Honing head for platform screen

A technology of platform mesh and honing head, applied in the field of platform mesh honing head, can solve the problems that affect the machining accuracy and processing efficiency, it is difficult to meet the needs of high-precision platform mesh honing, cannot meet the high-precision platform mesh, etc., Achieve the effect of improving quality and efficiency, strong versatility, and preventing errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

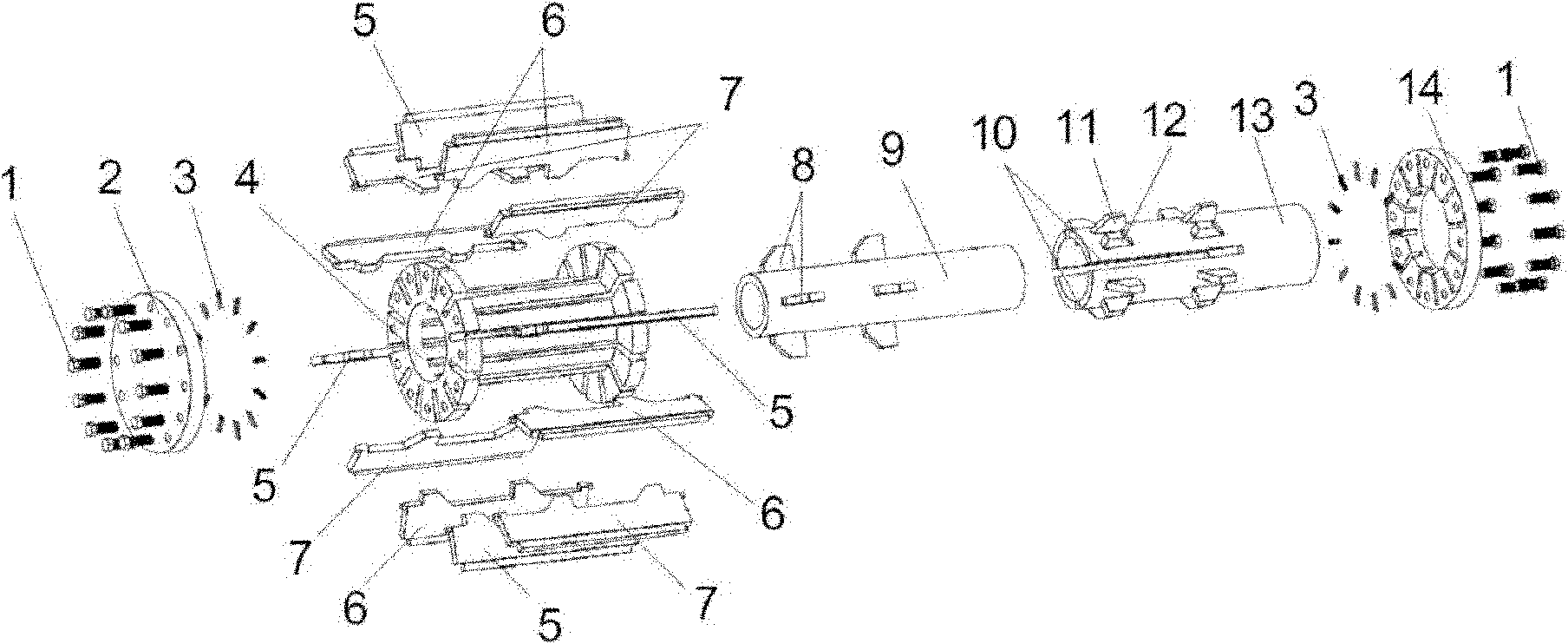

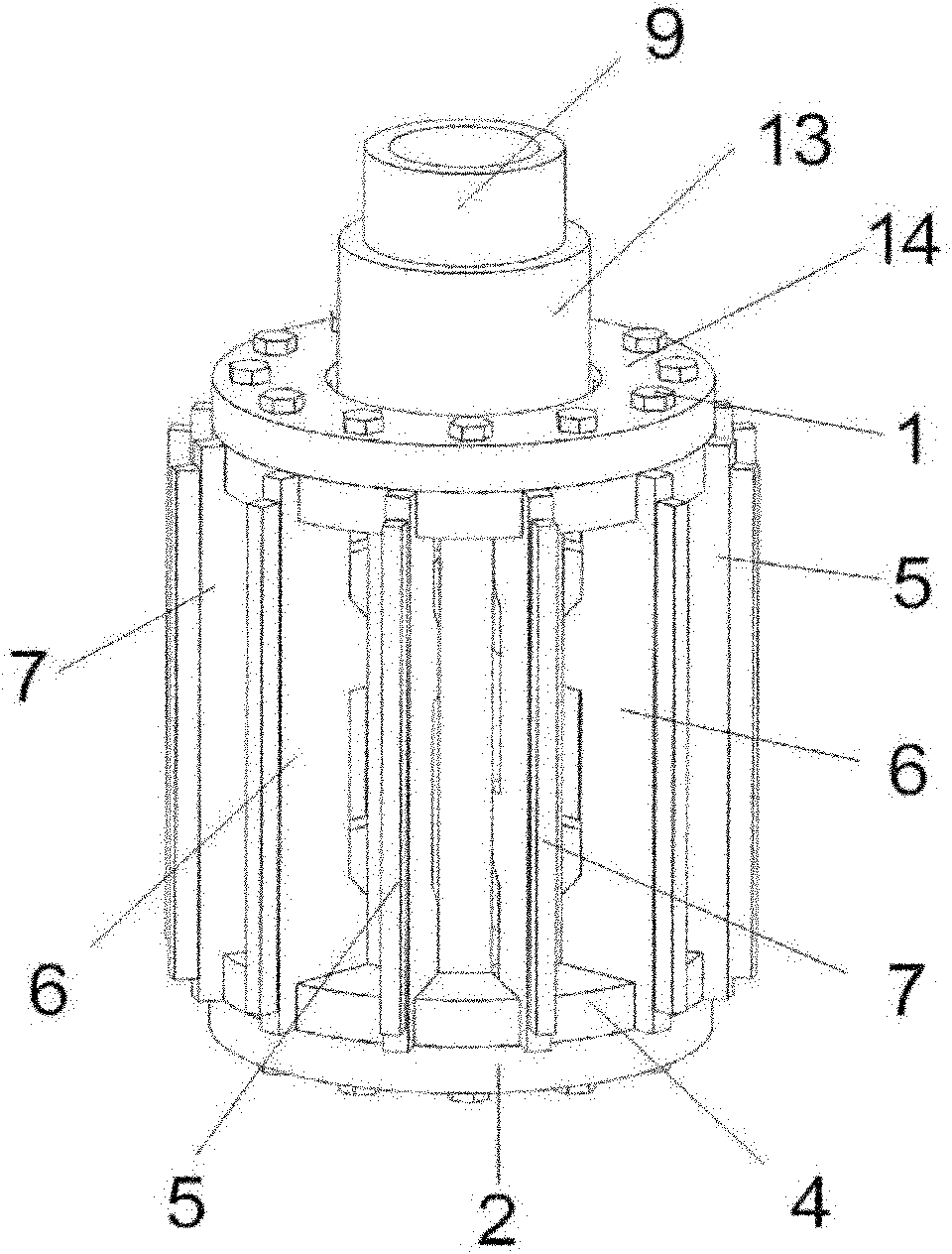

[0018] Such as figure 1 and figure 2 As shown, this embodiment includes: upper end cover 14, lower end cover 2, end cover screw 1, whetstone compression spring 3, bracket 4, rough honing whetstone 5, fine honing whetstone 6, brush honing whetstone 7, inner shaft 9, outer Shaft 13, wherein: the outer shaft 13 is sleeved on the inner shaft 9, the inner shaft 9 is arranged in the center hole of the support 4, the rough honing stone 5, the fine honing stone 6 and the brush honing stone 7 are evenly arranged on the circumference of the bracket 4 In the 12 card slots of the cloth, 4 rough honing stones 5, 4 fine honin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com