Honing oil composition and application thereof

A lubricating oil composition and the technology of the composition are applied in the directions of lubricating composition, petroleum industry, etc., which can solve the problems of complex honing oil product formulation and poor environmental protection, and achieve good anti-rust and anti-corrosion effect, low viscosity and excellent wetting. Effects of Features

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~7

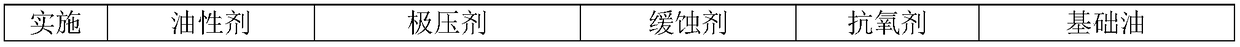

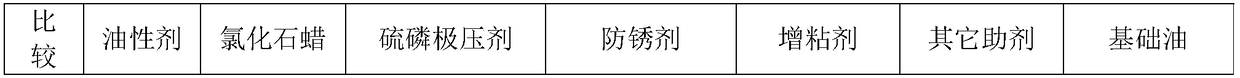

[0028] Pump the base oil into the blending kettle, start the agitator and the heating switch, and when the oil is heated to 50°C, add antioxidant, stir thoroughly for more than 30 minutes until completely dissolved, add extreme pressure agent and oily agent, and stir for 30 minutes Then add the corrosion inhibitor and stir for 2 hours until it is completely transparent, and a uniform yellow liquid is obtained. Each component and its content are shown in Table 1, and its corresponding performance indicators are shown in Table 3.

[0029] Table 1

[0030]

[0031]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com