Diamond honing oilstone and preparation method thereof

A honing oil stone and diamond technology, which is applied in the field of diamond honing oil stone and its preparation, can solve the problems of substandard surface roughness, low cylindricity, poor straightness, etc., and achieve the effects of sufficient wrapping, high ductility, and improved heat dissipation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

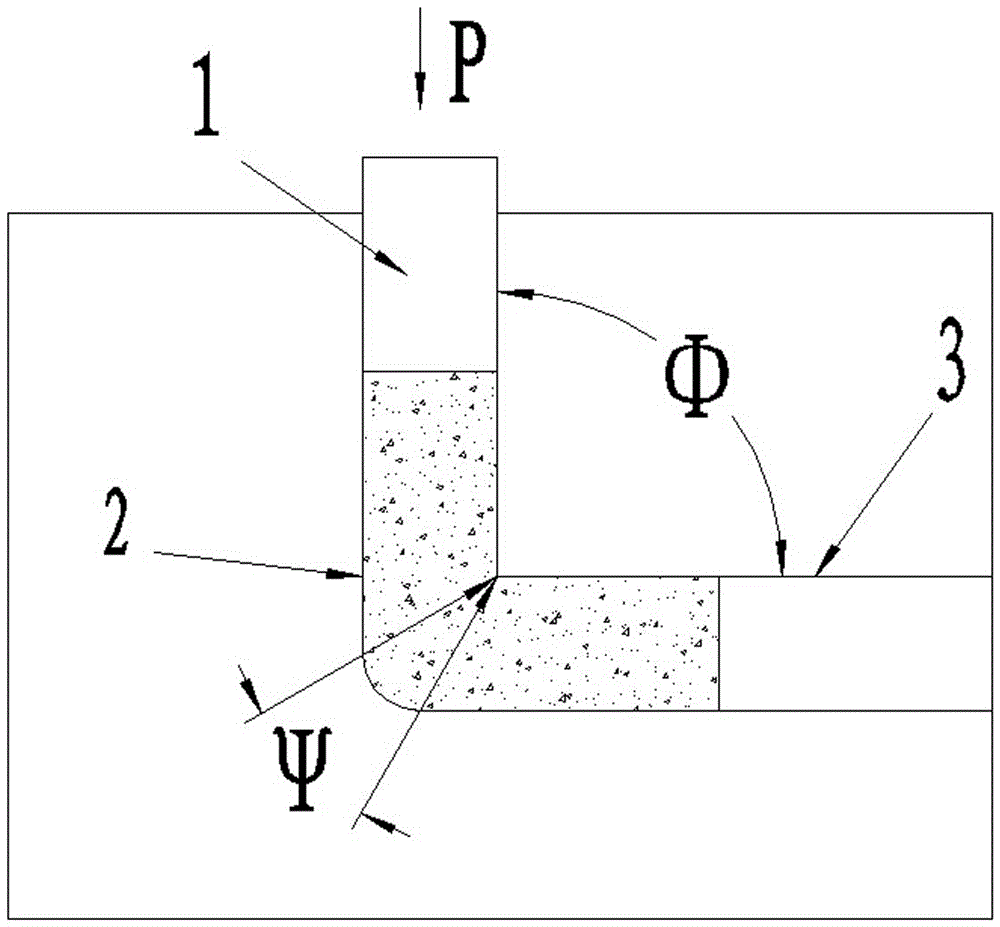

Image

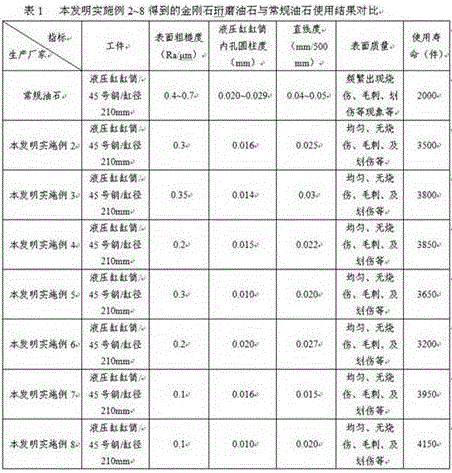

Examples

Embodiment 1

[0033] A diamond honing oil stone is made of the following raw materials in weight percent: 5% to 10% of diamond micropowder with a particle size of 400 mesh to 1000 mesh and 90% to 95% of a metal bond; 55%, silver powder 12-20%, magnesium powder 30-33% and talcum powder 2-5%; the copper-tin pre-alloyed powder is made of the following raw materials by weight percentage: copper 40-58% and tin 42-60% %.

[0034] The purity of the silver powder is ≥99.0%, and the particle size is 100 mesh to 200 mesh.

[0035] The purity of the magnesium powder is more than or equal to 99.0%, and the particle size is 100 mesh to 200 mesh.

[0036] The purity of copper in the raw materials for the preparation of the copper-tin pre-alloyed powder is ≥99.8%, and the particle size is 100 mesh to 200 mesh.

[0037]The purity of tin in the raw materials for the preparation of the copper-tin pre-alloyed powder is ≥99.8%, and the particle size is 100 mesh to 200 mesh.

[0038] A preparation method for...

Embodiment 2

[0045] A kind of diamond honing oil stone, is made of the raw material of following percentage by weight: particle size is 800 order diamond powder 7% and metal bonding agent 93%; Said metal bonding agent is made of copper-tin pre-alloy powder 55%, silver powder 12%, magnesium powder 30% and talcum powder 3%; the copper-tin pre-alloyed powder is made of the following raw materials in weight percentage: 52% copper and 48% tin.

[0046] The purity of the silver powder is ≥99.0%, and the particle size is 100 mesh to 200 mesh.

[0047] The purity of the magnesium powder is more than or equal to 99.0%, and the particle size is 100 mesh to 200 mesh.

[0048] The purity of copper in the raw materials for the preparation of the copper-tin pre-alloyed powder is ≥99.8%, and the particle size is 100 mesh to 200 mesh.

[0049] The purity of tin in the raw materials for the preparation of the copper-tin pre-alloyed powder is ≥99.8%, and the particle size is 100 mesh to 200 mesh

[0050] ...

Embodiment 3

[0057] A kind of diamond honing oil stone, is made of the raw material of following percentage by weight: particle size is 400 order diamond powder 5% and metal bonding agent 95%; Said metal bonding agent is made of copper-tin pre-alloy powder 50%, silver powder 14%, magnesium powder 33% and talcum powder 3%; the copper-tin pre-alloyed powder is made of the following raw materials in weight percentage: 40% copper and 60% tin.

[0058] The preparation method of this embodiment can refer to embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com