Novel automatic oil spout type honing lever

A kind of honing and automatic technology, which is applied in the direction of honing machine tools, honing tools, grinding/polishing equipment, etc., can solve the problems that affect the effect and efficiency of honing, low utilization efficiency of honing oil, uneven honing oil in processing parts, etc., and achieve improvement Honing efficiency and the effect of improving the surface quality of the workpiece

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

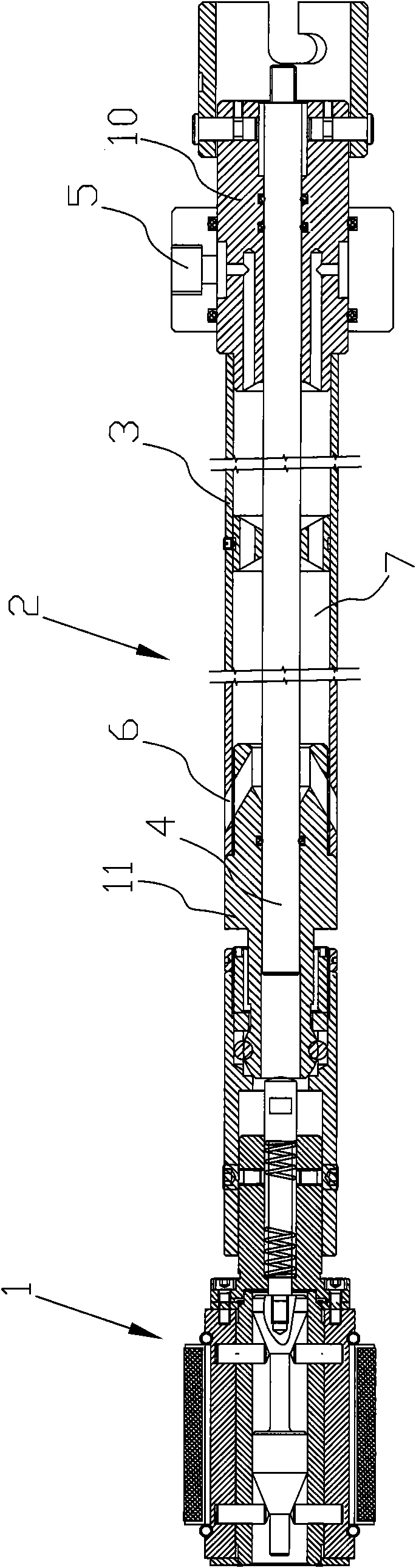

[0017] as attached figure 1 As shown, a new type of automatic oil injection honing rod, the honing rod is used for honing the inner wall of large pipe fittings. It includes a honing head 1 and a honing rod 2 that drives the honing head 1 to move, and the honing head 1 can advance and retreat under the action of the honing rod 2 . The honing rod 2 includes an outer tube 3 and a push rod 4 located inside the outer tube 3. The front end of the push rod 4 is connected to the honing head 1 through the second connector 11, and the rear end is connected to the motor through the first connector 10. The rod 4 can move forward under the drive of the motor, thereby pushing the honing head 1 out for honing.

[0018] The wall of the outer tube 3 is provided with a honing oil inlet 5 and a honing oil outlet 6 respectively. The honing oil outlet 6 is arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com