A kind of preparation method of hybrid superhard honing oil stone

A honing whetstone and hybrid technology, used in grinding/polishing equipment, abrasives, grinding devices, etc., can solve the problems affecting the honing performance of honing whetstones, and achieve high grinding efficiency, simple process and strong self-sharpening. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

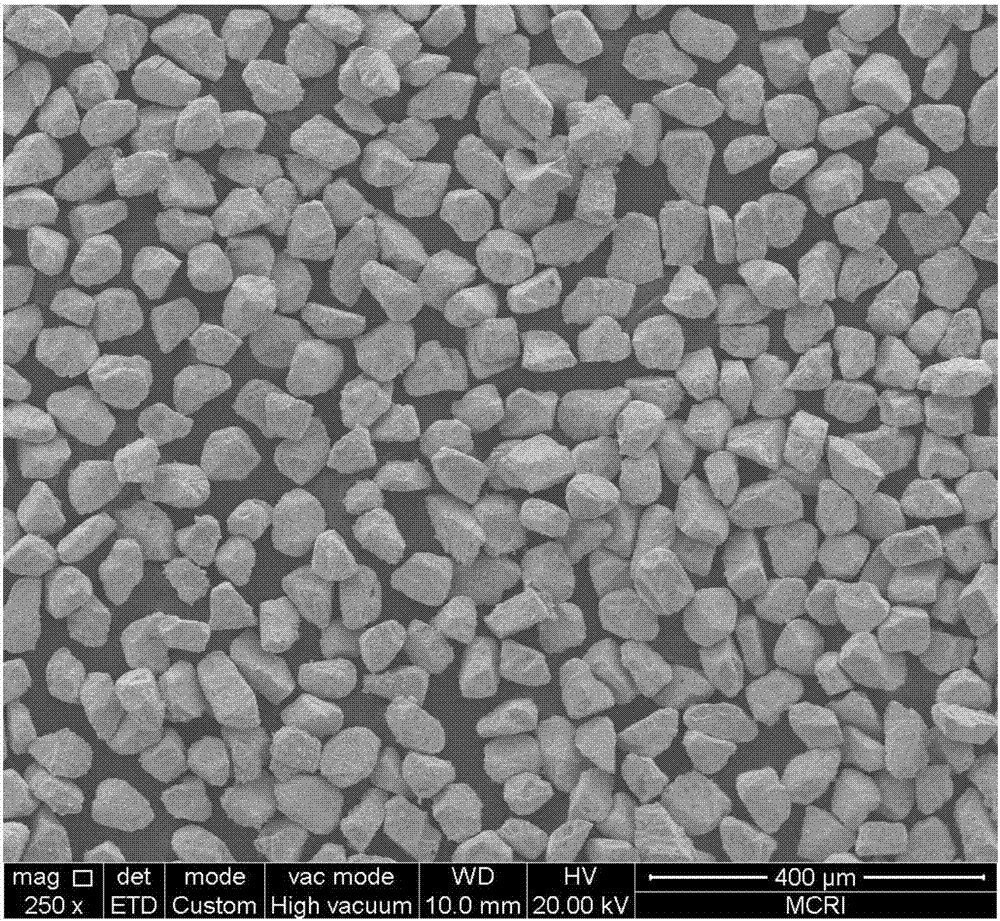

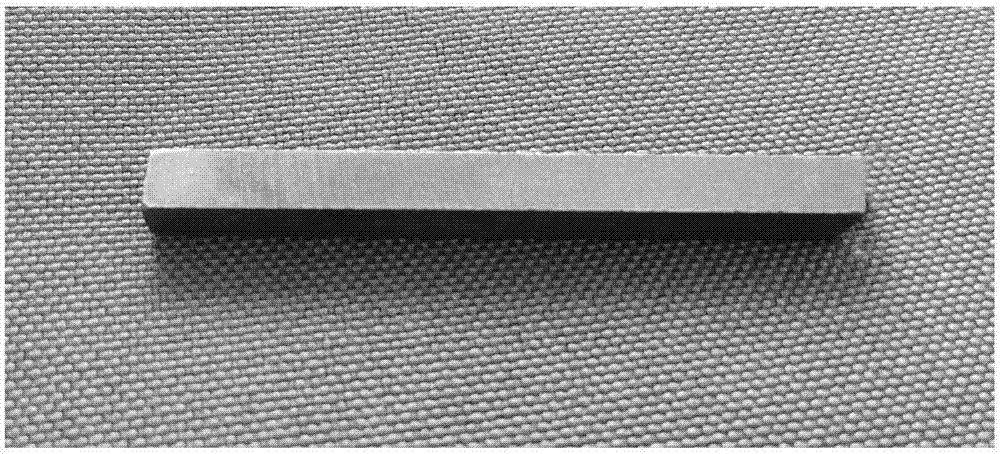

[0032] (1) Combine commercially available diamond with a particle size of about 120 μm, ammonium tungstate (calculated in moles of tungsten atoms), and salt (sodium chloride: potassium chloride = 1:1, molar ratio) at a molar ratio of 20:1:20 Mix and then put it in a ball mill jar for roller milling for 24 hours; take out the ball milled mixed powder, put it in an alumina crucible, heat it to 1000°C under vacuum, keep it warm for 120min, and subject the obtained product to multiple times of ultrasonic vibration and boiling in distilled water To remove the salt, tungsten-coated diamond is obtained. The commercially available CBN abrasive grains with a particle size of about 80 μm were sequentially placed in HNO 3 After being boiled in NaOH solution and rinsed and purified, it is placed in a magnetron sputtering coating machine, with a mass fraction of 99.9% tungsten as the target material, placed in a tray for ultrasonic vibration to make the coating uniform, and the thickness o...

Embodiment example 2

[0036] (1) The commercially available diamond with a particle size of about 120 μm, ammonium paratungstate (calculated in terms of moles of tungsten atoms), and salt (sodium chloride: sodium carbonate: barium chloride = 1:1:1, molar ratio) at a ratio of 15:1:15 The molar ratio is mixed, and then placed in a ball mill tank for roller milling for 48 hours; the milled mixed powder is taken out, placed in an alumina crucible, heated to 1100°C under vacuum, and kept for 60 minutes, and the obtained product is subjected to multiple ultrasonic vibrations Boil with distilled water to remove salt, and obtain tungsten-coated diamond; put commercially available CBN abrasive grains with a particle size of about 100 μm in HNO 3 After being boiled in NaOH solution and rinsed and purified, it is placed in a magnetron sputtering coating machine, with a mass fraction of 99.9% tungsten as the target material, placed in a tray for ultrasonic vibration to make the coating uniform, and the thicknes...

Embodiment example 3

[0040] (1) The commercially available diamond with a particle size of about 120 μm, ammonium metatungstate (calculated in terms of moles of tungsten atoms), and salt (sodium chloride: sodium carbonate: sodium sulfate = 1:1:1, molar ratio) are mixed in a ratio of 15:1 : 15 molar ratio, and then placed in a ball mill tank for roller milling for 36 hours; the ball-milled mixed powder was taken out, placed in an alumina crucible, heated to 1200°C under vacuum, kept for 30min, and the resulting product was subjected to multiple Ultrasonic vibration and distilled water boiling to remove salt, that is, to obtain tungsten-coated diamond; commercially available CBN abrasive grains with a particle size of about 90 μm were sequentially placed in HNO 3 After being boiled in NaOH solution and rinsed and purified, it is placed in a magnetron sputtering coating machine, with a mass fraction of 99.9% tungsten as the target material, which is placed in a tray and ultrasonically vibrated to make...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com