Honing material taking device and material taking method thereof

A material retrieving device and honing technology, which is applied in the direction of honing machine tools, grinding feed movement, grinding machine tool parts, etc., can solve the problems of low efficiency, pollution of honing oil, poor safety, etc., and achieve high safety and increased use Lifespan, finger protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

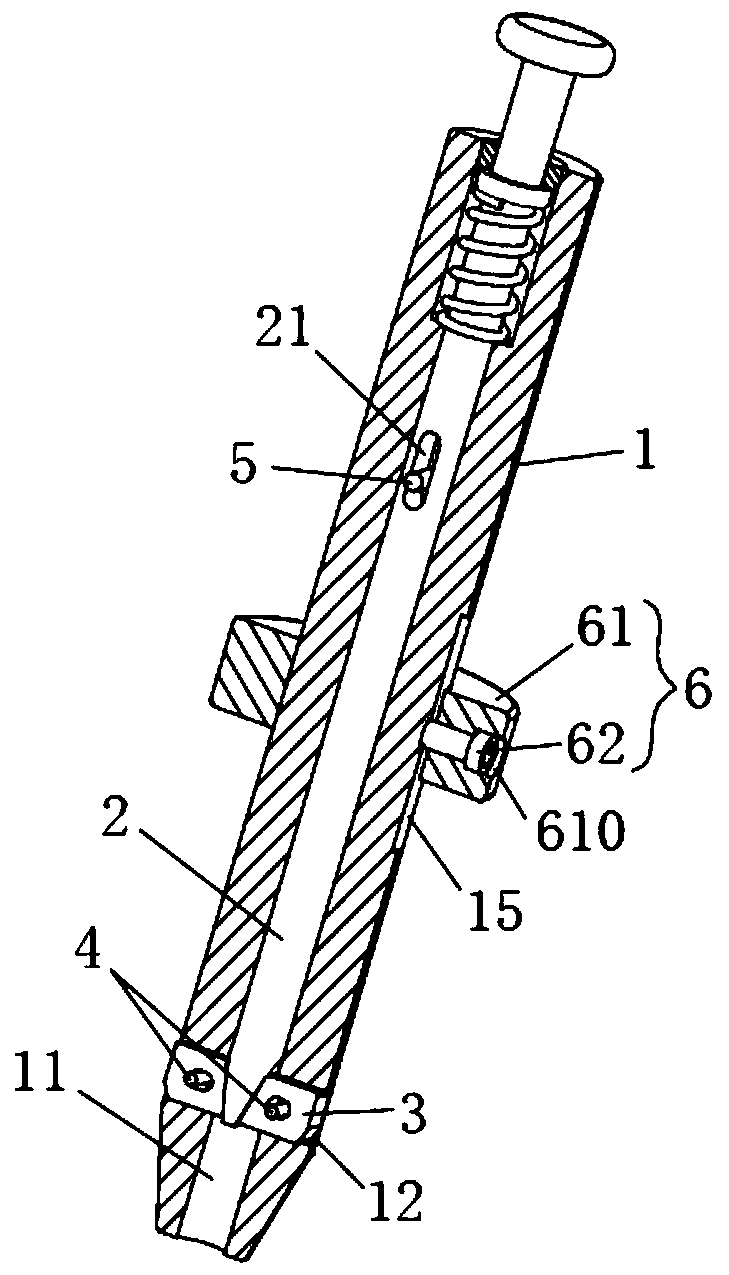

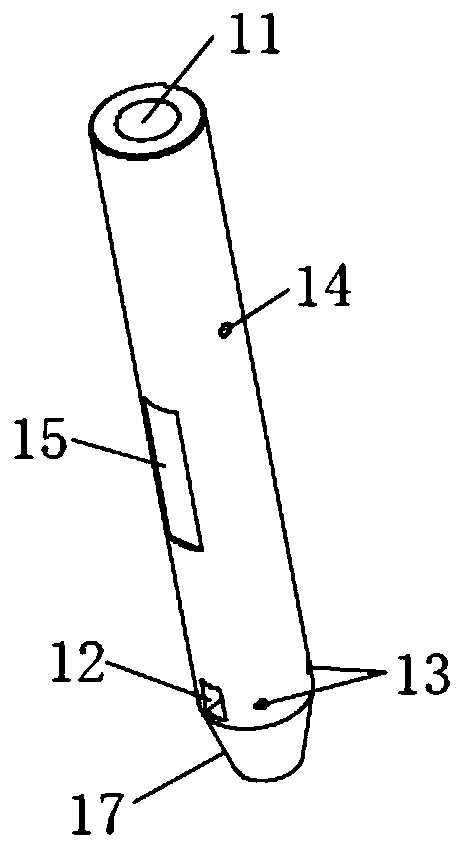

[0044] Such as figure 1As shown in , a honing and reclaiming device in this embodiment includes a cylindrical housing 1, which has a central hole 11 penetrating along its axial direction, and the lower part of the housing 1 has a At least one slider installation hole 12 radially penetrating to the central hole 11, preferably 2 to 4, and evenly distributed around the central axis of the housing 1; and the same number of slider installation holes 12 A slider 3, the slider 3 is movably installed in the slider mounting hole 12; and a movable push rod 2 inserted in the central hole 11, the movable push rod 2 is movable with the housing 1 Connection; push the movable push rod 2 to the lower end of the housing 1 along the central hole 11, and the movable push rod 2 squeezes the slider 3 so that the slider 3 moves along the slider installation hole 12 slides outward and pops out of the housing 1.

[0045] In this example, if figure 1 , 3 As shown in and 6, the slider 3 has a horiz...

Embodiment 2

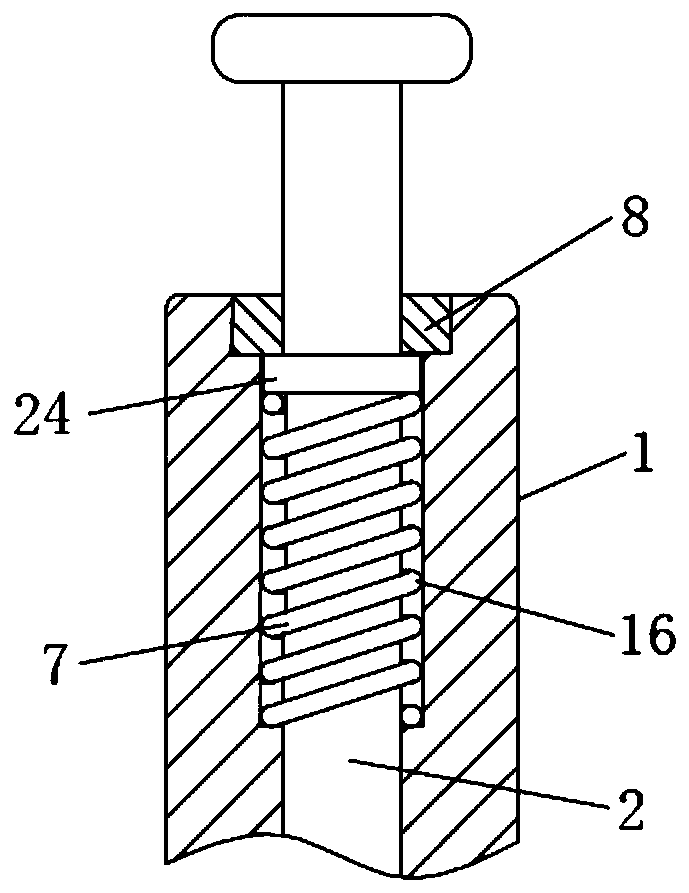

[0056] A kind of honing pick-up device of present embodiment, its basic structure is the same as in embodiment 1, and difference and improvement are, as figure 2 As shown in , the upper end of the housing 1 has an outer hole 16, and the outer hole 16 is provided with a return spring 7, and the return spring 7 is sleeved on the movable push rod 2, and the outer wall of the movable push rod 2 There is a boss 24 on the top, and the boss 24 is located at the upper end of the return spring 7; the entrance of the outer hole 16 is fixed with an annular pressure plate 8, which is used to block the movable push rod 2 in the housing 1 without being blocked. pull out.

[0057] After the workpiece 100 is transferred to the specified position according to the method of taking material in the embodiment 1, release the thumb, and the movable push rod 2 is pushed up by the rebound effect of the return spring 7, so that it is separated from the slide block 3, so that Therefore, the slide blo...

Embodiment 3

[0060] A kind of honing pick-up device in the present embodiment, its basic structure is the same as embodiment 1 or 2, and difference and improvement are, as Figure 4 , 5 , 6, the inner end of the slider 3 has an inclined surface 32, the lower end of the movable push rod 2 has an inclined surface 22 or a tapered surface 23 that cooperates with the inclined surface 32, and through the inclined surface 22 or the tapered surface The surface 23 cooperates with the inclined surface 32 on the slider 3, so that the movable push rod 2 can be inserted into the gap between the sliders 3 more easily, and in the process of pushing the movable push rod 2, the slider 3 can be slowly slid out of the slider The holes 12 are installed to prevent the slider 3 from moving too fast and hitting the inner wall of the workpiece 100 to cause damage.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com