Honing Whetstone Bonding Device and Honing Whetstone Bonding Method Using the Device

A technology for honing whetstone and bonding method, which is applied to grinding devices, honing tools, grinding/polishing equipment, etc., and can solve the problems of difficult to guarantee the bonding quality of honing whetstone, long preparation process cycle, low production efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

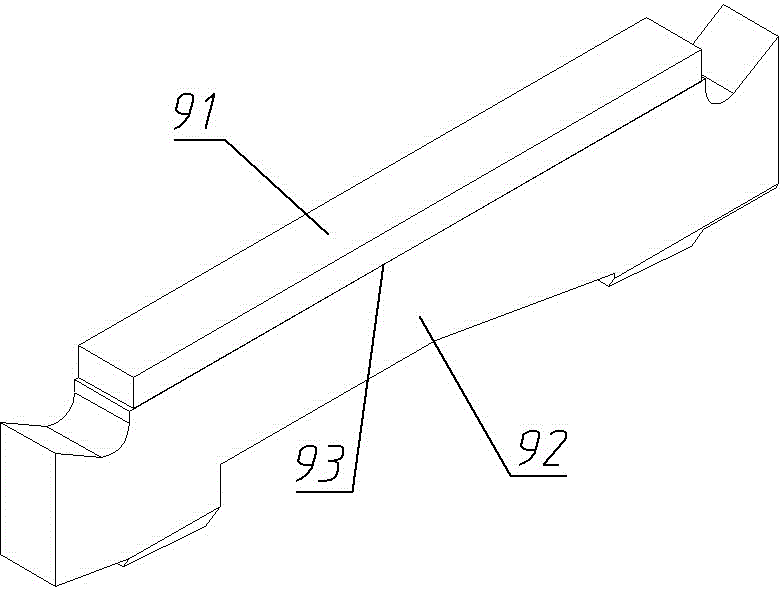

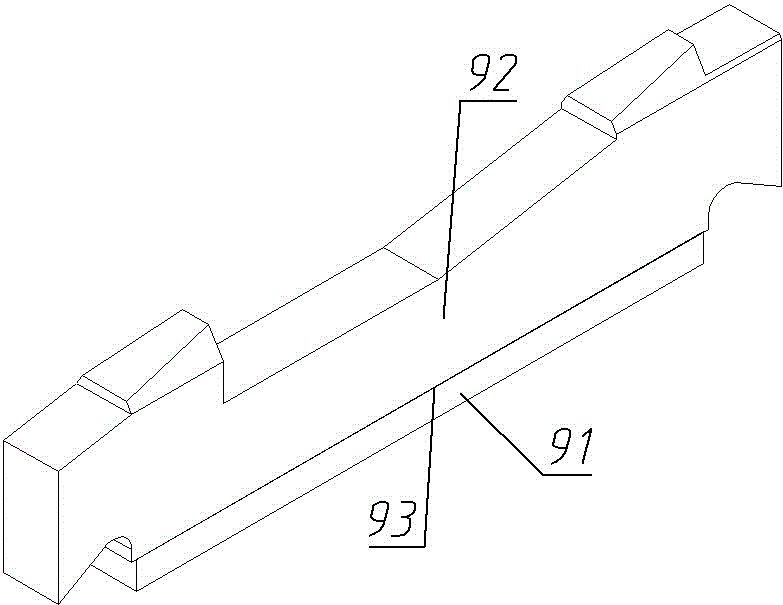

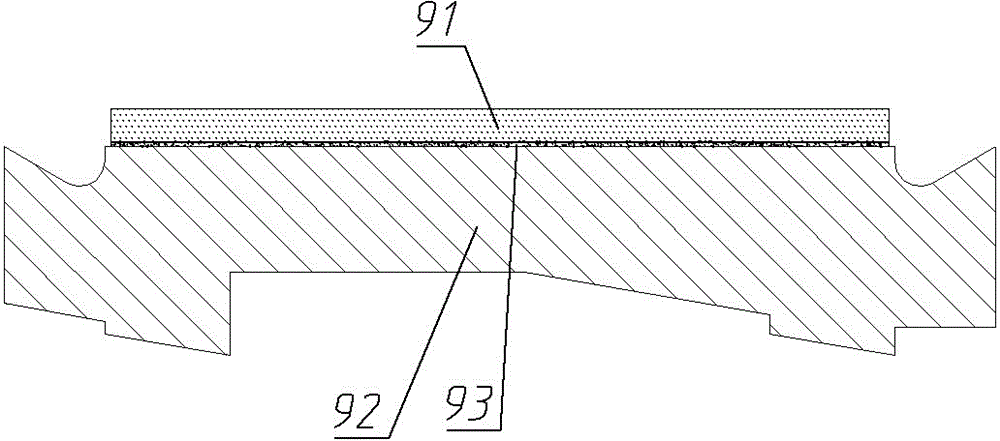

[0025] An embodiment of the honing oilstone bonding device in the present invention is as Figure 4~Figure 6 As shown, it includes a base 1, a positioning device for respectively positioning the whetstone strip 21 and the whetstone seat 22, and a pressure applying device for applying bonding pressure.

[0026] The positioning arrangement includes an oil stone bar positioning seat for positioning the oil stone bar 21 and an oil stone seat positioning seat for positioning the oil stone seat 22 . The oil stone bar positioning seat is the oil stone bar positioning plate 2 provided with the oil stone bar positioning groove 4. The base 1 is provided with a groove for the oil stone bar positioning plate 2 to be embedded. After the oil stone bar positioning plate 2 is embedded in the groove, it can rely on the screw and the base 1 fixed connection. Grooves are provided on the base 1 to position the oil stone bar positioning plate 2, which is convenient for replacement. The depth of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com