A large ball head size chrome plating device

A ball head and size technology, applied in the direction of the electrode, can solve the problems that the ball head cannot be chrome-plated, and it is difficult to control the uniformity of the chromium layer, so as to achieve the effect of improving uniformity, uniform current distribution, and improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

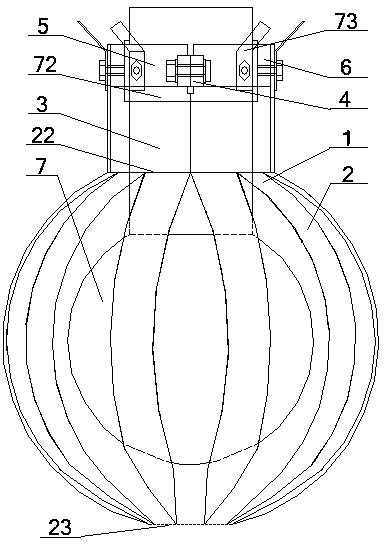

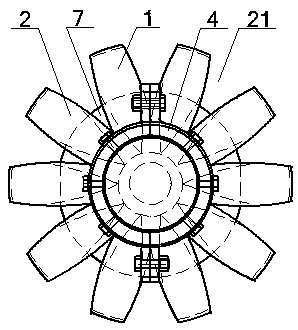

[0074] see Figure 1 to Figure 6 , a large ball head size chromium plating device, comprising a pictographic anode 1 and an anode fixing part 3, the pictographic anode 1 is fixedly connected to one end of the anode conductive plate 73 through the anode fixing part 3, and the other end of the anode conductive plate 73 is connected through a conductive copper row is connected with the power supply, and the pictographic anode 1 includes a plurality of anode bars 2, and the plurality of anode bars 2 form a spherical cage-like structure corresponding to the sphere to be plated 7, and the sphere to be plated 7 is located in the spherical cage inside the structure, and anode strip gaps 21 are formed between adjacent anode strips 2; the bottom ends of the anode strips 2 are evenly arranged along the same bottom circumference 23, and the top ends of the anode strips 2 are evenly arranged along the same top circumference 22 The anode strip 2 includes interconnected long arcs 24 and arc ...

Embodiment 2

[0093] The basic content of described embodiment 2 is the same as embodiment 1, and difference is:

[0094] see Figure 1 to Figure 6 , a large ball head size chrome-plated device:

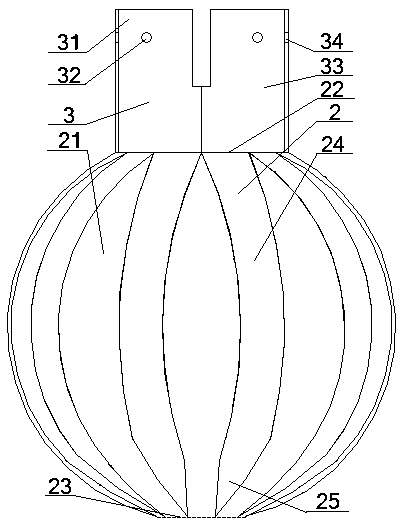

[0095] The anode fixing part 3 includes a left anode fixing part 31 and a right anode fixing part 33, the shapes of the left anode fixing part 31 and the right anode fixing part 33 are consistent, and the left anode fixing part 31 and the right anode fixing part 33 cooperate to surround Form a cylindrical structure, the bottom of the cylindrical structure is fixedly connected to the top circumference 22; the left anode fixing part 31 is evenly provided with at least two left anode fixing holes 32, and the right anode fixing part 33 is evenly provided with At least two right anode fixing holes 34;

[0096] The chrome plating device also includes a clamp 4, and the clamp 4 includes a left clamp 5 and a right clamp 6;

[0097] The left clamp 5 includes a left clamp body 53, a first connecting port...

Embodiment 3

[0104] Embodiment 3 basic content is the same as embodiment 2, and its difference is:

[0105] see Figure 2 to Figure 8 , in a method of using the above-mentioned large ball head size chrome plating device:

[0106] The workpiece to be plated also includes a flange connecting rod 74 and a flange 75, the top of the flange connecting rod 74 is fixedly connected with the bottom of the sphere 7 to be plated, and the bottom of the flange connecting rod 74 is connected to the bottom of the flange 75. top vertical connection;

[0107] In the workpiece installation process: when the sphere to be plated 7 is located at the middle position inside the pictographic anode 1, the plane where the bottom circumference 23 is located coincides with the top surface of the flange 75; the flange connecting rod 74, the flange 75 adopts plastic film band to carry out insulation wrapping treatment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com