Double-precision honing device

A double-precision, honing technology, applied in the field of mechanical honing, can solve the problems of reduced service life, large wear, and high processing cost, and achieve the effects of increasing service life, reducing processing cost, and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

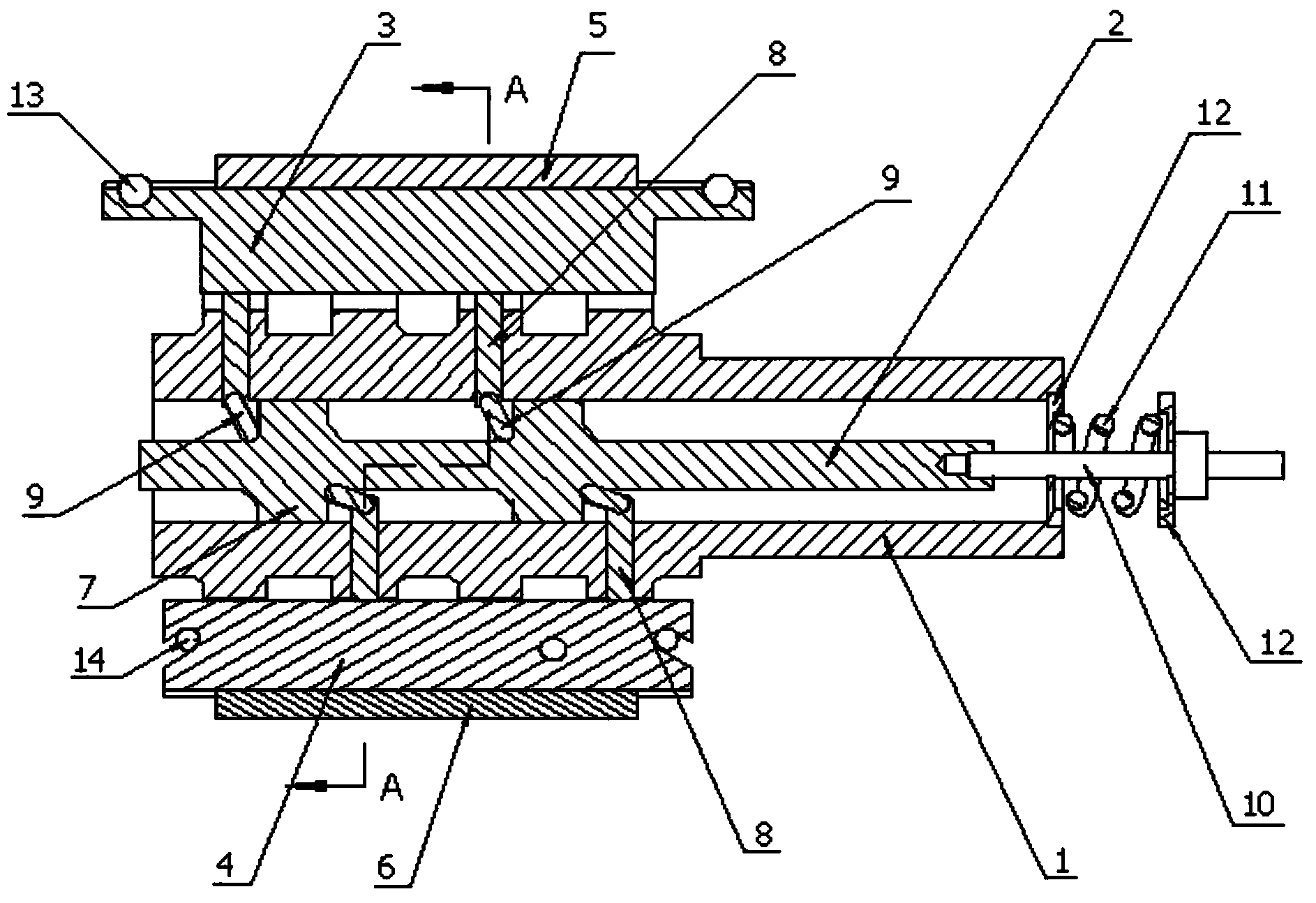

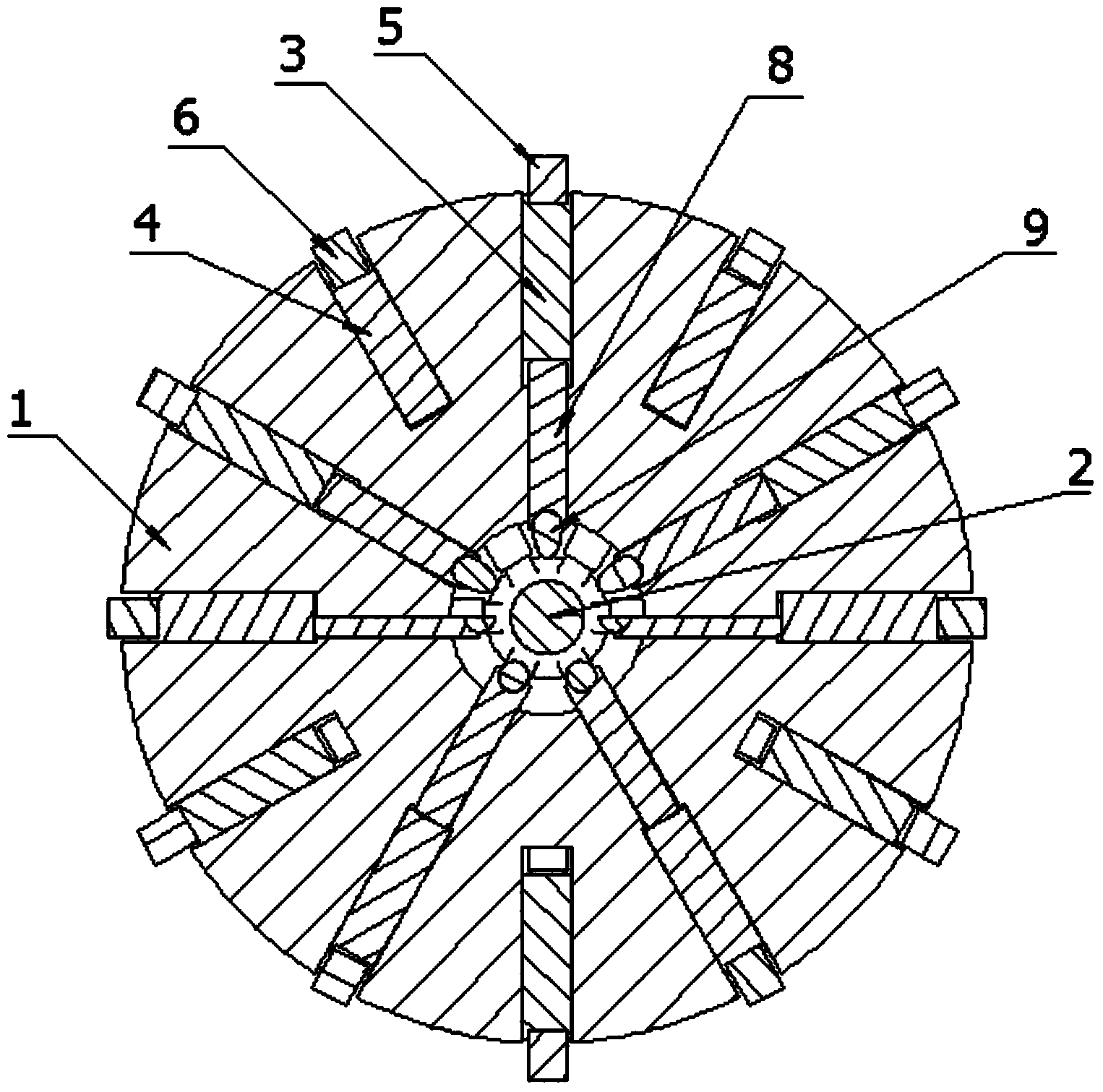

[0016] The present invention is described below in conjunction with accompanying drawing.

[0017] like Figure 1-2 As shown, a double-precision honing device according to the present invention includes a honing base 1, a push rod 2, a push rod assembly, a rough oil stone spring 13 and a refined oil stone spring 14; the push rod 2 is arranged on the honing base In 1, the ejector rod assembly is arranged at the rear end of the honing base 1; 6 rough oil stone grooves and 6 refined oil stone grooves are arranged on the outer circumference of the front end of the honed grinding base 1, and the rough oil stone grooves and the refined oil stone grooves are evenly distributed and are spaced from each other; each rough oil stone tank is provided with a rough oil stone seat 3, each essential oil stone seat 4, and each rough oil stone seat 3 is provided with a rough grinding oil stone 5, and each essential oil stone seat 4 are provided with fine honing oil stone 6; the front and rear ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com