Novel air cylinder sleeve honing treatment process

A treatment process and cylinder liner technology, which is applied in the field of new cylinder liner honing treatment process, can solve the problems of wasting manpower and material resources, achieve the effects of inhibiting oxidation, low friction coefficient, saving time and resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

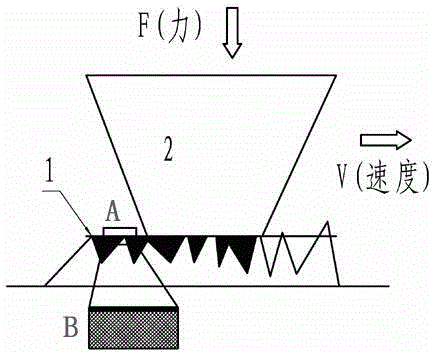

[0019] Such as figure 1 As shown, a new type of cylinder liner honing treatment process, the weight percentage of honing oil raw materials used in honing is: kerosene 97%, WS 2 Powder 3%. During honing, the surface of the inner hole of the cylinder liner 1 is squeezed by the honing abrasive strip 2, so that the contact force reaches 10% of the ultimate strength of the squeezed cylinder liner. Others can be carried out by referring to conventional techniques in the art, so details will not be repeated.

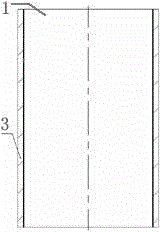

[0020] Such as figure 2 As shown, there is a layer of WS on the surface of the inner hole of the cylinder liner 1 obtained after honing 2 Film 3 has a thickness of about 0.6 μm.

Embodiment 2

[0022] A new type of cylinder liner honing treatment process, the weight percentage of honing oil raw materials selected for honing is: 98.5% kerosene, WS 2 Powder 1.5%. During honing, the surface of the inner hole of the cylinder liner 1 is extruded by the honing strip, so that the contact force reaches 8% of the ultimate strength of the extruded cylinder liner, and other operations can be carried out by referring to conventional techniques in the field.

[0023] Such as figure 2 As shown, there is a layer of WS on the surface of the inner hole of the cylinder liner 1 obtained after honing 2 Film 3 with a thickness of about 0.5 μm.

[0024] After testing: the cylinder liner sample treated with tungsten disulfide by the process of the present invention has a friction coefficient of 0.1319 under lubrication conditions, and a friction coefficient of 0.4759, 04800 under dry friction conditions; The friction coefficient is 0.1856 under the working condition, and the friction c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com