Precise honing aperture prediction and control method for hydraulic matching parts

A control method and honing technology, which is applied in the direction of honing machine tools, manufacturing tools, metal processing equipment, etc., can solve the problems that the processing parameters cannot predict the honing material removal rate, affect the hole processing accuracy and surface quality, and do not propose the material removal rate, etc. , to achieve the effect of improving the honing material removal rate, improving the material removal rate, and ensuring the uniformity of the hole diameter after honing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

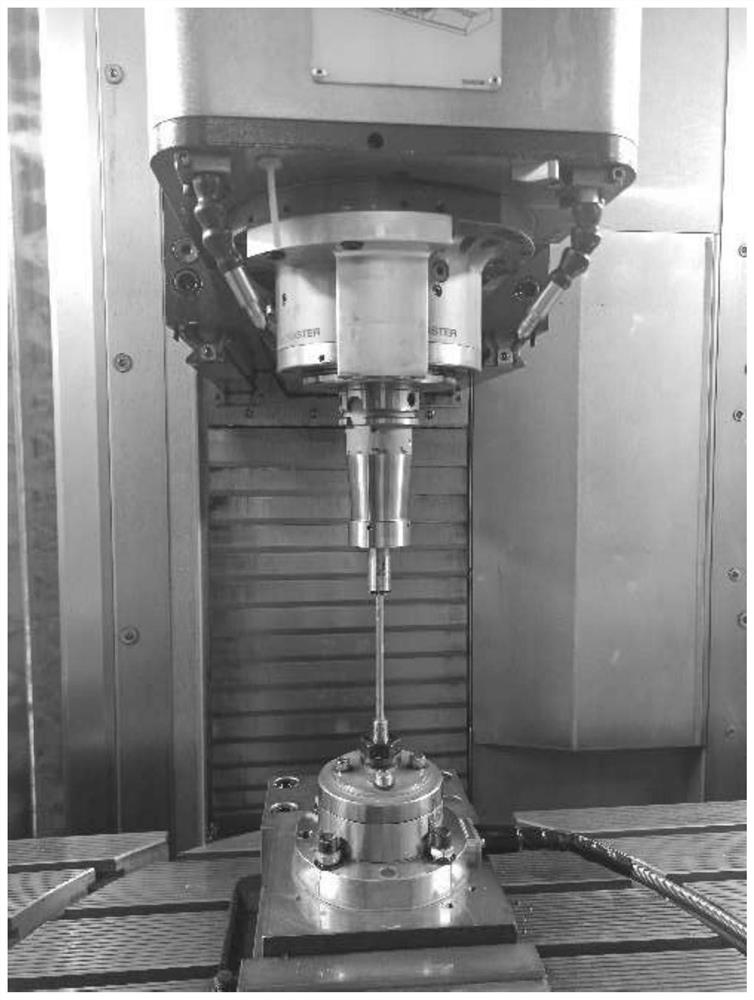

Image

Examples

Embodiment Construction

[0049] The present invention will be further described below in conjunction with accompanying drawings and examples.

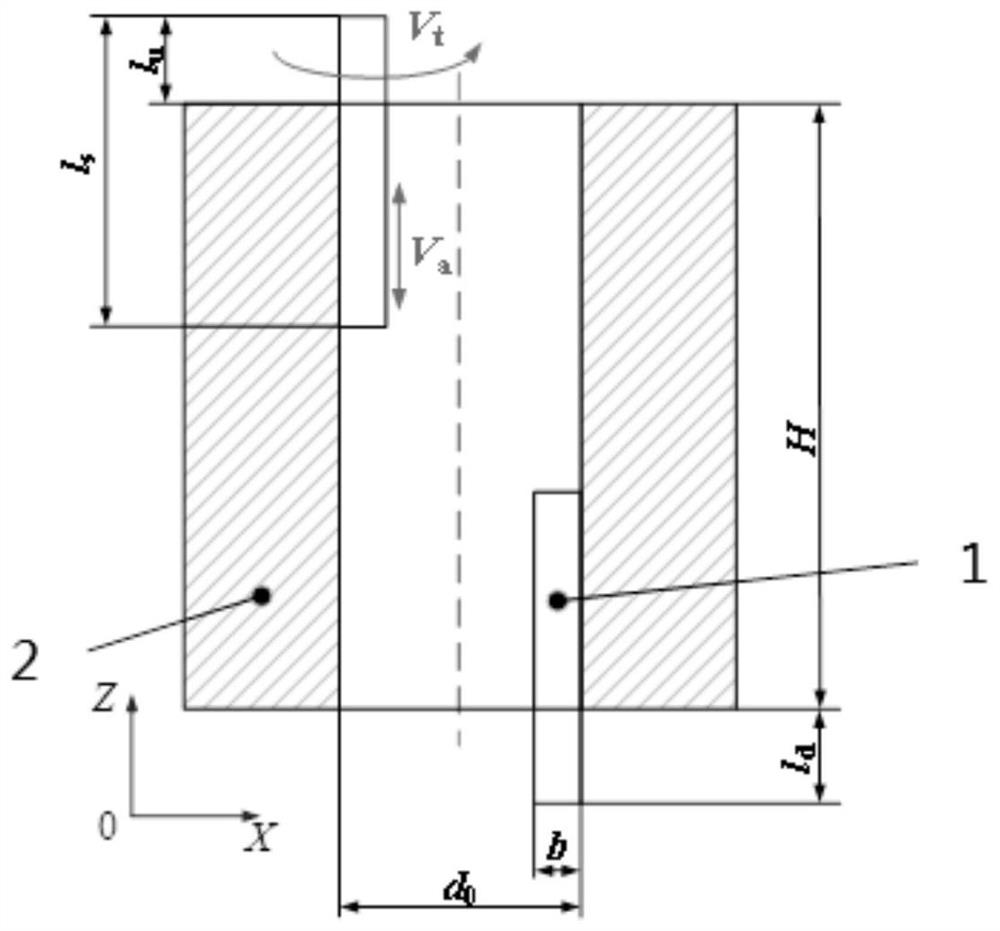

[0050] Such as figure 2 The schematic diagram of honing stone movement is shown. The movement of honing stone is a combination of the external expansion motion, axial reciprocating motion and rotary motion of the stone 1. Affected by the reverse acceleration, the stone will first accelerate and then decelerate at a constant speed. The movement process, and the height of the exposed surface of the valve sleeve 2 hole when the end face of the oil stone is at the overtravel stop position is taken as the overtravel amount.

[0051] The total length of oilstone 1 is denoted as l s , width b, where the overrun is l u , the amount of overrun is l d , the initial aperture of the valve is d 0 , the reciprocating speed is V a , speed with V n express.

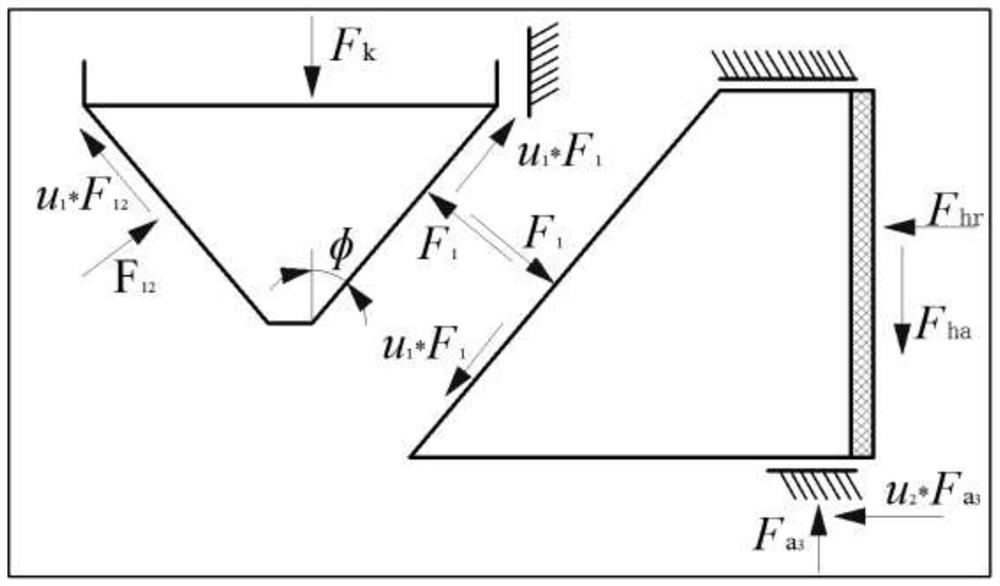

[0052] image 3 Shown is the force analysis diagram of the expansion cone pressure and the positive pressure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com