Deep hole machining honing tool

A honing and cutting tool technology, which is applied in the field of tool design, can solve the problems of difficult discharge of iron filings, influence on the surface quality of the inner hole, the service life of the sand bar, and poor cutting performance in deep hole processing, so as to improve chip performance and deep hole honing processing The effect of high environmental and processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

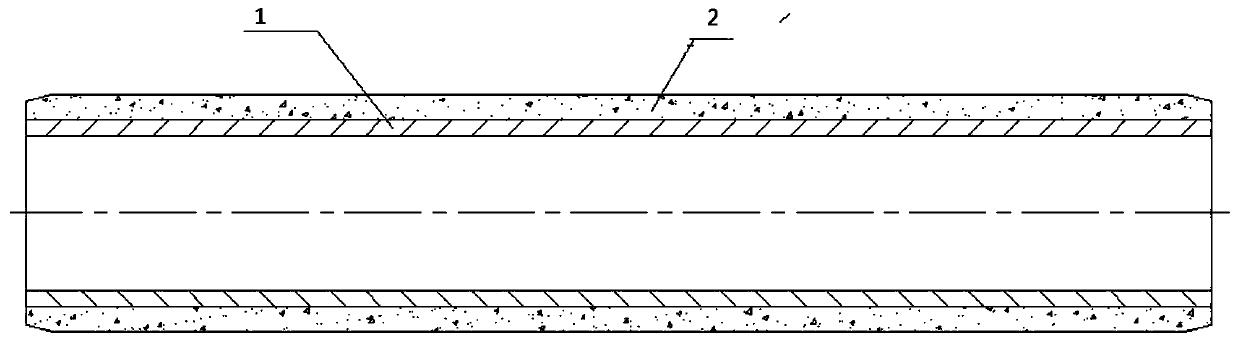

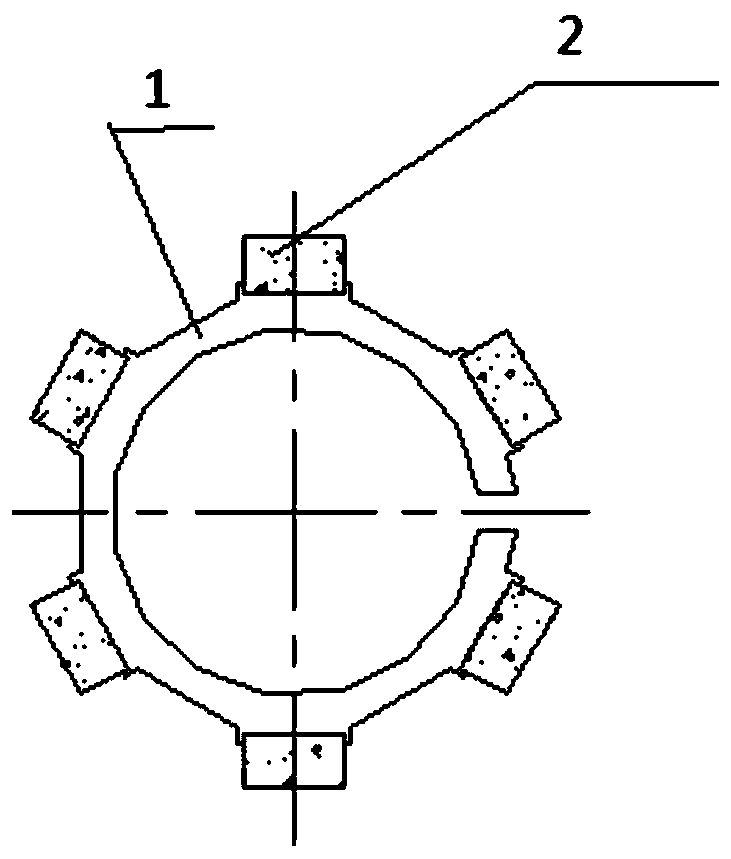

[0011] A honing tool for deep hole processing involved in this embodiment includes two parts: a knife cover 1 and a knife bar 2. The knife cover 1 and the knife bar 2 are connected and fixed by adhesive; Strip sand bars, there is sufficient chip space in the space between the sand bars, iron filings are not easy to attach to the sand bars, and are easily taken away under the action of honing oil.

[0012] The honing tool for deep hole processing in this embodiment solves the practical difficulty that iron filings are not easily discharged during deep hole processing, improves the environment for deep hole honing, prevents iron filings from scratching the surface of the high-precision inner hole, and improves the chipping performance of the sand bar. High efficiency, prolonging the service life of sand bar.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com