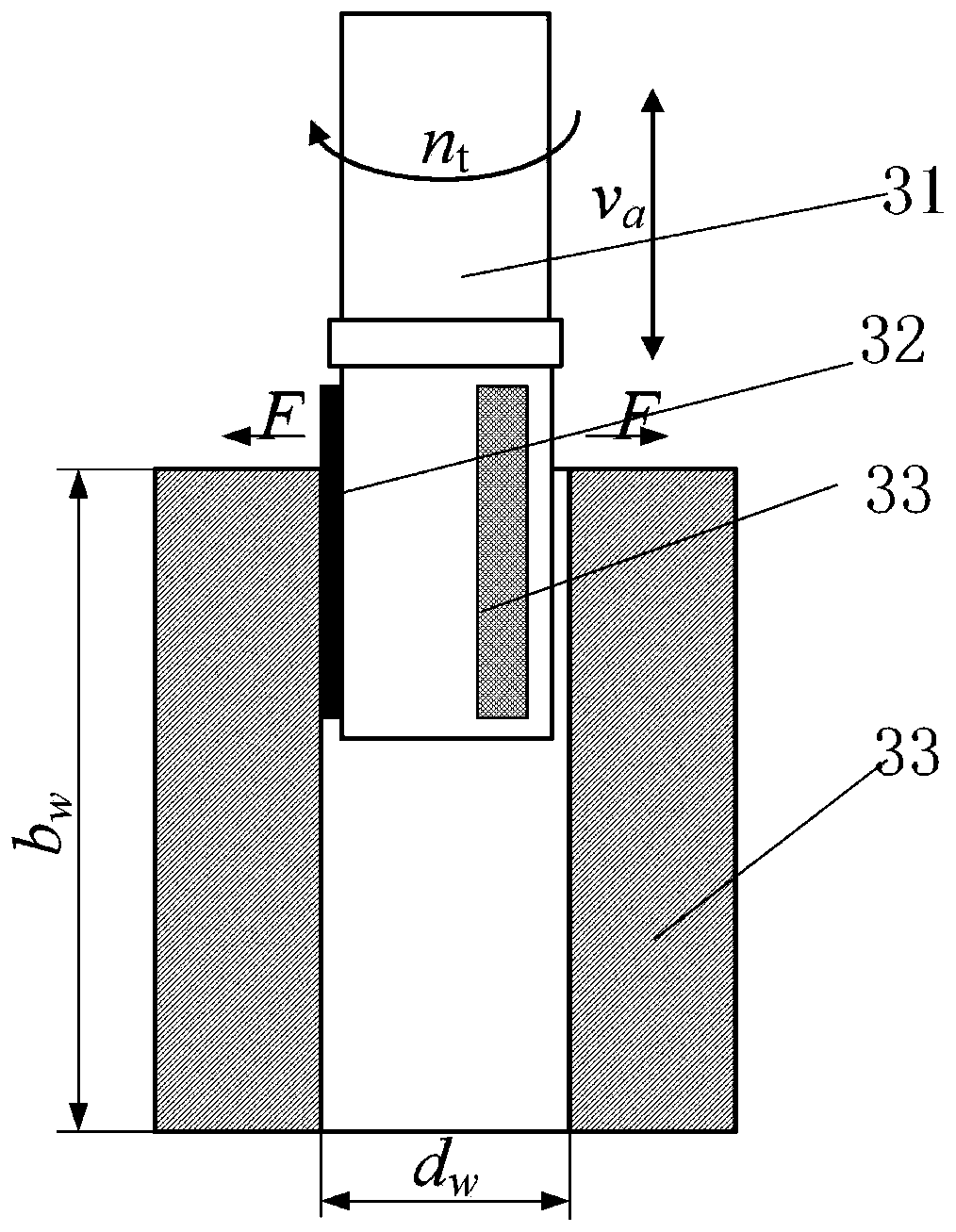

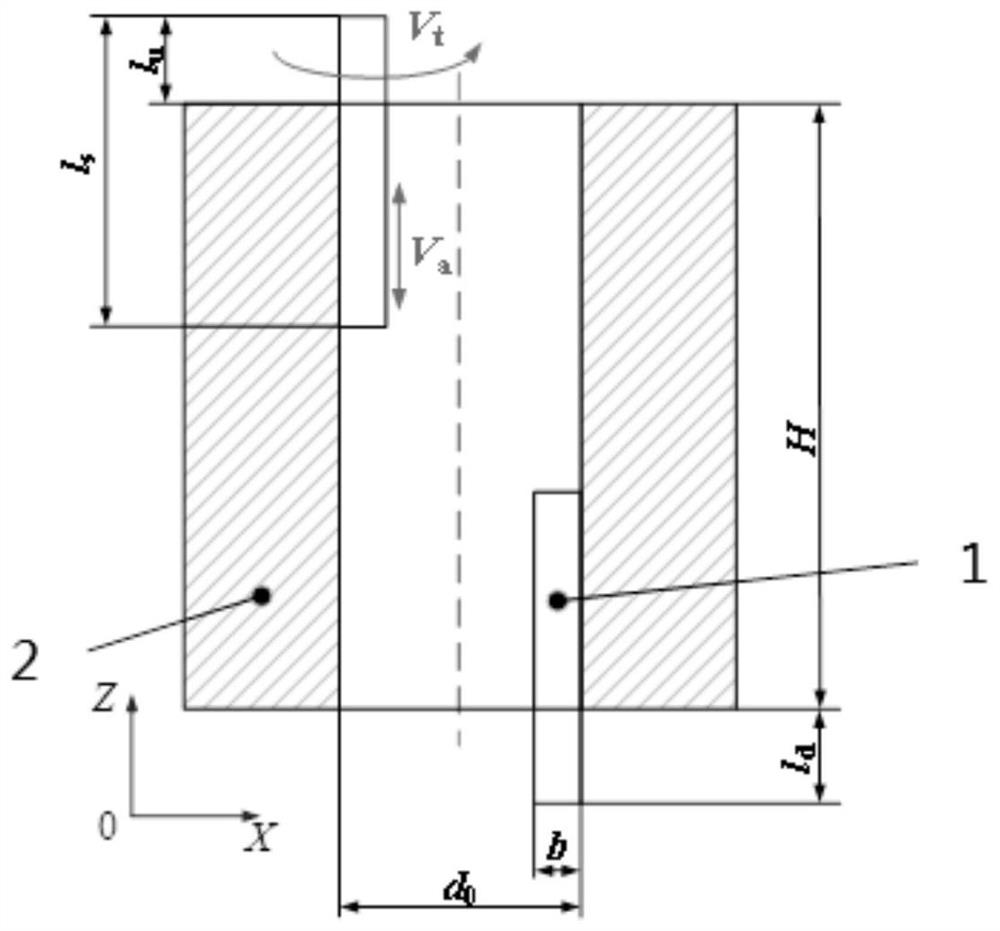

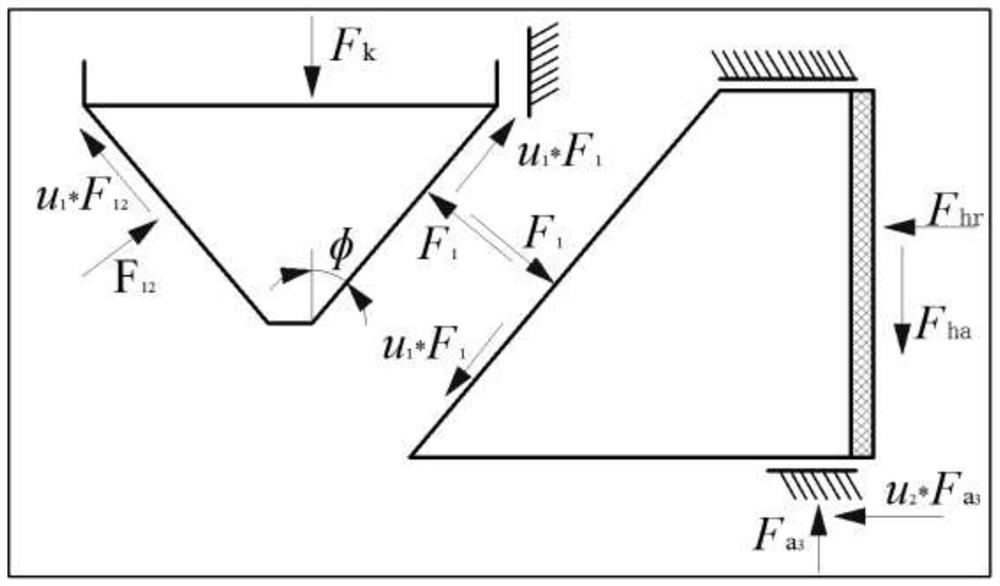

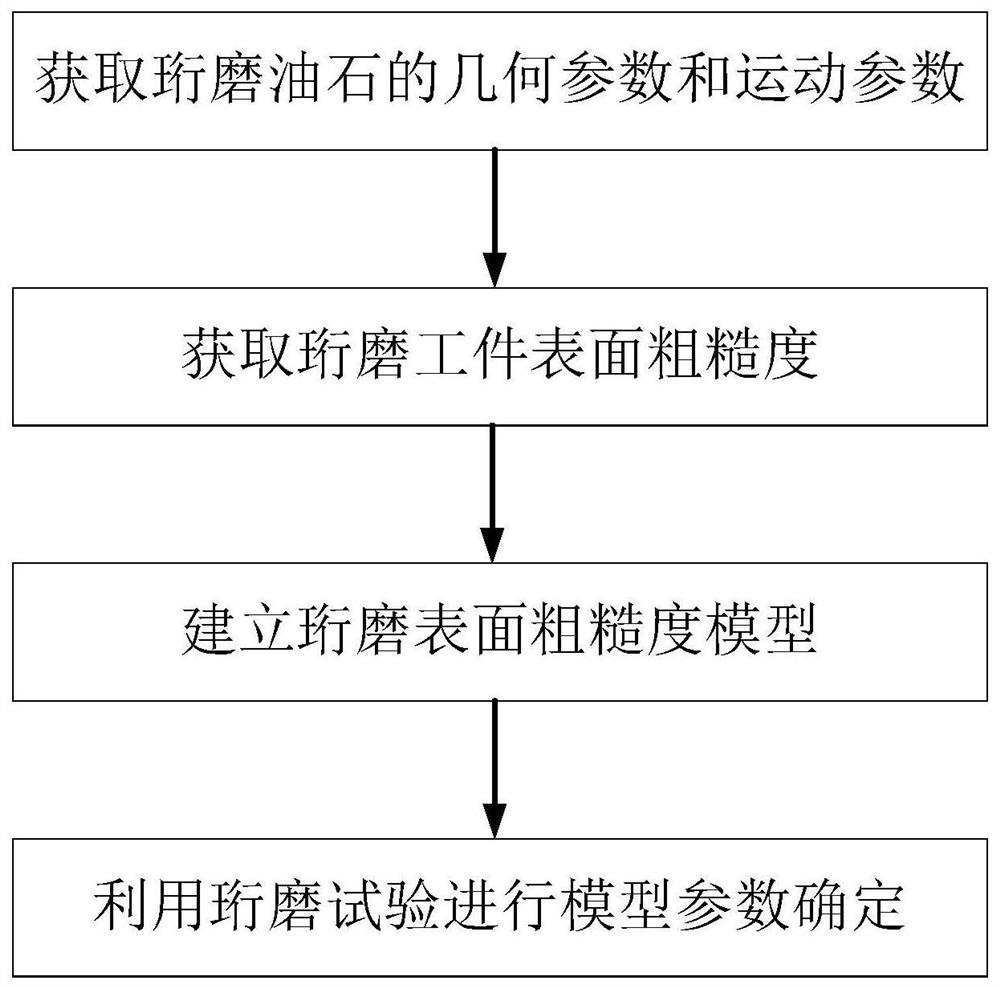

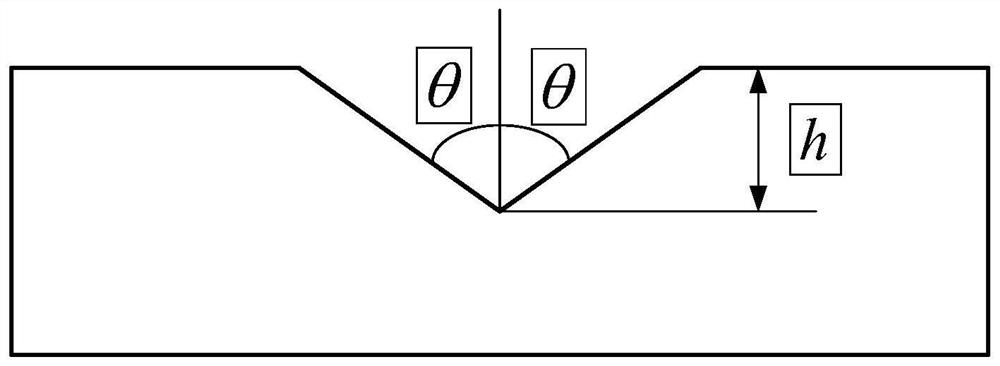

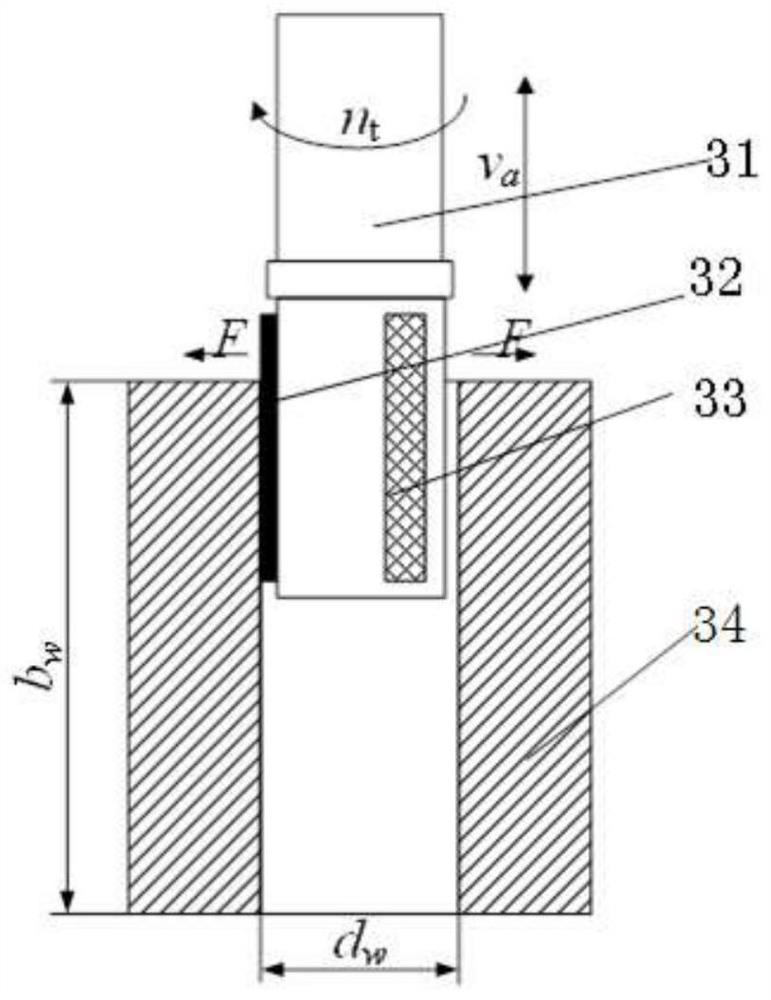

Honing surface roughness prediction method considering oilstone yielding

ActiveCN110893579AIncrease productivityShorten the timeDesign optimisation/simulationHoning machinesHoning oilSurface roughness

The invention discloses a honing surface roughness prediction method considering oilstone yielding, which comprises the following steps of: firstly, obtaining geometric parameters and honing process motion parameters of the surface of a honing oilstone, and finally predicting the honing surface roughness under the condition of considering grinding wheel yielding. The honing roughness is theoretically deduced according to the grinding principle, and the honing roughness of a small-diameter deep hole can be calculated by optimizing parameters through a small number of tests, so that a theoretical basis is provided for parameter selection of honing of the small-diameter deep hole, the production efficiency of enterprises is improved, and the production cost of the enterprises is reduced.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

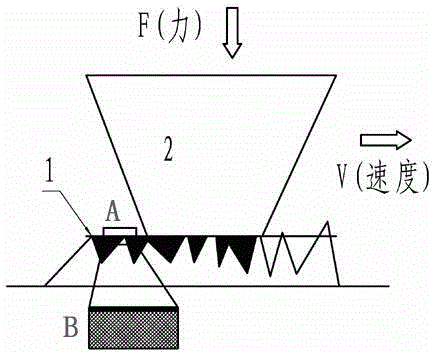

Honing technology for flat table reticulated lines at outside surface of piston ring

InactiveCN102039552AExtended service lifeEnhance oil storage lubrication performanceGrinding devicesHoning toolsHoning oilPiston ring

The invention relates to a honing technology for flat table reticulated lines at the outside surface of a piston ring, by which a honing head for honing an excircle is designed and a historical phenomenon that the honing technology only can be used for honing an inner hole but not the excircle in the world is changed. In the process of honing, a compression device at the outer part of the honing head is used for compressing honing oil at the inner part of the honing head to contact with the peripheral outside surface of the piston ring so as to form the flat table reticulated lines at the peripheral outside surface.

Owner:韦星野

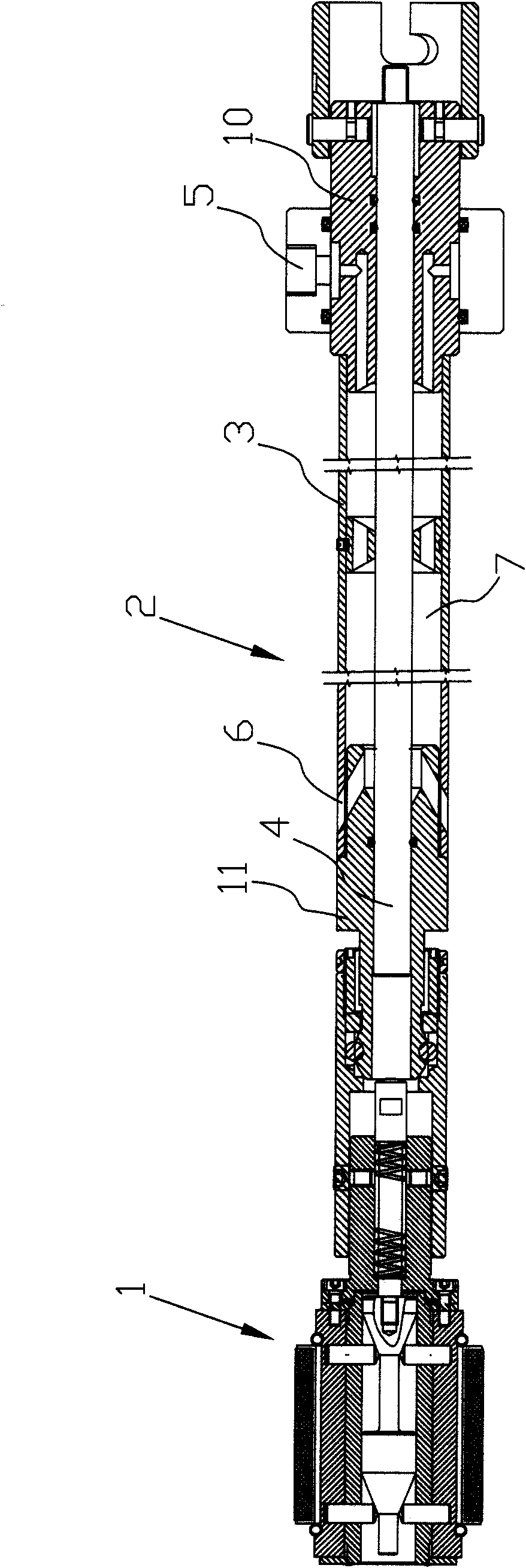

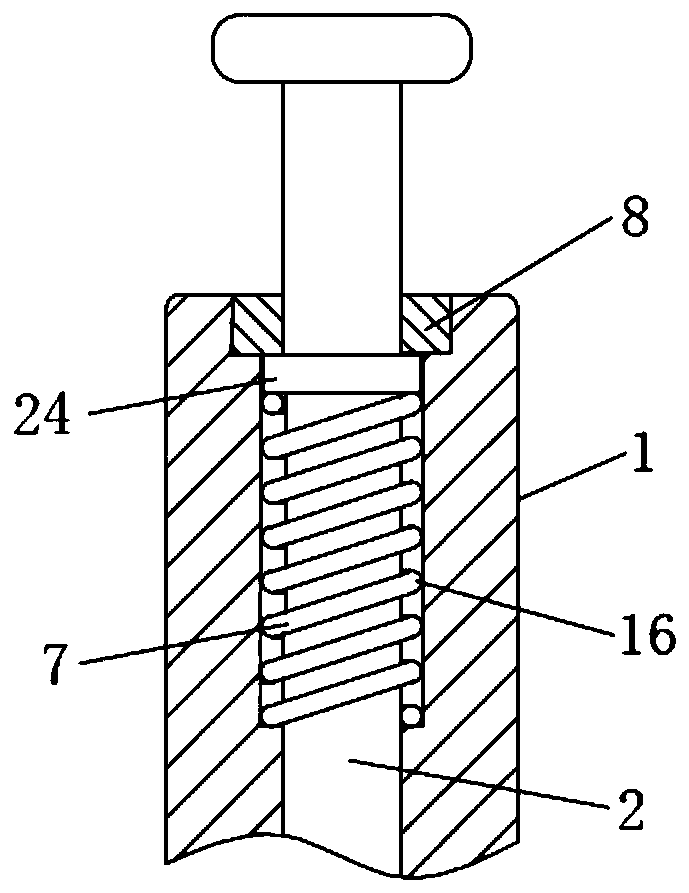

High-precision vertical internal oil injection diamond reamer

The invention relates to a high-precision vertical internal oil injection diamond reamer which comprises a reamer bar, a reamer bar female connector, a reamer sleeve and a push taper bar, wherein the reamer bar female connector is connected to the rear of the reamer bar, the reamer sleeve is sleeved in the middle of the reamer bar, and the push taper bar is arranged inside the reamer bar and the reamer bar female connector. A wedge block is arranged between an inclined surface of the push taper bar and the reamer sleeve, and radially expands along the reamer sleeve when the push taper bar moves forwards. An oil inlet hole is formed in the reamer bar female connector, oil outlet holes are formed in the reamer bar and the reamer sleeve respectively, and honing oil enters the reamer from the oil inlet hole, passes the insides of the reamer bar female connector and the reamer bar and flows out of the oil outlet holes. The high-precision vertical internal oil injection diamond reamer is novel and compact in structure, a guide position is long, the honing oil led in by the reamer bar female connector is injected from the oil outlet holes in the reamer bar and the reamer sleeve, cutting and wear heat can be rapidly dissipated, deformation of workpieces is decreased, and surface roughness is improved.

Owner:SUZHOU XINNENG PRECISE MACHINERY

Diamond honing oil stone for processing reticulate patterns on platform of cylinder sleeve and preparation method thereof

The invention discloses a diamond honing oil stone for processing reticulate patterns on the platform of a cylinder sleeve and a preparation method thereof. The diamond honing oil stone is characterized by being prepared by the following materials in percentage by weight: 50 to 88 percent of CuSn10 bronze powder, 5 to 20 percent of iron powder, 5 to 20 percent of nickel powder and 2 to 10 percent of artificial diamond, wherein the CuSn10 bronze powder, the iron powder and the nickel powder are used for preparing a metal bonding agent material, and the particle size of the artificial diamond is 100 to 320 meshes. The preparation method comprises the following steps of: mixing the raw materials; performing cold-press molding; and performing a vacuum hot-pressing process to obtain the honing oil stone. By the oil stone and the preparation method, the problems that the honed reticulate patterns cannot meet relevant indexes of cylinder sleeves in Euro III and Euro IV emission standards due to inconsistent depths and widths at the stage of processing the reticulate patterns of the cylinder sleeve by using the honing oil stone in the prior art are solved.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

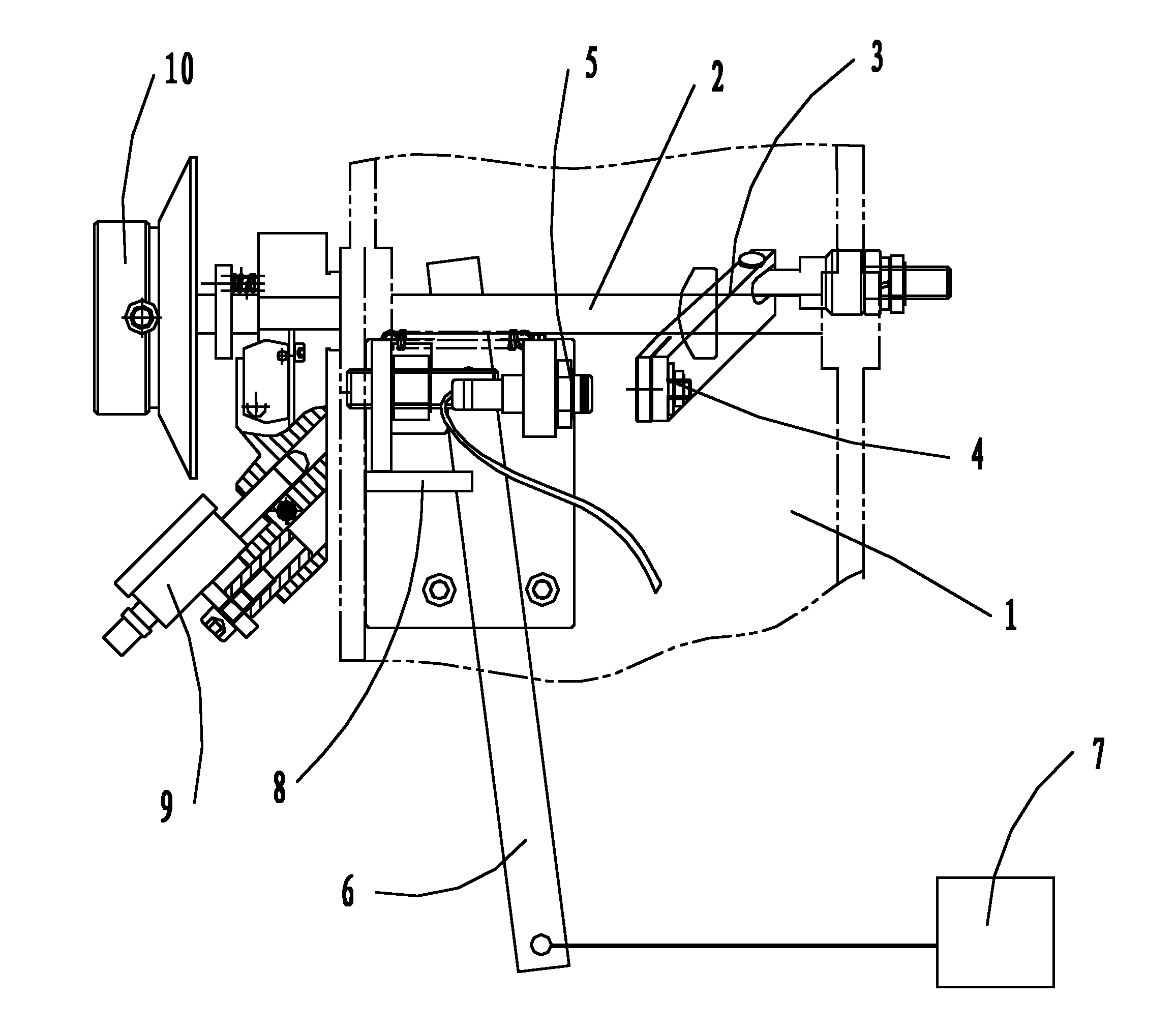

Automatic stop mechanism of honing machine

ActiveCN103170898ASimple structureEasy to operateGrinding drivesHoning machinesHoning oilProcess engineering

The invention discloses an automatic stop mechanism of a honing machine. A lever provided with an induction block is arranged on a feed screw, a spindle box is provided with an electromagnetic induction switch which can be connected with the induction block in an induction mode, and an electromagnet is arranged on the end portion of a draw bar and can be started when the induction block is connected with the electromagnetic induction switch in the induction mode. When the honing machine is used for homing and a honing oil stone mill starts to be abraded, the feed screw is enabled to recede, and the lever recedes along with the feed screw. When the lever recedes to a certain position, the induction block on the lever is connected with the electromagnetic induction switch in the induction mode and sends a signal to the electromagnet, the electromagnet is started to pull the end portion connected with the draw bar to move, the draw bar is enabled to rotate and break away from a hook plate, and then the honing machine stops. The automatic stop mechanism of the honing machine is simple in structure, convenient to operate and capable of stopping the honing machine quickly. Moreover, due to the fact that the electromagnet is used for control, the feed amount can be controlled accurately, the phenomenon that the honing machining is out of tolerance is avoided, and the quality of the honing machining is improved.

Owner:SUZHOU XINNENG PRECISE MACHINERY

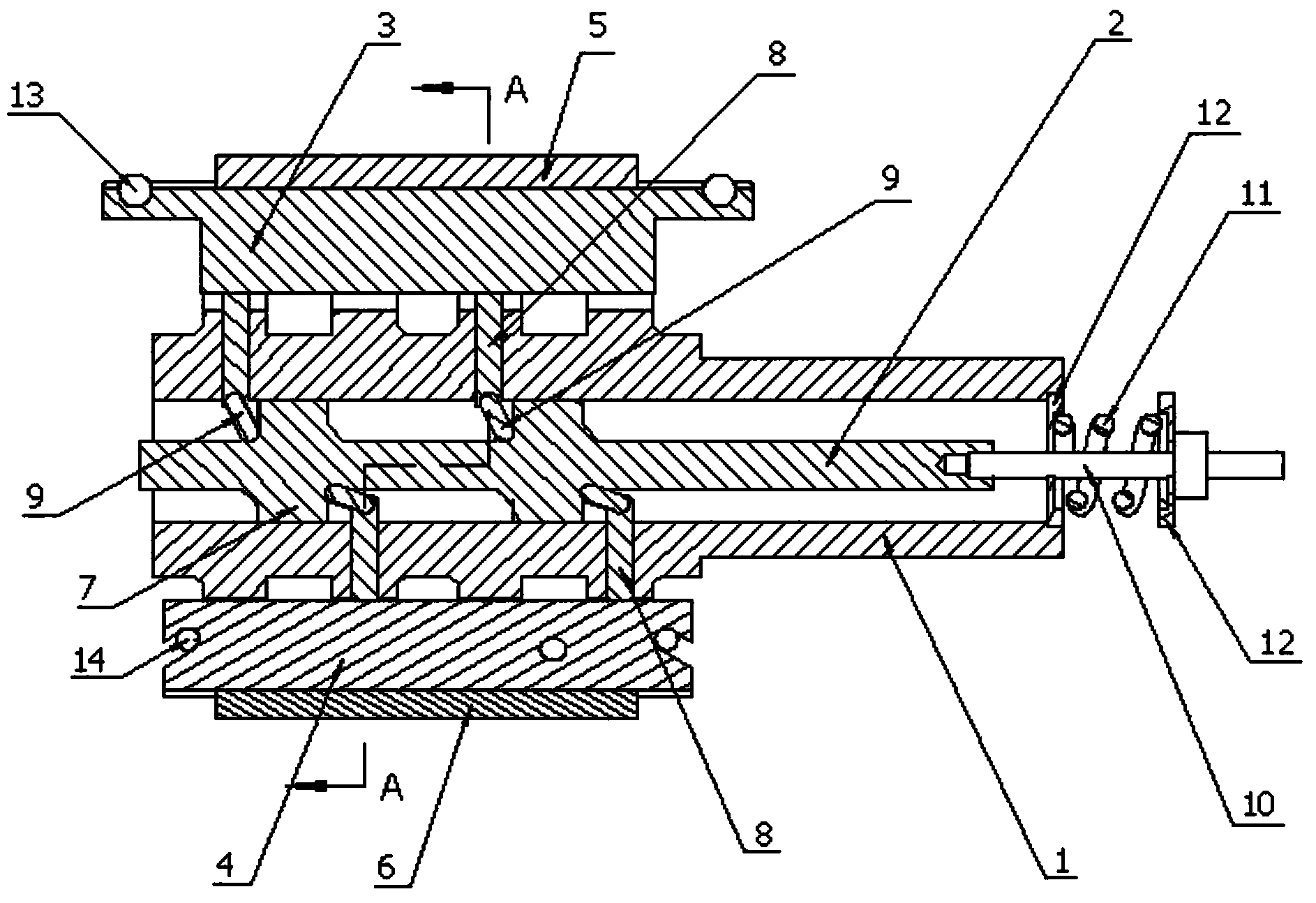

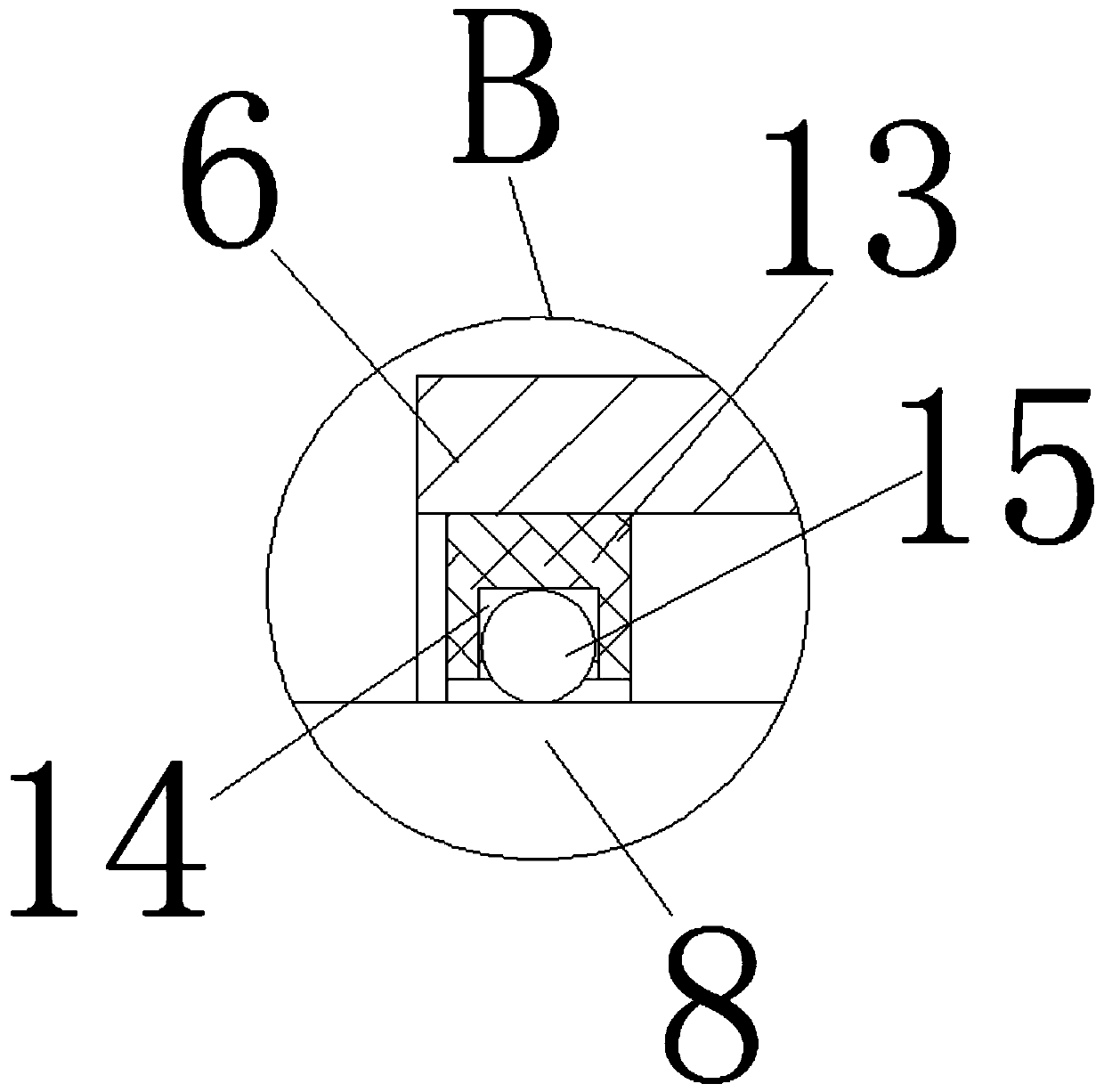

Double-precision honing device

ActiveCN103659564AImprove processing efficiencyReduce processing costsHoning toolsHoning machinesHoning oilPetroleum engineering

The invention discloses a double-precision honing device. The double-precision honing device comprises a honing base body, a push rod and a mandril assembly. A plurality of coarse oil stone grooves and fine oil stone grooves are formed in the outer circumference of the front end of the honing base body. A coarse oil stone base and a fine oil stone base are arranged in each coarse oil stone groove and each fine oil stone groove respectively, each coarse oil stone base is provided with a coarse honing oil stone, and each fine oil stone base is provided with a fine honing oil stone. Coarse oil stone pin holes and fine oil stone pin holes are formed in the coarse oil stone grooves and the fine oil stone grooves respectively. The push rod is provided with a shaft shoulder, and the coarse oil stone pin holes and the fine oil stone pin holes are placed in the front side and the rear side of the shaft shoulder respectively. Pins are arranged both in the coarse oil stone pin holes and the fine oil stone pin holes, and a ball pin is arranged between each pin and the shaft shoulder of the push rod. According to the double-precision honing device, the push rod, the pins and the ball pins are matched, the positions of the coarse honing oil stones and the positions of the fine honing oil stones in the radial direction can be adjusted, machining of two sorts of precision can be conducted on the same circular hole through the entire device, machining efficiency is improved, machining cost is lowered, and service life is prolonged.

Owner:SUZHOU VOCATIONAL UNIV

Polishing device capable of guaranteeing blank surface of hydraulic part

The invention relates to the technical field of polishing, and discloses a polishing device capable of guaranteeing a hydraulic part blank surface, which comprises a honing head body, a cylindrical mounting body is arranged on the periphery of the honing head body, an oilstone seat is slidably connected in the honing head body and the cylindrical mounting body, honing oilstones are fixed on the outer wall of the oilstone seat, and the honing oilstones are fixed on the outer wall of the oilstone seat. The two ends of the oilstone base are connected with springs in a penetrating mode, and a cone is movably connected into the honing head body. The groove is formed in the outer wall of the cone, the cone shaft drives the cone and the oilstone base to rotate asynchronously through meshing of the gear sleeve and the gear, when the oilstone base rotates to the groove, the oilstone base moves towards the interior of the groove under the action of the elastic force of the spring, honing oilstone is temporarily separated from the inner wall of a workpiece, and honing is completed. The honing oilstone and the inner wall of the workpiece can be flushed, the situation that flushing of the surface of the honing oilstone is affected due to the fact that the honing oilstone is tightly attached to the workpiece is avoided, and scraps attached to the surface of the honing oilstone are reduced.

Owner:徐州尚名机械有限公司

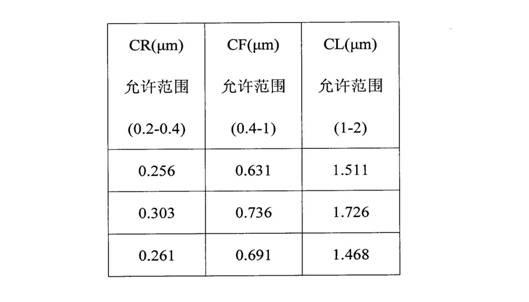

Precise honing aperture prediction and control method for hydraulic matching parts

The invention discloses a precise honing aperture prediction and control method for hydraulic matching parts. The method comprises the steps of acquiring the machining parameters and geometric parameters of honing oilstone and the aperture value of a bottom hole before honing; establishing a honing material removal volume prediction model, considering the influence of the retention time on the material removal volume of an overtravel section, obtaining an improved honing material removal rate formula, and preliminarily calculating the honing material removal rate Qm and Ds values; according to initial post-honing aperture distribution, calculating the retention time value of the overtravel section; establishing a honing material removal volume improvement prediction model, and predicting the honing material removal rate and the post-honing aperture value; and carrying out an orthogonal honing test, carrying out significance analysis on honing test data, analyzing the influence of various process parameters on the material removal rate and the post-honing aperture difference, and verifying the accuracy of the model. The result shows that the proper retention time is added, the optimal process parameters are adopted for honing machining, the requirement for post-honing aperture consistency can be met, and the honing material removal rate is increased.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

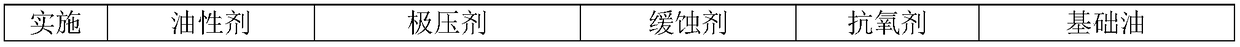

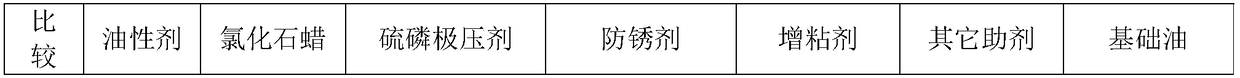

Honing oil composition and application thereof

InactiveCN108865366AImprove cooling effectImprove the lubrication effectLubricant compositionAntioxidantTackifier

The invention relates to a honing lubricating oil composition and application thereof. The honing lubricating oil is prepared from the following components in parts by weight: a) 90-98 parts of base oil, b) 1-4 parts of an extreme pressure agent, c) 2-6 parts of an oily agent, d) 0.1-1 part of antioxidant, and e) 0.1-1 part of corrosion inhibitor. In the honing lubricating oil, the low-viscosity base oil (the viscosity is not larger than 5 mm<2> / s at the temperature of 40 DEG C) is selected, and a tackifier or a viscosity index improver as well as chlorine elements and heavy metal elements badfor the environment is not added, so that the product has excellent cooling performance, settleability, permeability and high extreme pressure lubricity and anti-rust property and anti-corrosion property, and provides good lubrication protection for honing processing of precision parts such as an engine fuel injection pump, a fuel spray nozzle and a plunger and barrel assembly.

Owner:CHINA PETROLEUM & CHEM CORP

Novel air cylinder sleeve honing treatment process

InactiveCN104084875AReduce coefficient of frictionPrevent oxidationAdditivesHoning machinesHoning oilEngineering

The invention relates to a novel air cylinder sleeve honing treatment process. Honing oil selected during honing contains WS2 powder of 1.5-3wt%. By adding a certain amount of the WS2 powder in the honing oil, surface treatment is performed in the process of honing, in other words, a highly-thin WS2 friction film (with thickness not less than 0.05 micrometer) is formed on the surface of the inner wall of an air cylinder sleeve by means of extrusion and friction, so that friction characteristics of the surface of an inner hole of the air cylinder sleeve are changed, and friction reducing performance, wear resistance and corrosion resistance are improved.

Owner:ZYNP GRP

Method for improving bronzing effect of non-ferrous metal cardboard

The invention discloses a method for improving the bronzing effect on a non-ferrous metal paperboard, which comprises printing layer of UV honed oil on the part of the non-ferrous metal paperboard for bronzing before bronzing, and then performing the bronzing. If the honed effect is needed, the back part of a part needing the bronzing on the non-ferrous metal paperboard can be printed with a layer of the UV honed oil, and then the part needing the bronzing on the non-ferrous metal paperboard is printed with a layer of the UV honed oil again. Before the bronzing, if the UV honed oil is used for printing, for not influencing the bronzing effect, the part needing the bronzing on the non-ferrous metal paperboard is printed with a layer of UB honed oil contained in the UV honed oil before performing the bronzing, and then the part needing the bronzing is subjected to the bronzing.

Owner:JIANGSU DAREGLOBAL PRINTING CO LTD

Cylindrical honing machine

Owner:上海善能机械有限公司

Novel automatic oil spout type honing lever

ActiveCN101549475BAvoid scratchesQuality improvementHoning toolsHoning machinesHoning oilPetroleum engineering

The scheme of the invention is that a novel automatic oil spout type honing lever includes an external tube and a push bar arranged in the external tube, the front end of the push bar is connected with a honing head, the honing lever is also provided with a honing oil inlet and a honing oil outlet, a space between the outer wall of the push bar and the inner wall of the external tube forms a oil piping, two ends of the oil piping are connected with the honing oil inlet and the honing oil outlet; after feeding the honing oil to the oil piping from the honing oil inlet, the honing oil will be injected from the honing oil outlet. The advantage of the invention is that the honing lever is provided with the honing oil inlet and the honing oil outlet, the honing oil outlet is arranged nearby thehoning head, when honing, the honing oil is sprayed on an emery stick to wash away the abrasive dust, it is also capable of cooling honing parts rapidly, a great amount of cutting heat is carried off, a cutting burl which may scratch workpiece surface may be avoided, and the workpiece surface quality and honing efficiency is capable of being improved.

Owner:SUZHOU XINNENG PRECISE MACHINERY

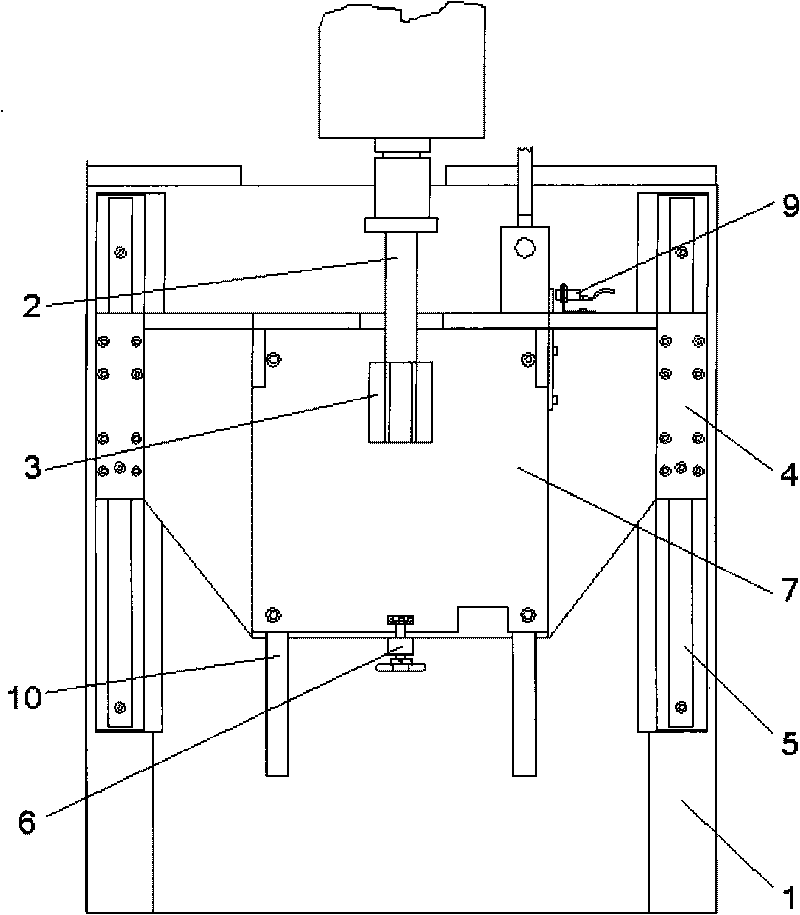

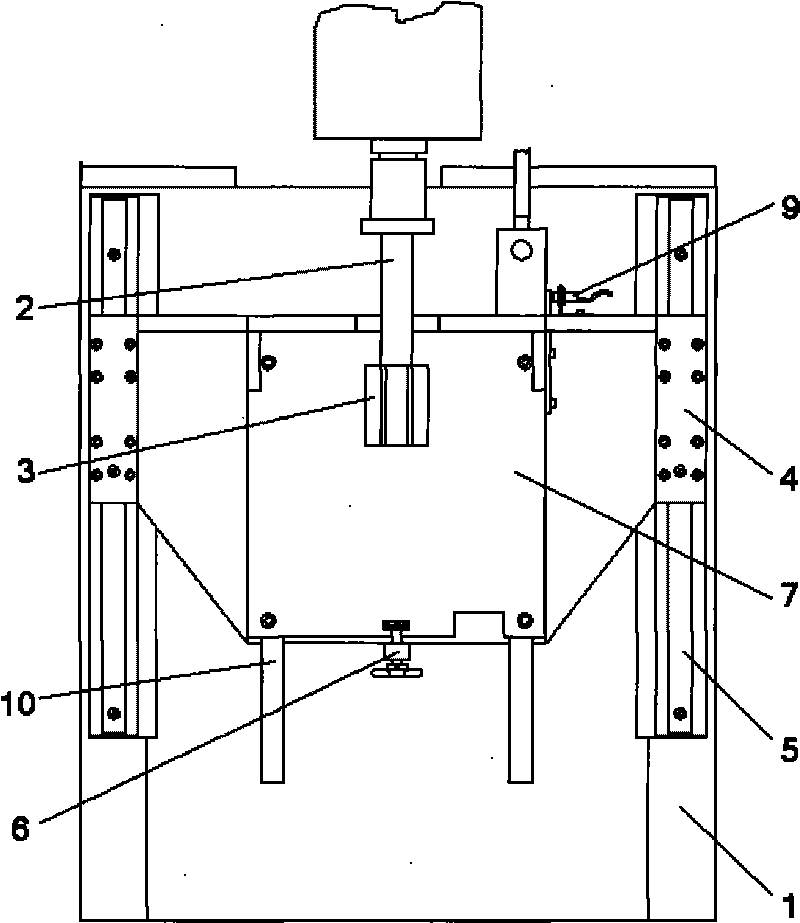

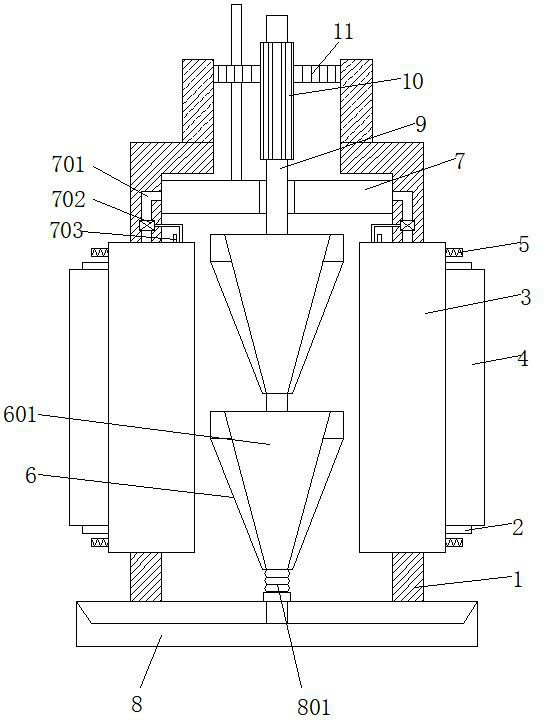

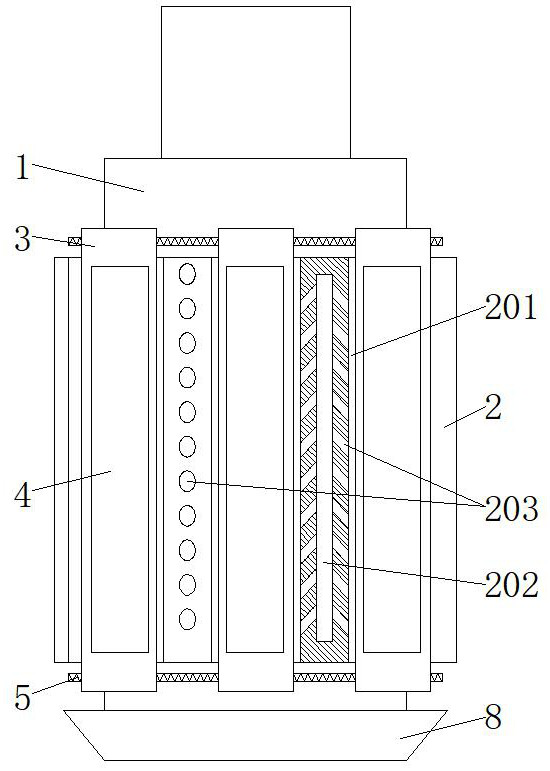

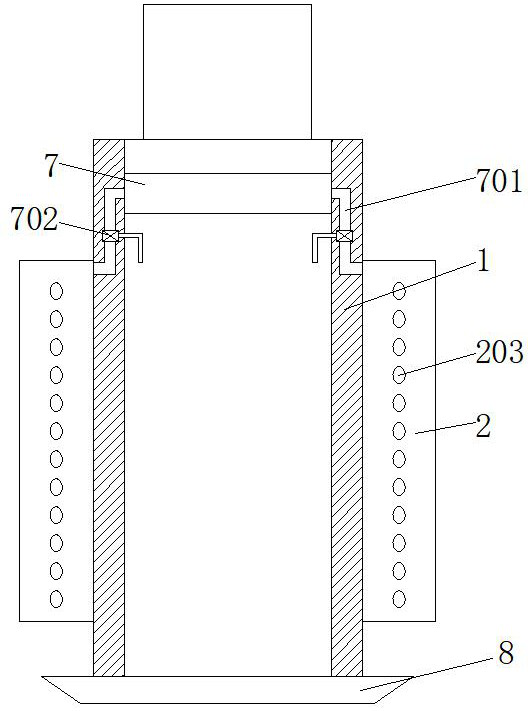

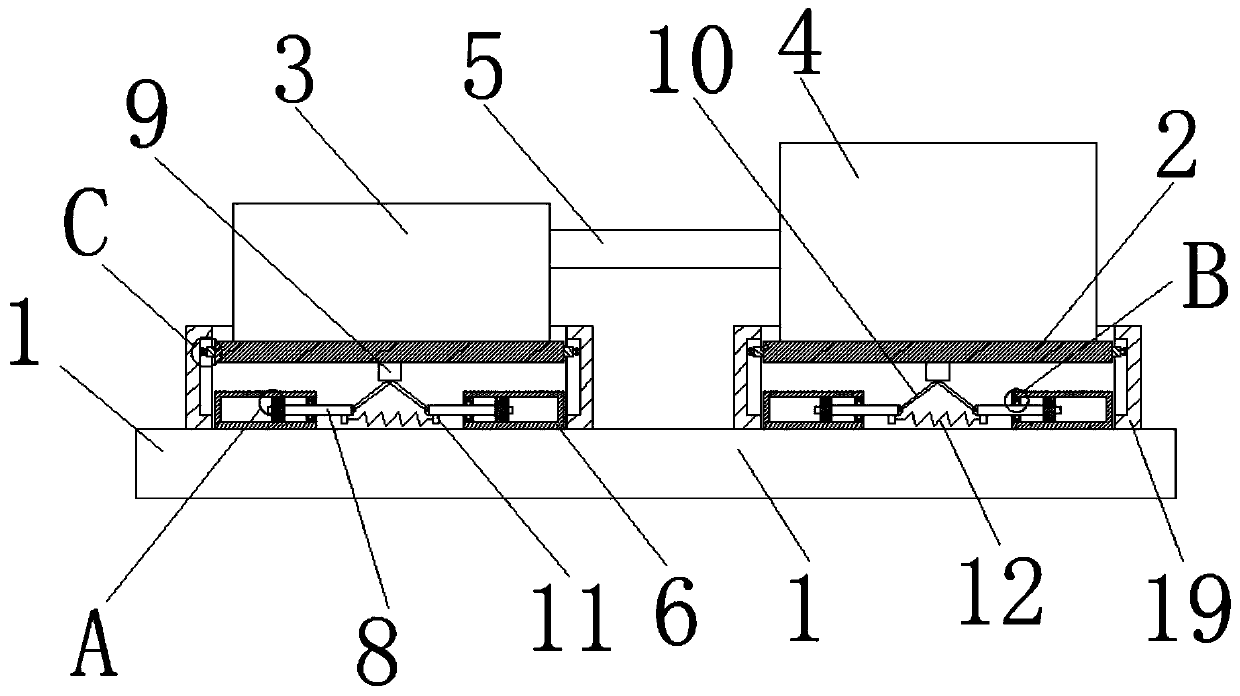

Automatic filtration separation and recycling system for vertical honing oil waste slag

InactiveCN110103148ASolve filterabilityReduce vibrationMagnetic separationGrinding/polishing safety devicesSlagHoning oil

The invention relates to the technical field of honing oil waste slag and discloses an automatic filtration separation and recycling system for vertical honing oil waste slag. The automatic filtrationseparation and recycling system comprises a workbench. Support plates are correspondingly connected to the upper end of the workbench through two symmetrically arranged noise reduction mechanisms. Acentrifuge and a magnetic adsorption filter are correspondingly connected to the ends, far away from the corresponding noise reduction mechanisms, of the support plates. A guide pipe is connected between the centrifuge and the magnetic adsorption filter. Each noise reduction mechanism comprises two noise reduction cylinders with one ends open. Cylinder openings of the two noise reduction cylindersare opposite. A piston is slidably connected to the inner cylinder wall of each noise reduction cylinder. Piston rods are correspondingly and fixedly connected to the centers of the opposite ends ofthe two pistons. The ends, far away from the pistons, of the piston rods penetrates the cylinder openings of the corresponding noise reduction cylinders and extend outwards. By the adoption of the automatic filtration separation and recycling system for the vertical honing oil waste slag, the problems that at present, a honing oil filtering system does not completely filter the honing oil, the service life of a honing head is affected, and the honing precision of a honing machine is reduced can be solved.

Owner:河南合秀汽车工程研究院有限公司

A Prediction Method of Honing Surface Roughness Considering Whetstone Concession

ActiveCN110893579BReduce manufacturing costIncrease productivityDesign optimisation/simulationHoning machinesHoning oilWhetstone

The invention discloses a honing surface roughness prediction method considering the honing stone retreat. First, the geometric parameters of the honing honing stone surface and the honing process motion parameters are obtained, and finally the honing surface roughness is predicted in consideration of the grinding wheel retreat; the present invention is based on Grinding principle theoretically deduces the honing roughness, and optimizes parameters through a small amount of experiments, and can calculate the honing roughness of small-diameter deep holes, thereby providing a theoretical basis for the selection of small-diameter deep-hole honing parameters and improving enterprise production efficiency. Reduce production costs of enterprises.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

High-precision vertical internal oil injection diamond reamer

Owner:SUZHOU XINNENG PRECISE MACHINERY

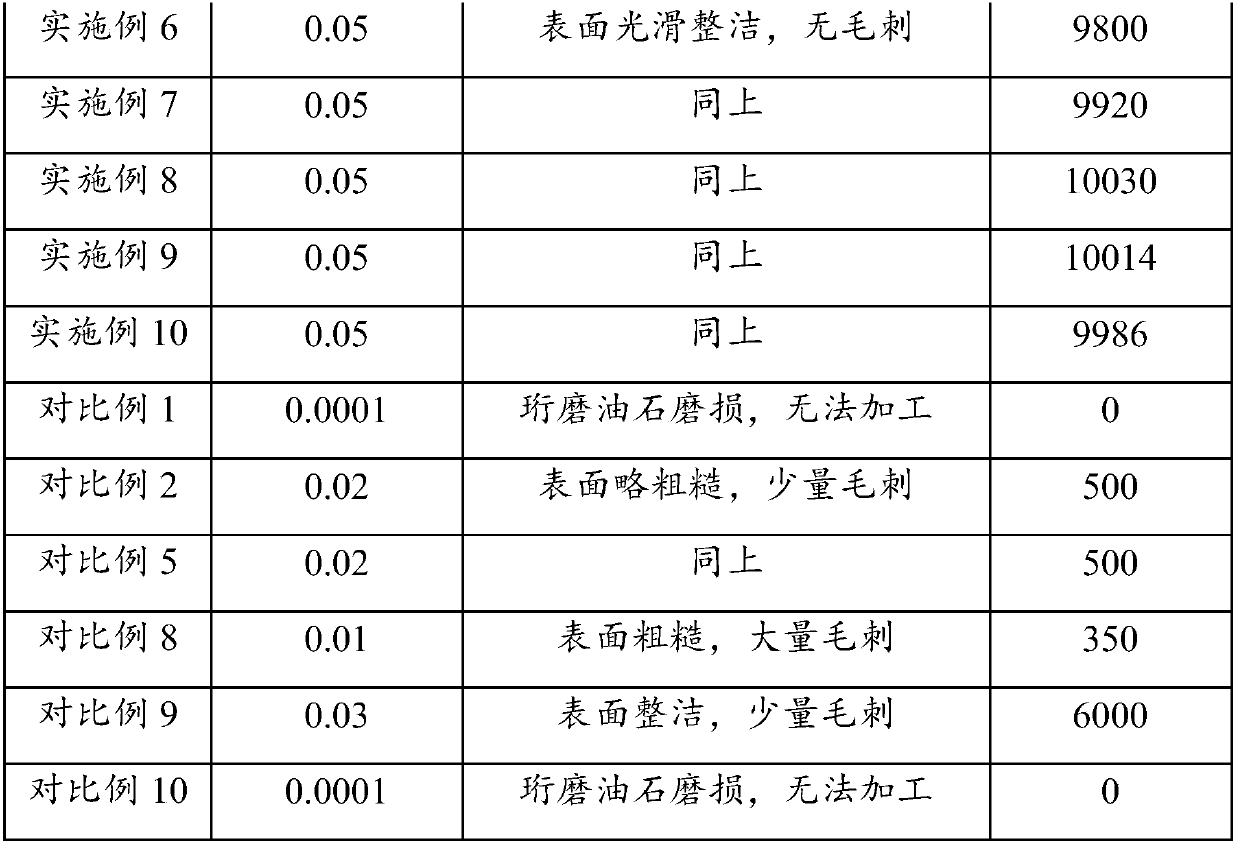

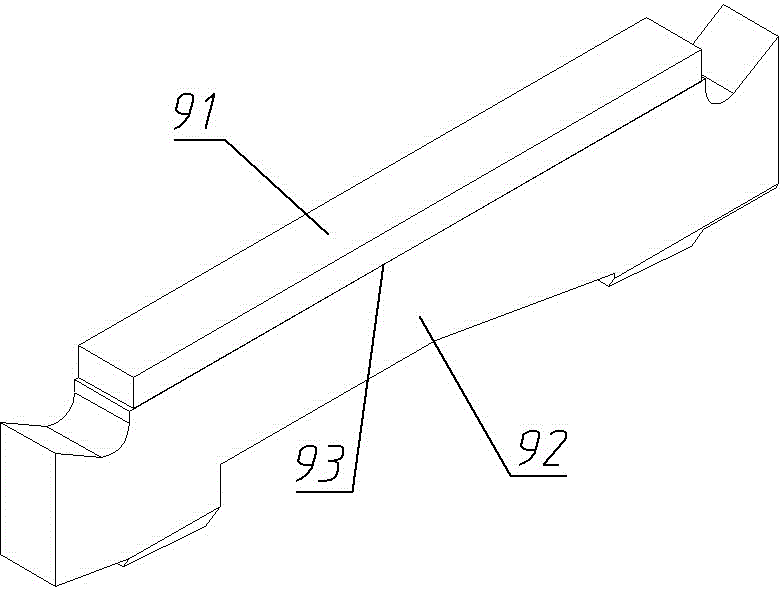

Honing stone containing vanadium and zirconium elements and preparation method thereof

ActiveCN106625197BImprove grinding efficiencyImprove grinding qualityAbrasion apparatusGrinding devicesSuperhard materialAdhesive

The invention provides honing oilstone containing vanadium and zirconium and a preparation method thereof, and relates to the technical field of precision machining. The honing oilstone is mainly composed of vanadium, zirconium, copper, silver, aluminum, zinc, tin, iron, nickel, cobalt, lead, an adhesive, a superhard material and the like. According to the honing oilstone, the problems that in the prior art, due to the single grinding property of honing oilstone composed of a single grinding material, the grinding effect on materials hard to machine is not ideal, certain use limitations exist, and even though multi-element mixed type honing oilstone imported from abroad can achieve a very good grinding machining effect, the multi-element mixed type honing oilstone is short in service life and high in price are solved. The prepared honing oilstone achieves the technical effects of being excellent in self-sharpening performance, sharp in grinding, high in grinding quality, high in grinding speed, resistant to high temperature and long in service life.

Owner:YINCHUAN HENGYIDA MACHINERY

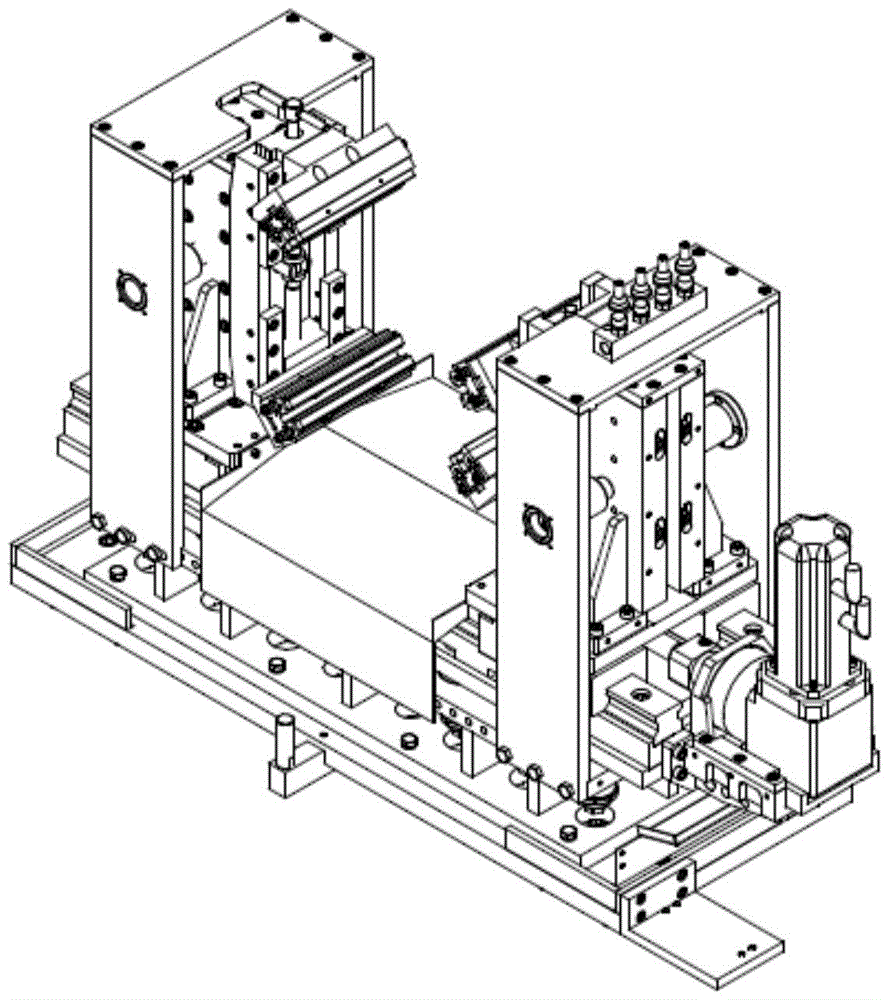

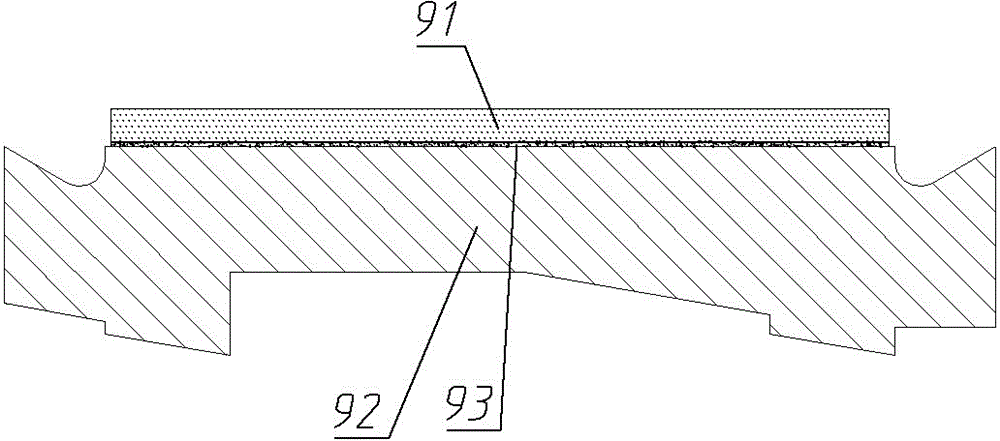

Honing Whetstone Bonding Device and Honing Whetstone Bonding Method Using the Device

InactiveCN104260005BReduce the effect of thicknessImprove bonding qualityGrinding devicesHoning toolsHoning oilEngineering

The invention relates to a honing oilstone bonding device and a honing oilstone bonding method using the same. The honing oilstone bonding device comprises an oilstone strip positioning base for oilstone strip positioning, an oilstone base positioning base for oilstone base positioning and a guide mechanism used for making the oilstone strip positioning base or the oilstone base positioning base to do opposite guide motion to approach or keep away from each other. The oilstone strip positioning base and the oilstone base positioning base are provided with a combination position and a separation position during the opposite guide motion, the combination position is used for connecting a bonding surface of an oilstone strip and a bonding surface of an oilstone base in an alignment mode, and the separation position is used for separating the oilstone strip and the oilstone base. The honing oilstone bonding device further comprises a pressing device used for exerting pressing force on the oilstone strip positioning base and the oilstone base positioning base which are located at the combination position to press tight the bonding surface of the oilstone strip and the bonding surface of the oilstone base. The honing oilstone bonding device can improve the butting connection accuracy and the bonding quality of honing oilstones.

Owner:ZHENGZHOU RES INST FOR ABRASIVES & GRINDING CO LTD

A kind of preparation method of hybrid superhard honing oil stone

ActiveCN105803248BImprove bindingStrong self-sharpeningTransportation and packagingAbrasion apparatusHoning oilSputtering

The invention relates to the technical field of superhard honing, in particular to a preparation method of a hybrid superhard honing whetstone. It is characterized in that a diamond and cubic boron nitride (CBN) treated with tungsten-plated metallization on the surface are used as abrasives to prepare honing oil stones, and the steps are first to carry out molten salt method and magnetron sputtering plating on diamond and CBN abrasive grains respectively. Tungsten pretreatment, and then the pretreated abrasive grains and metal bond powder are mixed in a certain proportion and then ball milled, and then the ball milled mixed powder is placed in a graphite mold for hot pressing and sintering, or placed in a steel mold and pressed into a body, and sintered in a reducing atmosphere without pressure. The honing oil stone prepared by the invention has the advantages of high strength and high hardness, high grinding efficiency, strong self-sharpening, long service life and the like.

Owner:ZHENJIANG N E T DIAMOND

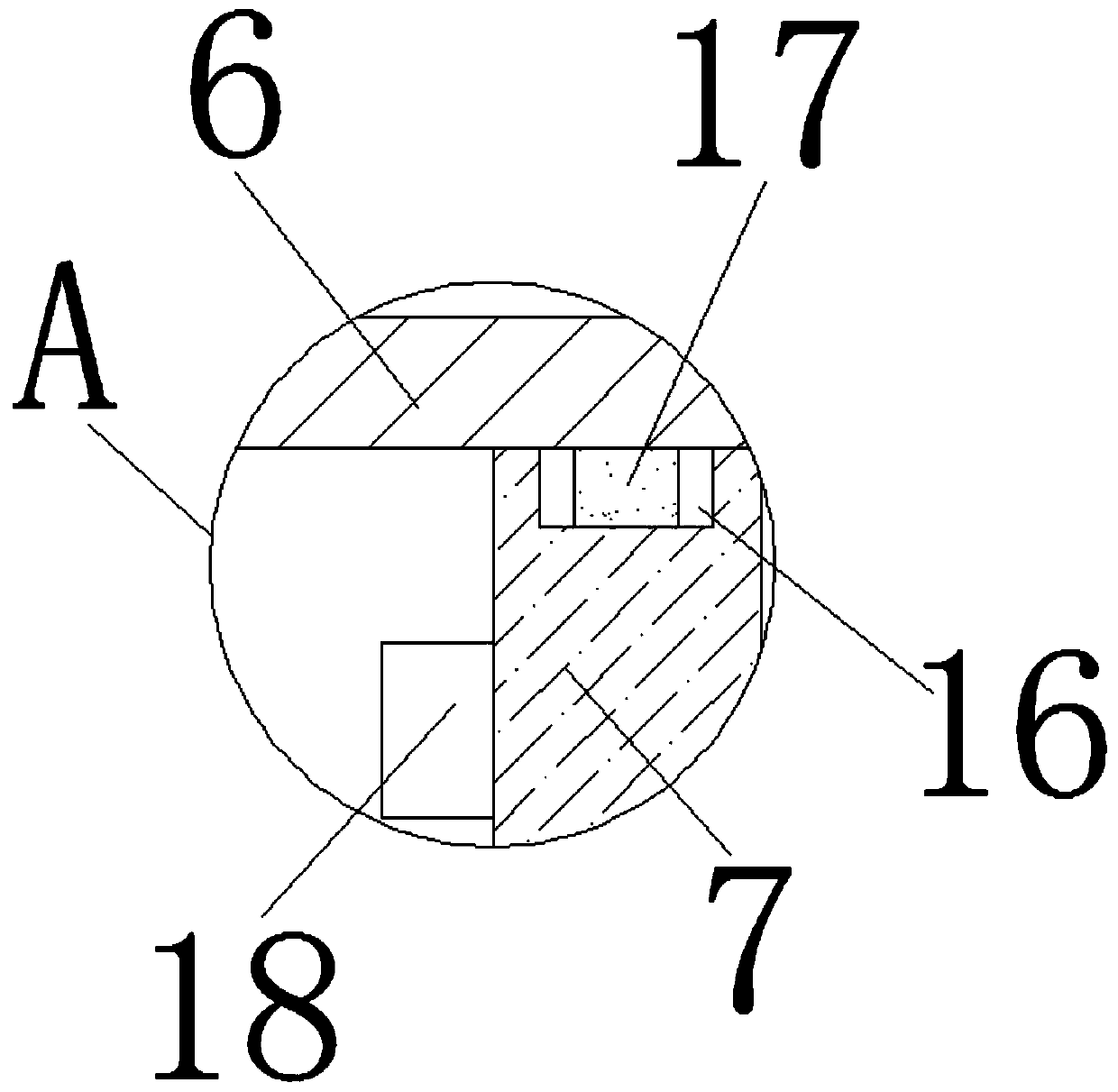

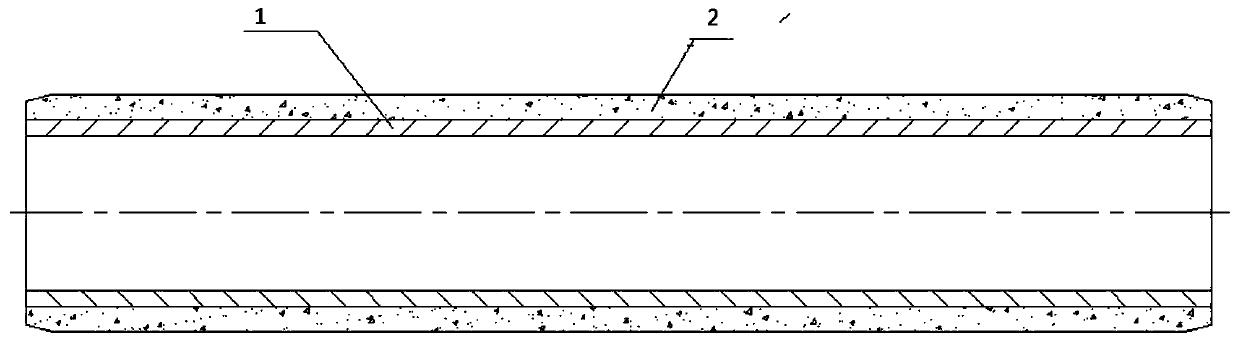

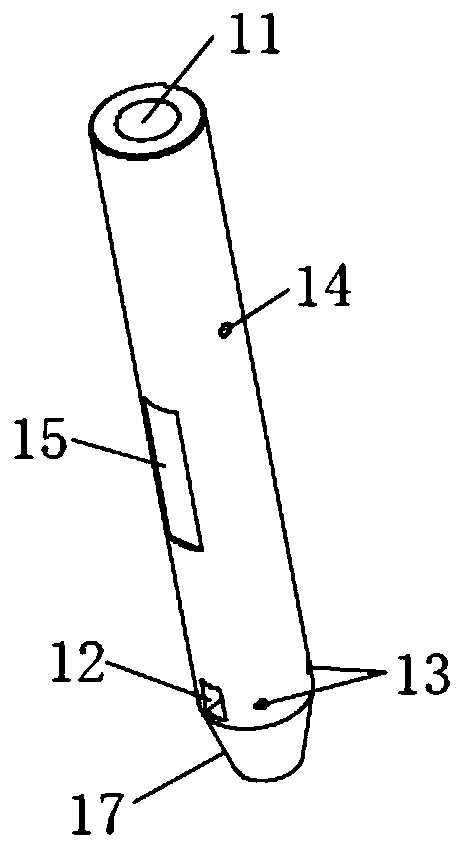

Deep hole machining honing tool

InactiveCN110834266ASolve practical difficulties that are not easy to dischargeAvoid scratchesHoning toolsHoning oilAdhesive

The invention relates to a deep hole machining honing tool. The deep hole machining honing tool comprises the two parts of a cutter sleeve (1) and a cutter bar (2), wherein the cutter sleeve (1) and the cutter bar (2) are fixedly connected through an adhesive. Six strip-shaped sand strips are uniformly distributed on the cutter bar (2) along the circumference. Sufficient scrap accommodating spaceis formed in empty grooves between the sand bars. Scrap iron is not easy to adhere to the sand bars, and is easy to carry away under the action of honing oil. The deep hole machining honing tool solves the practical difficulty that the scrap iron is not easy to discharge during deep hole machining, improves the deep hole honing machining environment, prevents the scrap iron from scratching high-precision inner hole surfaces, improves the chip cutting performance of the sand strips, is high in machining efficiency, and prolongs the service life of the sand strips.

Owner:CHANGAN AUTOMOBILE (GRP) CO LTD

Preparation method of high-performance low-viscosity honing oil

InactiveCN109810766AEasy to rinseExtend your lifeLubricant compositionRare-earth elementMetal forming

The invention discloses a preparation method of high-performance low-viscosity honing oil, and relates to the technical field of metal forming lubricating oil. According to the preparation method of the high-performance low-viscosity honing oil, the high-performance low-viscosity honing oil is prepared from honing oil formula materials in percentage by weight: 80-90% of base oil (Hydroseal G 3H),2.5-3.5% of base oil (HYDROSEAL G 232H), 6-6.8% of propylene glycol dioleate, 1.8-2.5% of palm (kernel) oil, 1-1.5% of anti-wear reagent (dimer acid lanthanum) at extreme pressure, and 0.04-0.05% of 2,6-butylated hydroxytoluene. The honing oil is low in viscosity, contains a proper quantity of ester lubricants and has the lightly-moderate extreme pressure characteristic, and the honing oil has thecharacteristics that the honing oil is compatible with nonferrous metal, spots are avoided, flushing is easy, and excellent surface finish machining and good size precision are achieved; and in various honing operation, carboxyl of the dimer acid lanthanum can be effectively adsorbed on a grinding wheel and grinding stone, the friction surfaces of rare earth elements diffuse towards a substratein the friction process to form a permeable layer, and the abrasion performance of the surfaces of the grinding wheel and the grinding stone is improved.

Owner:山东小松油品有限公司

Honing material taking device and material taking method thereof

ActiveCN110524405ACause some damagesExtended service lifeHoning machinesGrinding feedersHoning oilEngineering

The invention discloses a honing material taking device and a material taking method thereof, and belongs to the technical field of honing machining. The honing material taking device comprises a cylindrical shell; a center hole penetrating through the shell in the axis direction of the shell is formed in the shell, and at least one sliding block mounting hole penetrating through the center hole in the radial direction is formed in the lower portion of the shell; sliding blocks with the number same as that of the sliding block mounting holes are movably mounted in the sliding block mounting holes; a movable push rod is inserted into the center hole and is movably connected with the shell; the movable push rod is pushed to the lower end of the shell along the center hole, and the movable push rod extrudes the sliding blocks to enable the sliding blocks to slide outwards along the sliding block mounting holes and protrude out of the shell. During material taking, the honing material taking device is inserted into a workpiece, the upper end of the movable push rod is pressed, the sliding blocks are extruded out through the movable push rod and abut against the inner wall of the workpiece, and therefore the workpiece is taken out of a honing clamp. According to the honing material taking device, the honing material taking device is used for replacing finger material taking of workers, the operation is easy, safe and labor-saving, efficiency is high, and honing oil cannot be polluted.

Owner:安徽多邦珩磨技术有限公司

High-precision honing and grinding combined tool

PendingCN111496664AImprove processing efficiencyReduce mistakesHoning toolsHoning machinesHoning oilEngineering

The invention discloses a high-precision honing and grinding combined tool. The high-precision honing and grinding combined tool comprises a honing rod body, a honing pushing cone, an installation base, a honing oilstone and a grinding sleeve, wherein the interior of the honing rod body is hollowed and provided with a cavity, the honing rod body is provided with at least one installation groove along the circle, and the installation groove communicates with the cavity. The honing pushing cone is arranged in the cavity of the honing rod body and can move in the axial direction, one end of the honing pushing cone is provided with a cone body, and the outer wall of the cone body is a first conical face. The installation base is embedded into the installation groove, and the inner wall of theinstallation base makes contact with the cone body. The honing oilstone is arranged on the installation base, the honing pushing cone moves in the axial direction so that the cone body interferes withthe installation base, accordingly the honing oilstone can expand or retract in the radial direction, and the honing oilstone is used for honing an inner hole of a machining workpiece. The outer circumference of the honing rod body is sleeved with the grinding sleeve, and the front end of the grinding sleeve is used for honing a hole opening chamfer of the machining workpiece. The honing oilstoneand the grinding sleeve can hone the inner hole and the hole opening chamfer of the machining workpiece at the same time, the honing efficiency is improved, and errors are reduced.

Owner:江苏红业生智能科技有限公司

Diamond honing oil stone for processing reticulate patterns on platform of cylinder sleeve and preparation method thereof

Owner:HENAN UNIVERSITY OF TECHNOLOGY

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com