Honing surface roughness prediction method considering oilstone yielding

A surface roughness and prediction method technology, applied in honing machine tools, metal processing equipment, manufacturing tools, etc., can solve problems such as inconstant radial feed speed, uneven force on the expanding cone, and influence on radial feed speed, etc. , to achieve the effects of reducing production costs, improving production efficiency, saving time and manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

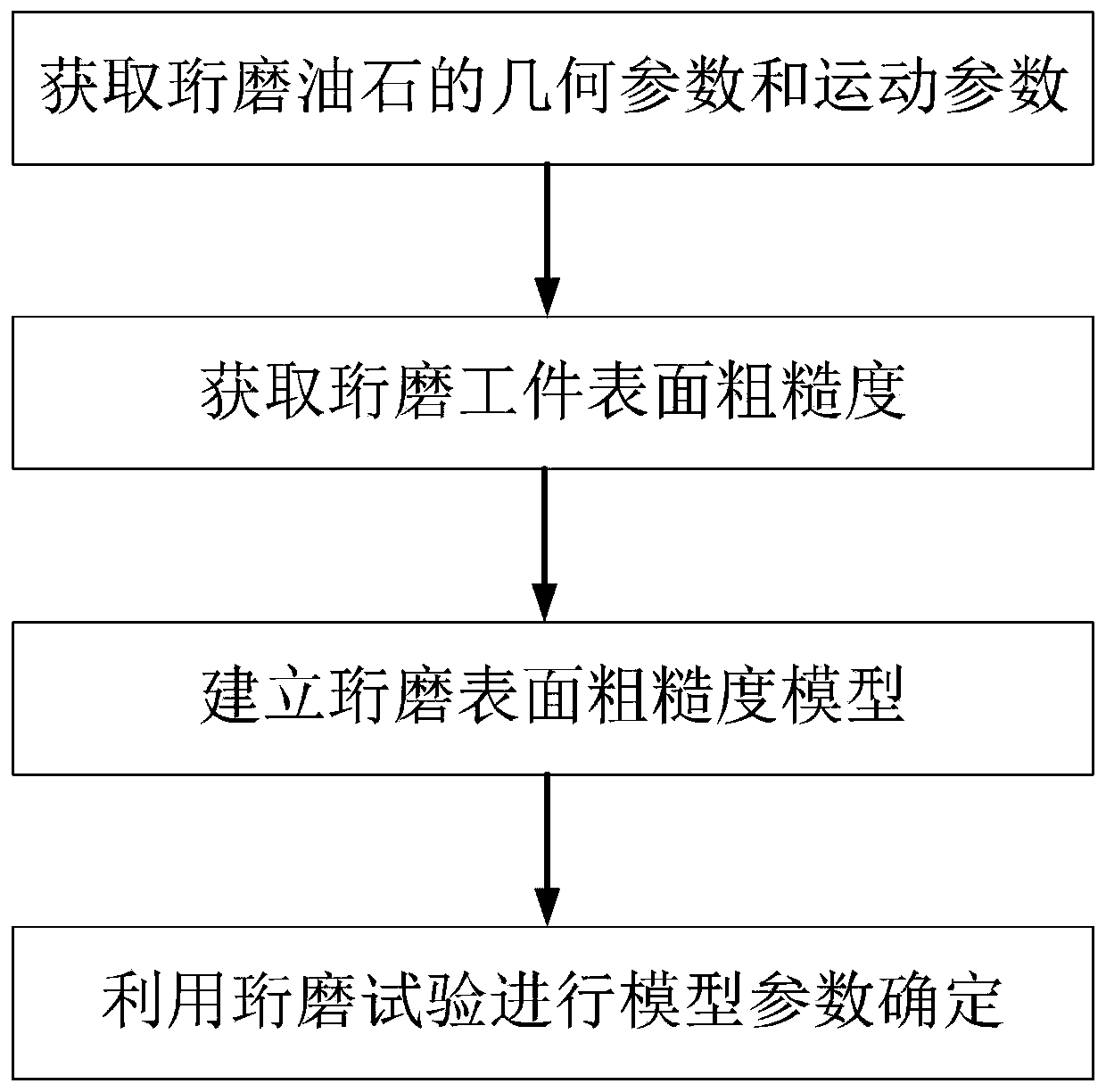

[0057] Such as figure 1 As shown, a flow chart of a honing surface roughness prediction method considering the oilstone retreat, specifically includes the following steps:

[0058] Step 1, obtaining the geometric parameters and motion parameters of the honing oilstone working surface;

[0059] Step 2, using a white light interferometer or a roughness meter to obtain the roughness of the honing workpiece surface;

[0060] Step 3. Establish a honing surface roughness prediction model:

[0061] Step 4. Determination of model parameters through experiments.

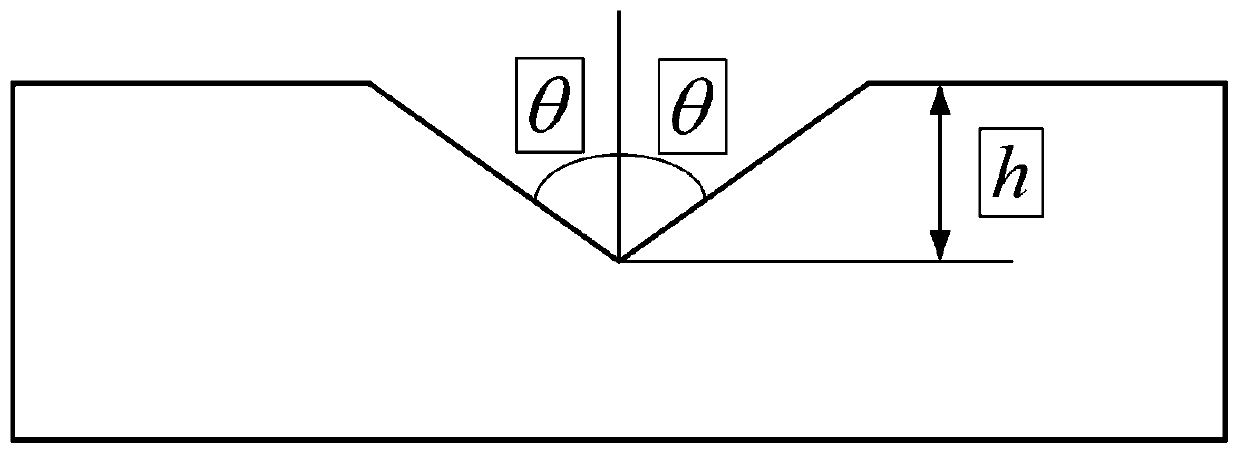

[0062] figure 2 It is a schematic diagram of the scratches of the abrasive grains of the honing stone on the surface of the workpiece. The abrasive grains on the honing stone pass through the workpiece with certain processing parameters to leave grooves (height h, angle 2θ), and finally form a surface with a specific roughness value .

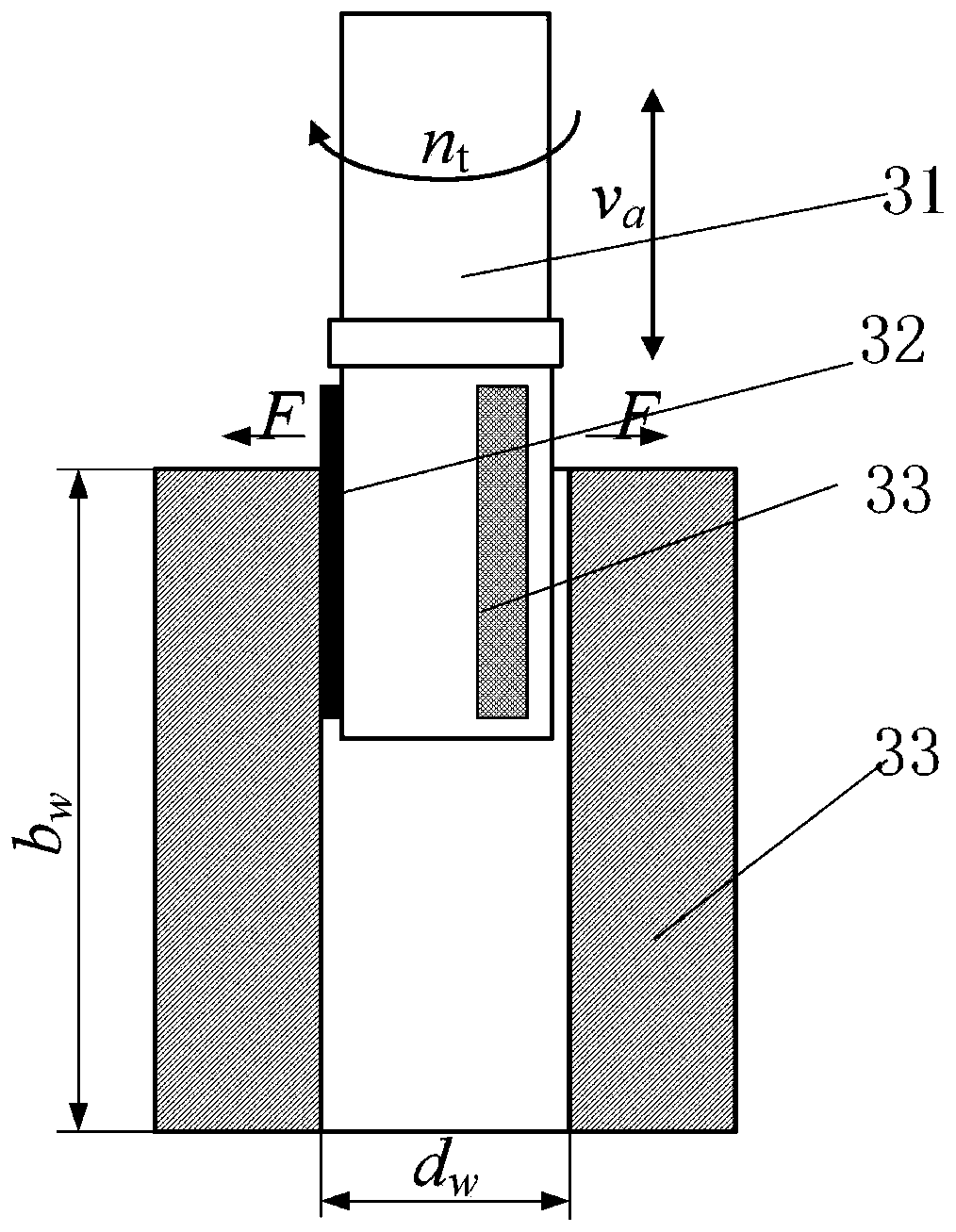

[0063] image 3 Schematic diagram of honing process; refer to image 3 As shown, du...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com